Advances in HDPE Fiber Reinforcement for Strength

HDPE Fiber Evolution

The evolution of High-Density Polyethylene (HDPE) fiber reinforcement for strength enhancement has been a significant development in materials science and engineering. This journey began in the mid-20th century when HDPE was first synthesized and its potential for fiber production was recognized.

In the 1960s, the initial attempts to create HDPE fibers were made, primarily focusing on their use in textiles and packaging. However, the true breakthrough came in the 1970s with the development of gel spinning technology. This process allowed for the production of ultra-high molecular weight polyethylene (UHMWPE) fibers, which exhibited exceptional strength-to-weight ratios.

The 1980s saw rapid advancements in HDPE fiber technology. Researchers discovered that by aligning the polymer chains during the spinning process, they could significantly enhance the fiber's tensile strength and modulus. This led to the commercialization of high-performance HDPE fibers under various trade names, such as Dyneema and Spectra.

Throughout the 1990s and early 2000s, efforts were focused on improving the production efficiency and expanding the application range of HDPE fibers. Innovations in spinning techniques and post-treatment processes resulted in fibers with even higher strength and better resistance to environmental factors.

A major milestone was reached in the mid-2000s with the development of nano-enhanced HDPE fibers. By incorporating nanoparticles or nanotubes into the fiber structure, researchers were able to further improve mechanical properties and introduce new functionalities, such as electrical conductivity and enhanced thermal stability.

In recent years, the focus has shifted towards sustainability and bio-based alternatives. Research is ongoing to develop HDPE fibers from renewable sources and to improve their recyclability without compromising strength. Additionally, advancements in fiber surface treatments have led to better adhesion properties, expanding their use in composite materials.

The latest frontier in HDPE fiber evolution involves the integration of smart technologies. Efforts are being made to develop HDPE fibers with embedded sensors or responsive elements, allowing for real-time monitoring of stress, strain, and environmental conditions. This development holds promise for creating intelligent textiles and advanced structural materials.

As we look to the future, the evolution of HDPE fibers continues to be driven by the demand for stronger, lighter, and more versatile materials. Emerging technologies such as 3D printing and molecular engineering are opening new avenues for customizing HDPE fiber properties at the nanoscale, potentially leading to a new generation of high-performance materials with unprecedented strength and functionality.

Market Demand Analysis

The market demand for HDPE fiber reinforcement in construction and infrastructure projects has been steadily increasing over the past decade. This growth is primarily driven by the superior strength-to-weight ratio, durability, and corrosion resistance of HDPE fibers compared to traditional reinforcement materials such as steel. The construction industry, in particular, has shown a strong interest in HDPE fiber reinforcement for concrete applications, as it offers improved crack resistance and long-term performance.

In the global construction market, the use of fiber-reinforced concrete is projected to grow significantly. HDPE fibers are gaining traction in this segment due to their ability to enhance the mechanical properties of concrete while reducing overall construction costs. The infrastructure sector, including roads, bridges, and tunnels, is another key driver of demand for HDPE fiber reinforcement. These applications require materials that can withstand harsh environmental conditions and provide long-term structural integrity.

The automotive and aerospace industries are also exploring the potential of HDPE fiber reinforcement for lightweight composite materials. As fuel efficiency and emissions regulations become more stringent, manufacturers are seeking innovative solutions to reduce vehicle weight without compromising strength. HDPE fibers offer a promising alternative to traditional reinforcement materials in these high-performance applications.

In the geotextile and erosion control markets, HDPE fiber reinforcement is experiencing increased adoption. The material's resistance to chemical degradation and its ability to maintain long-term stability in soil make it an attractive option for environmental protection and land stabilization projects. This trend is particularly evident in coastal areas and regions prone to soil erosion.

The packaging industry is another sector showing growing interest in HDPE fiber reinforcement. As sustainability concerns drive the development of more durable and recyclable packaging solutions, HDPE fibers are being incorporated into composite materials to enhance strength and reduce material usage. This application is expected to see significant growth in the coming years as companies strive to meet environmental targets and consumer demands for eco-friendly packaging.

