Outdoor thick type fireproof coating for steel structure and its manufacturing method

A technology for fire retardant coatings and steel structures, which can be used in fire retardant coatings and other directions to solve the problems of powder removal, water resistance of the coating, and easy cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below by embodiment the present invention will be further described:

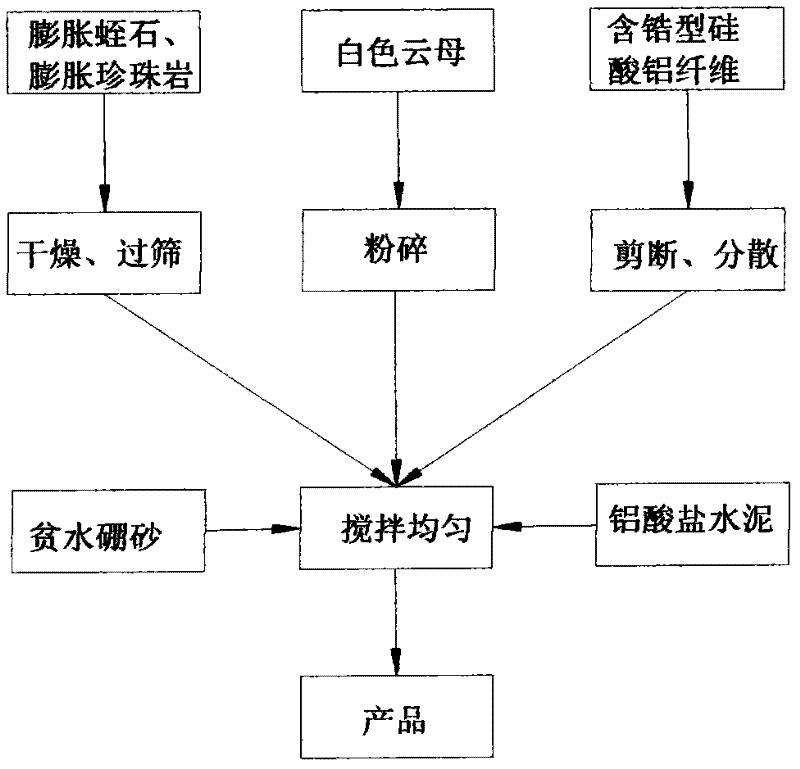

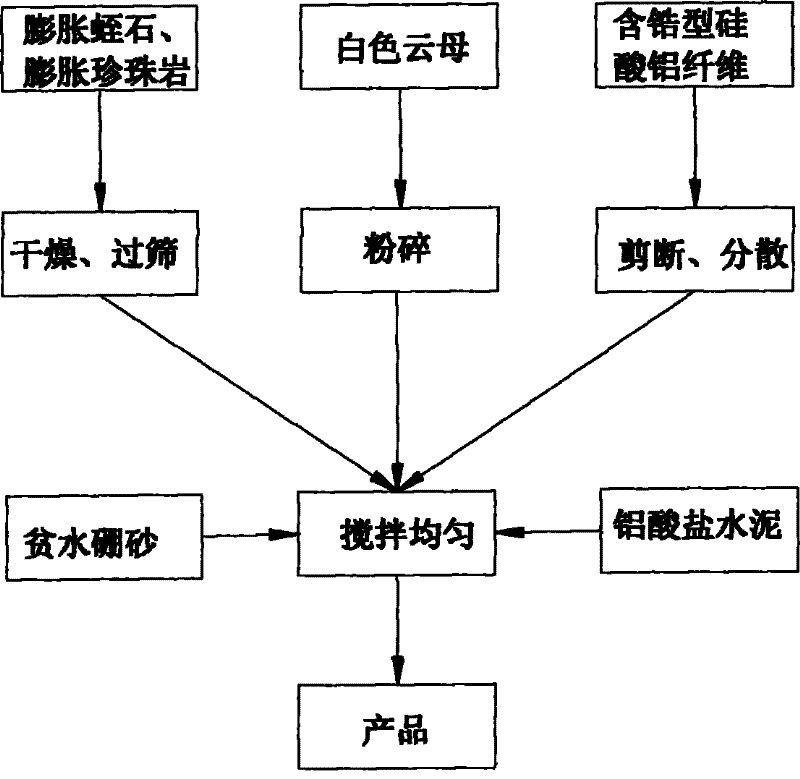

[0010] Firstly, the expanded perlite and expanded vermiculite are screened and dried separately, the particle size is controlled at 1-3 mm, the white flake mica is pulverized by a ball mill to make it less than 20 mesh, and the zirconium-containing aluminum silicate fiber is used with a cotton shear Cut and disperse; then add 13.0kg of expanded vermiculite, 21.0kg of expanded perlite, 5.0kg of flaky mica, 3.0kg of zirconium-containing aluminum silicate fiber, 22.5kg of aluminate cement, and 1.2kg of water-poor borax into the mixer for mixing , so that it is evenly dispersed. After passing the sampling inspection, it will be packaged and packaged.

[0011] During specific construction, add appropriate amount of water to the powder and stir evenly, and the stirring time is not less than 5 minutes to make it into a thick fluid state without agglomeration. Thin consistency should be suitable for easy c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com