How to Paint High Density Polyethylene?

HDPE Painting Background

High Density Polyethylene (HDPE) is a versatile thermoplastic polymer known for its high strength-to-density ratio, chemical resistance, and durability. Since its commercial introduction in the 1950s, HDPE has become a ubiquitous material in various industries, including packaging, construction, and automotive. However, one of the significant challenges associated with HDPE is its inherent difficulty in accepting paint or other surface coatings.

The need for painting HDPE arises from various industrial and consumer applications where aesthetics, branding, or additional functionality is required. For instance, in the automotive industry, HDPE components often need to match the vehicle's color scheme. In consumer goods, painted HDPE products can enhance visual appeal and brand recognition. Additionally, certain industrial applications may require painted HDPE for safety markings or corrosion resistance.

The primary challenge in painting HDPE stems from its low surface energy and non-polar nature. These properties result in poor adhesion between the paint and the HDPE surface, leading to peeling, flaking, or uneven coverage. Traditional painting methods that work well on other materials often fail when applied to HDPE, necessitating specialized techniques and surface treatments.

Over the years, various approaches have been developed to overcome the painting challenges associated with HDPE. These include surface preparation techniques such as flame treatment, corona discharge, and plasma treatment, which aim to increase the surface energy of HDPE and improve paint adhesion. Chemical etching and the use of specialized primers have also been explored as potential solutions.

The evolution of paint formulations has played a crucial role in addressing HDPE painting issues. Manufacturers have developed specialized paints and coatings designed specifically for polyolefin surfaces, including HDPE. These formulations often incorporate adhesion promoters and other additives that enhance bonding to the HDPE substrate.

Recent advancements in nanotechnology and material science have opened up new possibilities for HDPE surface modification and coating. Researchers are exploring novel approaches such as nanoparticle-enhanced coatings and plasma-assisted deposition techniques to achieve better adhesion and durability of paint on HDPE surfaces.

As environmental concerns gain prominence, there is a growing focus on developing eco-friendly and sustainable painting solutions for HDPE. This includes water-based paints, UV-curable coatings, and bio-based formulations that aim to reduce the environmental impact of the painting process while maintaining performance standards.

Market Demand Analysis

The market demand for painting high-density polyethylene (HDPE) has been steadily growing across various industries. HDPE, known for its durability, chemical resistance, and versatility, is widely used in manufacturing containers, pipes, automotive parts, and consumer goods. However, its low surface energy makes it challenging to paint, creating a significant market need for effective painting solutions.

In the packaging industry, painted HDPE containers are increasingly sought after for branding and product differentiation. Companies are looking for cost-effective ways to enhance the visual appeal of their packaging without compromising the material's inherent properties. This trend is particularly evident in the food and beverage sector, where attractive packaging plays a crucial role in consumer decision-making.

The automotive industry represents another major market for HDPE painting solutions. As automakers strive to reduce vehicle weight and improve fuel efficiency, HDPE is becoming a popular choice for various components. The ability to paint these parts to match or complement the vehicle's exterior color is essential for maintaining aesthetic consistency and perceived quality.

In the construction sector, there's a growing demand for painted HDPE pipes and fittings. This is driven by both functional and aesthetic considerations. Painted HDPE pipes can offer improved UV resistance, extending their lifespan in outdoor applications. Additionally, color-coded pipes facilitate easier identification and installation, particularly in complex plumbing systems.

The consumer goods market also shows significant potential for painted HDPE products. From outdoor furniture to household items, consumers are increasingly looking for durable, weather-resistant products that don't compromise on appearance. This has led to a surge in demand for HDPE items that can be painted in a wide range of colors and finishes.

Environmental concerns and regulations are shaping the market demand as well. There's a growing emphasis on eco-friendly painting solutions that minimize volatile organic compound (VOC) emissions and reduce environmental impact. This has spurred research and development into water-based and low-VOC paint formulations specifically designed for HDPE surfaces.

The global market for HDPE painting solutions is expected to expand further as manufacturers in emerging economies adopt more sophisticated production techniques. This growth is likely to be driven by increasing urbanization, infrastructure development, and rising consumer spending power in these regions.

As the demand for painted HDPE products continues to rise, there's a parallel increase in the need for innovative painting technologies and processes. This includes advancements in surface treatment methods, specialized paint formulations, and automated painting systems designed to handle the unique challenges posed by HDPE surfaces.

HDPE Painting Challenges

High Density Polyethylene (HDPE) presents significant challenges when it comes to painting due to its inherent properties. The non-polar, low surface energy nature of HDPE results in poor adhesion for most conventional paints and coatings. This characteristic makes it difficult for paint to bond effectively to the surface, often leading to peeling, flaking, or poor coverage.

One of the primary challenges is the smooth, waxy surface of HDPE, which repels many liquid substances, including paint. This hydrophobic property, while beneficial for many HDPE applications, becomes a major obstacle in painting processes. The lack of surface roughness or porosity further compounds the adhesion problem, as there are few anchor points for paint to grip onto.

