Hexavalent chromium adsorbent and preparation method and application thereof

An adsorbent, hexavalent chromium technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of chromium pollution in natural water and soil, pollution of the environment, waste of resources, etc., to achieve the scope of application Wide, high adsorption efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 6

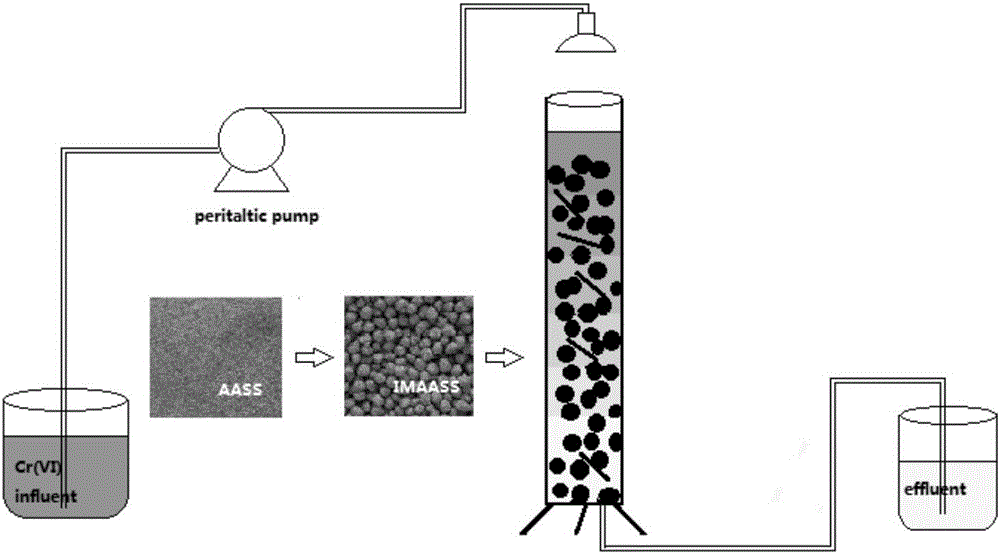

[0039] The preparation of embodiment 1 hexavalent chromium adsorbent

[0040] The preparation of hexavalent chromium adsorbent is carried out according to the following method:

[0041] (1) Pretreatment of bacterial chaff

[0042] Put the fungus chaff into a constant temperature drying incubator, dry at 80°C until constant weight, pulverize, and pass through a 40-mesh sieve. The sieved fungus bran powder was sterilized by high-pressure steam at 121°C, and stored in a dry environment for later use ( figure 1 ).

[0043] (2) Modification of bacterial chaff - grafting cationic groups

[0044]Choose hexadecyltrimethylammonium bromide as the modifier, take 0.34g of hexadecyltrimethylammonium bromide at 25°C, add 1L of deionized water, stir until completely dissolved, and make 1CMC critical For a solution with a micellar concentration, add 100g of fungus chaff powder to the solution, put it in a shaker, set it at 150r / min, modify it for 24 hours, filter it, wash it with deionize...

Embodiment 2

[0048] Embodiment 2 Application of adsorbent of the present invention in static adsorption of hexavalent chromium

[0049] 1. Method

[0050] According to the dosage of 0.5~5g / L, the hexavalent chromium adsorbent prepared in Example 1 is added to pH (2~8), and the hexavalent chromium ion concentration is 25~150mg / L in the waste water, in 15~ Under the condition of 35°C, on a shaker with a rotating speed of 60-180r / min, shake the adsorption for 0.5-5h, filter and remove the adsorbent, measure different pH (2-8), different initial concentration (25-150mg / L), different adsorption Dosing amount of agent (0.5~5g / L), different adsorption time (30~300min), different temperature (15~35℃), different speed (60~180r / min) on the adsorption effect. After the adsorption, the atomic absorption spectrophotometer measures the hexavalent chromium content in the filtrate. Calculate the adsorption rate R. The adsorption rate (%) is calculated according to the following formula:

[0051] ...

Embodiment 3

[0059] Example 3 Static adsorption efficiency comparison of unmodified bacterial chaff and modified bacterial chaff adsorbent for hexavalent chromium

[0060] Take the bacteria chaff adsorbent before modification and after modification according to the dosage of 3g / L, under the conditions of pH 5.5, initial concentration of hexavalent chromium 100mg / L, adsorption time 120min, temperature 25°C, speed 150r / min respectively Determination of adsorption capacity and adsorption rate, the results are shown in Table 1. It can be seen from Table 1 that the removal rate of hexavalent chromium by the modified fungus chaff adsorbent is increased by 16.3%, and the adsorption capacity is increased by 5.4mg / g.

[0061] Table 1

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com