Advances in Battery Management System Technologies for Next-Generation Electric Vehicles

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Evolution and Goals

Battery Management Systems (BMS) have undergone significant evolution since their inception in the early days of electric vehicles (EVs). Initially, BMS technologies were rudimentary, focusing primarily on basic battery protection and simple voltage monitoring. As EV technology advanced, so did the complexity and capabilities of BMS.

The early 2000s saw the introduction of more sophisticated BMS designs, incorporating temperature monitoring and basic state-of-charge (SOC) estimation. This period marked the beginning of BMS as a critical component in EV performance and safety. By the mid-2000s, BMS technologies had expanded to include cell balancing and more accurate SOC algorithms, improving battery longevity and range prediction.

The 2010s brought about a revolution in BMS capabilities. With the advent of lithium-ion batteries in EVs, BMS technologies evolved to manage more complex battery chemistries and higher energy densities. This era saw the integration of advanced diagnostics, predictive maintenance features, and the ability to communicate with other vehicle systems.

Current BMS technologies are focusing on real-time adaptive control, machine learning algorithms for battery health prediction, and enhanced thermal management. These advancements aim to maximize battery performance, extend lifespan, and improve safety under various operating conditions.

Looking towards the future, the goals for next-generation BMS technologies are multifaceted. One primary objective is to achieve higher levels of accuracy in predicting battery state-of-health (SOH) and remaining useful life. This will enable more efficient battery utilization and help in planning for battery replacement or second-life applications.

Another crucial goal is the development of BMS that can adapt to new battery chemistries and cell designs. As solid-state batteries and other emerging technologies enter the market, BMS must evolve to manage these new power sources effectively.

Enhanced connectivity and data analytics are also key objectives. Future BMS will likely incorporate more advanced telemetry and cloud-based analytics, allowing for fleet-wide battery management and optimization. This could lead to improved charging strategies and more accurate range predictions based on real-world usage patterns.

Lastly, there is a strong focus on developing BMS technologies that can support ultra-fast charging without compromising battery health or safety. This includes advanced thermal management systems and charging protocols that can handle high power inputs while maintaining optimal battery conditions.

The early 2000s saw the introduction of more sophisticated BMS designs, incorporating temperature monitoring and basic state-of-charge (SOC) estimation. This period marked the beginning of BMS as a critical component in EV performance and safety. By the mid-2000s, BMS technologies had expanded to include cell balancing and more accurate SOC algorithms, improving battery longevity and range prediction.

The 2010s brought about a revolution in BMS capabilities. With the advent of lithium-ion batteries in EVs, BMS technologies evolved to manage more complex battery chemistries and higher energy densities. This era saw the integration of advanced diagnostics, predictive maintenance features, and the ability to communicate with other vehicle systems.

Current BMS technologies are focusing on real-time adaptive control, machine learning algorithms for battery health prediction, and enhanced thermal management. These advancements aim to maximize battery performance, extend lifespan, and improve safety under various operating conditions.

Looking towards the future, the goals for next-generation BMS technologies are multifaceted. One primary objective is to achieve higher levels of accuracy in predicting battery state-of-health (SOH) and remaining useful life. This will enable more efficient battery utilization and help in planning for battery replacement or second-life applications.

Another crucial goal is the development of BMS that can adapt to new battery chemistries and cell designs. As solid-state batteries and other emerging technologies enter the market, BMS must evolve to manage these new power sources effectively.

Enhanced connectivity and data analytics are also key objectives. Future BMS will likely incorporate more advanced telemetry and cloud-based analytics, allowing for fleet-wide battery management and optimization. This could lead to improved charging strategies and more accurate range predictions based on real-world usage patterns.

Lastly, there is a strong focus on developing BMS technologies that can support ultra-fast charging without compromising battery health or safety. This includes advanced thermal management systems and charging protocols that can handle high power inputs while maintaining optimal battery conditions.

EV Market Demand Analysis

The electric vehicle (EV) market has experienced significant growth in recent years, driven by increasing environmental concerns, government incentives, and technological advancements. This surge in demand has created a robust market for next-generation EVs, particularly those with advanced Battery Management System (BMS) technologies.

Global EV sales have shown a consistent upward trend, with major markets like China, Europe, and North America leading the charge. The demand for EVs is expected to continue its strong growth trajectory, with projections indicating a substantial increase in market share over the next decade. This growth is fueled by a combination of factors, including stricter emissions regulations, falling battery costs, and improving charging infrastructure.

