HDPE Pipe Advances: Innovations to Watch

HDPE Pipe Evolution

High-density polyethylene (HDPE) pipes have undergone significant evolution since their introduction in the 1950s. Initially developed as a lightweight alternative to traditional materials, HDPE pipes have continuously improved in terms of durability, performance, and versatility.

In the early stages, HDPE pipes were primarily used for low-pressure applications such as irrigation and drainage. The first-generation pipes had limited pressure ratings and were susceptible to stress cracking. However, advancements in polymer science and manufacturing techniques led to the development of more robust HDPE resins.

The 1970s and 1980s saw the introduction of bimodal HDPE resins, which significantly enhanced the pipes' mechanical properties. These new materials offered improved stress crack resistance, higher pressure ratings, and better long-term performance. This breakthrough expanded the use of HDPE pipes into more demanding applications, including water distribution and gas transmission.

The 1990s marked a turning point with the development of PE100 grade resins. These high-performance materials allowed for the production of pipes with thinner walls while maintaining or even improving pressure ratings. This innovation reduced material costs and improved installation efficiency, making HDPE pipes increasingly competitive in the market.

In recent years, the focus has shifted towards enhancing the pipes' environmental sustainability and longevity. Manufacturers have developed HDPE pipes with improved resistance to chlorine and other chemicals, extending their service life in water treatment applications. Additionally, the incorporation of nanomaterials and advanced additives has further improved the pipes' strength and durability.

The evolution of HDPE pipes has also been driven by advancements in manufacturing processes. The introduction of continuous extrusion technologies and improved quality control measures has resulted in pipes with more consistent properties and fewer defects. This has led to increased reliability and reduced maintenance requirements in various applications.

Another significant development has been the introduction of large-diameter HDPE pipes, capable of replacing traditional materials in major infrastructure projects. These pipes offer advantages in terms of installation speed, corrosion resistance, and overall lifecycle costs.

Looking ahead, the HDPE pipe industry continues to innovate. Current research focuses on developing "smart" HDPE pipes with embedded sensors for real-time monitoring of structural integrity and flow conditions. Additionally, efforts are underway to improve the recyclability of HDPE pipes, aligning with global sustainability goals and circular economy principles.

Market Demand Analysis

The market demand for HDPE pipes has been steadily increasing due to their superior properties and versatile applications across various industries. The global HDPE pipe market is experiencing robust growth, driven by factors such as urbanization, infrastructure development, and the need for efficient water management systems.

In the construction sector, HDPE pipes are gaining popularity for their durability, flexibility, and resistance to corrosion. The growing emphasis on sustainable building practices has further boosted the demand for HDPE pipes, as they offer long-term cost-effectiveness and environmental benefits. The residential construction segment, in particular, has shown a significant uptake in HDPE pipe usage for plumbing and drainage systems.

The water and wastewater management industry represents a substantial market for HDPE pipes. With increasing concerns over water scarcity and the need for efficient distribution systems, many municipalities and water authorities are opting for HDPE pipes due to their leak-resistant properties and long service life. This trend is particularly evident in developing countries where large-scale water infrastructure projects are underway.

In the agriculture sector, HDPE pipes are widely used for irrigation systems. The shift towards precision agriculture and water-efficient farming practices has led to increased adoption of HDPE pipes for their ability to withstand varying soil conditions and provide consistent water flow. This market segment is expected to show steady growth as global food demand rises and water conservation becomes increasingly critical.

The oil and gas industry also contributes significantly to the HDPE pipe market. HDPE pipes are preferred for their chemical resistance and ability to withstand high pressures, making them ideal for transporting oil, gas, and other petrochemicals. As exploration and production activities continue to expand, particularly in offshore environments, the demand for HDPE pipes in this sector is projected to grow.

Emerging applications in the telecommunications industry, where HDPE pipes are used for cable conduits, are opening up new market opportunities. The ongoing expansion of fiber-optic networks and 5G infrastructure is expected to drive demand in this segment.

Market analysts predict a compound annual growth rate (CAGR) for the global HDPE pipe market in the range of 5-7% over the next five years. This growth is attributed to the increasing replacement of traditional piping materials with HDPE in various applications, as well as the expansion of end-use industries in developing economies.

Technical Challenges

Despite the widespread adoption of HDPE pipes in various industries, several technical challenges persist in advancing their performance and expanding their applications. One of the primary obstacles is improving the long-term durability of HDPE pipes, particularly in high-pressure and high-temperature environments. While HDPE pipes are known for their resistance to corrosion and chemical degradation, prolonged exposure to extreme conditions can lead to material fatigue and potential failure.

