Innovations in HDPE Welding Techniques: Efficiency Gains

HDPE Welding Evolution

The evolution of High-Density Polyethylene (HDPE) welding techniques has been marked by significant advancements in efficiency and reliability over the past few decades. Initially, HDPE welding was primarily performed using manual methods, which were time-consuming and often resulted in inconsistent weld quality. The introduction of semi-automated welding machines in the 1970s marked a crucial turning point, allowing for more precise control over welding parameters such as temperature, pressure, and time.

In the 1980s, the development of fully automated welding systems revolutionized the industry. These systems incorporated computer-controlled processes, enabling higher precision and repeatability in welding operations. This period also saw the introduction of non-destructive testing methods, such as ultrasonic inspection, which significantly improved quality control in HDPE welding.

The 1990s brought about advancements in welding materials and techniques. The introduction of electrofusion welding for HDPE pipes gained popularity, offering a more reliable method for joining pipes in challenging environments. This technique uses electrical resistance to heat and fuse the pipe and fitting together, providing a strong and leak-free joint.

The turn of the millennium saw a focus on improving energy efficiency and reducing environmental impact in HDPE welding processes. Innovations in heating element design and power management systems led to faster heat-up times and more uniform temperature distribution, resulting in quicker and more consistent welds.

In recent years, the integration of digital technologies has further transformed HDPE welding. The advent of Industry 4.0 concepts has led to the development of smart welding machines capable of real-time monitoring and adjustment of welding parameters. These systems can collect and analyze data from multiple sensors, ensuring optimal weld quality and providing valuable insights for process improvement.

The latest innovations in HDPE welding focus on enhancing efficiency through advanced automation and robotics. Collaborative robots, or cobots, are being increasingly employed in HDPE welding operations, offering flexibility and precision in complex welding tasks. Additionally, the use of artificial intelligence and machine learning algorithms is enabling predictive maintenance and adaptive welding processes, further improving efficiency and reducing downtime.

Looking ahead, the future of HDPE welding is likely to see continued advancements in areas such as additive manufacturing techniques for large-scale HDPE structures, the development of novel welding materials with enhanced properties, and the integration of augmented reality systems for training and quality assurance. These innovations promise to further improve the efficiency, reliability, and versatility of HDPE welding techniques across various industries.

Market Demand Analysis

The market demand for innovations in HDPE welding techniques, particularly those focused on efficiency gains, has been steadily increasing across various industries. This growth is primarily driven by the expanding applications of HDPE in sectors such as construction, water management, oil and gas, and manufacturing.

In the construction industry, there is a rising demand for more efficient HDPE welding techniques to support the rapid installation of large-diameter pipes for water and sewage systems. Municipalities and water management companies are seeking solutions that can reduce project timelines and labor costs while maintaining high-quality, leak-free joints.

The oil and gas sector has also shown significant interest in advanced HDPE welding technologies. As exploration and production activities expand into more challenging environments, the need for reliable and efficient pipe joining methods has become critical. Companies in this sector are looking for welding techniques that can withstand high pressures and extreme temperatures while minimizing downtime during installation.

Manufacturing industries, particularly those involved in chemical processing and storage, are another key driver of market demand. These industries require HDPE welding solutions that can ensure the integrity of tanks and containers, often in corrosive environments. The focus is on techniques that can provide consistent, high-strength welds with minimal material waste and reduced energy consumption.

The global push for sustainable infrastructure has further amplified the demand for efficient HDPE welding techniques. As governments and organizations invest in upgrading water distribution networks and waste management systems, there is a growing need for welding methods that can support the long-term durability and performance of HDPE pipes.

Market analysis indicates that regions with rapidly developing infrastructure, such as parts of Asia and Africa, are expected to see the highest growth in demand for advanced HDPE welding technologies. These regions are investing heavily in new water supply systems, industrial facilities, and urban development projects, all of which require extensive use of HDPE piping.