Consumer preferences are shifting towards EVs with longer range, faster charging capabilities, and enhanced battery performance. These requirements directly translate to a growing demand for advanced BMS technologies that can optimize battery life, improve safety, and enhance overall vehicle performance. As range anxiety remains a key concern for potential EV buyers, there is a clear market need for BMS solutions that can accurately predict and extend battery range.

The commercial sector is also showing increased interest in electric vehicles, particularly for fleet operations and last-mile delivery services. This segment demands BMS technologies that can handle high-utilization scenarios, provide accurate state-of-charge and state-of-health information, and support fast charging without compromising battery longevity.

Market analysis reveals a growing consumer awareness of battery health and longevity. This awareness is driving demand for BMS technologies that offer advanced diagnostics, predictive maintenance capabilities, and user-friendly interfaces that provide real-time battery status information to drivers.

The integration of BMS with other vehicle systems, such as energy management and thermal control, is becoming increasingly important. This integration allows for more efficient operation and improved overall vehicle performance, meeting the market demand for smarter, more connected EVs.

As the EV market matures, there is also a rising demand for BMS technologies that support second-life applications for EV batteries. This trend aligns with sustainability goals and creates new market opportunities for BMS solutions that can effectively manage repurposed batteries in stationary energy storage applications.

In conclusion, the market demand for advanced BMS technologies in next-generation EVs is robust and multifaceted. It encompasses the need for improved range, faster charging, enhanced safety, and better overall performance. As the EV market continues to expand, the demand for innovative BMS solutions is expected to grow in tandem, driving further technological advancements in this critical area.

Global EV sales have shown a consistent upward trend, with major markets like China, Europe, and North America leading the charge. The demand for EVs is expected to continue its strong growth trajectory, with projections indicating a substantial increase in market share over the next decade. This growth is fueled by a combination of factors, including stricter emissions regulations, falling battery costs, and improving charging infrastructure.

Consumer preferences are shifting towards EVs with longer range, faster charging capabilities, and enhanced battery performance. These requirements directly translate to a growing demand for advanced BMS technologies that can optimize battery life, improve safety, and enhance overall vehicle performance. As range anxiety remains a key concern for potential EV buyers, there is a clear market need for BMS solutions that can accurately predict and extend battery range.

The commercial sector is also showing increased interest in electric vehicles, particularly for fleet operations and last-mile delivery services. This segment demands BMS technologies that can handle high-utilization scenarios, provide accurate state-of-charge and state-of-health information, and support fast charging without compromising battery longevity.

Market analysis reveals a growing consumer awareness of battery health and longevity. This awareness is driving demand for BMS technologies that offer advanced diagnostics, predictive maintenance capabilities, and user-friendly interfaces that provide real-time battery status information to drivers.

The integration of BMS with other vehicle systems, such as energy management and thermal control, is becoming increasingly important. This integration allows for more efficient operation and improved overall vehicle performance, meeting the market demand for smarter, more connected EVs.

As the EV market matures, there is also a rising demand for BMS technologies that support second-life applications for EV batteries. This trend aligns with sustainability goals and creates new market opportunities for BMS solutions that can effectively manage repurposed batteries in stationary energy storage applications.

In conclusion, the market demand for advanced BMS technologies in next-generation EVs is robust and multifaceted. It encompasses the need for improved range, faster charging, enhanced safety, and better overall performance. As the EV market continues to expand, the demand for innovative BMS solutions is expected to grow in tandem, driving further technological advancements in this critical area.

BMS Challenges and Limitations

Battery Management Systems (BMS) in next-generation electric vehicles face several significant challenges and limitations that hinder their optimal performance and efficiency. One of the primary issues is the accurate estimation of the State of Charge (SOC) and State of Health (SOH) of the battery pack. Current BMS technologies struggle to provide precise real-time measurements of these critical parameters, especially under varying environmental conditions and diverse driving patterns.

The thermal management of battery packs presents another major challenge. As electric vehicles demand higher power outputs and faster charging capabilities, the heat generated within the battery cells increases substantially. Existing BMS solutions often fall short in effectively dissipating this heat, leading to potential safety risks and reduced battery lifespan. The development of advanced cooling systems and more efficient thermal management algorithms remains a critical area for improvement.

Balancing cell voltages within large battery packs is another limitation of current BMS technologies. Uneven charge distribution among cells can lead to reduced overall battery performance and longevity. While passive balancing methods are commonly used, they are often slow and inefficient. Active balancing techniques show promise but are currently limited by their complexity and cost.