Another significant challenge is the chemical inertness of HDPE. This material resists reaction with most solvents and chemicals commonly used in paint formulations, making it difficult to achieve a chemical bond between the paint and the substrate. This resistance to chemical interaction limits the effectiveness of many traditional painting techniques and requires specialized approaches.

The thermal properties of HDPE also pose challenges. The material has a relatively low melting point and is prone to warping or deformation under heat. This characteristic limits the use of heat-curing paints or high-temperature application methods, which are often employed to enhance paint adhesion and durability on other substrates.

Surface contamination is another hurdle in HDPE painting. The material's tendency to accumulate static charge attracts dust and other particulates, which can interfere with paint adhesion. Thorough cleaning is essential, but traditional cleaning methods may not be sufficient due to HDPE's resistance to many solvents.

The expansion and contraction of HDPE in response to temperature changes can also affect paint adhesion. As the material expands and contracts, it can cause stress on the paint layer, potentially leading to cracking or separation over time. This thermal behavior necessitates the use of flexible coatings that can accommodate these dimensional changes.

Achieving uniform paint coverage on HDPE surfaces is challenging due to the material's tendency to repel liquids. This can result in uneven application, with paint beading up or forming inconsistent layers. Specialized application techniques and paint formulations are often required to overcome this issue and achieve a smooth, even finish.

Current HDPE Painting Solutions

01 Manufacturing processes for HDPE

Various manufacturing processes are used to produce high-density polyethylene (HDPE), including polymerization techniques and extrusion methods. These processes aim to create HDPE with specific properties such as high strength, durability, and chemical resistance.- Manufacturing processes for HDPE: Various manufacturing processes are used to produce high-density polyethylene (HDPE), including different polymerization techniques and reactor designs. These processes aim to control the molecular weight, density, and other properties of the resulting HDPE material.

- HDPE blends and composites: HDPE is often blended with other materials or used in composites to enhance its properties or create specialized materials. These blends and composites can improve characteristics such as strength, durability, or specific performance attributes for various applications.

- HDPE applications in packaging and containers: High-density polyethylene is widely used in packaging and container applications due to its excellent chemical resistance, durability, and barrier properties. It is commonly used in bottles, food packaging, and industrial containers.

- HDPE in construction and infrastructure: HDPE finds extensive use in construction and infrastructure projects, including pipes, geomembranes, and structural components. Its resistance to corrosion, weathering, and chemicals makes it suitable for long-term outdoor applications.

- Modifications and additives for HDPE: Various modifications and additives are used to enhance the properties of HDPE for specific applications. These can include UV stabilizers, antioxidants, colorants, and other functional additives that improve the material's performance or processability.

02 HDPE blends and composites

HDPE is often blended with other materials or used in composites to enhance its properties. These blends and composites can improve characteristics such as impact resistance, thermal stability, and processability, making them suitable for a wide range of applications.Expand Specific Solutions03 HDPE applications in packaging and containers

HDPE is widely used in packaging and container applications due to its excellent barrier properties, chemical resistance, and durability. It is commonly used in the production of bottles, containers, and packaging materials for various industries.Expand Specific Solutions04 Recycling and sustainability of HDPE

Recycling processes and sustainable practices for HDPE are being developed to address environmental concerns. These include methods for collecting, sorting, and reprocessing HDPE materials, as well as the development of bio-based alternatives.Expand Specific Solutions05 HDPE modifications and additives

Various modifications and additives are used to enhance the properties of HDPE. These can include crosslinking agents, stabilizers, and other additives that improve characteristics such as UV resistance, long-term durability, and processing behavior.Expand Specific Solutions

Key Players in HDPE Coating

The market for painting high-density polyethylene (HDPE) is in a growth phase, driven by increasing demand across various industries. The global HDPE market size is projected to expand significantly, with key players like Dow Global Technologies LLC, ExxonMobil Chemical Patents, Inc., and SABIC Global Technologies BV leading innovation. Technological maturity varies, with companies such as Bayer AG and Eastman Chemical Co. focusing on advanced coating solutions. Emerging players like Anhui Yongli New Material Technology Co., Ltd. and Kingfa Sci. & Tech. Co., Ltd. are also contributing to the competitive landscape, particularly in developing regions. The industry is characterized by ongoing research and development efforts to improve adhesion, durability, and environmental sustainability of HDPE coatings.

Dow Global Technologies LLC

ExxonMobil Chemical Patents, Inc.

Innovative HDPE Adhesion Technologies

- A surface modification composition comprising a copolymer with a first monomer having an aliphatic group and a second monomer with an amino, epoxy, or ether group, combined with a solvent, is used to modify the surface of molded articles, promoting strong co-crystal interactions and improved adhesion and paintability.

