Innovation in HDPE Trends: Realizing Future Goals

HDPE Evolution and Objectives

High-density polyethylene (HDPE) has undergone significant evolution since its discovery in the 1950s. Initially developed as a more durable and versatile alternative to low-density polyethylene, HDPE has become a cornerstone material in various industries due to its exceptional properties and versatility.

The evolution of HDPE has been marked by continuous improvements in production processes, catalysts, and additives. Early developments focused on enhancing the material's strength and chemical resistance. Subsequent advancements led to the creation of specialized grades tailored for specific applications, such as high-molecular-weight HDPE for pipe systems and bimodal HDPE for blow molding.

In recent years, the HDPE industry has been driven by sustainability goals and circular economy principles. This has led to increased efforts in developing recycling technologies, improving the recyclability of HDPE products, and incorporating recycled content into new products without compromising performance.

The current objectives in HDPE innovation are multifaceted, addressing both technical and environmental challenges. One primary goal is to further enhance the material's properties, particularly in areas such as impact resistance, long-term durability, and barrier properties. This includes developing new catalyst systems and polymerization techniques to achieve more precise control over molecular structure and distribution.

Another critical objective is to reduce the environmental footprint of HDPE production and use. This encompasses efforts to decrease energy consumption in manufacturing processes, minimize waste generation, and develop bio-based alternatives that can match or exceed the performance of traditional HDPE.

Improving the recyclability of HDPE products is also a key focus. This involves designing products for easier disassembly and recycling, as well as developing advanced sorting and recycling technologies to increase the quality and quantity of recycled HDPE.

The industry is also exploring ways to expand HDPE's application range, particularly in high-performance sectors such as automotive and aerospace. This includes developing composite materials that combine HDPE with other materials to create products with enhanced properties.

Lastly, there is a growing emphasis on digitalization and Industry 4.0 principles in HDPE production. This involves implementing advanced process control systems, predictive maintenance, and data analytics to optimize production efficiency and product quality.

These evolving objectives reflect the industry's commitment to innovation, sustainability, and meeting the changing demands of various sectors. As HDPE continues to evolve, it is poised to play an increasingly important role in addressing global challenges related to resource efficiency, environmental protection, and technological advancement.

HDPE Market Demand Analysis

The global High-Density Polyethylene (HDPE) market has been experiencing steady growth, driven by increasing demand across various industries. The versatility and durability of HDPE make it a preferred material in packaging, construction, automotive, and consumer goods sectors. The market demand for HDPE is expected to continue its upward trajectory in the coming years.

In the packaging industry, HDPE remains a popular choice for bottles, containers, and films due to its excellent moisture barrier properties and chemical resistance. The growing e-commerce sector and the shift towards sustainable packaging solutions have further boosted the demand for HDPE in this segment. Additionally, the construction industry's recovery post-pandemic has led to increased usage of HDPE pipes and fittings in water supply and drainage systems.

The automotive sector is another significant contributor to HDPE market demand. As vehicle manufacturers focus on lightweight materials to improve fuel efficiency and reduce emissions, HDPE has gained traction in producing automotive components such as fuel tanks, interior trims, and exterior parts. The growing electric vehicle market is expected to further drive HDPE demand in this sector.

Consumer goods and household products continue to be a stable market for HDPE. The material's durability, recyclability, and cost-effectiveness make it ideal for manufacturing toys, household containers, and personal care product packaging. The increasing awareness of plastic recycling and circular economy principles has also positively impacted HDPE demand, as it is one of the most easily recyclable plastics.

Geographically, Asia-Pacific remains the largest market for HDPE, with China and India leading the demand. The rapid industrialization, urbanization, and growing middle-class population in these countries are key factors driving market growth. North America and Europe follow, with steady demand from established industries and increasing focus on sustainable plastic solutions.

The agriculture sector presents a growing opportunity for HDPE applications. The material is widely used in irrigation systems, greenhouse films, and crop protection products. As global food demand rises and agricultural practices evolve, the use of HDPE in this sector is expected to increase.

