HDPE's Potential in Combatting Climate Change Agendas

HDPE Climate Impact Overview

High-density polyethylene (HDPE) has emerged as a significant player in the global effort to combat climate change. This versatile plastic material, known for its durability and recyclability, offers several potential benefits in reducing greenhouse gas emissions and promoting sustainable practices across various industries.

HDPE's role in climate change mitigation primarily stems from its ability to replace more carbon-intensive materials in numerous applications. For instance, in the packaging industry, HDPE containers can substitute glass or metal alternatives, resulting in lower energy consumption during production and transportation. This substitution effect contributes to a reduction in overall carbon footprint throughout the product lifecycle.

Furthermore, HDPE's lightweight nature plays a crucial role in improving fuel efficiency in transportation. When used in automotive components or packaging for goods, it helps reduce vehicle weight, leading to decreased fuel consumption and, consequently, lower carbon emissions. This aspect is particularly significant in the context of global efforts to decarbonize the transportation sector.

The recyclability of HDPE is another key factor in its potential to combat climate change. Unlike many other plastics, HDPE can be recycled multiple times without significant degradation in quality. This characteristic promotes a circular economy model, reducing the need for virgin plastic production and minimizing waste sent to landfills or incineration facilities. The recycling process of HDPE typically requires less energy compared to the production of new plastic, further contributing to emission reductions.

In the construction industry, HDPE pipes and fittings offer advantages over traditional materials like concrete or metal. Their longevity and resistance to corrosion result in fewer replacements and repairs, reducing the overall environmental impact associated with infrastructure maintenance. Additionally, the smooth interior surface of HDPE pipes improves fluid flow efficiency, potentially leading to energy savings in water and wastewater systems.

HDPE also shows promise in renewable energy applications. Its durability and weather resistance make it suitable for solar panel components and wind turbine parts, supporting the expansion of clean energy infrastructure. Moreover, HDPE's potential use in energy storage systems, such as hydrogen storage tanks, could facilitate the transition to renewable energy sources.

However, it is important to acknowledge the challenges associated with HDPE in the context of climate change. The material's production still relies on fossil fuel feedstocks, and improper disposal can lead to environmental pollution. Addressing these issues through sustainable production methods, improved recycling infrastructure, and responsible consumption practices is crucial to maximizing HDPE's positive impact on climate change mitigation efforts.

Market Demand for Eco-Friendly Plastics

The global market for eco-friendly plastics has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations aimed at reducing plastic waste and carbon emissions. High-density polyethylene (HDPE), a versatile and recyclable plastic, has emerged as a key player in this evolving landscape, particularly in the context of climate change mitigation efforts.

Consumer demand for sustainable packaging solutions has been a primary driver of the eco-friendly plastics market. As public consciousness about environmental issues continues to rise, there is a growing preference for products packaged in materials that have a lower environmental impact. HDPE, with its recyclability and potential for bio-based production, aligns well with these consumer preferences.

The packaging industry, which accounts for a substantial portion of plastic consumption, has been at the forefront of adopting eco-friendly alternatives. HDPE's durability, chemical resistance, and ability to be recycled multiple times make it an attractive option for various packaging applications, from food containers to personal care product bottles. This has led to increased demand from manufacturers seeking to improve their sustainability profiles.

In the construction sector, there is a growing interest in sustainable building materials. HDPE's resistance to weathering, UV radiation, and chemicals makes it suitable for outdoor applications such as pipes, decking, and fencing. As the construction industry increasingly focuses on green building practices, the demand for HDPE as an eco-friendly alternative to traditional materials is expected to rise.

The automotive industry represents another significant market for eco-friendly plastics. As automakers strive to reduce vehicle weight and improve fuel efficiency to meet stringent emissions standards, HDPE's lightweight properties make it an attractive material for various automotive components. This trend is likely to accelerate with the shift towards electric vehicles, where weight reduction is crucial for extending battery range.

Government policies and regulations aimed at reducing plastic waste and promoting circular economy principles have also been instrumental in driving market demand for eco-friendly plastics like HDPE. Many countries have implemented or are considering measures such as plastic taxes, bans on single-use plastics, and mandatory recycling targets, which create a favorable environment for the adoption of recyclable materials.