The integration of BMS with other vehicle systems poses interoperability challenges. As electric vehicles become more sophisticated, the BMS must seamlessly communicate and coordinate with various subsystems, including the powertrain, charging systems, and advanced driver assistance systems. Achieving this level of integration while maintaining system reliability and security remains a significant hurdle.

Data management and processing capabilities of BMS are also reaching their limits as the complexity of battery systems increases. The sheer volume of data generated by modern battery packs, coupled with the need for real-time analysis and decision-making, strains current BMS architectures. This challenge is further compounded by the growing demand for predictive maintenance and adaptive control strategies.

Lastly, the cost and complexity of implementing advanced BMS technologies present a significant barrier to widespread adoption. As electric vehicles strive for mass-market appeal, the need for more sophisticated BMS features must be balanced against the overall cost of the vehicle. Finding cost-effective solutions that do not compromise on performance or safety remains a key challenge for BMS developers and automotive manufacturers alike.

The thermal management of battery packs presents another major challenge. As electric vehicles demand higher power outputs and faster charging capabilities, the heat generated within the battery cells increases substantially. Existing BMS solutions often fall short in effectively dissipating this heat, leading to potential safety risks and reduced battery lifespan. The development of advanced cooling systems and more efficient thermal management algorithms remains a critical area for improvement.

Balancing cell voltages within large battery packs is another limitation of current BMS technologies. Uneven charge distribution among cells can lead to reduced overall battery performance and longevity. While passive balancing methods are commonly used, they are often slow and inefficient. Active balancing techniques show promise but are currently limited by their complexity and cost.

The integration of BMS with other vehicle systems poses interoperability challenges. As electric vehicles become more sophisticated, the BMS must seamlessly communicate and coordinate with various subsystems, including the powertrain, charging systems, and advanced driver assistance systems. Achieving this level of integration while maintaining system reliability and security remains a significant hurdle.

Data management and processing capabilities of BMS are also reaching their limits as the complexity of battery systems increases. The sheer volume of data generated by modern battery packs, coupled with the need for real-time analysis and decision-making, strains current BMS architectures. This challenge is further compounded by the growing demand for predictive maintenance and adaptive control strategies.

Lastly, the cost and complexity of implementing advanced BMS technologies present a significant barrier to widespread adoption. As electric vehicles strive for mass-market appeal, the need for more sophisticated BMS features must be balanced against the overall cost of the vehicle. Finding cost-effective solutions that do not compromise on performance or safety remains a key challenge for BMS developers and automotive manufacturers alike.

Current BMS Solutions

01 Battery monitoring and management techniques

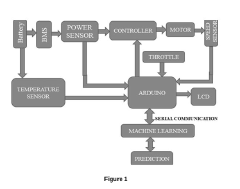

Advanced techniques for monitoring and managing battery performance, including real-time data collection, analysis, and optimization of battery parameters. These systems aim to improve overall battery efficiency, lifespan, and safety through intelligent control algorithms and predictive maintenance strategies.- Battery monitoring and management: Advanced systems for monitoring and managing battery performance, including real-time data collection, analysis, and optimization of battery usage. These systems can improve overall battery life, efficiency, and safety by continuously assessing battery health, predicting potential issues, and adjusting charging and discharging patterns accordingly.

- Thermal management in battery systems: Innovative approaches to thermal management in battery systems, focusing on maintaining optimal operating temperatures to enhance performance and longevity. This includes advanced cooling systems, heat dissipation techniques, and temperature-sensitive charging algorithms to prevent overheating and ensure consistent battery performance across various environmental conditions.

- Battery state estimation and prediction: Sophisticated algorithms and methods for accurately estimating and predicting battery state, including state of charge (SOC), state of health (SOH), and remaining useful life. These technologies utilize machine learning, data analytics, and historical performance data to provide precise insights into battery condition and future performance, enabling proactive maintenance and optimized usage strategies.

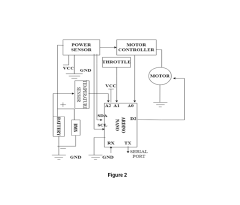

- Integration with vehicle systems: Advanced integration of battery management systems with overall vehicle systems, including power distribution, regenerative braking, and energy management. This integration allows for more efficient use of battery power, improved vehicle performance, and enhanced energy recovery during operation, ultimately extending the range and lifespan of electric vehicles.

