How to Revamp Infrastructure with HDPE Solutions?

HDPE Infrastructure Evolution and Objectives

High-density polyethylene (HDPE) has emerged as a revolutionary material in infrastructure development, offering a robust and sustainable alternative to traditional materials. The evolution of HDPE in infrastructure applications spans several decades, with significant advancements in material science and manufacturing processes driving its adoption across various sectors.

Initially introduced in the 1950s, HDPE's potential for infrastructure applications was quickly recognized due to its exceptional durability, chemical resistance, and flexibility. The material's journey in infrastructure began with small-scale applications, such as water and gas distribution pipes. As research and development progressed, HDPE's use expanded to larger and more complex infrastructure projects.

The 1970s and 1980s saw a surge in HDPE adoption for underground utilities, particularly in water and wastewater systems. This period marked a crucial turning point, as engineers and city planners began to appreciate HDPE's long-term cost-effectiveness and environmental benefits compared to traditional materials like concrete and metal.

In recent years, the focus has shifted towards developing advanced HDPE formulations and manufacturing techniques to enhance its performance in demanding infrastructure applications. These innovations have led to HDPE solutions capable of withstanding higher pressures, extreme temperatures, and harsh environmental conditions, further expanding its applicability in critical infrastructure projects.

The primary objective of revamping infrastructure with HDPE solutions is to address the growing challenges faced by aging and deteriorating infrastructure worldwide. HDPE offers a unique combination of properties that make it an ideal material for infrastructure renewal: longevity, corrosion resistance, flexibility, and ease of installation. By leveraging these attributes, infrastructure projects aim to extend service life, reduce maintenance costs, and improve overall system performance.

Another key objective is to enhance the sustainability of infrastructure systems. HDPE's recyclability and lower carbon footprint compared to traditional materials align with global efforts to reduce environmental impact. Additionally, the material's resistance to leaks and infiltration contributes to water conservation efforts and reduces the risk of environmental contamination.

Looking ahead, the evolution of HDPE in infrastructure is expected to continue, with ongoing research focused on further improving material properties, developing new application techniques, and exploring innovative designs that fully exploit HDPE's unique characteristics. The ultimate goal is to create more resilient, efficient, and sustainable infrastructure systems that can meet the demands of growing populations and changing environmental conditions.

Market Analysis for HDPE Infrastructure Solutions

The global market for High-Density Polyethylene (HDPE) infrastructure solutions is experiencing significant growth, driven by the increasing demand for durable, cost-effective, and environmentally friendly materials in various sectors. The construction industry, in particular, has shown a strong inclination towards HDPE products due to their superior properties and long-term performance benefits.

The market size for HDPE infrastructure solutions was valued at approximately $25 billion in 2020 and is projected to reach $35 billion by 2025, growing at a compound annual growth rate (CAGR) of 7%. This growth is primarily attributed to the rising investments in infrastructure development, especially in emerging economies, and the increasing awareness of the benefits of HDPE over traditional materials.

Key market segments for HDPE infrastructure solutions include water and wastewater systems, telecommunications, gas distribution, and industrial applications. The water and wastewater segment holds the largest market share, accounting for about 40% of the total market value. This is due to the growing need for efficient water management systems and the replacement of aging infrastructure in developed countries.

Geographically, Asia-Pacific dominates the HDPE infrastructure solutions market, followed by North America and Europe. The Asia-Pacific region is expected to maintain its leading position during the forecast period, with a CAGR of 8.5%, driven by rapid urbanization, industrialization, and government initiatives for infrastructure development in countries like China and India.

The market is characterized by intense competition among key players, including Chevron Phillips Chemical Company, LyondellBasell Industries, and Borealis AG. These companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position and expand their product portfolios.

Several trends are shaping the HDPE infrastructure solutions market. The increasing adoption of trenchless technology for pipeline installation and rehabilitation is driving the demand for HDPE pipes. Additionally, the growing emphasis on sustainable and recyclable materials is boosting the use of HDPE in various infrastructure applications.

Challenges in the market include fluctuating raw material prices and the availability of alternative materials such as PVC and steel. However, the superior properties of HDPE, including its chemical resistance, flexibility, and long service life, continue to drive its adoption in infrastructure projects.

In conclusion, the market for HDPE infrastructure solutions presents significant opportunities for growth and innovation. As governments and industries increasingly prioritize sustainable and cost-effective infrastructure solutions, HDPE is well-positioned to play a crucial role in revamping and modernizing infrastructure systems across various sectors.

