High Density Polyethylene: A Driver for Global Green Initiatives

HDPE Evolution and Sustainability Goals

High Density Polyethylene (HDPE) has emerged as a key player in the global push towards sustainability and environmental responsibility. The evolution of HDPE technology has been closely intertwined with the growing awareness of environmental issues and the need for more sustainable materials. Initially developed in the 1950s, HDPE has undergone significant advancements in its production processes and applications, driven by the increasing demand for eco-friendly alternatives to traditional plastics.

The journey of HDPE towards sustainability began with improvements in its manufacturing efficiency, reducing energy consumption and waste generation. As environmental concerns gained prominence in the 1970s and 1980s, researchers and industry leaders focused on enhancing HDPE's recyclability and developing bio-based alternatives. These efforts aligned with the broader goals of reducing carbon footprints and minimizing reliance on fossil fuels.

In recent years, the sustainability goals for HDPE have become more ambitious and comprehensive. The industry has set targets for increasing the use of recycled content in HDPE products, with some companies aiming for 100% recycled or renewable-based HDPE by 2030. This shift is driven by both consumer demand for environmentally friendly products and regulatory pressures to reduce plastic waste and greenhouse gas emissions.

The development of advanced recycling technologies has been crucial in this evolution. Chemical recycling methods, which break down HDPE into its molecular components, have opened up new possibilities for creating high-quality recycled materials that can be used in a wide range of applications, including food packaging and medical devices. This technological advancement addresses one of the major challenges in plastic recycling: maintaining material quality through multiple recycling cycles.

Biodegradable and compostable HDPE alternatives are another focus area in the material's sustainability journey. Research into bio-based HDPE, derived from renewable resources such as sugarcane or cellulose, aims to reduce the carbon footprint associated with traditional petroleum-based production. These innovations not only contribute to reducing plastic pollution but also align with circular economy principles.

The evolution of HDPE is also closely tied to advancements in product design and manufacturing processes. Lightweight design techniques and improved material formulations have led to HDPE products that use less material while maintaining or even enhancing performance. This approach not only reduces resource consumption but also contributes to energy savings in transportation and distribution.

As HDPE continues to evolve, its role in global green initiatives is becoming increasingly significant. The material's versatility, coupled with ongoing innovations in sustainability, positions HDPE as a critical component in the transition towards a more environmentally responsible future. The industry's commitment to sustainability goals is driving research into new applications, such as renewable energy infrastructure and sustainable building materials, further expanding HDPE's potential to contribute to global environmental solutions.

Global Market Demand for Green Plastics

The global market demand for green plastics, particularly High Density Polyethylene (HDPE), has been experiencing significant growth in recent years. This surge is driven by increasing environmental awareness, stringent regulations, and a shift towards sustainable practices across industries. HDPE, known for its versatility and recyclability, has emerged as a key player in the green plastics market.

Consumer preferences have notably shifted towards eco-friendly products, with a growing willingness to pay premium prices for sustainable alternatives. This trend has prompted manufacturers to invest in green plastic solutions, with HDPE being a primary focus due to its favorable properties and potential for recycling. The packaging industry, in particular, has seen a substantial increase in demand for HDPE-based green plastics, as companies strive to reduce their environmental footprint and meet consumer expectations.

The construction sector has also contributed significantly to the rising demand for green HDPE. Its durability, resistance to chemicals, and long lifespan make it an attractive option for sustainable building materials. Additionally, the automotive industry has been incorporating more HDPE components to reduce vehicle weight and improve fuel efficiency, aligning with global efforts to decrease carbon emissions.

Geographically, Europe and North America lead the market demand for green plastics, including HDPE, due to stringent environmental regulations and high consumer awareness. However, rapidly developing economies in Asia-Pacific, particularly China and India, are expected to drive substantial growth in the coming years as these countries implement stricter environmental policies and witness increasing urbanization.