The market is also being shaped by increasing regulatory standards for pipe installation and safety. This has led to a demand for welding techniques that not only improve efficiency but also meet or exceed stringent quality and safety requirements. Manufacturers and contractors are seeking solutions that can provide documented proof of weld integrity and traceability.

As the global focus on reducing carbon footprints intensifies, there is a growing market for HDPE welding techniques that minimize energy consumption and material waste. This trend aligns with the broader industry movement towards more sustainable construction and manufacturing practices.

Technical Challenges

High-density polyethylene (HDPE) welding techniques have seen significant advancements in recent years, yet several technical challenges persist in achieving optimal efficiency gains. One of the primary obstacles is the inherent thermal sensitivity of HDPE, which requires precise temperature control during the welding process. Fluctuations in temperature can lead to inconsistent weld quality, reduced strength, and potential failure points.

Another significant challenge lies in the development of automated welding systems that can adapt to various pipe sizes and configurations. While automation has improved efficiency in many aspects of HDPE welding, creating versatile systems capable of handling a wide range of pipe diameters and wall thicknesses remains a complex task. This challenge is particularly evident in field applications where environmental conditions and pipe specifications can vary greatly.

The issue of weld contamination continues to be a persistent problem in HDPE welding. Dust, moisture, and other contaminants can significantly impact weld integrity, necessitating stringent cleaning procedures and environmental controls. Developing more robust welding techniques that are less susceptible to contamination could greatly enhance efficiency and reliability.

Time constraints in large-scale projects present another hurdle. Traditional HDPE welding methods often require extended cooling periods, which can cause significant delays in project timelines. Innovations aimed at reducing cooling times without compromising weld strength are crucial for improving overall efficiency.

The energy consumption of HDPE welding processes is also a concern, particularly in remote or off-grid locations. Current welding equipment often requires substantial power input, which can be challenging to provide in certain environments. Developing more energy-efficient welding technologies is essential for both cost reduction and environmental sustainability.

Quality control and non-destructive testing of HDPE welds remain challenging. Unlike metal welds, which can be easily inspected using various non-destructive testing methods, HDPE welds often require more complex and time-consuming inspection techniques. Improving the speed and accuracy of weld inspection methods is critical for ensuring both efficiency and safety in HDPE pipe installations.

Lastly, the development of new HDPE materials with enhanced weldability characteristics poses both an opportunity and a challenge. While these materials offer the potential for improved welding efficiency, they also require the adaptation of existing welding techniques and equipment, necessitating ongoing research and development efforts.

Current Welding Methods

01 Improved HDPE welding equipment

Advanced welding equipment specifically designed for HDPE materials has been developed to enhance efficiency. These innovations include automated welding machines, precision control systems, and specialized heating elements that optimize the welding process for HDPE pipes and structures.- Improved HDPE welding equipment: Advanced welding equipment specifically designed for HDPE materials has been developed to enhance efficiency. These innovations include automated welding machines, precision control systems, and specialized heating elements that optimize the welding process for HDPE pipes and structures.

- Optimized welding parameters: Research has focused on determining the optimal welding parameters for HDPE, including temperature, pressure, and welding time. By fine-tuning these parameters, the efficiency and quality of HDPE welds can be significantly improved, resulting in stronger and more durable joints.

- Novel welding techniques: Innovative welding techniques have been developed specifically for HDPE materials. These include ultrasonic welding, friction stir welding, and laser welding methods that offer improved efficiency, precision, and strength compared to traditional welding approaches for HDPE.

- Surface preparation and treatment: Efficient HDPE welding techniques often involve specialized surface preparation and treatment methods. These processes enhance the bonding capabilities of HDPE surfaces, leading to stronger welds and improved overall efficiency of the welding process.

- Quality control and testing methods: Advanced quality control and testing methods have been developed to ensure the efficiency and reliability of HDPE welding techniques. These include non-destructive testing procedures, real-time monitoring systems, and automated inspection technologies that help maintain high standards in HDPE welding processes.