The agriculture sector presents another growing market for HDPE, particularly in applications such as greenhouse films, irrigation systems, and crop protection. As climate change impacts agricultural practices, there is an increasing need for durable, weather-resistant materials that can help improve crop yields while minimizing environmental impact.

While the market demand for eco-friendly plastics, including HDPE, is robust, challenges remain. These include the need for improved recycling infrastructure, consumer education on proper disposal and recycling practices, and ongoing research to enhance the material's properties and reduce its carbon footprint throughout its lifecycle. Addressing these challenges will be crucial for realizing HDPE's full potential in combating climate change and meeting the growing market demand for sustainable plastic solutions.

HDPE Sustainability Challenges

High-density polyethylene (HDPE) faces significant sustainability challenges as the world grapples with climate change and environmental concerns. One of the primary issues is the material's durability, which, while beneficial for many applications, contributes to long-term environmental persistence. HDPE can take hundreds of years to decompose naturally, leading to accumulation in landfills and ecosystems.

The production of HDPE is another area of concern. The manufacturing process relies heavily on fossil fuels, both as raw materials and energy sources. This dependence contributes to greenhouse gas emissions and exacerbates climate change. The extraction of these fossil fuels also poses environmental risks, including habitat destruction and potential oil spills.

Recycling HDPE presents its own set of challenges. While technically recyclable, the efficiency and widespread implementation of HDPE recycling systems remain inadequate. Contamination issues, varying quality of recycled materials, and the lack of economic incentives for recycling all hinder the development of a circular economy for HDPE products.

The use of HDPE in single-use plastics is particularly problematic. Despite efforts to reduce consumption, these products continue to contribute significantly to plastic pollution in oceans and terrestrial environments. The breakdown of HDPE into microplastics poses additional threats to wildlife and potentially human health.

Energy consumption throughout the HDPE lifecycle is another sustainability challenge. From production to transportation and eventual disposal or recycling, each stage requires substantial energy inputs, often derived from non-renewable sources. This energy-intensive process contributes to the overall carbon footprint of HDPE products.

Water pollution is an often-overlooked aspect of HDPE sustainability. The manufacturing process can release pollutants into water systems, while improperly disposed HDPE products can leach harmful chemicals into groundwater and marine environments over time.

Addressing these sustainability challenges requires a multifaceted approach. Innovations in bio-based alternatives, improvements in recycling technologies, and the development of more energy-efficient production methods are all crucial areas for advancement. Additionally, policy measures to incentivize sustainable practices and consumer education to promote responsible use and disposal of HDPE products are essential components of a comprehensive strategy to mitigate the environmental impact of this widely used material.

Current HDPE Climate Mitigation Solutions

01 Recycling and upcycling of HDPE

Recycling and upcycling of HDPE contribute to climate change mitigation by reducing the demand for virgin plastic production and decreasing waste. This process involves collecting, sorting, and processing used HDPE products to create new materials or products, thereby reducing greenhouse gas emissions associated with the production of new plastic.- Recycling and upcycling of HDPE: Recycling and upcycling of HDPE contribute to climate change mitigation by reducing the demand for virgin plastic production and minimizing waste. This process involves collecting, sorting, and processing used HDPE products to create new materials or products, thereby reducing greenhouse gas emissions associated with the production of new plastics.

- Biodegradable HDPE composites: Development of biodegradable HDPE composites helps mitigate climate change by reducing the environmental impact of plastic waste. These composites incorporate natural fibers or biodegradable additives into HDPE, enhancing its degradability while maintaining desirable properties, thus reducing long-term pollution and carbon footprint.

- Carbon capture and storage in HDPE production: Implementing carbon capture and storage technologies in HDPE production processes helps reduce greenhouse gas emissions. This approach involves capturing CO2 emissions from manufacturing facilities and storing them underground or utilizing them in other industrial processes, thereby mitigating the climate impact of HDPE production.

- Energy-efficient HDPE manufacturing: Developing energy-efficient manufacturing processes for HDPE production contributes to climate change mitigation. This includes optimizing production methods, using renewable energy sources, and implementing advanced process control systems to reduce energy consumption and associated greenhouse gas emissions in HDPE manufacturing.

