High Density Polyethylene and Biodegradable Plastics Synergy

HDPE-Bioplastic Synergy Background and Objectives

The synergy between High Density Polyethylene (HDPE) and biodegradable plastics represents a significant area of research in the field of sustainable materials. This technological convergence aims to address the growing environmental concerns associated with plastic waste while maintaining the desirable properties of conventional plastics. The evolution of this field can be traced back to the early 1990s when the first biodegradable plastics were introduced, sparking interest in combining them with traditional polymers.

The primary objective of this research is to develop hybrid materials that leverage the strengths of both HDPE and biodegradable plastics. HDPE, known for its excellent mechanical properties, chemical resistance, and low cost, has been a staple in various industries for decades. However, its persistence in the environment has become a major concern. Biodegradable plastics, on the other hand, offer environmentally friendly end-of-life options but often lack the performance characteristics of conventional plastics.

By exploring the synergy between these materials, researchers aim to create composites that maintain the durability and versatility of HDPE while incorporating the biodegradability of bioplastics. This approach could potentially lead to materials that degrade more readily in natural environments or controlled composting facilities, reducing the long-term environmental impact of plastic products.

The technological trend in this field is moving towards optimizing the blend ratios, improving compatibility between HDPE and biodegradable polymers, and enhancing the overall performance of the resulting composites. Recent advancements have focused on developing compatibilizers and processing techniques that allow for better integration of these disparate materials.

Key milestones in this research area include the successful incorporation of starch-based biodegradable polymers into HDPE matrices, the development of oxo-biodegradable additives for HDPE, and the creation of multi-layer structures combining HDPE with biodegradable layers. These achievements have paved the way for further innovations in packaging, agricultural films, and consumer goods.

As the research progresses, the ultimate goal is to create a new generation of plastics that combine the best attributes of both material types. This includes developing products that maintain their structural integrity during use but can biodegrade efficiently after disposal. Additionally, researchers are exploring ways to ensure that these hybrid materials can be recycled or composted within existing waste management systems.

The synergy between HDPE and biodegradable plastics represents a promising avenue for addressing the plastic waste crisis while meeting the performance demands of various industries. As this field continues to evolve, it has the potential to revolutionize plastic production and consumption, aligning with global sustainability goals and circular economy principles.

Market Analysis for Hybrid Plastic Solutions

The market for hybrid plastic solutions combining High Density Polyethylene (HDPE) and biodegradable plastics is experiencing significant growth and transformation. This synergy addresses the increasing demand for environmentally friendly packaging solutions while maintaining the durability and versatility of traditional plastics.

Consumer awareness and environmental concerns are driving the market expansion for these hybrid solutions. As governments worldwide implement stricter regulations on single-use plastics, manufacturers are seeking innovative alternatives that balance performance with sustainability. The food and beverage industry, in particular, has shown keen interest in these hybrid materials for packaging applications.

The global market for biodegradable plastics is projected to grow substantially in the coming years, with a compound annual growth rate (CAGR) exceeding 10%. This growth is expected to positively impact the demand for hybrid HDPE-biodegradable plastic solutions. The packaging sector remains the largest end-user of these materials, followed by agriculture and textiles.

Regional markets show varying levels of adoption and growth potential. Europe leads in terms of market share and regulatory support for biodegradable and hybrid plastic solutions. North America and Asia-Pacific regions are also experiencing rapid growth, driven by increasing environmental awareness and government initiatives to reduce plastic waste.

Key market drivers include the rising demand for eco-friendly packaging, technological advancements in polymer science, and the push for circular economy principles in plastic production and recycling. However, challenges such as higher production costs and the need for specialized recycling infrastructure may impact market growth.

The competitive landscape is characterized by both established petrochemical companies and innovative start-ups. Major players are investing in research and development to improve the performance and cost-effectiveness of hybrid plastic solutions. Collaborations between HDPE manufacturers and biodegradable plastic producers are becoming more common, fostering innovation in this space.

Consumer goods companies are increasingly adopting these hybrid materials in their product packaging, driven by corporate sustainability goals and consumer preferences. This trend is expected to further boost market demand and accelerate technological advancements in hybrid plastic formulations.

