HDPE: Emerging as a Dynamic Industrial Catalyst

HDPE Catalyst Evolution

The evolution of High-Density Polyethylene (HDPE) catalysts represents a significant journey in the field of polymer science and industrial chemistry. This progression can be traced through several key developmental stages, each marked by groundbreaking innovations and technological advancements.

The initial phase of HDPE catalyst development began in the 1950s with the introduction of Ziegler-Natta catalysts. These revolutionary catalysts, developed by Karl Ziegler and Giulio Natta, enabled the production of HDPE at lower pressures and temperatures compared to previous methods. This breakthrough not only improved the efficiency of HDPE production but also enhanced the polymer's properties, leading to its widespread adoption in various industries.

The 1960s and 1970s saw the refinement of Ziegler-Natta catalysts, with researchers focusing on improving catalyst activity and selectivity. This period was characterized by the development of supported catalysts, where the active components were dispersed on a solid support material. This innovation significantly increased catalyst efficiency and allowed for better control over polymer properties.

A major leap forward occurred in the 1980s with the advent of metallocene catalysts. These single-site catalysts offered unprecedented control over polymer structure and properties. Metallocenes allowed for the production of HDPE with narrower molecular weight distributions and improved mechanical properties, opening up new applications for the material.

The 1990s and early 2000s witnessed the emergence of post-metallocene catalysts, including constrained geometry catalysts (CGCs) and late transition metal catalysts. These new catalyst systems further expanded the range of achievable polymer structures and properties, enabling the production of HDPE with enhanced toughness, clarity, and processability.

In recent years, the focus has shifted towards developing more sustainable and environmentally friendly catalyst systems. This includes research into bio-based catalysts and catalysts that enable the production of recyclable or biodegradable HDPE variants. Additionally, there has been significant progress in the development of hybrid catalyst systems that combine the benefits of different catalyst types.

The latest frontier in HDPE catalyst evolution involves the application of nanotechnology and computational modeling. Researchers are exploring nanostructured catalysts that offer even greater control over polymer properties at the molecular level. Simultaneously, advanced computational techniques are being employed to predict catalyst behavior and optimize catalyst design, accelerating the development process.

Throughout this evolution, each new generation of catalysts has not only improved the efficiency and quality of HDPE production but also expanded its applications across various sectors, from packaging to automotive and construction industries. The ongoing research in this field continues to push the boundaries of what is possible with HDPE, promising further innovations in the years to come.

Market Demand Analysis

The market demand for High-Density Polyethylene (HDPE) as an industrial catalyst has been experiencing significant growth in recent years. This surge is primarily driven by the increasing need for efficient and cost-effective catalytic processes across various industries. HDPE's unique properties, including its high thermal stability, chemical resistance, and mechanical strength, make it an attractive option for catalyst support and as a catalyst itself in certain applications.

In the petrochemical industry, HDPE-based catalysts have shown promising results in processes such as hydrocracking, hydrodesulfurization, and polymerization reactions. The demand for cleaner fuels and stricter environmental regulations have further boosted the adoption of HDPE catalysts in refinery operations. Additionally, the growing emphasis on sustainable and green chemistry has led to increased research and development efforts to utilize HDPE as a catalyst support for various environmentally friendly processes.

The automotive sector has also emerged as a significant consumer of HDPE-based catalysts, particularly in emission control systems. As global automotive production continues to rise and emission standards become more stringent, the demand for efficient catalytic converters incorporating HDPE components is expected to grow substantially. This trend is further amplified by the shift towards electric vehicles, where HDPE catalysts play a crucial role in battery technologies and fuel cell systems.

In the pharmaceutical industry, HDPE catalysts have found applications in the synthesis of complex organic compounds and active pharmaceutical ingredients. The biocompatibility and inertness of HDPE make it an ideal candidate for catalytic processes in drug manufacturing, where purity and consistency are paramount. As the pharmaceutical sector expands and new drug discovery efforts intensify, the demand for HDPE-based catalytic solutions is projected to increase.