Another significant challenge lies in enhancing the mechanical properties of HDPE pipes without compromising their flexibility and ease of installation. Researchers and manufacturers are striving to develop HDPE formulations that offer increased strength and stiffness while maintaining the material's characteristic ductility. This balance is crucial for applications in demanding sectors such as oil and gas transportation or high-pressure water systems.

The joining of HDPE pipes remains a technical hurdle, particularly for large-diameter pipes and in situations requiring rapid installation. Current fusion welding techniques, while effective, can be time-consuming and require specialized equipment. Developing more efficient and reliable joining methods that ensure leak-tight connections under various environmental conditions is an ongoing area of research.

Improving the fire resistance of HDPE pipes is another critical challenge. Although HDPE pipes have low flame spread characteristics, they can contribute to fire propagation in certain scenarios. Enhancing the fire retardancy of HDPE without significantly altering its other beneficial properties is a complex task that researchers are actively pursuing.

The recycling and sustainability of HDPE pipes also present technical challenges. While HDPE is recyclable, the process of separating and recycling pipes from mixed plastic waste streams can be complex. Developing more efficient recycling technologies and incorporating recycled content into new HDPE pipes without compromising performance are areas of focus for the industry.

Addressing the permeation of gases and hydrocarbons through HDPE pipes is another technical challenge, particularly in applications involving fuel transportation or storage. Researchers are exploring various barrier technologies and composite structures to minimize permeation while maintaining the overall benefits of HDPE pipes.

Lastly, the development of smart HDPE pipes with integrated sensing and monitoring capabilities is an emerging challenge. Incorporating sensors and communication technologies into the pipe structure without affecting its integrity or performance requires innovative approaches in materials science and manufacturing processes.

Current HDPE Solutions

01 Improved HDPE pipe manufacturing processes

Innovations in manufacturing processes for HDPE pipes, including advanced extrusion techniques, optimized cooling methods, and enhanced quality control systems. These improvements lead to better pipe consistency, increased production efficiency, and reduced defects.- Improved HDPE pipe manufacturing processes: Innovations in manufacturing processes for HDPE pipes, including advanced extrusion techniques, optimized cooling methods, and enhanced quality control systems. These improvements lead to better pipe consistency, increased production efficiency, and reduced defects.

- Enhanced HDPE pipe material compositions: Development of new HDPE material compositions with improved properties such as increased strength, better chemical resistance, and enhanced durability. These innovations may include the use of additives, nanocomposites, or specialized blending techniques to achieve superior performance characteristics.

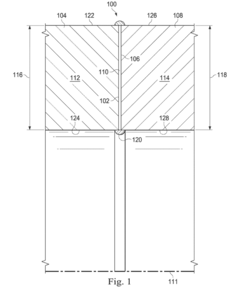

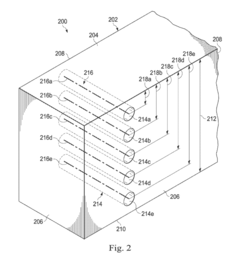

- Novel HDPE pipe designs and structures: Innovative designs and structural modifications for HDPE pipes, including multi-layer configurations, reinforced structures, and specialized profiles. These designs aim to improve pipe performance, increase load-bearing capacity, and enhance resistance to various environmental factors.

- Advanced HDPE pipe joining and installation techniques: Development of new methods for joining and installing HDPE pipes, including improved welding technologies, innovative coupling systems, and efficient installation tools. These advancements aim to enhance pipe system integrity, reduce installation time, and improve overall project efficiency.

- Smart HDPE pipe systems and monitoring technologies: Integration of smart technologies and monitoring systems into HDPE pipe networks, including sensors for leak detection, pressure monitoring, and flow analysis. These innovations enable real-time data collection, predictive maintenance, and improved overall system management.