02 Optimized welding parameters

Research has focused on determining the optimal welding parameters for HDPE, including temperature, pressure, and welding time. By fine-tuning these parameters, the efficiency and quality of HDPE welds can be significantly improved, resulting in stronger and more durable joints.Expand Specific Solutions03 Novel welding techniques

Innovative welding techniques have been developed specifically for HDPE materials. These include ultrasonic welding, friction stir welding, and laser welding methods that offer improved efficiency, reduced welding time, and enhanced joint strength compared to traditional welding approaches.Expand Specific Solutions04 Surface preparation and treatment

Efficient HDPE welding techniques often involve specialized surface preparation and treatment methods. These may include chemical treatments, plasma activation, or mechanical abrasion to improve weld adhesion and overall joint strength, leading to more efficient and reliable welding processes.Expand Specific Solutions05 Quality control and monitoring systems

Advanced quality control and monitoring systems have been integrated into HDPE welding processes to ensure consistent weld quality and efficiency. These systems may include real-time monitoring of welding parameters, non-destructive testing methods, and automated inspection technologies to detect and prevent welding defects.Expand Specific Solutions

Industry Leaders

The HDPE welding techniques market is in a growth phase, driven by increasing demand for efficient and durable joining methods in various industries. The market size is expanding, with a focus on innovations that enhance productivity and reduce costs. Technologically, the field is advancing rapidly, with major players like Dow Global Technologies LLC, ExxonMobil Chemical Patents, Inc., and SABIC Global Technologies BV leading research and development efforts. These companies, along with others such as Nippon Steel Welding & Engineering Co., Ltd. and Chevron Phillips Chemical Co. LP, are pushing the boundaries of HDPE welding technology, focusing on improving efficiency, strength, and reliability of welds. The competitive landscape is characterized by a mix of established petrochemical giants and specialized welding technology firms, all vying to develop and commercialize cutting-edge HDPE welding solutions.

Dow Global Technologies LLC

SABIC Global Technologies BV

Key Innovations

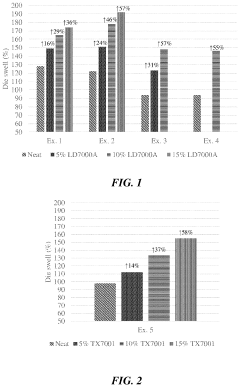

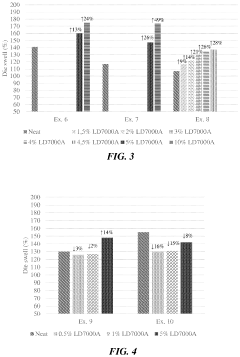

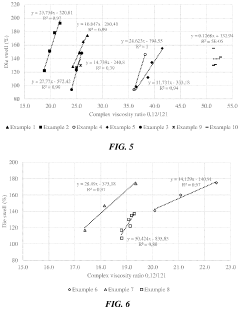

- A multimodal high-density polyethylene composition is developed, comprising a lower molecular weight fraction and a higher molecular weight fraction, with the addition of low-density polyethylene, enhancing die swell and elasticity, thereby improving environmental stress cracking resistance and processability.

- A method involving the preparation of HDPE filaments using a twin screw extruder at specific temperature and speed settings to achieve a uniform diameter, followed by 3D printing with fused filament fabrication technology using a textured Polyetherimide-coated build plate, ensuring high infill density and brim size to produce pure HDPE articles with improved mechanical properties.

Environmental Impact

The environmental impact of innovations in HDPE welding techniques is a critical consideration in the pursuit of efficiency gains. As the industry strives for more effective welding processes, it is essential to evaluate the ecological footprint of these advancements.

One of the primary environmental benefits of improved HDPE welding techniques is the reduction in material waste. More precise and efficient welding methods result in fewer defects and less scrap material, ultimately reducing the amount of plastic waste generated during manufacturing and installation processes. This not only conserves raw materials but also minimizes the environmental burden associated with disposal or recycling of waste HDPE.

