Fostering HDPE's Place in Smart Housing Solutions

HDPE in Smart Housing: Background and Objectives

High-density polyethylene (HDPE) has emerged as a promising material in the realm of smart housing solutions, offering a unique combination of durability, versatility, and sustainability. The evolution of HDPE in construction has been marked by significant technological advancements, transitioning from its initial use in plumbing systems to becoming an integral component in various aspects of modern housing.

The journey of HDPE in smart housing began with its introduction as a reliable alternative to traditional materials in piping and insulation. Over time, researchers and engineers have recognized its potential to address broader challenges in the construction industry, particularly in the context of creating intelligent and sustainable living spaces. This shift in perspective has led to a surge in research and development efforts aimed at expanding HDPE's applications in smart housing technologies.

The primary objective of incorporating HDPE into smart housing solutions is to enhance the overall performance, efficiency, and sustainability of residential structures. By leveraging HDPE's unique properties, such as its excellent chemical resistance, low thermal conductivity, and high strength-to-weight ratio, developers aim to create innovative solutions that can revolutionize the way we build and inhabit our homes.

One of the key trends driving the adoption of HDPE in smart housing is the growing demand for energy-efficient and environmentally friendly building materials. As global awareness of climate change and resource conservation increases, there is a pressing need for materials that can contribute to reducing the carbon footprint of residential buildings. HDPE, with its recyclability and long lifespan, aligns perfectly with these sustainability goals.

Furthermore, the integration of HDPE into smart housing systems opens up new possibilities for the implementation of advanced technologies. From smart plumbing systems that can detect leaks and optimize water usage to intelligent wall panels that enhance thermal insulation and incorporate sensors for home automation, HDPE serves as a versatile platform for embedding smart functionalities into the very fabric of our homes.

The technological trajectory of HDPE in smart housing is expected to focus on several key areas. These include the development of HDPE-based composites with enhanced properties, the creation of modular and prefabricated housing components for efficient construction, and the exploration of 3D printing techniques using HDPE to enable customized and on-demand production of housing elements.

As we look towards the future, the goal is to establish HDPE as a cornerstone material in the construction of intelligent, sustainable, and adaptable living spaces. This involves not only improving the material properties of HDPE but also developing innovative manufacturing processes and design methodologies that can fully harness its potential in the context of smart housing solutions.

Market Analysis for HDPE Smart Housing Solutions

The market for HDPE smart housing solutions is experiencing significant growth, driven by the increasing demand for sustainable, durable, and cost-effective building materials. High-Density Polyethylene (HDPE) has emerged as a promising material in the construction industry, particularly in the context of smart housing solutions. The global smart home market is projected to reach substantial value in the coming years, with HDPE playing a crucial role in this expansion.

HDPE's unique properties make it an attractive option for smart housing applications. Its durability, resistance to weathering, and low maintenance requirements align well with the long-term sustainability goals of smart housing projects. The material's versatility allows for integration with various smart technologies, including sensors, wiring systems, and modular construction techniques.

The market demand for HDPE in smart housing is primarily driven by several factors. Firstly, the growing awareness of environmental issues has led to increased interest in eco-friendly building materials. HDPE, being recyclable and having a lower carbon footprint compared to traditional materials, fits well into this trend. Secondly, the rising costs of traditional construction materials and labor have made HDPE an economically viable alternative, especially in prefabricated and modular construction methods often employed in smart housing.

Geographically, the market for HDPE smart housing solutions shows varying levels of adoption. Developed regions such as North America and Europe are at the forefront, with a strong focus on sustainable building practices and smart home technologies. These markets are characterized by stringent building codes and a high consumer willingness to invest in smart home features. In contrast, emerging markets in Asia-Pacific and Latin America are showing rapid growth potential, driven by urbanization, rising disposable incomes, and government initiatives promoting smart city development.

The construction industry's shift towards off-site manufacturing and prefabrication is another key driver for HDPE in smart housing. This trend aligns well with HDPE's properties, allowing for the creation of lightweight, yet sturdy components that can be easily transported and assembled on-site. This approach not only reduces construction time and costs but also enables greater precision in integrating smart technologies during the manufacturing process.

However, the market also faces certain challenges. The perception of plastic materials in construction, concerns about long-term durability, and the need for specialized installation techniques are some of the barriers that the industry needs to address. Education and awareness campaigns, along with demonstrable long-term performance data, will be crucial in overcoming these challenges and fostering wider acceptance of HDPE in smart housing solutions.