The agricultural sector has also recognized the benefits of HDPE in sustainable farming practices. Its use in irrigation systems, greenhouse films, and crop protection has grown, contributing to the overall market demand. Furthermore, the textile industry has been exploring HDPE-based fibers as an eco-friendly alternative to traditional synthetic materials, opening up new avenues for market expansion.

Despite the positive outlook, challenges such as higher production costs compared to conventional plastics and the need for improved recycling infrastructure persist. However, ongoing technological advancements and increasing economies of scale are expected to address these issues, further boosting the adoption of green HDPE across various industries.

HDPE Technical Challenges and Limitations

Despite its widespread use and numerous advantages, High Density Polyethylene (HDPE) faces several technical challenges and limitations that hinder its full potential as a driver for global green initiatives. One of the primary concerns is the material's recyclability. While HDPE is theoretically 100% recyclable, the practical reality is far more complex. Contamination from labels, adhesives, and other materials often compromises the quality of recycled HDPE, leading to downcycling rather than true recycling.

Another significant challenge lies in HDPE's production process. The current methods of manufacturing HDPE are energy-intensive and heavily reliant on fossil fuels, which contradicts the material's potential as a sustainable solution. The high temperatures and pressures required for polymerization contribute to substantial carbon emissions, offsetting some of the environmental benefits gained from HDPE's durability and recyclability.

HDPE's resistance to degradation, while beneficial for many applications, poses environmental concerns when the material is improperly disposed of. Unlike biodegradable materials, HDPE can persist in the environment for hundreds of years, contributing to plastic pollution in landfills and oceans. This longevity becomes problematic when considering the material's end-of-life management.

The material's limited gas barrier properties present another technical challenge, particularly in packaging applications. HDPE's permeability to certain gases can restrict its use in food packaging and other sensitive applications where oxygen or moisture barrier properties are crucial. This limitation often necessitates the use of multi-layer packaging solutions, which further complicate recycling efforts.

HDPE's susceptibility to stress cracking under certain conditions is another technical limitation. Environmental stress cracking can occur when the material is exposed to specific chemicals or subjected to prolonged stress, potentially leading to premature failure in critical applications. This vulnerability requires careful consideration in product design and material selection processes.

The challenge of incorporating recycled content into new HDPE products without compromising performance is an ongoing issue. While the use of recycled HDPE is growing, maintaining consistent quality and meeting stringent performance requirements with high percentages of recycled content remains difficult. This challenge is particularly acute in high-performance applications where material properties must meet specific standards.

Addressing these technical challenges and limitations is crucial for enhancing HDPE's role in global green initiatives. Innovations in recycling technologies, improvements in production efficiency, and advancements in material properties are necessary to overcome these hurdles and fully realize HDPE's potential as a sustainable material solution.

Current HDPE Sustainability Solutions

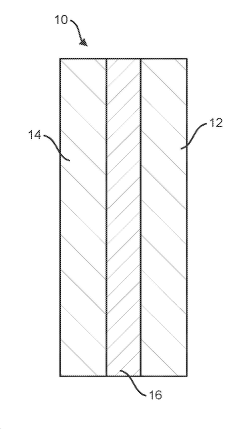

01 Manufacturing processes for HDPE

Various manufacturing processes are used to produce high-density polyethylene (HDPE), including polymerization techniques and extrusion methods. These processes aim to create HDPE with specific properties such as high strength, durability, and chemical resistance.- Manufacturing processes for HDPE: Various manufacturing processes are used to produce high-density polyethylene (HDPE), including polymerization techniques and extrusion methods. These processes aim to create HDPE with specific properties such as high strength, durability, and chemical resistance. Different catalysts and reaction conditions can be employed to control the molecular weight and distribution of the polymer chains.

- HDPE blends and composites: HDPE can be blended with other materials or reinforced with additives to enhance its properties. These blends and composites can improve characteristics such as impact resistance, thermal stability, or specific mechanical properties. The selection of blend components or reinforcing materials depends on the desired end-use application of the HDPE product.