- HDPE in renewable energy applications: Utilizing HDPE in renewable energy applications supports climate change mitigation efforts. HDPE can be used in the production of components for solar panels, wind turbines, and other renewable energy technologies, contributing to the transition towards cleaner energy sources and reducing reliance on fossil fuels.

02 Biodegradable HDPE composites

Development of biodegradable HDPE composites helps mitigate climate change by reducing the persistence of plastic waste in the environment. These composites incorporate natural fibers or biodegradable additives into HDPE, enhancing its biodegradability while maintaining desirable properties for various applications.Expand Specific Solutions03 Carbon capture and storage in HDPE production

Implementing carbon capture and storage technologies in HDPE production processes helps reduce greenhouse gas emissions. This approach involves capturing CO2 emissions from manufacturing facilities and storing them underground or utilizing them in other industrial processes, thereby mitigating the climate impact of HDPE production.Expand Specific Solutions04 Energy-efficient HDPE manufacturing

Developing energy-efficient manufacturing processes for HDPE production contributes to climate change mitigation by reducing energy consumption and associated emissions. This includes optimizing production equipment, implementing heat recovery systems, and utilizing renewable energy sources in the manufacturing process.Expand Specific Solutions05 HDPE-based materials for renewable energy applications

Utilizing HDPE-based materials in renewable energy applications supports climate change mitigation efforts. This includes developing HDPE components for solar panels, wind turbines, and other clean energy technologies, leveraging the material's durability and weather resistance to enhance the performance and longevity of renewable energy systems.Expand Specific Solutions

Key HDPE Manufacturers and Innovators

The HDPE market for climate change mitigation is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The market size is expanding as industries seek sustainable alternatives, with HDPE's recyclability and durability positioning it favorably. Technologically, HDPE is mature but evolving, with companies like ExxonMobil Chemical, Dow Global Technologies, and Chevron Phillips Chemical leading innovation. These firms, along with others like Braskem and SABIC, are focusing on enhancing HDPE's properties and production methods to further reduce its carbon footprint and improve its performance in climate-related applications. The competitive landscape is characterized by ongoing research and development efforts to optimize HDPE's environmental benefits while maintaining its industrial versatility.

ExxonMobil Chemical Patents, Inc.

Dow Global Technologies LLC

Breakthrough HDPE Eco-Innovations

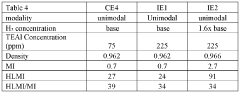

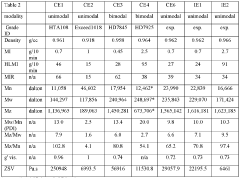

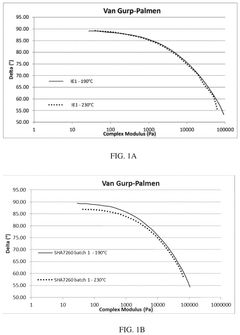

- A unimodal HDPE composition is developed with specific molecular weight ranges and distribution characteristics, achieved through controlled polymerization in a loop reactor with varying cocatalyst amounts, allowing for low MI and enhanced crystallization, thereby reducing the need for nucleating agents and simplifying the manufacturing process.

- A polymer composition comprising high-density polyethylene (HDPE) where at least a portion of the ethylene is sourced from renewable carbon, combined with a primary antioxidant (isocyanurate), a secondary antioxidant (diphosphite), and a neutralizer (layered double hydroxide), which enhances thermal stability, reduces die-buildup and additive migration, and improves processing efficiency.

HDPE Environmental Regulations

The environmental regulations surrounding High-Density Polyethylene (HDPE) are becoming increasingly stringent as governments worldwide strive to combat climate change and reduce plastic pollution. These regulations are shaping the future of HDPE production, use, and disposal, with significant implications for manufacturers, consumers, and the environment.

In the European Union, the Single-Use Plastics Directive has set ambitious targets for reducing plastic waste, including HDPE products. This directive mandates that by 2030, all plastic packaging in the EU market must be reusable or recyclable in a cost-effective manner. For HDPE manufacturers, this means investing in eco-friendly product designs and improving recycling infrastructure.