HDPE Technology: Current Status and Challenges

High-Density Polyethylene (HDPE) has emerged as a significant material in the construction industry, particularly in smart housing solutions. However, its current status and challenges present a complex landscape that requires careful examination.

The global HDPE market has witnessed substantial growth, driven by its versatile properties and increasing applications in construction. In smart housing, HDPE is utilized for various components, including piping systems, electrical conduits, and structural elements. Its resistance to corrosion, chemical inertness, and durability make it an attractive option for long-lasting, low-maintenance building solutions.

Despite its advantages, HDPE faces several challenges in the smart housing sector. One primary concern is its thermal properties. While HDPE offers excellent insulation, its relatively high thermal expansion coefficient can lead to dimensional instability in extreme temperature conditions. This characteristic necessitates careful design considerations and may limit its use in certain structural applications.

Another significant challenge lies in HDPE's recyclability within the context of smart housing. Although HDPE is recyclable, the integration of smart technologies and composite materials in housing solutions can complicate the recycling process. This issue raises questions about the material's long-term sustainability and its alignment with circular economy principles in construction.

The fire resistance of HDPE remains a critical concern in smart housing applications. While additives can improve its flame-retardant properties, achieving the necessary fire safety standards without compromising other desirable characteristics presents an ongoing challenge for manufacturers and researchers.

In terms of technological integration, HDPE's compatibility with smart home systems and sensors is an area of active development. The material's non-conductive nature offers opportunities for embedding electronic components, but challenges persist in ensuring seamless integration and long-term reliability of these smart features within the HDPE matrix.

The current research landscape focuses on addressing these challenges through various approaches. Efforts are underway to develop HDPE composites with enhanced thermal stability and fire resistance. Additionally, researchers are exploring methods to improve the material's compatibility with smart technologies, such as the incorporation of conductive fillers or the development of hybrid materials that combine HDPE with other smart materials.

Geographically, the development and application of HDPE in smart housing solutions show regional variations. North America and Europe lead in research and implementation, driven by stringent building codes and a strong focus on sustainable construction. Asia-Pacific regions, particularly China and India, are rapidly adopting HDPE technologies in housing, spurred by urbanization and the need for durable, cost-effective building materials.

In conclusion, while HDPE holds significant promise for smart housing solutions, overcoming its current limitations in thermal stability, fire resistance, and smart technology integration remains crucial for its widespread adoption and long-term success in this sector.

Existing HDPE Smart Housing Solutions

01 Composition and manufacturing of HDPE

High-Density Polyethylene (HDPE) is a thermoplastic polymer produced from ethylene monomers. Various methods and compositions are used to manufacture HDPE with specific properties, including the use of catalysts, additives, and different polymerization techniques. These processes aim to enhance the material's strength, durability, and chemical resistance.- Composition and properties of HDPE: High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength, stiffness, and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications in packaging, construction, and automotive industries.

- HDPE blends and composites: HDPE can be blended with other materials or reinforced with additives to enhance its properties. These blends and composites can improve characteristics such as impact resistance, thermal stability, or specific mechanical properties. The resulting materials find applications in areas where standard HDPE may not meet all requirements.

- HDPE processing techniques: Various processing techniques are used to manufacture HDPE products, including injection molding, extrusion, and blow molding. Each method offers specific advantages and is suited for different product types. Innovations in processing techniques aim to improve efficiency, reduce waste, and enhance the quality of HDPE products.

- Recycling and sustainability of HDPE: HDPE is recyclable and efforts are being made to improve its recycling processes and increase the use of recycled HDPE in new products. This includes developing better sorting and cleaning methods for recycled HDPE, as well as finding new applications for recycled material. The focus on sustainability aims to reduce the environmental impact of HDPE production and use.

- HDPE applications in specific industries: HDPE finds applications in various industries due to its versatile properties. It is used in packaging for food and beverages, construction materials like pipes and fittings, automotive components, and medical devices. New applications are continually being developed, expanding the use of HDPE in different sectors.