The agricultural sector presents another growing market for HDPE catalysts, particularly in the production of fertilizers and pesticides. HDPE-supported catalysts have shown improved efficiency in the synthesis of various agrochemicals, leading to increased crop yields and reduced environmental impact. With the global population growth and the need for sustainable agricultural practices, the demand for HDPE catalysts in this sector is expected to rise steadily.

Furthermore, the renewable energy sector has begun to explore the potential of HDPE-based catalysts in biofuel production and solar energy applications. As the world transitions towards cleaner energy sources, the demand for efficient catalytic processes in these areas is likely to drive further innovation and adoption of HDPE catalysts.

Technical Challenges

The emergence of High-Density Polyethylene (HDPE) as a dynamic industrial catalyst presents several technical challenges that researchers and industry professionals are actively addressing. One of the primary hurdles is optimizing the catalytic activity of HDPE while maintaining its structural integrity under various reaction conditions. The high molecular weight and crystalline structure of HDPE can limit its surface area and accessibility to reactants, potentially reducing its effectiveness as a catalyst.

Another significant challenge lies in enhancing the selectivity of HDPE-based catalysts. While HDPE shows promise in catalyzing a range of reactions, fine-tuning its selectivity for specific products or reaction pathways remains a complex task. This requires a deep understanding of the interaction between HDPE's surface properties and different reactants, as well as the ability to modify these properties without compromising the material's overall stability.

The durability and longevity of HDPE catalysts in industrial settings pose additional technical hurdles. Exposure to harsh chemical environments, high temperatures, and mechanical stress can lead to degradation of the HDPE structure over time, potentially reducing its catalytic efficiency and lifespan. Developing strategies to enhance the material's resistance to these factors without sacrificing its catalytic properties is crucial for its widespread adoption in industrial applications.

Furthermore, the scalability of HDPE-based catalytic systems presents challenges in terms of process engineering and cost-effectiveness. Transitioning from laboratory-scale experiments to large-scale industrial processes requires overcoming issues related to heat and mass transfer, as well as ensuring uniform catalytic activity across larger volumes of material. This scaling up process often unveils unforeseen technical difficulties that need innovative solutions.

The environmental impact and sustainability of HDPE catalysts also present technical challenges. While HDPE itself is a recyclable material, its use as a catalyst may introduce complexities in the recycling process. Developing methods for efficient recovery and regeneration of HDPE catalysts after use, as well as minimizing any potential environmental risks associated with their production and application, are critical areas of research.

Lastly, the integration of HDPE catalysts into existing industrial processes and equipment poses technical challenges. Adapting current manufacturing systems to accommodate HDPE-based catalytic processes may require significant modifications to reactor designs, separation techniques, and process control systems. Overcoming these integration challenges is essential for the practical implementation of HDPE catalysts in various industries.

Current Catalyst Tech

01 Composition and properties of HDPE

High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength, stiffness, and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications, including packaging, pipes, and automotive parts.- Composition and properties of HDPE: High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength, stiffness, and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications, including packaging, pipes, and industrial products.

- HDPE blends and composites: HDPE can be blended with other materials or reinforced with additives to enhance its properties. These blends and composites can improve characteristics such as impact resistance, thermal stability, or specific functional properties. The resulting materials find applications in diverse industries, including automotive, construction, and consumer goods.

- HDPE processing techniques: Various processing techniques are employed to manufacture HDPE products, including injection molding, extrusion, and blow molding. These methods allow for the production of a wide range of HDPE items, from thin films to large containers. Advancements in processing technologies focus on improving efficiency, reducing waste, and enhancing the quality of the final products.

- Recycling and sustainability of HDPE: HDPE is highly recyclable, making it an environmentally friendly option for many applications. Recycling processes for HDPE involve collection, sorting, cleaning, and reprocessing into new products. Innovations in recycling technologies aim to improve the quality of recycled HDPE and expand its use in various industries, contributing to circular economy initiatives.

- HDPE applications in specific industries: HDPE finds extensive use in various industries due to its versatile properties. In the packaging industry, it is used for bottles, containers, and films. In construction, HDPE is utilized for pipes, geomembranes, and insulation. Other applications include automotive parts, toys, and medical devices. Ongoing research focuses on expanding HDPE's use in specialized applications, such as 3D printing and advanced composites.

