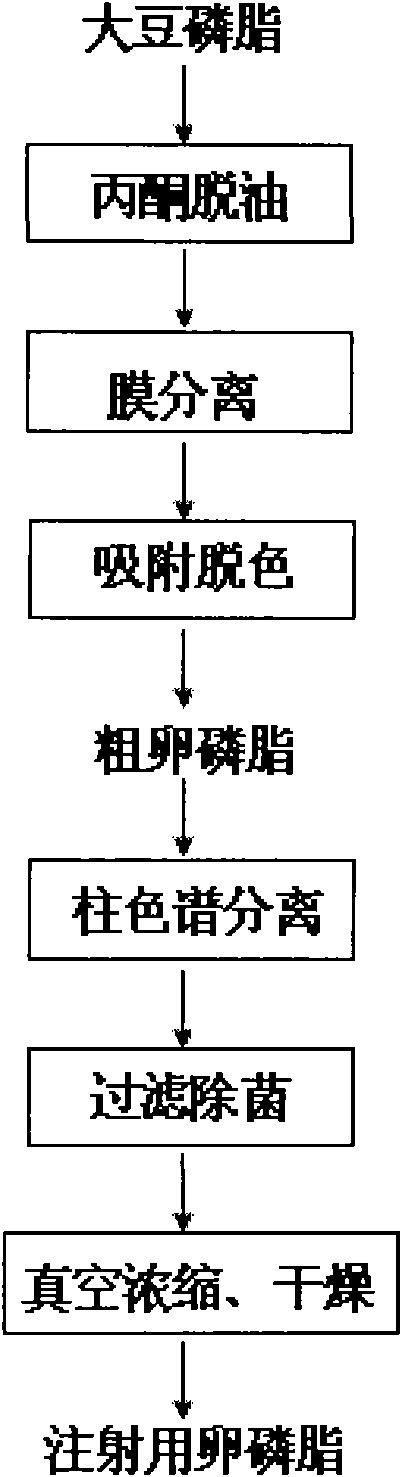

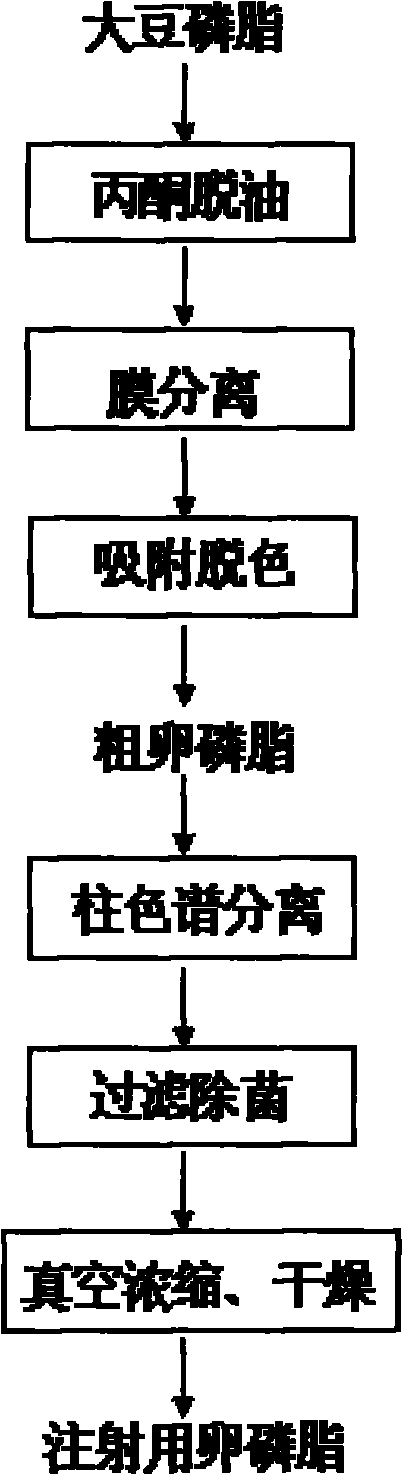

Preparation technology of soybean lecithin for injection

A technique for preparing soybean lecithin, which is applied in the field of preparation technology for soybean lecithin for injection, can solve the problems of low recovery rate of high-purity lecithin, large amount of eluent, and influence on product quality, and achieve low price and high product quality. Improved purity and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 100g of concentrated soybean phospholipids, first use 300g of acetone to deoil at 40°C for 3 times, each time for 30min, filter, add 300g of n-hexane and 100g of isopropanol mixed solvent to the acetone insoluble matter to dissolve it. The mixed solution was passed through a polyacrylonitrile membrane with a molecular weight cut off of 15,000 at a temperature of 25° C. and a pressure of 0.38 MPa to obtain a permeate. Add 6.4 g of activated alumina to the permeate, conduct adsorption treatment at 35° C. for 60 min, filter, concentrate the filtrate under reduced pressure, and dry in vacuum to obtain crude lecithin. Through HPLC analysis, the content of phosphatidylcholine in the crude lecithin is 53.2%.

[0024] Take 120g of silica gel (100-200 mesh) soaked in chloroform, put it into a φ25mm×900mm glass chromatography column, weigh 4.5g of crude lecithin, dissolve it in 37g of chloroform, and load it with 400ml of 2:1 chloroform / Rinse with methanol, the flow rate i...

Embodiment 2

[0027] Take 80g of concentrated soybean phospholipids, first use 400g of acetone at 25°C to deoil twice, each time for 40min, filter, add 300g of n-hexane and 80g of isopropanol mixed solvent to the acetone insoluble matter to dissolve it. The mixed solution was passed through a polyvinylidene fluoride membrane with a molecular weight cut-off of 10,000 at a temperature of 35° C. and a pressure of 0.5 MPa to obtain a permeate. Add 2.56 g of activated clay to the permeate, decolorize it by adsorption at 50°C for 40 minutes, filter, concentrate the filtrate under reduced pressure, and dry it in vacuum to obtain crude lecithin. Through HPLC analysis, the content of phosphatidylcholine in the crude lecithin is 54.8%.

[0028]Take 90g of diatomite (300-400 mesh) soaked in dichloromethane, put it into a φ20mm×700mm glass chromatography column, weigh 3.7g of crude lecithin, dissolve it in 26g of dichloromethane, and load it with 300ml 4:1 dichloromethane / methanol flushing, the flow r...

Embodiment 3

[0031] Take 50g of soybean concentrated phospholipids, deoil with 250g of acetone at 25°C for 4 times, each time for 30min, filter, add 200g of n-hexane and 50g of isopropanol mixed solvent to the acetone insoluble matter to dissolve it. The mixed solution was passed through a polysulfone membrane with a molecular weight cut off of 20,000 at a temperature of 35° C. and a pressure of 0.5 MPa to obtain a permeate. Add 1.92 g of activated carbon to the permeate, conduct adsorption treatment at 45° C. for 120 min, filter, concentrate the filtrate under reduced pressure, and dry in vacuum to obtain crude lecithin. Through HPLC analysis, the content of phosphatidylcholine in the crude lecithin is 57.3%.

[0032] Take 80g of attapulgite (200-300 mesh) soaked in n-hexane, put it into a φ25mm×600mm glass chromatography column, weigh 2.5g of crude lecithin, dissolve it in 10g of n-hexane, and load it with 200ml of 1 : 1 n-hexane / ethanol flushing, the flow rate is controlled at 1.1ml / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com