Market analysts predict that the global demand for HDPE fiber reinforcement will continue to expand across various industries. The construction sector is expected to remain the largest consumer, followed by infrastructure and transportation. Emerging applications in renewable energy, such as wind turbine blades and solar panel supports, are also likely to contribute to market growth. As research and development efforts continue to improve the performance and cost-effectiveness of HDPE fiber reinforcement, its market penetration is expected to accelerate, potentially disrupting traditional reinforcement material markets.

Technical Challenges

The development of High-Density Polyethylene (HDPE) fiber reinforcement for enhanced strength faces several significant technical challenges. One of the primary obstacles is the inherent low surface energy of HDPE, which results in poor adhesion between the fibers and the matrix material. This weak interfacial bonding limits the effective transfer of stress from the matrix to the fibers, reducing the overall composite strength and performance.

Another major challenge lies in the processing of HDPE fibers. The high molecular weight and crystallinity of HDPE make it difficult to achieve consistent fiber properties during production. Controlling the fiber diameter, orientation, and crystalline structure requires precise manipulation of processing parameters, which can be technically demanding and costly to implement at scale.

The thermal stability of HDPE fibers presents an additional hurdle. When exposed to elevated temperatures, HDPE fibers tend to soften and lose their mechanical properties. This thermal sensitivity limits their application in high-temperature environments and poses challenges in composite manufacturing processes that involve heat, such as thermoset curing or thermoplastic molding.

Achieving a uniform dispersion of HDPE fibers within the matrix material is another technical challenge. Fiber agglomeration can lead to stress concentrations and reduced overall strength of the composite. Developing effective dispersion techniques that maintain fiber integrity while ensuring even distribution throughout the matrix is crucial for optimal reinforcement.

The long-term durability of HDPE fiber-reinforced composites is also a concern. HDPE is susceptible to degradation from UV radiation and oxidation, which can compromise the mechanical properties of the fibers over time. Developing effective stabilization methods to enhance the environmental resistance of HDPE fibers without sacrificing their reinforcing capabilities remains a significant challenge.

Furthermore, the relatively low modulus of HDPE fibers compared to other reinforcing materials like glass or carbon fibers limits their effectiveness in applications requiring high stiffness. Enhancing the modulus of HDPE fibers while maintaining their desirable properties, such as low density and high tensile strength, is an ongoing area of research and development.

Lastly, the recyclability and end-of-life management of HDPE fiber-reinforced composites pose environmental and technical challenges. Separating the fibers from the matrix for recycling can be difficult, and the potential for fiber degradation during the recycling process may limit the reuse of these materials in high-performance applications.

Current Reinforcement

01 Improving HDPE fiber strength through processing techniques

Various processing techniques can be employed to enhance the strength of HDPE fibers. These methods include optimizing extrusion parameters, drawing processes, and heat treatment. By carefully controlling these processes, the molecular orientation and crystallinity of the HDPE fibers can be improved, resulting in increased tensile strength and overall mechanical properties.- HDPE fiber production methods: Various methods are employed to produce high-strength HDPE fibers, including gel spinning, melt spinning, and drawing processes. These techniques aim to enhance the molecular orientation and crystallinity of the fibers, resulting in improved mechanical properties and strength.

- Fiber reinforcement in composites: HDPE fibers are utilized as reinforcement materials in composite structures to enhance overall strength and durability. The incorporation of these fibers in matrices such as concrete, polymers, or other materials can significantly improve the mechanical properties of the resulting composite.

- Surface treatment and modification: Various surface treatments and modifications are applied to HDPE fibers to improve their adhesion properties and compatibility with different matrices. These treatments can include plasma treatment, chemical etching, or the application of coupling agents, resulting in enhanced interfacial bonding and improved overall strength of the composite material.

- Blending and additives: The strength of HDPE fibers can be enhanced through blending with other polymers or incorporating additives. This approach can improve various properties such as tensile strength, impact resistance, and thermal stability, resulting in fibers with superior performance characteristics.

- Testing and characterization methods: Various testing and characterization techniques are employed to evaluate the strength and mechanical properties of HDPE fibers. These methods include tensile testing, impact testing, and microscopic analysis, which provide valuable insights into the fiber's performance and help optimize production processes for improved strength.