However, the HDPE market faces challenges from environmental concerns and regulatory pressures. The push for reducing single-use plastics and promoting biodegradable alternatives could potentially impact HDPE demand in certain applications. To address these concerns, industry players are investing in recycling technologies and developing more sustainable HDPE grades.

In conclusion, the HDPE market demand analysis reveals a positive outlook with growth opportunities across multiple sectors. The material's versatility, coupled with ongoing innovations in production and recycling, positions HDPE to maintain its significance in various industries. Adapting to sustainability requirements and exploring new application areas will be crucial for realizing future growth goals in the HDPE market.

HDPE Tech Challenges

High-density polyethylene (HDPE) has been a cornerstone in the plastics industry for decades, but it faces several significant challenges in meeting future sustainability and performance goals. One of the primary technical hurdles is improving the material's recyclability without compromising its desirable properties. Current recycling processes often result in downcycling, where the recycled HDPE has inferior mechanical properties compared to virgin material.

Another major challenge lies in enhancing HDPE's barrier properties, particularly against oxygen and moisture. While HDPE is excellent for many packaging applications, it falls short in high-barrier requirements, limiting its use in certain food and pharmaceutical packaging. Developing HDPE formulations with improved barrier characteristics without sacrificing other properties remains a complex task.

The quest for increased sustainability also presents technical difficulties. Incorporating bio-based content into HDPE while maintaining its performance characteristics is an ongoing challenge. Researchers are working on developing bio-based alternatives that can match or exceed the properties of traditional petroleum-based HDPE, but achieving cost-effectiveness and scalability remains elusive.

HDPE's limited heat resistance is another area requiring innovation. The material's relatively low melting point restricts its use in high-temperature applications. Enhancing HDPE's thermal stability without significantly altering its other beneficial properties, such as flexibility and chemical resistance, is a complex balancing act.

Furthermore, improving HDPE's compatibility with other materials for multi-layer or composite applications presents technical challenges. Enhancing adhesion and compatibility between HDPE and other polymers or materials could open up new application areas but requires sophisticated material science solutions.

The drive towards lighter-weight products for transportation and packaging applications also puts pressure on HDPE manufacturers. Developing grades with higher strength-to-weight ratios without compromising durability or processability is a key focus area for innovation.

Lastly, addressing the environmental concerns associated with HDPE production and use remains a significant challenge. This includes reducing energy consumption and emissions during manufacturing, as well as developing more efficient degradation or decomposition mechanisms for end-of-life management without compromising the material's durability during its useful life.

These technical challenges underscore the need for continued research and development in HDPE technology. Overcoming these hurdles will be crucial for realizing future goals in sustainability, performance, and expanding applications for this versatile polymer.

Current HDPE Solutions

01 Composition and properties of HDPE

High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications, including packaging, pipes, and containers.- Composition and properties of HDPE: High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength, stiffness, and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications, including packaging, pipes, and industrial products.

- HDPE blends and composites: HDPE can be blended with other materials or reinforced with fillers to enhance its properties. These blends and composites can improve mechanical strength, thermal stability, or specific functional characteristics. Examples include HDPE blended with other polymers, reinforced with natural fibers, or combined with nanoparticles to create materials with tailored properties for specific applications.

- HDPE processing techniques: Various processing techniques are used to manufacture HDPE products, including injection molding, extrusion, blow molding, and rotational molding. Each technique offers specific advantages for different product types and applications. Innovations in processing methods focus on improving efficiency, reducing cycle times, and enhancing the quality of HDPE products.

- Recycling and sustainability of HDPE: HDPE is recyclable and efforts are being made to improve its recycling processes and increase the use of recycled HDPE in new products. Research focuses on enhancing the properties of recycled HDPE, developing more efficient recycling methods, and creating closed-loop recycling systems. These initiatives aim to reduce environmental impact and promote sustainability in HDPE usage.