As the market evolves, there is a growing focus on developing standardized testing methods and certification processes for hybrid plastic materials. This standardization is crucial for ensuring product quality, performance, and environmental claims, which in turn will build consumer trust and drive market acceptance.

Current Challenges in HDPE-Bioplastic Integration

The integration of High Density Polyethylene (HDPE) and biodegradable plastics presents several significant challenges that researchers and industry professionals are actively working to overcome. One of the primary obstacles is the inherent incompatibility between these two materials. HDPE, being a non-biodegradable polymer, has different chemical and physical properties compared to biodegradable plastics, which can lead to phase separation and poor mechanical properties in blended products.

Another major challenge is maintaining the desired performance characteristics of HDPE while incorporating biodegradable components. HDPE is valued for its strength, durability, and chemical resistance, properties that can be compromised when blended with biodegradable materials. Achieving a balance between biodegradability and the high-performance attributes of HDPE remains a complex task for materials scientists.

The processing of HDPE-bioplastic blends also poses technical difficulties. Different melting points and processing temperatures of the two materials can result in degradation of the biodegradable component during manufacturing, leading to inconsistent product quality. Additionally, the moisture sensitivity of many biodegradable plastics can cause processing issues and affect the long-term stability of the final product.

Cost considerations present another significant hurdle in the widespread adoption of HDPE-bioplastic synergies. Biodegradable plastics are generally more expensive than conventional HDPE, which can increase the overall cost of production. This economic factor often deters manufacturers from incorporating biodegradable components, especially in price-sensitive markets.

Environmental concerns also complicate the integration process. While the goal is to create more sustainable plastic products, the actual environmental impact of HDPE-bioplastic blends is not always straightforward. Questions arise regarding the true biodegradability of these composites in real-world conditions and their potential to contaminate recycling streams for pure HDPE.

Regulatory challenges further complicate the landscape. The lack of standardized testing methods and certification processes for biodegradable-conventional plastic blends creates uncertainty in product development and marketing. Manufacturers struggle to make verifiable claims about the environmental benefits of their products, which can hinder consumer acceptance and market growth.

Lastly, the end-of-life management of HDPE-bioplastic products remains a significant challenge. Current recycling infrastructure is not well-equipped to handle mixed plastic waste, potentially leading to these hybrid materials being diverted to landfills or incineration rather than being properly recycled or composted.

Existing HDPE-Bioplastic Synergy Solutions

01 Blending HDPE with biodegradable polymers

High-density polyethylene (HDPE) can be blended with biodegradable polymers to create materials with improved biodegradability while maintaining desirable properties of HDPE. This approach combines the strength and durability of HDPE with the environmental benefits of biodegradable plastics, resulting in materials suitable for various applications.- Blending HDPE with biodegradable polymers: High-density polyethylene (HDPE) can be blended with biodegradable polymers to create materials with improved biodegradability while maintaining some of HDPE's desirable properties. This approach combines the strength and durability of HDPE with the environmental benefits of biodegradable plastics, resulting in a more eco-friendly material for various applications.

- Modification of HDPE for enhanced biodegradability: Chemical or physical modifications can be applied to HDPE to enhance its biodegradability. These modifications may include the incorporation of pro-oxidants, photosensitizers, or other additives that promote the breakdown of the polymer structure when exposed to environmental factors such as sunlight, heat, or microorganisms.

- Development of biodegradable alternatives to HDPE: Research efforts are focused on developing fully biodegradable alternatives to HDPE that offer similar performance characteristics. These alternatives may include bio-based polymers derived from renewable resources or synthetic polymers designed to degrade under specific environmental conditions, providing more sustainable options for applications traditionally dominated by HDPE.

- Composite materials combining HDPE and biodegradable components: Composite materials that combine HDPE with biodegradable components, such as natural fibers or biodegradable fillers, are being developed. These composites aim to reduce the overall environmental impact of the material while maintaining the beneficial properties of HDPE, such as strength and chemical resistance.

