Heating Methods to Boost HDPE Molding Efficiency

HDPE Molding Efficiency Goals

High-density polyethylene (HDPE) molding is a critical process in the plastics industry, and improving its efficiency has become a paramount goal for manufacturers. The primary objective in enhancing HDPE molding efficiency is to reduce cycle times while maintaining or improving product quality. This involves optimizing the heating methods to achieve faster and more uniform melting of HDPE pellets, as well as ensuring rapid and consistent cooling of the molded parts.

One of the key targets is to decrease the overall cycle time by at least 20-30% compared to conventional molding processes. This reduction would significantly increase production output and reduce energy consumption per unit produced. Additionally, manufacturers aim to achieve a more uniform temperature distribution throughout the mold, which is crucial for producing high-quality parts with consistent properties and minimal defects.

Another important goal is to enhance the energy efficiency of the heating process. This includes exploring alternative heating technologies that can provide more precise and rapid heating, such as induction heating or infrared heating systems. The ideal solution would offer better control over temperature profiles and reduce energy waste, potentially cutting energy costs by 15-25%.

Improving melt homogeneity is also a critical objective. By ensuring a more uniform melt, manufacturers can reduce the occurrence of defects such as warpage, sink marks, and inconsistent wall thickness. The target is to achieve a melt temperature variation of less than ±5°C throughout the molded part, which would lead to enhanced product quality and reduced scrap rates.

Furthermore, there is a strong focus on developing heating methods that allow for better process control and automation. This includes implementing advanced sensors and control systems that can dynamically adjust heating parameters based on real-time data. The goal is to create a more responsive and adaptive molding process that can automatically optimize heating profiles for different part geometries and material grades.

Lastly, sustainability is an increasingly important consideration in HDPE molding efficiency goals. Manufacturers are seeking heating methods that not only improve productivity but also reduce the carbon footprint of the molding process. This involves exploring technologies that can utilize renewable energy sources or recover and reuse waste heat from the molding process, with the aim of reducing overall energy consumption by up to 30-40% compared to traditional methods.

Market Demand Analysis

The market demand for efficient HDPE molding processes has been steadily increasing, driven by the growing use of HDPE products across various industries. The global HDPE market size was valued at USD 84.79 billion in 2021 and is expected to expand at a compound annual growth rate (CAGR) of 4.2% from 2022 to 2030. This growth is primarily attributed to the rising demand for HDPE in packaging, construction, and automotive sectors.

In the packaging industry, HDPE is widely used for producing bottles, containers, and films. The increasing consumer preference for lightweight, durable, and recyclable packaging materials has fueled the demand for HDPE products. The construction sector also contributes significantly to the market growth, with HDPE being used in pipes, fittings, and geomembranes. The automotive industry utilizes HDPE for fuel tanks, interior parts, and under-the-hood components, further driving market demand.

The need for improved HDPE molding efficiency is particularly acute in high-volume manufacturing environments. Manufacturers are constantly seeking ways to reduce cycle times, minimize energy consumption, and enhance product quality. This has led to a growing interest in advanced heating methods that can boost HDPE molding efficiency.

One of the key market trends is the shift towards more sustainable and energy-efficient manufacturing processes. This trend aligns well with research on innovative heating methods for HDPE molding, as improved efficiency often translates to reduced energy consumption and lower carbon footprint. Manufacturers are increasingly willing to invest in technologies that can help them meet sustainability goals while improving productivity.

The Asia-Pacific region dominates the HDPE market, accounting for over 40% of the global market share. This region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing disposable incomes. North America and Europe follow, with mature markets focusing on technological advancements and sustainable practices in HDPE production.

The COVID-19 pandemic has had a mixed impact on the HDPE market. While it initially disrupted supply chains and manufacturing processes, the increased demand for packaging materials in e-commerce and healthcare sectors has provided a boost to the market. As economies recover, the demand for efficient HDPE molding processes is expected to rise further.

In conclusion, the market demand for research on heating methods to boost HDPE molding efficiency is strong and growing. The industry's focus on productivity, sustainability, and product quality aligns well with the objectives of such research. As the global HDPE market continues to expand, innovations in molding efficiency will play a crucial role in meeting the increasing demand while addressing environmental concerns.