02 HDPE blends and composites

HDPE is often blended with other materials or used in composites to improve its properties or create new materials with enhanced characteristics. These blends and composites can include other polymers, fibers, or inorganic materials, resulting in products with improved mechanical properties, thermal stability, or specific functionalities.Expand Specific Solutions03 HDPE applications in packaging and containers

HDPE is widely used in packaging and container applications due to its excellent chemical resistance, durability, and moisture barrier properties. Innovations in this area focus on improving the material's performance in specific packaging applications, such as food containers, bottles, and industrial packaging solutions.Expand Specific Solutions04 Recycling and sustainability of HDPE

As environmental concerns grow, there is increasing focus on recycling and improving the sustainability of HDPE products. This includes developing more efficient recycling processes, creating products from recycled HDPE, and designing HDPE materials that are more easily recyclable or biodegradable.Expand Specific Solutions05 HDPE in construction and industrial applications

HDPE finds extensive use in construction and various industrial applications due to its strength, chemical resistance, and durability. Innovations in this area include the development of HDPE products for piping systems, geomembranes, industrial components, and structural applications, often focusing on improving the material's performance under specific conditions.Expand Specific Solutions

Key Players in HDPE Smart Housing Market

The market for HDPE in smart housing solutions is in a growth phase, driven by increasing demand for sustainable and energy-efficient building materials. The global market size for HDPE in construction is expanding, with projections indicating significant growth in the coming years. Technologically, HDPE applications in smart housing are evolving rapidly, with companies like Dow Global Technologies LLC, ExxonMobil Chemical Patents, Inc., and Borealis AG leading innovation. These firms are developing advanced HDPE formulations with enhanced properties for smart housing applications. Emerging players such as PetroChina Co., Ltd. and Braskem SA are also contributing to technological advancements, particularly in areas of durability, insulation, and integration with smart home systems.

Dow Global Technologies LLC

Borealis AG

Innovative HDPE Technologies for Smart Homes

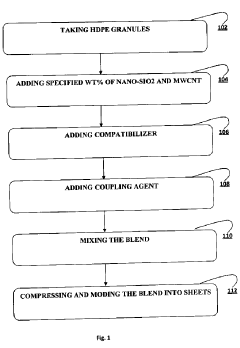

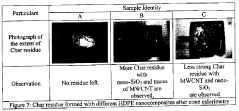

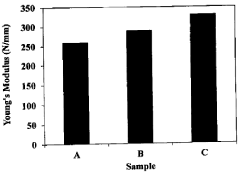

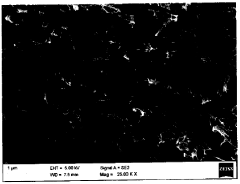

- A high density polyethylene (HDPE) nanocomposite material is developed, incorporating acid functionalized Multi-Walled Carbon Nanotubes (MWCNT) and nano-Silicon dioxide (SiO2) with specific weight percentages, along with a silane coupling agent and blending agents, to enhance dielectric, mechanical, and flame retardant properties, while meeting environmental safety standards.

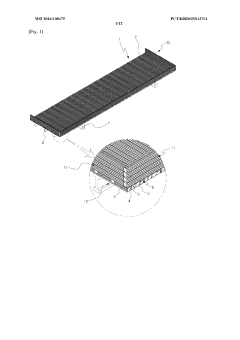

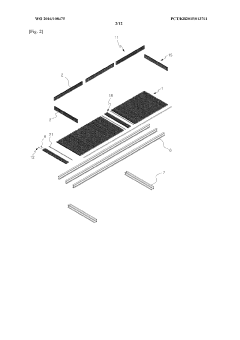

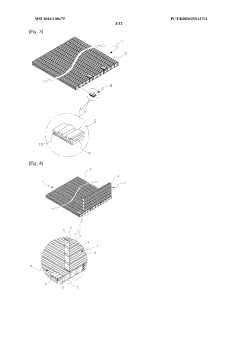

- A scaffold system utilizing high-density polyethylene (HDPE) panels with standardized sizes for mass production, featuring angled connections, integrated fall prevention, and gap closing mechanisms, allowing for easy assembly and installation, and reducing material costs through recyclability and lightweight design.

Sustainability Aspects of HDPE in Smart Housing

The integration of High-Density Polyethylene (HDPE) in smart housing solutions presents a significant opportunity to enhance sustainability in the construction industry. HDPE's inherent properties make it an excellent candidate for promoting eco-friendly practices in smart homes.