- Recycling and upcycling of HDPE in combination with biodegradable plastics: Innovative recycling and upcycling processes are being developed to address the end-of-life management of HDPE and biodegradable plastic blends. These processes aim to recover valuable materials from mixed plastic waste streams and create new products with improved environmental profiles, contributing to a more circular economy approach in plastic management.

02 Modification of HDPE for enhanced biodegradability

Chemical or physical modifications can be applied to HDPE to enhance its biodegradability. These modifications may include the incorporation of pro-oxidants, photodegradable additives, or other substances that promote the breakdown of the polymer structure under specific environmental conditions.Expand Specific Solutions03 Development of biodegradable HDPE alternatives

Research efforts focus on developing new biodegradable polymers that can serve as alternatives to HDPE in various applications. These materials aim to provide similar mechanical properties and processability as HDPE while offering improved environmental performance through enhanced biodegradability.Expand Specific Solutions04 Composite materials combining HDPE and natural fibers

Composites made from HDPE and natural fibers, such as wood, cellulose, or agricultural residues, can improve the overall biodegradability of the material while maintaining some of the desirable properties of HDPE. These composites often exhibit enhanced mechanical properties and reduced environmental impact compared to pure HDPE.Expand Specific Solutions05 Recycling and upcycling of HDPE in biodegradable plastic products

Techniques for incorporating recycled HDPE into biodegradable plastic products are being developed to reduce waste and improve sustainability. This approach involves combining recycled HDPE with biodegradable materials or applying treatments to enhance the biodegradability of the recycled HDPE in the final product.Expand Specific Solutions

Key Players in Hybrid Plastic Development

The research on synergy between High Density Polyethylene (HDPE) and Biodegradable Plastics is in a growth phase, with increasing market size due to environmental concerns and regulatory pressures. The global market for biodegradable plastics is expanding rapidly, driven by consumer demand for sustainable packaging solutions. Technologically, the field is advancing, with companies like Carbiolice SAS, Dow Global Technologies LLC, and Mitsui Chemicals, Inc. leading innovations. However, the technology is not fully mature, as evidenced by ongoing research at institutions like Tianjin University and Changchun Institute of Applied Chemistry. The competitive landscape is diverse, with both established petrochemical companies and specialized bioplastic firms vying for market share and technological breakthroughs.

Carbiolice SAS

Kaneka Corp.

Core Innovations in Polymer Compatibility

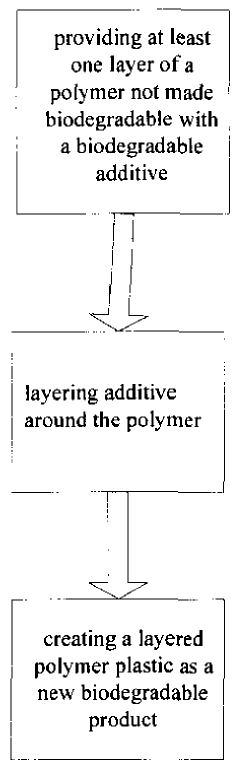

- The composition combines polyethylene with a biodegradable filler, specifically using pro-degradant d2w, to create a biodegradable highly-filled thermoplastic material.

- The inclusion of magnesium oxide in nanofibre form, which likely contributes to improved mechanical properties and potentially accelerates biodegradation.

- The use of a super concentrate of white CGP-004 and an adhesive of INDOPOL, which may enhance the material's processability and final product quality.

- A biodegradable additive comprising a chemoattractant compound, glutaric acid or its derivative, a polymer, and a swell agent, which can include microbes, compatibilizing additives, and metal particles, is mixed with polymeric materials to enhance biodegradability, allowing for controlled release and accelerated degradation by microorganisms.

Environmental Impact Assessment

The environmental impact assessment of the synergy between High Density Polyethylene (HDPE) and biodegradable plastics is a critical aspect of evaluating their combined use in various applications. This assessment considers the lifecycle of these materials, from production to disposal, and their effects on ecosystems, resource consumption, and overall environmental sustainability.

HDPE, a non-biodegradable plastic, has been widely used due to its durability and versatility. However, its persistence in the environment has raised significant concerns. The introduction of biodegradable plastics aims to address these issues, but their integration with HDPE presents both opportunities and challenges from an environmental perspective.