HDPE Technology: Current Status and Challenges

High-Density Polyethylene (HDPE) technology has made significant strides in recent years, positioning itself as a versatile and robust solution for infrastructure revitalization. The current status of HDPE technology is characterized by its widespread adoption across various sectors, including water and wastewater systems, gas distribution networks, and telecommunications infrastructure.

HDPE pipes and fittings have gained prominence due to their exceptional durability, corrosion resistance, and flexibility. These properties make HDPE an ideal material for replacing aging metal and concrete infrastructure, particularly in underground applications. The technology's current state allows for the production of large-diameter pipes capable of withstanding high pressures, expanding its utility in major infrastructure projects.

One of the key advancements in HDPE technology is the development of enhanced material formulations. These innovations have resulted in HDPE products with improved stress crack resistance, higher temperature resistance, and better long-term performance under various environmental conditions. Such improvements have significantly extended the lifespan of HDPE infrastructure components, making them a cost-effective choice for long-term investments.

Despite its many advantages, HDPE technology faces several challenges in its widespread implementation for infrastructure revamping. One primary concern is the initial cost of HDPE materials, which can be higher than traditional alternatives. This cost factor often presents a barrier to adoption, particularly for budget-constrained municipalities and organizations.

Another challenge lies in the specialized installation techniques required for HDPE systems. While these methods, such as heat fusion joining, provide superior joint integrity, they necessitate skilled labor and specialized equipment. The shortage of trained personnel and the learning curve associated with these techniques can slow down the adoption of HDPE solutions in infrastructure projects.

Environmental concerns also pose challenges to HDPE technology. Although HDPE is recyclable, the current recycling infrastructure for large-scale HDPE products used in infrastructure is limited. Improving the end-of-life management and recycling capabilities for HDPE materials remains a critical area for development.

Furthermore, the integration of HDPE solutions with existing infrastructure presents technical challenges. Compatibility issues between HDPE and other materials, as well as the need for specialized transition fittings, require careful engineering and planning. This complexity can sometimes lead to hesitation in adopting HDPE for partial infrastructure upgrades.

Lastly, the regulatory landscape surrounding HDPE use in critical infrastructure varies across regions. Inconsistent standards and approval processes can hinder the widespread adoption of HDPE solutions, particularly in conservative sectors like public water systems. Harmonizing regulations and increasing awareness among decision-makers about the long-term benefits of HDPE technology are ongoing challenges that need to be addressed.

Current HDPE Infrastructure Solutions

01 HDPE pipe systems for infrastructure

High-density polyethylene (HDPE) pipes are widely used in infrastructure projects due to their durability, flexibility, and corrosion resistance. These pipes are suitable for various applications including water supply, sewage systems, and gas distribution. HDPE pipes offer advantages such as leak-free joints, long service life, and resistance to environmental factors.- HDPE pipe systems for infrastructure: High-density polyethylene (HDPE) pipes are widely used in infrastructure projects due to their durability, flexibility, and corrosion resistance. These pipes are suitable for various applications including water supply, sewage systems, and gas distribution. HDPE pipes offer advantages such as leak-free joints, long service life, and resistance to environmental factors.

- HDPE material composition and properties: The composition and properties of HDPE materials used in infrastructure are crucial for their performance. Researchers focus on improving the mechanical strength, thermal stability, and chemical resistance of HDPE through various additives and processing techniques. These enhancements contribute to the material's suitability for demanding infrastructure applications.

- HDPE in construction and building materials: HDPE is increasingly used in construction and building materials for infrastructure projects. Applications include geomembranes for landfills, moisture barriers, and insulation materials. The material's lightweight nature, durability, and resistance to moisture make it an attractive option for various construction elements in infrastructure development.

- Recycling and sustainability of HDPE in infrastructure: The recycling and sustainability aspects of HDPE in infrastructure are gaining importance. Efforts are being made to incorporate recycled HDPE into new infrastructure products, reducing environmental impact. Additionally, research is focused on improving the recyclability of HDPE materials used in infrastructure, contributing to a more circular economy.

- HDPE in specialized infrastructure applications: HDPE is finding use in specialized infrastructure applications due to its unique properties. These include marine structures, underground storage tanks, and protective linings for industrial facilities. The material's resistance to chemicals, UV radiation, and impact makes it suitable for these demanding environments, extending the lifespan of infrastructure components.