Energy consumption is another significant factor in the environmental impact of HDPE welding. Innovations that reduce welding time or lower the required heat input can lead to substantial energy savings. For instance, advancements in electrofusion welding technology have resulted in more energy-efficient processes, reducing the carbon footprint associated with HDPE pipe installation and repair.

The durability and longevity of HDPE welds also play a crucial role in environmental sustainability. Improved welding techniques that result in stronger, more reliable joints can extend the lifespan of HDPE products and infrastructure. This reduces the frequency of replacements and repairs, thereby decreasing the overall environmental impact associated with manufacturing and installation of new HDPE components.

Innovations in HDPE welding may also contribute to the reduction of volatile organic compound (VOC) emissions. Traditional welding methods often involve the use of solvents or adhesives that can release harmful VOCs into the atmosphere. New techniques that minimize or eliminate the need for such substances can significantly improve air quality and reduce the environmental hazards associated with HDPE welding operations.

Furthermore, advancements in portable and on-site welding equipment can lead to reduced transportation requirements. By enabling more efficient field welding, these innovations can decrease the need for pre-fabricated components, thereby reducing fuel consumption and emissions associated with transporting large HDPE structures.

The development of more environmentally friendly welding consumables is another area where innovations can have a positive impact. Research into biodegradable or recyclable welding rods and fillers could potentially reduce the environmental footprint of HDPE welding processes, aligning with broader sustainability goals in the plastics industry.

In conclusion, while the primary focus of innovations in HDPE welding techniques may be on efficiency gains, the environmental implications of these advancements are far-reaching and significant. By reducing waste, energy consumption, and emissions, while improving product longevity, these innovations contribute to a more sustainable approach to HDPE utilization across various industries.

Safety Considerations

Safety considerations are paramount in the development and implementation of innovative HDPE welding techniques. As efficiency gains are sought, it is crucial to maintain and enhance safety standards to protect workers, equipment, and the environment.

One of the primary safety concerns in HDPE welding is the risk of thermal injuries. The high temperatures required for welding can cause severe burns if proper precautions are not taken. Innovations in this area focus on developing safer heat sources and improved insulation techniques to minimize the risk of accidental contact with hot surfaces. Advanced temperature control systems are being integrated into welding equipment to ensure precise heat application and reduce the likelihood of overheating.

Fume and vapor emissions during the welding process pose another significant safety challenge. HDPE welding can release potentially harmful substances, including volatile organic compounds (VOCs) and particulate matter. Recent innovations have led to the development of more efficient fume extraction systems and improved ventilation techniques. These advancements not only enhance worker safety but also contribute to a cleaner working environment and reduced environmental impact.

Electrical safety is a critical aspect of HDPE welding, particularly with the introduction of more sophisticated welding equipment. Innovations in this area include enhanced grounding systems, improved insulation of electrical components, and the integration of advanced circuit protection mechanisms. These developments aim to minimize the risk of electrical shocks and prevent equipment-related accidents.

Ergonomic considerations have gained increased attention in recent years. As welding techniques become more efficient, there is a growing focus on reducing the physical strain on operators. Innovations in this area include the development of lighter, more maneuverable welding equipment and the implementation of automated systems that reduce the need for prolonged manual handling.

The introduction of new materials and additives in HDPE welding processes necessitates ongoing safety assessments. Researchers are working on developing safer alternatives to traditional welding materials and conducting comprehensive studies on the long-term health effects of exposure to new compounds. This proactive approach ensures that safety considerations keep pace with technological advancements.

Training and education play a crucial role in maintaining safety standards as new welding techniques are introduced. Innovative training programs, including virtual reality simulations and interactive e-learning modules, are being developed to ensure that operators are well-versed in the latest safety protocols and can effectively use new equipment and techniques.