One of the primary sustainability advantages of HDPE in smart housing is its recyclability. HDPE can be recycled multiple times without significant degradation of its properties, reducing the need for virgin materials and minimizing waste. This closed-loop recycling potential aligns well with the circular economy principles increasingly adopted in sustainable construction practices.

HDPE's durability and resistance to environmental factors contribute to the longevity of smart housing components. This extended lifespan reduces the frequency of replacements, thereby conserving resources and energy over time. The material's resistance to moisture, chemicals, and UV radiation ensures that HDPE-based smart home elements maintain their performance and efficiency for extended periods.

Energy efficiency is another crucial aspect where HDPE contributes to sustainability in smart housing. HDPE's excellent insulation properties can be leveraged in the design of smart home systems, reducing heating and cooling requirements. This translates to lower energy consumption and reduced carbon footprint over the building's lifecycle.

The lightweight nature of HDPE offers additional sustainability benefits in smart housing applications. Lighter materials require less energy for transportation and installation, reducing the overall carbon footprint associated with construction and renovation processes. This characteristic also facilitates easier upgrades and modifications to smart home systems, promoting adaptability and reducing waste from obsolete components.

HDPE's potential in water management systems for smart homes is particularly noteworthy from a sustainability perspective. Its corrosion resistance and flexibility make it ideal for innovative rainwater harvesting and greywater recycling systems, contributing to water conservation efforts in smart housing developments.

Furthermore, the production of HDPE can be less energy-intensive compared to some traditional building materials, especially when recycled HDPE is used. This factor, combined with its long service life, results in a favorable life-cycle assessment for HDPE in smart housing applications.

As smart homes increasingly incorporate IoT devices and sensors, HDPE's compatibility with these technologies becomes crucial. Its non-conductive nature and ability to be molded into complex shapes allow for seamless integration of smart systems without compromising on sustainability goals.

In conclusion, HDPE's sustainability aspects in smart housing encompass its recyclability, durability, energy efficiency, and versatility. These characteristics position HDPE as a valuable material in the development of sustainable, intelligent living spaces that meet the growing demand for environmentally responsible housing solutions.

Regulatory Framework for HDPE in Construction

The regulatory framework for HDPE in construction plays a crucial role in fostering its adoption in smart housing solutions. As the construction industry increasingly recognizes the benefits of HDPE, regulatory bodies are adapting to ensure its safe and effective use in building applications.

At the national level, many countries have established specific standards and codes for HDPE in construction. These regulations typically cover aspects such as material properties, installation methods, and performance requirements. For instance, the American Society for Testing and Materials (ASTM) has developed several standards related to HDPE pipes and fittings used in construction, including ASTM D3350 for polyethylene pipes and fittings materials.

In Europe, the European Committee for Standardization (CEN) has implemented harmonized standards for HDPE products in construction. These standards ensure consistency across EU member states and facilitate the free movement of HDPE products within the European market. The EN 12201 series, for example, specifies requirements for HDPE piping systems for water supply and drainage applications.

Local building codes and regulations also play a significant role in shaping the use of HDPE in construction. Many municipalities have updated their building codes to include provisions for HDPE materials, particularly in plumbing and drainage systems. These local regulations often reference national or international standards while addressing specific regional concerns such as climate conditions or seismic activity.

Environmental regulations have further influenced the adoption of HDPE in construction. As sustainability becomes a key focus in the building industry, many regulatory bodies are encouraging the use of materials with lower environmental impacts. HDPE's recyclability and long lifespan align well with these environmental objectives, leading to its inclusion in green building standards and certification programs.

Safety regulations also play a crucial role in the regulatory framework for HDPE in construction. Fire safety codes, for instance, have been updated to address the use of plastic materials like HDPE in buildings. These regulations often specify requirements for flame retardancy and smoke emission, ensuring that HDPE components meet necessary safety standards.

As smart housing solutions continue to evolve, regulatory frameworks are adapting to accommodate innovative uses of HDPE. This includes regulations for integrating HDPE components with smart home technologies, such as sensor-equipped piping systems for leak detection or energy-efficient HDPE-based insulation materials.

The ongoing development of regulatory frameworks for HDPE in construction demonstrates the material's growing importance in the building industry. As research continues and new applications emerge, it is likely that these regulations will further evolve to support the safe and effective use of HDPE in smart housing solutions.