02 HDPE blends and composites

HDPE can be blended with other materials or reinforced with additives to enhance its properties. These blends and composites can improve characteristics such as impact resistance, thermal stability, or specific mechanical properties. The resulting materials find applications in areas where standard HDPE may not meet all requirements.Expand Specific Solutions03 HDPE processing techniques

Various processing techniques are used to manufacture HDPE products, including injection molding, extrusion, and blow molding. Each method offers specific advantages and is suited for different product types. Innovations in processing techniques focus on improving efficiency, reducing cycle times, and enhancing the quality of the final products.Expand Specific Solutions04 Recycling and sustainability of HDPE

HDPE is recyclable, and efforts are being made to improve its recycling processes and increase the use of recycled HDPE in new products. This includes developing better sorting and cleaning methods for post-consumer HDPE, as well as finding ways to maintain or enhance the properties of recycled HDPE for various applications.Expand Specific Solutions05 HDPE applications in specific industries

HDPE finds applications in various industries due to its versatile properties. It is used in packaging, construction, automotive, and medical industries, among others. Ongoing research focuses on expanding HDPE's use in specialized applications, such as in the production of high-performance parts or in the development of novel packaging solutions.Expand Specific Solutions

Key Industry Players

The HDPE industry is in a mature growth phase, with a global market size expected to reach $84.79 billion by 2023. The technology's maturity is evident in the diverse applications across various sectors. Key players like ExxonMobil Chemical Patents, SABIC Global Technologies, and China Petroleum & Chemical Corp. are driving innovation in catalyst technologies and production processes. The competitive landscape is characterized by intense R&D efforts from major petrochemical companies and research institutions, focusing on improving HDPE properties and sustainability. Emerging trends include the development of advanced catalysts by companies such as Dow Global Technologies and LG Chem, aiming to enhance HDPE performance and reduce environmental impact.

ExxonMobil Chemical Patents, Inc.

SABIC Global Technologies BV

Innovative HDPE Catalysts

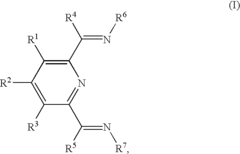

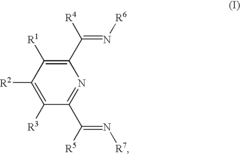

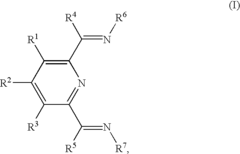

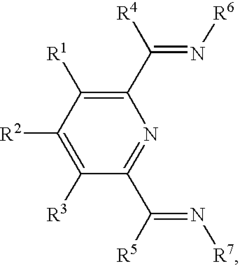

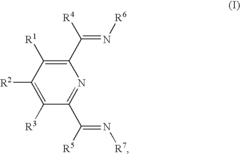

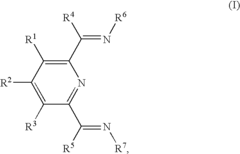

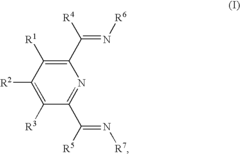

- HDPE is produced using polymerization catalysts comprising iron or cobalt complexes of specific compounds, such as those with aryl and substituted aryl groups, which significantly reduce water vapor and oxygen transmission rates, making them suitable for improved packaging.

- The use of HDPE polymerized in the presence of an iron or cobalt complex catalyst, specifically a compound of formula (I), (II), or (III), to form a package with reduced water vapor and oxygen transmission rates, achieved by replacing or blending HDPE layers with the catalyst-complex-polymerized HDPE in packaging materials.

Environmental Impact

The environmental impact of High-Density Polyethylene (HDPE) as an emerging industrial catalyst is a complex and multifaceted issue that requires careful consideration. HDPE catalysts have shown promising potential in various industrial processes, offering improved efficiency and selectivity. However, their widespread adoption also raises concerns about their environmental footprint throughout their lifecycle.

