Green synthesizing method for thiuram rubber vulcanizing accelerant

A technology of rubber vulcanization and thiuram, which is applied in the green synthesis of rubber vulcanization accelerators and green synthesis of thiuram disulfide) rubber accelerators, can solve the problems of a large amount of waste water and sodium sulfate waste salt, and achieve The effect of reducing the amount of waste water and inorganic waste salt, rich sources of raw materials, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

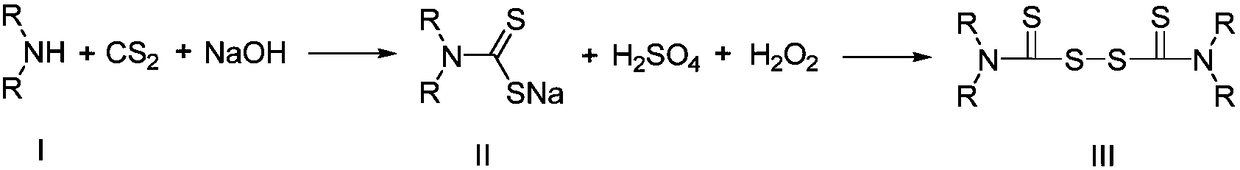

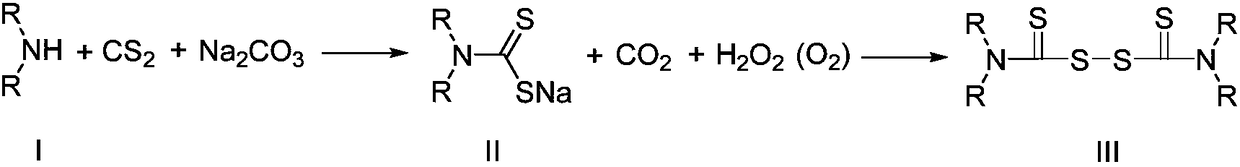

Method used

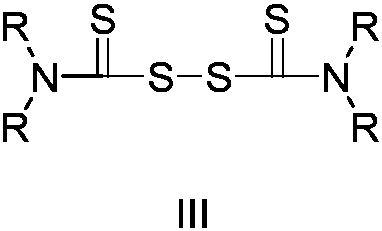

Image

Examples

Embodiment 1

[0022] Dissolve 10.6g Na in 100mL water with stirring 2 CO 3 , add 22.5g 40% dimethylamine aqueous solution, control the temperature to 20°C, slowly add 7.6g CS 2 After the dropwise addition, the stirring was continued for 30 min to obtain a dithiocarbamate solution. The temperature of the solution was lowered to 5 °C, and CO was slowly introduced into the 2 , and then slowly dropwise added 5.7 g of 30% H 2 o 2 The aqueous solution was kept warm for 60 minutes after the dropwise addition was completed, and the product tetramethylthiuram disulfide was obtained by filtration, and the mother liquor was retained for future use. Concentrate the obtained mother liquor by evaporation and add 0.5gNa 2 CO 3 , repeat the above experiment, the mother solution can be applied mechanically more than 3 times. In the cycle experiment, the yield of tetramethylthiuram disulfide was >97.0%, and the product purity by liquid chromatography was >98%.

Embodiment 2

[0024] Dissolve 27.6g of K in 250mL of water with stirring 2 CO 3 And 7.2g diethylamine, control temperature is 30 ℃, slowly drop 7.6g CS 2 After the dropwise addition, the stirring was continued for 30 min to obtain a dithiocarbamate solution. The temperature of the solution was stabilized at 30 °C, and CO was slowly introduced into the 2 , and then slowly dropwise added 20 g of 10% H 2 o 2 The aqueous solution was kept warm for 60 minutes after the dropwise addition was completed, and the product tetraethylthiuram disulfide was obtained by filtration, and the mother liquor was retained for future use. The obtained mother liquor was concentrated by evaporation and supplemented with 0.8g K 2 CO 3 , repeat the above experiment, the mother solution can be applied mechanically more than 3 times. In the cycle experiment, the yield of tetraethylthiuram disulfide was >96.0%, and the product purity by liquid chromatography was >98%.

Embodiment 3

[0026] Dissolve 55.2g K in 500mL water with stirring 2 CO 3 And 10.1g dipropylamine, control the temperature at 30°C, slowly add 7.6g CS 2 After the dropwise addition, the stirring was continued for 30 min to obtain a dithiocarbamate solution. Raise the temperature of the solution to 60°C, and condense the evaporated water vapor to reflux, and slowly introduce CO 2 , and then slowly introduce air to bubble for 5 hours, and filter to obtain the product tetrapropylthiuram disulfide after the bubbling is over, and keep the mother liquor for future use. Add 50 mL of water and 0.9 g of K to the obtained mother liquor 2 CO 3 , repeat the above experiment, the mother solution can be applied mechanically more than 5 times. In the cycle experiment, the yield of tetrapropylthiuram disulfide was >95.0%, and the product purity by liquid chromatography was >97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com