- HDPE applications in packaging and containers: HDPE is widely used in packaging applications and container manufacturing due to its excellent barrier properties, chemical resistance, and durability. It is commonly used for bottles, drums, and various types of packaging materials. The material's properties can be tailored to meet specific requirements for different packaging applications.

- Recycling and sustainability of HDPE: Recycling processes for HDPE have been developed to address environmental concerns and promote sustainability. These processes involve collecting, sorting, cleaning, and reprocessing HDPE products to create new materials. Innovations in recycling technologies aim to improve the quality of recycled HDPE and expand its potential applications.

- HDPE modifications for specific properties: Various modification techniques are employed to enhance specific properties of HDPE for targeted applications. These modifications can include crosslinking, surface treatments, or the incorporation of specific additives. Such modifications can improve characteristics like wear resistance, adhesion properties, or electrical insulation capabilities of HDPE materials.

02 HDPE blends and composites

HDPE is often blended with other materials or used in composites to enhance its properties. These blends and composites can improve characteristics such as impact resistance, thermal stability, and processability, making them suitable for a wide range of applications.Expand Specific Solutions03 HDPE applications in packaging and containers

HDPE is widely used in packaging and container applications due to its excellent barrier properties, chemical resistance, and durability. It is commonly used in the production of bottles, containers, and packaging materials for various industries.Expand Specific Solutions04 Recycling and sustainability of HDPE

Recycling processes and sustainable practices for HDPE are being developed to address environmental concerns. These include methods for collecting, sorting, and reprocessing HDPE materials, as well as the development of bio-based alternatives.Expand Specific Solutions05 HDPE modifications and additives

Various modifications and additives are used to enhance the properties of HDPE. These can include crosslinking agents, stabilizers, and other additives that improve characteristics such as UV resistance, long-term durability, and processing behavior.Expand Specific Solutions

Key Players in HDPE Green Technology

The High Density Polyethylene (HDPE) market is in a mature growth stage, driven by global green initiatives and sustainable packaging demands. The market size is substantial, with steady expansion projected due to HDPE's versatility and recyclability. Technologically, HDPE production is well-established, but innovation continues in areas like catalyst systems and process efficiency. Major players such as ExxonMobil Chemical, China Petroleum & Chemical Corp, and SABIC Global Technologies are at the forefront of HDPE technology development. These companies, along with others like Univation Technologies and Dow Global Technologies, are focusing on enhancing HDPE properties, improving production processes, and developing more sustainable solutions to meet evolving market needs and environmental regulations.

China Petroleum & Chemical Corp.

SABIC Global Technologies BV

Breakthrough HDPE Green Technologies

- Production of high-density polyethylene polymers using bio-based ethylene monomers derived from carbon-negative or carbon-neutral sources, such as biogas, biomass, and other sustainable resources, through processes like thermal decomposition, partial oxidation, and fermentation, ensuring high molecular weights and purity levels.

- Producing high density polyethylene polymers using bio-based ethylene monomers derived from carbon negative or carbon neutral sources, such as biomass, biogas, and vegetable oils, which are converted into ethylene through various processes like pyrolysis, hydrogenation, or fermentation, allowing for a significant reduction in carbon emissions while maintaining high molecular weights and purity levels.

Environmental Impact Assessment of HDPE

The environmental impact assessment of High Density Polyethylene (HDPE) reveals a complex interplay between its benefits and potential drawbacks. HDPE, known for its durability and versatility, has become a cornerstone in various industries, particularly in packaging and construction. However, its widespread use has raised concerns about its environmental footprint.

One of the primary environmental advantages of HDPE is its recyclability. When properly collected and processed, HDPE can be recycled multiple times without significant degradation in quality. This characteristic contributes to the circular economy, reducing the demand for virgin plastic production and minimizing waste. Additionally, the production of HDPE requires less energy compared to many alternative materials, potentially lowering greenhouse gas emissions associated with manufacturing.