One of the primary benefits of this synergy is the potential reduction in long-term plastic pollution. By incorporating biodegradable components into HDPE products, the overall environmental persistence of plastic waste could be decreased. This is particularly significant in scenarios where proper waste management systems are lacking or where plastic litter is likely to end up in natural environments.

However, the environmental impact of producing these hybrid materials must be carefully considered. The manufacturing processes for both HDPE and biodegradable plastics have their own ecological footprints, including energy consumption, greenhouse gas emissions, and resource utilization. The synergistic approach may require additional processing steps, potentially increasing the overall environmental burden during production.

The end-of-life scenario for these hybrid materials is a crucial aspect of their environmental assessment. While biodegradable components may break down more readily, the presence of HDPE could complicate recycling processes and potentially contaminate existing recycling streams. This highlights the need for developing specialized recycling technologies and infrastructure to handle these hybrid materials effectively.

Water and soil impacts are also important considerations. As biodegradable components break down, they may release substances that affect local ecosystems. The interaction between degrading biodegradable plastics and persistent HDPE fragments in aquatic and terrestrial environments requires thorough investigation to ensure no unintended negative consequences.

Carbon footprint analysis of the entire lifecycle of these hybrid materials is essential. While biodegradable plastics often derive from renewable resources, potentially offering a lower carbon footprint, the energy-intensive production of HDPE from fossil fuels must be factored into the overall environmental impact assessment.

In conclusion, the environmental impact assessment of the synergy between HDPE and biodegradable plastics reveals a complex interplay of benefits and challenges. While this approach shows promise in reducing long-term plastic pollution, careful consideration must be given to production processes, end-of-life management, and ecosystem interactions to ensure a net positive environmental outcome.

Regulatory Framework for Hybrid Plastics

The regulatory framework for hybrid plastics, particularly those combining High Density Polyethylene (HDPE) and biodegradable plastics, is evolving rapidly to address the unique challenges and opportunities presented by these innovative materials. As governments and international bodies recognize the potential of hybrid plastics to reduce environmental impact while maintaining the desirable properties of conventional plastics, new regulations and standards are being developed.

In the European Union, the Packaging and Packaging Waste Directive (PPWD) has been amended to include specific provisions for hybrid plastics. These regulations require manufacturers to demonstrate the biodegradability of the composite material and ensure that the presence of HDPE does not hinder the decomposition process of the biodegradable component. The EU has also introduced labeling requirements to clearly communicate the hybrid nature of these materials to consumers and recycling facilities.

The United States Environmental Protection Agency (EPA) has issued guidelines for the development and use of hybrid plastics, focusing on their end-of-life management. These guidelines emphasize the importance of designing hybrid plastics that can be effectively separated into their constituent components for recycling or composting. The EPA also mandates extensive testing to verify the environmental claims made by manufacturers of hybrid plastic products.

In Asia, countries like Japan and South Korea have taken the lead in establishing regulatory frameworks for hybrid plastics. The Japanese Industrial Standards Committee has developed specific standards for testing the biodegradability of hybrid materials, while South Korea's Ministry of Environment has implemented a certification system for products made from hybrid plastics that meet strict environmental criteria.

International organizations, such as the International Organization for Standardization (ISO), are working on developing global standards for hybrid plastics. The ISO/TC 61/SC 14 committee is currently drafting guidelines for the characterization and testing of hybrid plastics, which will provide a unified approach to assessing their environmental impact and performance.

Regulatory bodies are also addressing the potential for greenwashing in the marketing of hybrid plastics. The Federal Trade Commission in the United States has updated its Green Guides to include specific provisions for environmental claims related to hybrid materials, ensuring that consumers are not misled by exaggerated or unsubstantiated environmental benefits.

As the technology for hybrid plastics continues to advance, regulatory frameworks are expected to evolve further. Future regulations may focus on incentivizing the use of hybrid plastics in specific applications where they offer significant environmental advantages over traditional materials. Additionally, extended producer responsibility schemes are being considered to ensure proper collection and processing of hybrid plastic waste.