Current Heating Challenges

The current heating challenges in HDPE molding efficiency primarily stem from the material's inherent properties and the limitations of conventional heating methods. HDPE, being a semi-crystalline polymer, requires precise temperature control during the molding process to achieve optimal crystallization and mechanical properties. Traditional heating techniques often struggle to provide uniform and rapid heating, leading to extended cycle times and potential quality issues.

One of the main challenges is the low thermal conductivity of HDPE, which results in slow heat transfer from the mold surface to the core of the material. This can lead to uneven heating, causing warpage, shrinkage, and inconsistent part quality. The slow heating rate also extends the overall cycle time, reducing production efficiency and increasing energy consumption.

Another significant challenge is the narrow processing window of HDPE. The material requires careful temperature control to avoid degradation or incomplete melting. Overheating can lead to thermal degradation, while insufficient heating may result in poor fusion and weak weld lines. This delicate balance is difficult to maintain with conventional heating methods, especially for complex part geometries or varying wall thicknesses.

The energy efficiency of current heating systems is also a concern. Many traditional heating methods, such as convection ovens or infrared heaters, have limited energy transfer efficiency, resulting in higher energy costs and environmental impact. This inefficiency is particularly pronounced when dealing with large-scale production or thick-walled parts.

Furthermore, the heating uniformity across the mold surface poses a significant challenge. Hot spots or cold spots can lead to localized overheating or underheating, affecting the part's dimensional stability and mechanical properties. This issue is exacerbated in molds with complex geometries or multiple cavities.

The heating rate and temperature ramp-up time also present challenges in HDPE molding. Rapid and uniform heating is crucial for reducing cycle times and improving productivity. However, conventional heating methods often struggle to provide the necessary heating rates without compromising temperature uniformity or risking material degradation.

Lastly, the integration of heating systems with existing molding equipment and processes can be challenging. Retrofitting advanced heating technologies into established production lines may require significant modifications and investments, potentially disrupting production schedules and increasing costs.

Addressing these heating challenges is crucial for improving HDPE molding efficiency. Innovative heating methods that can provide rapid, uniform, and precise temperature control while maintaining energy efficiency are needed to overcome these limitations and enhance the overall molding process.

Existing Heating Solutions

01 Improved mold design for HDPE molding

Enhancing mold design can significantly improve HDPE molding efficiency. This includes optimizing cooling channels, using advanced materials for mold construction, and implementing innovative mold structures. These improvements can lead to faster cycle times, better part quality, and reduced energy consumption.- Improved mold design for HDPE molding: Enhancing mold design can significantly improve HDPE molding efficiency. This includes optimizing cooling channels, using advanced materials for mold construction, and implementing innovative mold structures. These improvements can lead to faster cycle times, better part quality, and reduced energy consumption.

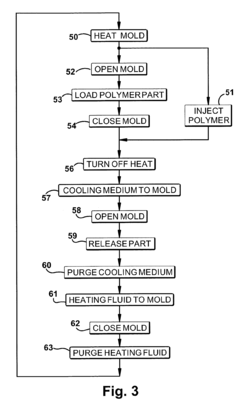

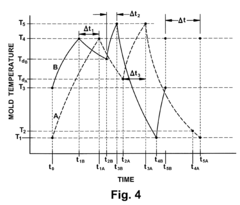

- Advanced heating and cooling systems: Implementing advanced heating and cooling systems in HDPE molding processes can greatly enhance efficiency. This may involve using rapid heat cycle molding techniques, conformal cooling channels, or intelligent temperature control systems. These methods can reduce cycle times and improve part quality.

- Optimization of HDPE material properties: Tailoring HDPE material properties can lead to improved molding efficiency. This includes modifying molecular weight distribution, incorporating additives, or developing specialized HDPE grades. These optimizations can result in better flow characteristics, reduced cycle times, and enhanced part performance.

- Process automation and intelligent control: Implementing automation and intelligent control systems in HDPE molding processes can significantly increase efficiency. This may include using robotics for part handling, implementing machine learning algorithms for process optimization, or utilizing real-time monitoring and adjustment systems. These technologies can reduce human error, improve consistency, and optimize production parameters.