Despite these benefits, the environmental impact of HDPE is not without challenges. The production of HDPE relies heavily on fossil fuels, contributing to carbon emissions and resource depletion. While recyclable, a significant portion of HDPE products still end up in landfills or the environment due to inadequate waste management systems and consumer behavior.

The persistence of HDPE in the environment is a major concern. When improperly disposed of, HDPE can take hundreds of years to decompose, leading to long-term pollution in terrestrial and marine ecosystems. Microplastic particles derived from HDPE degradation have been found in various environmental compartments, raising concerns about their impact on wildlife and potential entry into the food chain.

Water pollution is another significant issue associated with HDPE. Plastic waste, including HDPE products, often finds its way into water bodies, contributing to the global problem of marine plastic pollution. This not only affects marine life through entanglement and ingestion but also poses risks to human health through the consumption of contaminated seafood.

The lifecycle assessment of HDPE products reveals varying environmental impacts depending on the specific application and end-of-life scenario. While HDPE's durability can lead to extended product lifespans in some applications, it may also result in prolonged environmental presence when discarded. The transportation of HDPE products and raw materials also contributes to its overall carbon footprint.

Efforts to mitigate the environmental impact of HDPE include improving recycling infrastructure, developing bio-based alternatives, and implementing extended producer responsibility programs. Innovations in HDPE formulations, such as incorporating recycled content or enhancing biodegradability, are also being explored to address environmental concerns while maintaining the material's beneficial properties.

In conclusion, the environmental impact assessment of HDPE underscores the need for a balanced approach in its use and management. While HDPE offers significant benefits in terms of durability and recyclability, addressing its environmental challenges requires concerted efforts across the value chain, from production to disposal and recycling.

Circular Economy Strategies for HDPE

Circular economy strategies for High Density Polyethylene (HDPE) are becoming increasingly crucial in the global push towards sustainability and environmental responsibility. These strategies aim to maximize the value of HDPE throughout its lifecycle while minimizing waste and environmental impact.

One of the primary circular economy approaches for HDPE is the implementation of efficient collection and sorting systems. This involves establishing comprehensive infrastructure for the collection of post-consumer HDPE products, coupled with advanced sorting technologies to separate HDPE from other materials. Optical sorting systems and artificial intelligence-driven technologies are being employed to enhance the accuracy and speed of HDPE identification and separation.

Mechanical recycling remains a cornerstone of HDPE circularity. This process involves cleaning, grinding, and reprocessing HDPE into pellets that can be used to manufacture new products. Advancements in mechanical recycling technologies have led to improved quality of recycled HDPE, making it suitable for a wider range of applications, including food-grade packaging in some cases.

Chemical recycling is emerging as a promising complementary strategy to mechanical recycling. This process breaks down HDPE into its chemical building blocks, which can then be used to create new plastics or other chemical products. Chemical recycling has the potential to handle contaminated or mixed plastic waste that is challenging for mechanical recycling processes.

Design for recyclability is another critical aspect of HDPE circular economy strategies. This involves creating products that are easier to recycle at the end of their life. Manufacturers are increasingly focusing on mono-material designs, easily separable components, and the use of compatible additives to enhance the recyclability of HDPE products.

The development of closed-loop systems within industries is gaining traction. In these systems, HDPE products are collected, recycled, and remanufactured within the same supply chain, reducing the need for virgin materials and minimizing waste. This approach is particularly effective in industries such as packaging and automotive manufacturing.

Extended producer responsibility (EPR) schemes are being implemented in various regions to encourage manufacturers to take responsibility for the entire lifecycle of their HDPE products. These schemes often involve financial incentives or penalties to promote the use of recycled content and the development of more sustainable product designs.

Lastly, the promotion of reuse models for HDPE products is an essential strategy in the circular economy. This includes the development of refillable packaging systems, the establishment of product-as-a-service models, and the creation of durable HDPE products designed for multiple use cycles.