- HDPE applications in various industries: HDPE finds applications in numerous industries due to its versatile properties. It is widely used in packaging, construction, automotive, agriculture, and healthcare sectors. Specific applications include food packaging, water pipes, fuel tanks, medical devices, and agricultural films. Ongoing research explores new potential applications and improvements in existing uses of HDPE across different industries.

02 HDPE blends and composites

HDPE can be blended with other materials or reinforced with fillers to enhance its properties. These blends and composites can improve mechanical strength, thermal stability, or specific functional characteristics. Examples include HDPE-based nanocomposites, fiber-reinforced HDPE, and blends with other polymers to achieve desired performance attributes.Expand Specific Solutions03 HDPE processing techniques

Various processing techniques are employed to manufacture HDPE products. These include injection molding, extrusion, blow molding, and rotational molding. Each technique offers specific advantages for different applications, allowing for the production of a wide range of HDPE products with varying shapes, sizes, and properties.Expand Specific Solutions04 HDPE recycling and sustainability

HDPE is recyclable and efforts are being made to improve its recycling processes and increase the use of recycled HDPE in various applications. This includes developing new recycling technologies, improving the quality of recycled HDPE, and finding innovative uses for recycled material to promote sustainability and reduce environmental impact.Expand Specific Solutions05 HDPE applications in specific industries

HDPE finds applications in various industries due to its versatile properties. It is used in packaging for food and beverages, construction materials such as pipes and fittings, automotive components, medical devices, and consumer goods. The material's durability, chemical resistance, and ease of processing make it suitable for a wide range of products across different sectors.Expand Specific Solutions

Key HDPE Industry Players

The innovation landscape in HDPE trends is characterized by a mature market with steady growth, driven by increasing demand across various industries. The global HDPE market size is substantial, with projections indicating continued expansion. Technologically, the field is advancing, with major players like ExxonMobil Chemical Patents, Dow Global Technologies, and SABIC Global Technologies leading research and development efforts. These companies, along with others such as Borealis AG and Chevron Phillips Chemical, are focusing on enhancing HDPE properties, developing sustainable solutions, and improving production processes. The competitive landscape is intense, with established petrochemical giants and specialized polymer companies vying for market share through technological advancements and strategic partnerships.

Borealis AG

Saudi Basic Industries Corp.

HDPE Core Innovations

- A process involving two interconnected gas-phase reactors with different polymerization zones, where ethylene is polymerized under fast fluidization conditions in one zone and densified flow in another, allowing for the separation and reintroduction of polymer particles, enabling the incorporation of comonomers only into the high molecular weight fraction to achieve a broad and homogeneous molecular weight distribution.

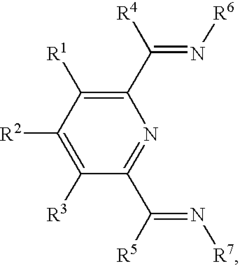

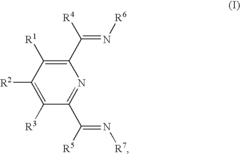

- The use of HDPE polymerized in the presence of an iron or cobalt complex catalyst, specifically a compound of formula (I), (II), or (III), to form a package with reduced water vapor and oxygen transmission rates, achieved by replacing or blending HDPE layers with the catalyst-complex-polymerized HDPE in packaging materials.

HDPE Sustainability Impact

The sustainability impact of High-Density Polyethylene (HDPE) is a critical consideration in the evolving landscape of plastic materials. As global environmental concerns intensify, the HDPE industry faces increasing pressure to address its ecological footprint. This has led to significant innovations aimed at enhancing the sustainability profile of HDPE throughout its lifecycle.

One of the primary areas of focus is the reduction of carbon emissions associated with HDPE production. Manufacturers are investing in energy-efficient processes and exploring renewable energy sources to power their facilities. This shift not only reduces the environmental impact but also aligns with global carbon reduction targets set by various international agreements.