02 Incorporating additives to enhance HDPE fiber strength

The addition of specific additives to HDPE can significantly improve fiber strength. These additives may include nanoparticles, reinforcing agents, or compatibilizers. By carefully selecting and incorporating these materials, the mechanical properties of HDPE fibers can be enhanced, leading to improved tensile strength, impact resistance, and overall durability.Expand Specific Solutions03 Blending HDPE with other polymers for improved fiber strength

Blending HDPE with other compatible polymers can result in fibers with enhanced strength properties. This approach allows for the combination of desirable characteristics from different materials, potentially leading to fibers with improved tensile strength, elongation at break, and overall mechanical performance. The selection of appropriate polymer blends and optimization of blending ratios are crucial for achieving the desired strength improvements.Expand Specific Solutions04 Modifying HDPE molecular structure for increased fiber strength

Altering the molecular structure of HDPE through techniques such as crosslinking, grafting, or copolymerization can lead to significant improvements in fiber strength. These modifications can enhance the intermolecular forces within the polymer, resulting in fibers with increased tensile strength, improved creep resistance, and enhanced overall mechanical properties.Expand Specific Solutions05 Optimizing fiber production and post-treatment processes

The strength of HDPE fibers can be significantly improved through careful optimization of production and post-treatment processes. This includes fine-tuning spinning conditions, implementing advanced drawing techniques, and applying appropriate heat treatments or surface modifications. By optimizing these processes, the molecular orientation, crystallinity, and overall structure of the fibers can be enhanced, leading to improved strength and mechanical properties.Expand Specific Solutions

Key Industry Players

The HDPE fiber reinforcement market is in a growth phase, driven by increasing demand for high-strength, lightweight materials across various industries. The market size is expanding, with significant potential in construction, automotive, and aerospace sectors. Technologically, HDPE fiber reinforcement is advancing rapidly, with companies like TAC Technologies LLC, Equistar Chemicals LP, and Borealis AG leading innovation. Research institutions such as Sichuan University and Beijing University of Chemical Technology are contributing to technological maturity. Companies like SABIC Global Technologies BV and Solvay Specialty Polymers USA LLC are pushing boundaries in material science, while Kingfa Sci. & Tech. Co., Ltd. and Anhui Glant Advanced Material Co., Ltd. are focusing on application-specific developments, indicating a competitive and evolving landscape in HDPE fiber reinforcement technology.

Solvay Specialty Polymers USA LLC

Borealis AG

Core HDPE Innovations

- A composite material of UHMWPE/PPR alloy blending system and activated semi-reinforced carbon black, coupling agent, antioxidant, lubricant and heat stabilizer is used to control the alloying through mixing technology and twin-screw extrusion technology. The degree and dispersion of carbon black improve the strength, toughness and fluidity of the material.

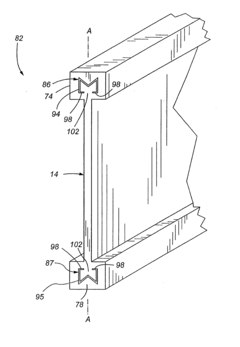

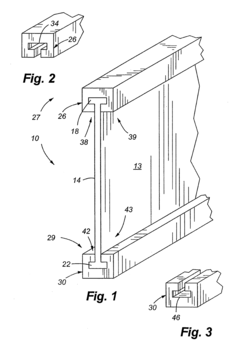

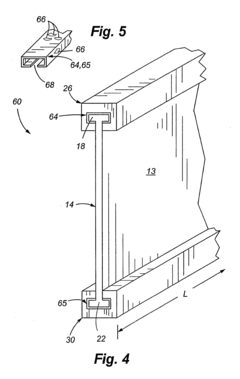

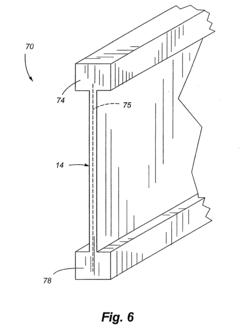

- The development of thermoplastic structural members, like HDPE, reinforced with aluminum or carbon fiber cores, which provide enhanced strength, weather resistance, and compatibility with standard tools, allowing for customizable sizes and recycling capabilities.