- Innovative injection and compression techniques: Developing and applying innovative injection and compression techniques can enhance HDPE molding efficiency. This may involve using gas-assisted injection molding, multi-component molding, or advanced compression molding methods. These techniques can improve material distribution, reduce part weight, and decrease cycle times.

02 Advanced heating and cooling systems

Implementing advanced heating and cooling systems in HDPE molding processes can greatly enhance efficiency. This may involve using rapid heating and cooling techniques, precise temperature control mechanisms, and innovative heat transfer methods. These systems can reduce cycle times and improve overall product quality.Expand Specific Solutions03 Optimization of HDPE material properties

Tailoring the properties of HDPE materials can lead to improved molding efficiency. This includes modifying molecular weight distribution, adjusting melt flow index, and incorporating additives to enhance processability. Optimized material properties can result in faster molding cycles and better end-product characteristics.Expand Specific Solutions04 Automation and process control in HDPE molding

Integrating automation and advanced process control systems can significantly improve HDPE molding efficiency. This involves implementing robotics for part handling, using sensors for real-time monitoring, and employing artificial intelligence for process optimization. These technologies can reduce human error, increase consistency, and maximize production output.Expand Specific Solutions05 Energy-efficient HDPE molding techniques

Developing and implementing energy-efficient molding techniques can enhance overall HDPE molding efficiency. This includes using electric or hybrid injection molding machines, recovering and reusing waste heat, and optimizing process parameters to minimize energy consumption. These approaches can lead to reduced operating costs and improved sustainability in HDPE molding operations.Expand Specific Solutions

Key Industry Players

The research on heating methods to boost HDPE molding efficiency is in a mature stage of development, with a significant market size due to HDPE's widespread use in various industries. The technology's maturity is evident from the involvement of major players across academia and industry. Companies like BASF Corp., Dow Global Technologies LLC, and China Petroleum & Chemical Corp. are at the forefront, leveraging their extensive R&D capabilities. Academic institutions such as Sichuan University and Beijing University of Chemical Technology contribute to fundamental research. The competitive landscape is diverse, with specialized firms like JSP Corp. and JNC Corp. focusing on niche applications, while global conglomerates like Mitsubishi Electric Corp. and Robert Bosch GmbH integrate these advancements into their broader product portfolios.

China Petroleum & Chemical Corp.

BASF Corp.

Innovative Heating Methods

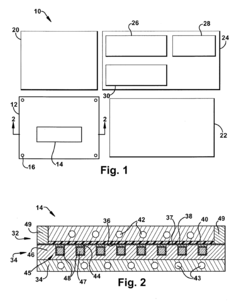

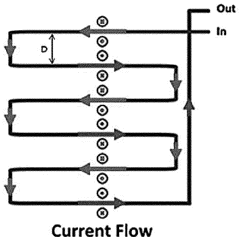

- A system and method utilizing two different heat energy sources to heat the mold, where a first energy source, such as heating fluid, raises the mold temperature, and a second energy source, like induction heating, further increases the mold temperature beyond that achieved by the fluid, allowing for reduced peak power requirements and faster cycle times by using a heating fluid in conjunction with an alternative heat source.

- The method involves modifying the surface of reinforcing fibers and introducing a dielectric heating material with a hydrophilic functional group, chemically bonding it to the fibers, and using an induction heating coil with a specific winding spacing to ensure uniform heating of polymer composites, regardless of mold shape or size, by adjusting the winding spacing of the induction heating coil and incorporating a dielectric heating material.

Energy Efficiency Analysis

Energy efficiency analysis is a critical aspect of improving HDPE molding processes. The heating methods employed in HDPE molding significantly impact energy consumption and overall efficiency. Traditional heating techniques often result in substantial energy losses, leading to increased production costs and environmental concerns.

Recent studies have shown that optimizing heating methods can reduce energy consumption by up to 30% in HDPE molding operations. This improvement is achieved through a combination of advanced heating technologies and process control strategies. Infrared heating systems, for instance, have demonstrated superior energy efficiency compared to conventional convection heating methods. These systems provide more precise and localized heating, reducing overall energy requirements.