The United States has implemented various state-level regulations targeting HDPE and other plastics. California's Rigid Plastic Packaging Container (RPPC) program requires manufacturers to meet specific recycling rates or use a minimum percentage of post-consumer recycled content in their packaging. Similar initiatives are being adopted by other states, creating a patchwork of regulations that HDPE producers must navigate.

In Asia, countries like China and India are also tightening their environmental policies. China's ban on importing plastic waste has forced many nations to reconsider their recycling strategies, leading to increased pressure on domestic HDPE recycling capabilities. India has introduced the Plastic Waste Management Rules, which phased out single-use plastics, including certain HDPE products, by 2022.

Global efforts to reduce greenhouse gas emissions are indirectly affecting HDPE production. As the petrochemical industry faces increasing scrutiny for its carbon footprint, HDPE manufacturers are under pressure to adopt more sustainable production methods. This includes exploring bio-based alternatives and investing in carbon capture technologies.

Extended Producer Responsibility (EPR) schemes are gaining traction worldwide, holding manufacturers accountable for the entire lifecycle of their products, including HDPE items. These regulations require producers to finance and manage the collection, recycling, and disposal of their products, encouraging more sustainable design and production practices.

The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal has been amended to include plastic waste, affecting the global trade of HDPE scrap. This change aims to make the global trade in plastic waste more transparent and better regulated, potentially impacting the recycling economics of HDPE.

As environmental regulations continue to evolve, the HDPE industry must adapt to remain compliant and competitive. This regulatory landscape is driving innovation in recycling technologies, product design, and alternative materials, positioning HDPE as a potential solution in the fight against climate change, provided it can meet increasingly strict environmental standards.

HDPE Lifecycle Assessment

The lifecycle assessment of High-Density Polyethylene (HDPE) is crucial in evaluating its potential to combat climate change. This assessment encompasses the entire journey of HDPE, from raw material extraction to end-of-life disposal or recycling.

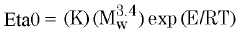

The production phase of HDPE begins with the extraction of fossil fuels, primarily natural gas or petroleum. These raw materials undergo a series of energy-intensive processes, including cracking and polymerization, to create HDPE pellets. This stage typically accounts for a significant portion of the material's carbon footprint, with greenhouse gas emissions primarily stemming from energy consumption and chemical reactions.

During the use phase, HDPE demonstrates several advantages that contribute to its potential in addressing climate change. Its durability and resistance to degradation mean that HDPE products often have long lifespans, reducing the need for frequent replacements. This longevity can lead to a decrease in overall resource consumption and associated emissions. Additionally, HDPE's lightweight nature compared to alternative materials can result in reduced transportation-related emissions when used in packaging or automotive applications.

The end-of-life stage of HDPE presents both challenges and opportunities in the context of climate change mitigation. HDPE is highly recyclable, and when properly collected and processed, it can be transformed into new products with minimal quality loss. This recycling potential significantly reduces the need for virgin material production, thereby lowering overall emissions. However, the effectiveness of HDPE recycling is heavily dependent on efficient collection systems and consumer participation.

Incineration and landfilling are alternative end-of-life scenarios for HDPE. While incineration can recover energy, it also releases greenhouse gases. Landfilling, on the other hand, results in long-term carbon storage but poses risks of environmental contamination if not properly managed.

Recent innovations in HDPE production and recycling technologies have the potential to further enhance its role in combating climate change. Bio-based HDPE, derived from renewable resources such as sugarcane, offers a promising alternative to fossil fuel-based production. Advanced recycling technologies, including chemical recycling, are also emerging as methods to process mixed plastic waste streams more effectively, potentially increasing the recycling rates of HDPE.

To fully realize HDPE's potential in addressing climate change, a holistic approach is necessary. This includes optimizing production processes to reduce energy consumption, improving waste management infrastructure to increase recycling rates, and developing more sustainable end-of-life solutions. Additionally, the implementation of circular economy principles in HDPE lifecycle management could significantly reduce its overall environmental impact and contribute to climate change mitigation efforts.