Environmental Impact

The environmental impact of HDPE fiber reinforcement for strength is a critical consideration in its adoption and development. HDPE fibers offer several environmental advantages over traditional reinforcement materials. Firstly, HDPE is a recyclable material, which contributes to the circular economy and reduces waste. The production process of HDPE fibers generally requires less energy compared to steel or glass fiber reinforcement, resulting in a lower carbon footprint.

However, the environmental benefits of HDPE fiber reinforcement are not without challenges. The production of HDPE relies on fossil fuels, which raises concerns about resource depletion and greenhouse gas emissions. While recycling is possible, the current infrastructure for recycling HDPE fibers from reinforced structures is limited, potentially leading to increased landfill waste if not properly managed.

In terms of durability, HDPE fiber-reinforced structures often have longer lifespans than traditional alternatives, reducing the need for frequent replacements and associated environmental impacts. The lightweight nature of HDPE fibers also contributes to reduced transportation costs and emissions during construction and installation phases.

Recent advancements in HDPE fiber technology have focused on improving its environmental profile. Researchers are exploring bio-based HDPE derived from renewable resources, which could significantly reduce the reliance on fossil fuels. Additionally, efforts are being made to enhance the recyclability of HDPE fiber-reinforced materials, including the development of more efficient separation techniques and the design of easily dismantlable structures.

The use of HDPE fibers in concrete and other construction materials has shown potential for reducing the overall environmental impact of buildings and infrastructure. By improving strength and durability, HDPE fiber reinforcement can lead to thinner structural elements, reducing the amount of material needed and consequently lowering the embodied energy and carbon emissions of construction projects.

Furthermore, the corrosion resistance of HDPE fibers eliminates the need for protective coatings or treatments often required for steel reinforcement, avoiding the use of potentially harmful chemicals and reducing maintenance-related environmental impacts over the structure's lifetime.

As sustainability becomes increasingly important in construction and engineering, the environmental impact of HDPE fiber reinforcement will likely play a crucial role in its future development and adoption. Ongoing research and innovation in this field are expected to further improve the environmental performance of HDPE fibers, potentially positioning them as a key material in sustainable construction practices.

Manufacturing Process

The manufacturing process for HDPE fiber reinforcement involves several key steps to produce high-strength fibers suitable for various applications. The process begins with the selection of high-density polyethylene (HDPE) resin, which is carefully chosen based on its molecular weight and distribution to ensure optimal mechanical properties.

The first stage of production involves melting the HDPE resin in an extruder. The molten polymer is then forced through a spinneret, a device with numerous tiny holes, to form continuous filaments. As these filaments emerge, they are rapidly cooled and solidified in a quenching bath. This rapid cooling is crucial for preserving the molecular orientation and achieving the desired fiber structure.

Following the initial extrusion and cooling, the fibers undergo a drawing process. This step is critical for enhancing the strength and stiffness of the HDPE fibers. The drawing process involves stretching the fibers at elevated temperatures, typically just below the melting point of HDPE. This stretching aligns the polymer chains along the fiber axis, significantly improving the mechanical properties of the fibers.

Recent advancements in the manufacturing process have focused on optimizing the drawing conditions. Researchers have explored multi-stage drawing processes, where fibers are drawn at different temperatures and rates to achieve an optimal balance of strength and ductility. Some manufacturers have implemented ultra-high draw ratios, pushing the limits of molecular alignment to produce fibers with exceptional tensile strength.

Another area of innovation in the manufacturing process is the development of surface treatments and coatings. These treatments are applied to the HDPE fibers to enhance their adhesion properties, which is crucial for their effectiveness as reinforcement in composite materials. Plasma treatments and chemical modifications have shown promising results in improving the interfacial bonding between HDPE fibers and various matrix materials.

Quality control is an integral part of the manufacturing process. Advanced inline monitoring systems are employed to ensure consistent fiber diameter, surface quality, and mechanical properties throughout the production run. These systems often utilize laser sensors and high-speed cameras to detect and correct any deviations in real-time.

The final stages of the manufacturing process involve winding the fibers onto spools or processing them into various forms such as woven fabrics, non-woven mats, or chopped fibers, depending on the intended application. Some manufacturers have developed specialized winding techniques to produce HDPE fiber reinforcements in formats that are easily integrated into existing composite manufacturing processes.