02 HDPE material composition and manufacturing

The development of specialized HDPE compositions for infrastructure applications involves optimizing the polymer's properties. This includes improving the material's strength, impact resistance, and long-term performance. Advanced manufacturing techniques are employed to produce HDPE products with enhanced characteristics suitable for demanding infrastructure environments.Expand Specific Solutions03 HDPE in construction and building materials

HDPE is increasingly used in construction and building materials for infrastructure projects. Applications include geomembranes for landfills, moisture barriers, and insulation materials. The material's properties, such as chemical resistance and low permeability, make it suitable for various construction-related uses in infrastructure development.Expand Specific Solutions04 Recycling and sustainability of HDPE in infrastructure

The recyclability of HDPE is a significant advantage in infrastructure applications. Efforts are being made to incorporate recycled HDPE into new infrastructure products, reducing environmental impact and promoting sustainability. This includes developing methods for efficiently recycling HDPE from various sources and reintegrating it into the production of new infrastructure materials.Expand Specific Solutions05 HDPE in specialized infrastructure applications

HDPE is being utilized in specialized infrastructure applications, leveraging its unique properties. This includes the use of HDPE in marine structures, underground storage tanks, and protective casings for cables and utilities. The material's resistance to chemicals, UV radiation, and mechanical stress makes it suitable for these demanding applications in infrastructure development.Expand Specific Solutions

Key Players in HDPE Infrastructure Industry

The infrastructure revitalization using HDPE solutions is in a growth phase, with increasing market size and technological maturity. The global HDPE pipe market is expanding, driven by urbanization and infrastructure development. Companies like China Petroleum & Chemical Corp. and Anhui Wanfang Pipe Industry Group Co., Ltd. are leading in technological advancements, while international players such as egeplast international GmbH contribute to the competitive landscape. The technology's maturity is evident in its widespread adoption, with firms like Beijing GeoEnviron Engineering & Technology, Inc. and China Construction Eighth Bureau Second Construction Co., Ltd. implementing HDPE solutions in various infrastructure projects. This competitive environment fosters innovation and efficiency in HDPE applications for infrastructure revitalization.

Anhui Wanfang Pipe Industry Group Co., Ltd.

Beijing Bestone Pipeline Technology Co., Ltd.

Innovative HDPE Technologies and Patents

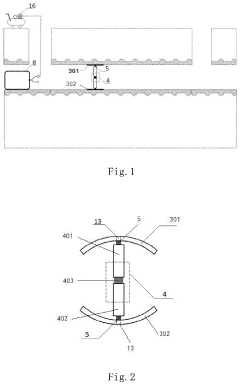

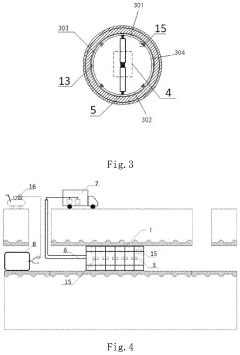

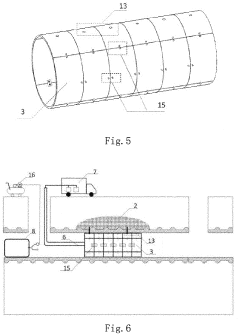

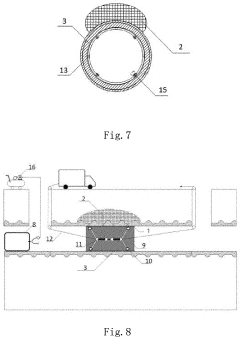

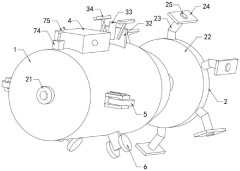

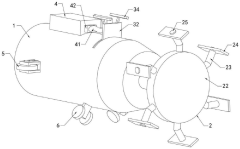

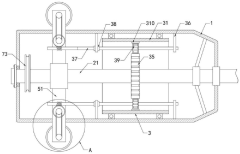

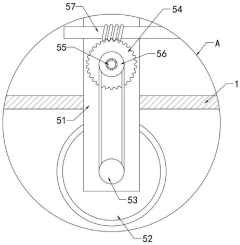

- A trenchless rehabilitation system integrating lining steel ring supporting, polymer injection, and CIPP (Cured-in-place pipe) processes, utilizing a water blocking device, support structure, injection machine, resin impregnated lining hose, and light curing machine to stabilize and repair deformative HDPE pipelines by forming a CIPP liner.