One of the primary environmental benefits of HDPE catalysts is their potential to reduce energy consumption in industrial processes. By enhancing reaction rates and selectivity, these catalysts can lower the energy requirements for chemical transformations, potentially leading to reduced greenhouse gas emissions associated with energy production. Additionally, the improved efficiency can result in less waste generation, further minimizing the environmental impact of industrial operations.

However, the production of HDPE catalysts themselves presents environmental challenges. The manufacturing process often involves energy-intensive steps and the use of potentially hazardous chemicals. This raises questions about the overall environmental balance when considering the entire lifecycle of these catalysts. Efforts are underway to develop more sustainable production methods, including the use of renewable feedstocks and greener synthesis techniques.

The durability and recyclability of HDPE catalysts also play a crucial role in their environmental impact. Long-lasting catalysts reduce the need for frequent replacements, thereby minimizing waste generation and resource consumption. Research is ongoing to improve the stability and reusability of these catalysts, which could significantly enhance their environmental profile.

Another important aspect to consider is the end-of-life management of HDPE catalysts. Proper disposal or recycling of spent catalysts is essential to prevent environmental contamination. Developing effective recycling processes for these materials is an area of active research, with the aim of recovering valuable components and minimizing waste.

The use of HDPE catalysts may also indirectly impact the environment through the products they help create. If these catalysts enable the production of more environmentally friendly materials or facilitate more efficient manufacturing processes, their overall environmental impact could be positive. However, this requires a holistic assessment of the entire value chain and product lifecycle.

As HDPE catalysts continue to emerge as dynamic industrial tools, ongoing research and development efforts are focusing on enhancing their environmental performance. This includes exploring bio-based alternatives, improving catalyst efficiency to reduce resource consumption, and developing more sustainable production and recycling methods. The goal is to harness the benefits of these catalysts while minimizing their environmental footprint, aligning with broader sustainability objectives in the industrial sector.

Regulatory Framework

The regulatory framework surrounding High-Density Polyethylene (HDPE) as an industrial catalyst is complex and multifaceted, reflecting the material's growing importance in various industrial applications. Regulatory bodies worldwide have established guidelines and standards to ensure the safe production, handling, and use of HDPE catalysts in industrial processes.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating HDPE catalysts under the Toxic Substances Control Act (TSCA). The EPA requires manufacturers to submit premanufacture notices (PMNs) for new chemical substances, including novel HDPE catalyst formulations. This process involves rigorous safety assessments and environmental impact evaluations before approval for commercial use.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to HDPE catalysts. Under REACH, manufacturers and importers must register their substances with the European Chemicals Agency (ECHA) and provide comprehensive safety data. This regulation aims to protect human health and the environment while promoting innovation in the chemical industry.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Ministry of Ecology and Environment oversees the registration and management of new chemical substances, including HDPE catalysts, through the Measures for Environmental Management of New Chemical Substances. Japan's Chemical Substances Control Law (CSCL) requires manufacturers to notify the government of new chemical substances and undergo safety evaluations.

International standards organizations, such as the International Organization for Standardization (ISO), have developed specific standards for HDPE materials and their production processes. These standards often influence regulatory decisions and industry practices globally, ensuring consistency in quality and safety across borders.

Occupational safety regulations also play a significant role in the use of HDPE catalysts. Organizations like the Occupational Safety and Health Administration (OSHA) in the US and the European Agency for Safety and Health at Work (EU-OSHA) have established guidelines for handling and working with chemical catalysts, including those used in HDPE production.

As HDPE catalysts continue to evolve and find new applications, regulatory frameworks are adapting to keep pace. There is an increasing focus on sustainability and circular economy principles, leading to regulations that encourage the development of more environmentally friendly catalysts and processes. This includes initiatives to promote the use of bio-based feedstocks and improve the recyclability of HDPE products.

The regulatory landscape for HDPE catalysts is dynamic, with ongoing efforts to balance innovation, industrial growth, and environmental protection. As research advances and new applications emerge, regulatory bodies are likely to refine their approaches, potentially leading to more harmonized global standards for the production and use of HDPE catalysts in industrial settings.