Another promising approach is the implementation of adaptive heating control systems. These systems utilize real-time temperature monitoring and machine learning algorithms to optimize heating patterns based on the specific requirements of each molding cycle. By minimizing unnecessary heating and reducing temperature fluctuations, adaptive control systems can significantly enhance energy efficiency.

The integration of waste heat recovery systems has also shown considerable potential in improving overall energy efficiency. By capturing and repurposing heat that would otherwise be lost to the environment, these systems can reduce the net energy input required for the molding process. Some advanced facilities have reported energy savings of up to 20% through the implementation of waste heat recovery technologies.

Material preheating techniques have emerged as another effective strategy for boosting energy efficiency in HDPE molding. By preheating the raw material before it enters the main molding process, the overall energy requirement for heating can be reduced. This approach not only improves energy efficiency but also contributes to more consistent material properties and reduced cycle times.

The use of high-efficiency electric motors and variable frequency drives in molding equipment has further contributed to energy savings. These components allow for more precise control of energy input and can adapt to varying load conditions, resulting in optimized energy consumption throughout the molding process.

Comprehensive energy audits and simulation tools have become invaluable in identifying areas for improvement in HDPE molding operations. These tools enable manufacturers to analyze energy flow within their processes and pinpoint opportunities for efficiency enhancements. By leveraging data-driven insights, companies can make informed decisions regarding equipment upgrades and process modifications to maximize energy efficiency.

As the industry continues to prioritize sustainability and cost reduction, ongoing research in heating methods for HDPE molding is likely to yield further advancements in energy efficiency. The development of novel heating technologies, coupled with improved process control strategies, holds promise for significant reductions in energy consumption and environmental impact in the coming years.

Material Property Impact

The material properties of High-Density Polyethylene (HDPE) play a crucial role in determining the efficiency of its molding process. HDPE is a thermoplastic polymer known for its high strength-to-density ratio, chemical resistance, and durability. These properties, while beneficial for many applications, can present challenges during the molding process, particularly in terms of heating and shaping.

HDPE has a relatively high melting point, typically ranging from 120°C to 180°C, which necessitates significant energy input during the heating phase of molding. This characteristic impacts the overall efficiency of the process, as it requires longer heating times and higher temperatures compared to some other thermoplastics. The polymer's high molecular weight and crystalline structure contribute to its thermal stability, which can be both an advantage and a challenge in molding applications.

The thermal conductivity of HDPE is relatively low, approximately 0.45-0.52 W/(m·K) at room temperature. This property affects the rate at which heat can be transferred through the material during the molding process. Consequently, achieving uniform heating throughout the HDPE material can be challenging, potentially leading to inconsistencies in the final product if not properly managed.

HDPE exhibits a significant volume change during the transition from solid to liquid state, with a typical shrinkage rate of 1.5% to 3%. This property must be carefully considered in mold design and process parameters to ensure dimensional accuracy of the final product. The shrinkage behavior also influences the cooling phase of the molding process, affecting cycle times and overall efficiency.

The viscosity of molten HDPE is another critical factor impacting molding efficiency. HDPE typically has a high melt viscosity, which can make it challenging to fill complex mold geometries quickly and uniformly. This property necessitates careful control of injection pressures and temperatures to achieve optimal flow characteristics and prevent defects such as short shots or warpage.

HDPE's resistance to chemical degradation is generally beneficial but can pose challenges when attempting to modify its properties or incorporate additives to enhance processability. This resistance limits the effectiveness of certain chemical heating methods or processing aids that might be applicable to other polymers.

The crystallinity of HDPE, which can range from 60% to 80%, significantly influences its mechanical properties and processing behavior. Higher crystallinity leads to increased strength and stiffness but can also result in longer cooling times and greater shrinkage, potentially impacting molding cycle times and efficiency.

Understanding and optimizing these material properties are essential for developing innovative heating methods to boost HDPE molding efficiency. Strategies may include targeted heating techniques, advanced mold designs, or the development of specialized HDPE grades with modified properties to enhance processability while maintaining the desired end-use characteristics.