- A concrete-lined HDPE pipe repair device is designed, including a high-pressure water pipe, sector gear, transmission gear, internal toothed ring, traveling wheel, worm gear, worm, pulley and drying assembly. The rotation of the high-pressure water pipe drives the mortar nozzle to reciprocate and spray. sand, realizing automatic walking and rapid drying and solidification.

Environmental Impact of HDPE Infrastructure

The implementation of HDPE (High-Density Polyethylene) solutions in infrastructure revitalization presents significant environmental implications. HDPE's durability and longevity contribute to reduced replacement frequency, minimizing the environmental impact associated with frequent construction and maintenance activities. This material's resistance to corrosion and chemical degradation ensures a longer service life, reducing the need for resource-intensive repairs and replacements.

HDPE's lightweight nature compared to traditional materials like concrete or metal results in lower transportation emissions during installation and maintenance. This characteristic also facilitates easier handling and installation, potentially reducing the energy consumption and carbon footprint of construction processes. Furthermore, HDPE pipes and structures require less energy-intensive manufacturing processes compared to alternatives, contributing to overall reduced energy consumption and associated greenhouse gas emissions.

The material's flexibility and resistance to cracking make HDPE infrastructure less susceptible to damage from ground movements or seismic activities, reducing the likelihood of leaks or failures that could lead to environmental contamination. In water distribution systems, HDPE's smooth interior surface reduces friction, leading to improved energy efficiency in pumping operations and potentially lower overall energy consumption in water management systems.

HDPE's recyclability is a significant environmental advantage. At the end of its service life, HDPE infrastructure can be recycled and repurposed, contributing to a circular economy and reducing the demand for virgin materials. This recyclability helps mitigate the environmental impact associated with waste disposal and resource extraction for new materials.

However, the environmental impact of HDPE infrastructure is not without challenges. The production of HDPE relies on fossil fuel resources, raising concerns about its long-term sustainability. While efforts are being made to develop bio-based alternatives, the current dependence on petrochemicals remains an environmental consideration. Additionally, the potential for microplastic pollution from wear and tear of HDPE infrastructure over time is an emerging environmental concern that requires further research and mitigation strategies.

In aquatic environments, HDPE's use in drainage systems and erosion control can help prevent soil loss and water pollution. Its inert nature reduces the risk of chemical leaching into soil or water bodies, protecting ecosystems from contamination. However, proper installation and maintenance practices are crucial to fully realize these environmental benefits and prevent unintended consequences.

Cost-Benefit Analysis of HDPE Solutions

The cost-benefit analysis of HDPE solutions for infrastructure revitalization reveals compelling advantages that justify the initial investment. HDPE pipes offer superior durability and longevity compared to traditional materials, with an expected service life of up to 100 years. This extended lifespan significantly reduces the frequency and costs associated with repairs and replacements, leading to substantial long-term savings for municipalities and utility companies.

The installation process for HDPE pipes is notably more efficient and cost-effective than conventional methods. Trenchless technologies, such as horizontal directional drilling, can be employed with HDPE pipes, minimizing surface disruption and reducing labor costs. This approach not only accelerates project timelines but also mitigates the indirect costs associated with traffic disruptions and business interruptions during construction.

HDPE's resistance to corrosion, chemicals, and abrasion translates to lower maintenance requirements and reduced operational expenses over time. The material's flexibility and leak-free fusion joints contribute to a more resilient infrastructure, capable of withstanding ground movements and seismic activities without compromising integrity. This resilience factor is particularly valuable in areas prone to natural disasters, potentially saving millions in repair costs and preventing service interruptions.

From an environmental perspective, HDPE solutions offer significant benefits. The material's recyclability and lower carbon footprint during production and transportation contribute to reduced environmental impact. Additionally, the smooth interior surface of HDPE pipes improves flow efficiency, potentially leading to energy savings in pumping operations for water and wastewater systems.

While the initial material costs for HDPE may be higher than some traditional alternatives, the total cost of ownership over the infrastructure's lifecycle is often lower. Factoring in reduced installation times, minimal maintenance needs, and extended service life, HDPE solutions present a compelling economic argument. Case studies from various municipalities have demonstrated cost savings of up to 30-40% over the lifespan of HDPE infrastructure projects compared to traditional materials.

However, it's important to consider potential challenges in the cost-benefit equation. The specialized equipment and skilled labor required for HDPE installation may present initial hurdles in some regions. Additionally, the cost-effectiveness of HDPE solutions can vary based on project scale, local regulations, and specific application requirements. A thorough analysis of these factors is crucial for accurate cost-benefit projections in each unique infrastructure revitalization scenario.