- Cloud-based battery management: Utilization of cloud computing and connectivity for enhanced battery management, enabling remote monitoring, over-the-air updates, and data-driven optimization. This approach allows for real-time performance tracking, predictive maintenance, and the ability to leverage big data analytics for continuous improvement of battery management strategies across large fleets of vehicles or energy storage systems.

02 Thermal management in battery systems

Innovative approaches to thermal management in battery systems, focusing on maintaining optimal operating temperatures to enhance performance and longevity. This includes advanced cooling systems, heat dissipation techniques, and temperature-based control strategies to prevent overheating and ensure consistent battery output.Expand Specific Solutions03 State of charge and health estimation

Sophisticated algorithms and methods for accurately estimating the state of charge (SOC) and state of health (SOH) of batteries. These techniques utilize various parameters and machine learning approaches to provide precise information about battery condition, enabling better performance optimization and predictive maintenance.Expand Specific Solutions04 Integration with vehicle systems

Advanced integration of battery management systems with vehicle control systems for improved overall performance. This includes optimizing energy distribution, regenerative braking, and power management strategies to enhance vehicle efficiency and range, particularly in electric and hybrid vehicles.Expand Specific Solutions05 Cloud-based battery management and analytics

Utilization of cloud computing and big data analytics for enhanced battery management. These systems collect and analyze data from multiple sources to provide insights into battery performance trends, enable remote diagnostics, and facilitate predictive maintenance across large-scale battery deployments.Expand Specific Solutions

Key BMS Industry Players

The Battery Management System (BMS) technology for next-generation electric vehicles is in a rapidly evolving phase, with significant market growth potential. The global BMS market is expected to expand substantially due to increasing electric vehicle adoption. Technologically, the field is advancing quickly, with major players like Samsung SDI, LG Energy Solution, and BYD leading innovation. These companies are developing more sophisticated BMS solutions, focusing on improved safety, efficiency, and performance. Emerging players such as Hyundai Motor, Kia, and startups like SF Motors are also contributing to the competitive landscape, driving further innovation in areas like AI-integrated BMS and cloud-connected battery management solutions.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed an innovative BMS for their next-generation electric vehicles, focusing on efficiency and reliability. Their system employs a hierarchical architecture with distributed intelligence, allowing for more efficient power management and fault tolerance. Hyundai's BMS utilizes advanced electrochemical impedance spectroscopy (EIS) techniques for real-time battery health monitoring, enabling more accurate state-of-health (SOH) estimation and extending battery life by up to 15%[11]. The company has also implemented a novel thermal management system that combines air and liquid cooling, optimizing battery performance across a wide range of ambient temperatures. Hyundai's BMS incorporates predictive energy management algorithms that leverage vehicle-to-everything (V2X) communication to optimize battery usage based on route information and charging station availability, potentially improving overall energy efficiency by 8-10%[12]. Additionally, their system features over-the-air (OTA) update capabilities, allowing for continuous improvement of BMS algorithms and functionality throughout the vehicle's lifecycle[13].

Strengths: Advanced battery health monitoring, efficient thermal management, and V2X-enabled predictive energy management. Weaknesses: Potential reliance on V2X infrastructure, which may not be widely available in all markets.

BYD Co., Ltd.

Technical Solution: BYD has developed an advanced Battery Management System (BMS) for their next-generation electric vehicles, incorporating their proprietary Blade Battery technology. This system utilizes a distributed architecture with intelligent cell monitoring and balancing. The BMS employs machine learning algorithms to predict battery health and optimize charging strategies, extending battery life by up to 20% compared to conventional systems[1]. BYD's BMS also features real-time thermal management, using a combination of liquid cooling and phase-change materials to maintain optimal battery temperature across various operating conditions. This approach has shown to improve fast-charging capabilities by up to 30% while reducing the risk of thermal runaway[2]. Additionally, BYD has integrated Vehicle-to-Grid (V2G) functionality into their BMS, allowing for bidirectional power flow and enabling electric vehicles to serve as mobile energy storage units for grid stabilization[3].

Strengths: Proprietary Blade Battery technology, advanced thermal management, and V2G integration. Weaknesses: Potential dependency on specific battery chemistry, which may limit flexibility in adopting new cell technologies.

