Konjac humectant and application thereof in cigarettes

A moisturizing agent, konjac technology, applied in the application, tobacco, tobacco processing and other directions, can solve the problems of high price of glycerin and propylene glycol, easy coagulation, poor moisturizing performance, etc. The effect of strong moisturizing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

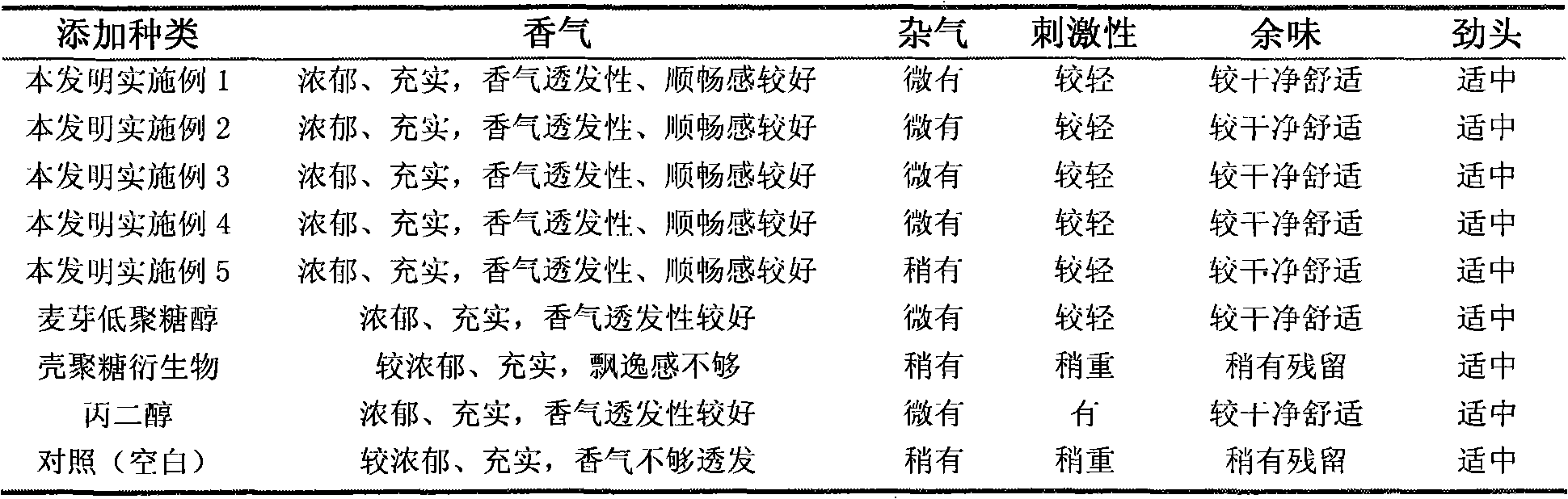

Embodiment 1

[0029] Get 100 grams of konjac powder, add 200 milliliters of 25% ethanol solution to extract, then add acetic acid to adjust the pH value to 4.5, make the konjac powder fully swell for 10 hours, then filter with a 100-mesh nylon mesh filter, and add 200 milliliters of 25 % ethanol solution for leaching 3 times, and then filtering with a 100-mesh nylon mesh filter after leaching. Add 150 milliliters of 95% ethanol to the resulting filter residue for elution for 1 hour, then filter with a 120-mesh nylon mesh filter, place the filter residue in a vacuum oven at 60°C and dry for 10 hours to obtain the initial product of konjac moisturizer, konjac The primary product of the moisturizer is crushed and passed through a 60-mesh sieve to obtain finished granules of the Konjac moisturizer. The konjac humectant granules are dissolved in 2000 times distilled water, and then the obtained konjac humectant solution is evenly sprayed on the tobacco leaves at 1% of the mass of the tobacco lea...

Embodiment 2

[0031] Get 100 grams of konjac flour, add 300 milliliters of 30% ethanol solution for leaching, then add citric acid to adjust the pH value to 4.8, make the konjac flour fully swell for 10 hours, then filter with a 120-mesh nylon mesh filter, and add 300 milliliters of the obtained filter residue The 30% ethanol solution was extracted twice, and filtered with a 120-mesh nylon mesh filter after the extraction. Add 200 milliliters of 95% ethanol to the resulting filter residue to elute for 1.5 hours, then filter with a 120-mesh nylon mesh filter, place the filter residue in a vacuum oven at 70°C and dry for 8 hours to obtain the initial product of konjac moisturizer, konjac The primary product of the moisturizer is crushed and passed through an 80-mesh sieve to obtain finished granules of the konjac moisturizer. The konjac humectant granules are dissolved in 5000 times distilled water, and the obtained konjac humectant solution is evenly sprayed on the tobacco leaves at 0.8% of ...

Embodiment 3

[0033] Get 200 grams of konjac powder, add 500 milliliters of 30% ethanol solution to extract, then add acetic acid to adjust the pH value to 4.8, make the konjac powder fully swell for 12 hours, then filter with a 100 order nylon mesh filter, and add 500 milliliters of 30 % ethanol solution for leaching 4 times, and then filtering with a 100-mesh nylon mesh filter after leaching. Add 400 milliliters of absolute ethanol to the resulting filter residue to elute for 2 hours, then filter with a 120-mesh nylon mesh filter, place the filter residue in a vacuum oven at 80°C and dry for 10 hours to obtain the initial product of konjac moisturizer. The primary product of the moisturizer is crushed and passed through an 80-mesh sieve to obtain finished granules of the konjac moisturizer. The konjac humectant granules are dissolved in 5000 times distilled water, and the obtained konjac humectant solution is uniformly sprayed on the tobacco leaves at 1.2% of the mass of the tobacco leave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com