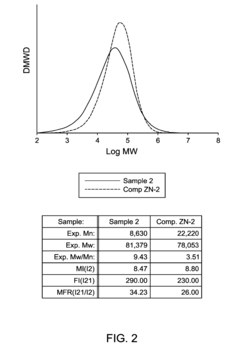

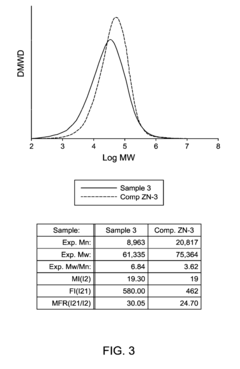

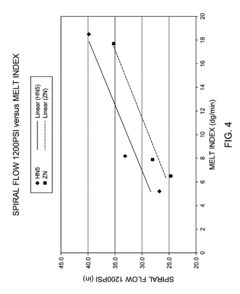

- A method involving a gas phase reactor that contacts ethylene and non-ethylene comonomers with a catalyst system, including bis amides or bis(2-(pentamethyl phenyl amido)ethyl) amine zirconium dibenzyl supported on fumed silica with methylalumoxane, at high ethylene partial pressures, to produce polyethylene copolymers with specific density, melt index, and molecular weight distribution for improved injection moldability.

Environmental Regulations

Environmental regulations play a crucial role in shaping the practices and technologies used for painting high-density polyethylene (HDPE). As concerns about environmental protection and sustainability continue to grow, regulatory bodies worldwide have implemented stringent guidelines to minimize the environmental impact of painting processes.

One of the primary focuses of environmental regulations in HDPE painting is the reduction of volatile organic compounds (VOCs) emissions. Traditional solvent-based paints often contain high levels of VOCs, which contribute to air pollution and pose health risks. As a result, many jurisdictions have set limits on VOC content in paints and coatings used for HDPE. This has led to the development and adoption of low-VOC and zero-VOC paint formulations specifically designed for HDPE surfaces.

Water-based paints have gained popularity as an environmentally friendly alternative to solvent-based options. These paints typically have lower VOC content and reduced odor, making them compliant with stricter environmental standards. However, the challenge lies in ensuring proper adhesion and durability of water-based paints on the non-porous surface of HDPE.

Regulations also address the disposal of paint waste and the management of painting processes. Many jurisdictions require proper handling and disposal of paint residues, including recycling or treatment of leftover paint and contaminated materials. This has led to the development of more efficient paint application techniques that minimize waste and overspray.

The use of hazardous substances in paint formulations is another area of regulatory focus. Restrictions on heavy metals, such as lead and chromium, have been implemented to protect both human health and the environment. Manufacturers are required to disclose the composition of their paints and ensure compliance with these substance restrictions.

Energy efficiency in the painting process has also come under scrutiny. Regulations may require the use of energy-efficient equipment and processes, such as low-temperature curing systems or UV-curable coatings, which can significantly reduce energy consumption compared to traditional heat-curing methods.

As environmental regulations continue to evolve, the HDPE painting industry must adapt by investing in research and development of compliant technologies. This includes exploring bio-based and renewable raw materials for paint formulations, as well as improving the overall sustainability of the painting process from production to application and disposal.

Cost-Benefit Analysis

When considering the implementation of painting techniques for High Density Polyethylene (HDPE), a thorough cost-benefit analysis is crucial for making informed decisions. The initial investment in specialized equipment and materials for HDPE painting must be weighed against the long-term benefits and potential cost savings.

One of the primary benefits of painting HDPE is the enhanced aesthetic appeal, which can significantly increase the marketability of products. This improved appearance can lead to higher sales volumes and potentially command premium pricing, resulting in increased revenue. Additionally, painted HDPE surfaces often exhibit improved durability and resistance to environmental factors, potentially extending the lifespan of products and reducing replacement costs.

However, the costs associated with HDPE painting can be substantial. Specialized surface preparation techniques, such as flame or corona treatment, are often required to ensure proper paint adhesion. These processes necessitate additional equipment and energy consumption, contributing to higher production costs. Furthermore, the paints and primers specifically formulated for HDPE can be more expensive than standard alternatives.

Labor costs must also be factored into the equation. The painting process for HDPE typically requires skilled technicians and may involve multiple steps, including surface preparation, priming, and applying multiple coats. This can result in increased labor hours and potentially higher wages for specialized workers.

On the benefit side, painted HDPE products often command higher prices in the market due to their improved aesthetics and perceived quality. This price premium can offset the additional production costs and potentially increase profit margins. Moreover, the ability to offer customized colors and finishes can open up new market segments and business opportunities.

Environmental considerations play a role in the cost-benefit analysis as well. While the painting process may involve the use of chemicals and generate some waste, it can also extend the useful life of HDPE products, reducing the overall environmental impact associated with frequent replacements. Additionally, some modern painting techniques for HDPE utilize more environmentally friendly materials, which may align with sustainability goals and potentially attract environmentally conscious consumers.

In terms of long-term benefits, painted HDPE surfaces often require less maintenance and cleaning, which can translate to cost savings for end-users. This improved performance can enhance customer satisfaction and brand loyalty, potentially leading to repeat business and positive word-of-mouth marketing.

When conducting a cost-benefit analysis for HDPE painting, it is essential to consider the specific application and market demands. For high-value products or those in competitive markets where aesthetics play a crucial role, the benefits of painting may outweigh the costs. Conversely, for low-margin or utilitarian products, the additional expenses may not be justified by the potential benefits.