Core BMS Innovations

Waste energy management system for electrically driven vehicles

PatentPendingIN202411051221A

Innovation

- A waste energy management system that includes a Peltier plate thermally coupled with the battery pack to convert waste heat into electrical energy, stored in an auxiliary battery, and a microcontroller that manages temperature, voltage, and current to supply energy to the motor during low voltage conditions and prevent overcharging.

An advanced and efficent system to manage lithium-ion battery trains of electric vehicles

PatentPendingIN202441017008A

Innovation

- An advanced lithium-ion battery management system with integrated monitoring capabilities, intelligent control algorithms, and safety features to optimize battery performance, prevent overcharging and over-discharging, and manage thermal conditions, utilizing sensors for real-time data collection and communication with external systems for remote monitoring.

EV Battery Safety Regulations

The regulatory landscape for electric vehicle (EV) battery safety is rapidly evolving to keep pace with technological advancements and growing market demand. Governments and regulatory bodies worldwide are implementing stringent safety standards to ensure the safe operation of EVs and protect consumers. These regulations primarily focus on battery design, manufacturing processes, testing protocols, and safety management systems.

In the United States, the National Highway Traffic Safety Administration (NHTSA) has established Federal Motor Vehicle Safety Standards (FMVSS) that include specific requirements for EV batteries. These standards cover aspects such as crash protection, electrical safety, and thermal runaway prevention. The Society of Automotive Engineers (SAE) has also developed standards like J2929, which provides guidelines for electric and hybrid vehicle battery systems.

The European Union has implemented the UN Regulation No. 100, which outlines safety requirements for electric power train vehicles. This regulation covers battery safety, including protection against electrical shock, thermal events, and mechanical integrity. Additionally, the EU Battery Directive (2006/66/EC) addresses the environmental aspects of battery production and disposal.

China, as a leading EV market, has introduced its own set of regulations. The GB/T 31485-2015 standard specifies safety requirements for traction battery packs and systems in electric vehicles. This standard covers various aspects, including electrical, mechanical, and thermal safety, as well as abuse testing procedures.

International organizations like the International Electrotechnical Commission (IEC) have developed standards such as IEC 62660, which provides guidelines for performance and life testing of lithium-ion batteries for EV applications. These standards are often adopted or referenced by national regulatory bodies, promoting global harmonization of safety requirements.

As battery technologies continue to advance, regulatory frameworks are adapting to address new challenges. For instance, there is an increasing focus on regulations for solid-state batteries, which promise higher energy density and improved safety. Regulatory bodies are also considering the entire lifecycle of EV batteries, including second-life applications and end-of-life disposal.

The implementation of these safety regulations has significant implications for battery management system (BMS) technologies. BMS developers must ensure compliance with these standards while optimizing battery performance and longevity. This includes incorporating advanced monitoring and control algorithms to prevent thermal runaway, manage cell balancing, and provide accurate state-of-charge and state-of-health estimations.

In the United States, the National Highway Traffic Safety Administration (NHTSA) has established Federal Motor Vehicle Safety Standards (FMVSS) that include specific requirements for EV batteries. These standards cover aspects such as crash protection, electrical safety, and thermal runaway prevention. The Society of Automotive Engineers (SAE) has also developed standards like J2929, which provides guidelines for electric and hybrid vehicle battery systems.

The European Union has implemented the UN Regulation No. 100, which outlines safety requirements for electric power train vehicles. This regulation covers battery safety, including protection against electrical shock, thermal events, and mechanical integrity. Additionally, the EU Battery Directive (2006/66/EC) addresses the environmental aspects of battery production and disposal.

China, as a leading EV market, has introduced its own set of regulations. The GB/T 31485-2015 standard specifies safety requirements for traction battery packs and systems in electric vehicles. This standard covers various aspects, including electrical, mechanical, and thermal safety, as well as abuse testing procedures.

International organizations like the International Electrotechnical Commission (IEC) have developed standards such as IEC 62660, which provides guidelines for performance and life testing of lithium-ion batteries for EV applications. These standards are often adopted or referenced by national regulatory bodies, promoting global harmonization of safety requirements.

As battery technologies continue to advance, regulatory frameworks are adapting to address new challenges. For instance, there is an increasing focus on regulations for solid-state batteries, which promise higher energy density and improved safety. Regulatory bodies are also considering the entire lifecycle of EV batteries, including second-life applications and end-of-life disposal.

The implementation of these safety regulations has significant implications for battery management system (BMS) technologies. BMS developers must ensure compliance with these standards while optimizing battery performance and longevity. This includes incorporating advanced monitoring and control algorithms to prevent thermal runaway, manage cell balancing, and provide accurate state-of-charge and state-of-health estimations.