Recycling initiatives have gained substantial traction in recent years. Advanced recycling technologies are being developed to improve the quality and efficiency of HDPE recycling processes. These innovations enable the production of recycled HDPE with properties comparable to virgin material, expanding its potential applications and reducing reliance on new plastic production.

The development of bio-based HDPE represents another significant stride towards sustainability. Derived from renewable resources such as sugarcane or corn, bio-based HDPE offers a lower carbon footprint compared to its petroleum-based counterpart. While challenges remain in scaling up production and ensuring competitive pricing, this innovation holds promise for a more sustainable future.

Efforts to enhance the durability and longevity of HDPE products are also contributing to sustainability goals. By improving the material's resistance to degradation and extending its useful life, manufacturers are reducing the overall demand for new plastic production and minimizing waste generation.

The impact of HDPE on marine ecosystems has been a particular concern. In response, research is underway to develop biodegradable additives that can accelerate the breakdown of HDPE in marine environments without compromising its performance during its intended use. This innovation aims to mitigate the long-term environmental impact of plastic pollution in oceans and waterways.

Furthermore, the HDPE industry is embracing circular economy principles. This involves redesigning products for easier recycling, implementing take-back programs, and exploring new business models that prioritize material recovery and reuse. These initiatives are reshaping the entire value chain of HDPE, from production to end-of-life management.

As regulations and consumer preferences continue to evolve, the sustainability impact of HDPE remains a driving force for innovation. The industry's ongoing efforts to address environmental concerns while maintaining the material's valuable properties are crucial in realizing future goals for sustainable plastic use.

HDPE Regulatory Landscape

The regulatory landscape for High-Density Polyethylene (HDPE) is complex and evolving, reflecting growing environmental concerns and the push for sustainable practices in the plastics industry. Governments and regulatory bodies worldwide are implementing stricter guidelines to address the environmental impact of HDPE production, use, and disposal.

In the European Union, the Plastic Strategy and Circular Economy Action Plan have set ambitious targets for plastic recycling and reuse. These regulations aim to ensure that all plastic packaging in the EU market is either reusable or recyclable by 2030. This has significant implications for HDPE manufacturers, who must now focus on developing more easily recyclable products and incorporating recycled content into their production processes.

The United States has seen a patchwork of state-level regulations emerging, with some states implementing bans on single-use plastic bags, many of which are made from HDPE. California, for instance, has enacted comprehensive plastic reduction laws, including mandates for recycled content in certain plastic products. At the federal level, the EPA has been reviewing its regulations on plastic waste management and exploring potential new guidelines for the industry.

In Asia, countries like China and India have introduced new policies to combat plastic pollution. China's ban on importing plastic waste has reshaped global recycling markets, while India has pledged to phase out single-use plastics by 2022. These changes are driving innovation in HDPE recycling technologies and pushing manufacturers to explore alternative materials.

The regulatory focus is not limited to end-of-life management. Increasingly, regulations are addressing the entire lifecycle of HDPE products. This includes scrutiny of production processes, with an emphasis on reducing greenhouse gas emissions and improving energy efficiency. The EU's Emissions Trading System and similar carbon pricing mechanisms in other regions are incentivizing HDPE producers to adopt cleaner technologies and optimize their operations.

Safety regulations for HDPE in food contact applications continue to be a critical area of focus. Agencies like the FDA in the US and EFSA in Europe regularly update their guidelines on the use of HDPE in food packaging, ensuring that products meet stringent safety standards. This ongoing regulatory oversight drives continuous improvement in HDPE formulations and manufacturing processes.

As the regulatory landscape becomes more stringent, HDPE manufacturers are increasingly adopting proactive approaches. Many are investing in research and development to create more sustainable HDPE products, anticipating future regulatory requirements. This includes exploring bio-based HDPE alternatives and developing advanced recycling technologies to improve the circularity of HDPE products.