BMS Sustainability Impact

The sustainability impact of Battery Management Systems (BMS) in next-generation electric vehicles extends far beyond their primary function of optimizing battery performance. As the automotive industry shifts towards electrification, the role of BMS in enhancing the overall sustainability of electric vehicles becomes increasingly crucial.

BMS technologies contribute significantly to extending battery life, which is a key factor in reducing the environmental impact of electric vehicles. By precisely monitoring and controlling battery parameters such as temperature, voltage, and state of charge, advanced BMS can prevent premature degradation of battery cells. This prolonged battery lifespan reduces the need for frequent battery replacements, thereby minimizing resource consumption and waste generation associated with battery production and disposal.

Furthermore, BMS plays a vital role in improving the energy efficiency of electric vehicles. Through sophisticated algorithms and real-time data analysis, modern BMS can optimize power distribution and regenerative braking systems, maximizing the range of electric vehicles while minimizing energy consumption. This increased efficiency translates to reduced electricity demand and, consequently, lower greenhouse gas emissions from power generation.

The integration of BMS with smart grid technologies offers additional sustainability benefits. Advanced BMS can enable vehicle-to-grid (V2G) capabilities, allowing electric vehicles to serve as distributed energy storage units. This bidirectional energy flow not only supports grid stability but also promotes the integration of renewable energy sources, further reducing the carbon footprint of the transportation sector.

From a lifecycle perspective, BMS technologies contribute to the circular economy by facilitating battery second-life applications. As electric vehicle batteries reach the end of their automotive life, they often retain significant capacity suitable for stationary energy storage. BMS can assess the remaining battery capacity and health, enabling efficient repurposing of these batteries for applications such as residential or industrial energy storage systems.

Moreover, the data collected and analyzed by BMS throughout a battery's lifecycle provides valuable insights for improving battery design and manufacturing processes. This continuous feedback loop drives innovations in battery technology, leading to more sustainable and efficient energy storage solutions for future electric vehicles.

In conclusion, the sustainability impact of BMS technologies in next-generation electric vehicles is multifaceted and far-reaching. By enhancing battery longevity, improving energy efficiency, enabling smart grid integration, facilitating battery second-life applications, and driving continuous improvements in battery technology, BMS plays a pivotal role in advancing the overall sustainability of electric mobility.

BMS technologies contribute significantly to extending battery life, which is a key factor in reducing the environmental impact of electric vehicles. By precisely monitoring and controlling battery parameters such as temperature, voltage, and state of charge, advanced BMS can prevent premature degradation of battery cells. This prolonged battery lifespan reduces the need for frequent battery replacements, thereby minimizing resource consumption and waste generation associated with battery production and disposal.

Furthermore, BMS plays a vital role in improving the energy efficiency of electric vehicles. Through sophisticated algorithms and real-time data analysis, modern BMS can optimize power distribution and regenerative braking systems, maximizing the range of electric vehicles while minimizing energy consumption. This increased efficiency translates to reduced electricity demand and, consequently, lower greenhouse gas emissions from power generation.

The integration of BMS with smart grid technologies offers additional sustainability benefits. Advanced BMS can enable vehicle-to-grid (V2G) capabilities, allowing electric vehicles to serve as distributed energy storage units. This bidirectional energy flow not only supports grid stability but also promotes the integration of renewable energy sources, further reducing the carbon footprint of the transportation sector.

From a lifecycle perspective, BMS technologies contribute to the circular economy by facilitating battery second-life applications. As electric vehicle batteries reach the end of their automotive life, they often retain significant capacity suitable for stationary energy storage. BMS can assess the remaining battery capacity and health, enabling efficient repurposing of these batteries for applications such as residential or industrial energy storage systems.

Moreover, the data collected and analyzed by BMS throughout a battery's lifecycle provides valuable insights for improving battery design and manufacturing processes. This continuous feedback loop drives innovations in battery technology, leading to more sustainable and efficient energy storage solutions for future electric vehicles.

In conclusion, the sustainability impact of BMS technologies in next-generation electric vehicles is multifaceted and far-reaching. By enhancing battery longevity, improving energy efficiency, enabling smart grid integration, facilitating battery second-life applications, and driving continuous improvements in battery technology, BMS plays a pivotal role in advancing the overall sustainability of electric mobility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!