02 Enhanced HDPE pipe material compositions

Development of new HDPE material compositions with improved properties such as increased strength, better chemical resistance, and enhanced durability. These innovations may include the use of additives, nanocomposites, or specialized blends to achieve superior performance characteristics.Expand Specific Solutions03 Novel HDPE pipe designs and structures

Innovative designs and structural modifications for HDPE pipes, including multi-layer configurations, reinforced structures, and specialized profiles. These designs aim to improve pipe performance, increase load-bearing capacity, and enhance resistance to environmental factors.Expand Specific Solutions04 Advanced joining and installation techniques

Development of new methods for joining HDPE pipes and improving installation processes. This includes innovations in welding technologies, mechanical coupling systems, and trenchless installation techniques, leading to faster and more reliable pipe connections and installations.Expand Specific Solutions05 Smart HDPE pipe systems and monitoring

Integration of smart technologies and monitoring systems into HDPE pipes, enabling real-time data collection, leak detection, and performance monitoring. These innovations enhance the overall efficiency and reliability of HDPE pipe networks in various applications.Expand Specific Solutions

Key Industry Players

The HDPE pipe industry is in a mature growth phase, with ongoing innovations driving market expansion. The global market size for HDPE pipes is projected to reach significant figures, fueled by increasing demand in various sectors. Technologically, the field is advancing rapidly, with companies like SABIC Global Technologies BV, ExxonMobil Chemical Patents, Inc., and Chevron Phillips Chemical Co. LP leading research and development efforts. These industry giants, along with specialized firms such as Smart Pipe Co., Inc. and Prinsco, Inc., are pushing the boundaries of HDPE pipe technology. Innovations focus on enhancing durability, performance, and sustainability, with emerging players like Zhejiang Liansu Technology Industry Co. Ltd. and Fujian Hengjie Plastic Industry New Material Co. Ltd. contributing to the competitive landscape.

Guizhou Lianchuang Pipe Industry Co., Ltd.

Fujian Hengjie Plastic Industry New Material Co. Ltd.

Core HDPE Innovations

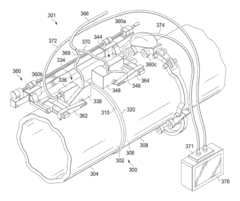

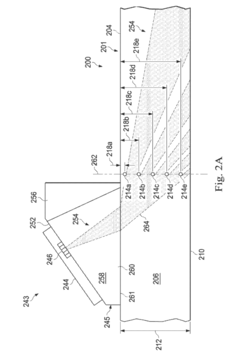

- A pipe inspection tool is developed that includes two search units, a pipe scanner, a pulser-receiver module, and a phased array testing instrument, calibrated using an HDPE calibration tool with bores of varying depths, to propagate acoustical waves at different angles and patterns, facilitating the detection of flaws by using longitudinal sound waves instead of shear waves, which are more effective in HDPE.

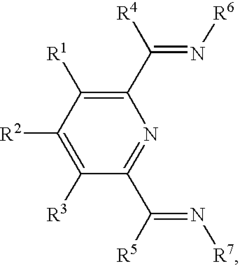

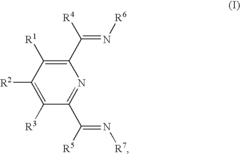

- The use of HDPE polymerized in the presence of an iron or cobalt complex catalyst, specifically a compound of formula (I), (II), or (III), to form a package with reduced water vapor and oxygen transmission rates, achieved by replacing or blending HDPE layers with the catalyst-complex-polymerized HDPE in packaging materials.

Environmental Impact

The environmental impact of HDPE pipe innovations is a critical consideration in the advancement of this technology. HDPE pipes have already demonstrated significant environmental benefits over traditional materials, but recent innovations are pushing these advantages even further.

One of the most notable environmental improvements in HDPE pipe technology is the increased use of recycled materials. Manufacturers are developing methods to incorporate a higher percentage of post-consumer and post-industrial recycled HDPE into new pipes without compromising performance. This not only reduces the demand for virgin plastic but also helps divert plastic waste from landfills and oceans.

Enhanced durability and longevity of HDPE pipes contribute to their positive environmental profile. Recent innovations in material composition and manufacturing processes have resulted in pipes that can withstand harsh conditions for even longer periods, reducing the frequency of replacements and associated environmental disruptions. Some advanced HDPE pipes now boast lifespans of over 100 years, significantly reducing the lifecycle environmental impact compared to traditional materials.

Water conservation is another area where HDPE pipe innovations are making a difference. New designs and joining techniques have dramatically reduced leakage rates, helping to conserve water resources. This is particularly crucial in regions facing water scarcity, where every drop saved contributes to environmental sustainability.

The lightweight nature of HDPE pipes continues to offer environmental benefits in transportation and installation. Innovations in pipe design have further reduced weight while maintaining strength, leading to lower fuel consumption during transport and easier installation with less heavy machinery. This translates to reduced carbon emissions throughout the pipe's lifecycle.

Advancements in HDPE pipe technology are also contributing to improved energy efficiency in various applications. For instance, in geothermal heating and cooling systems, enhanced HDPE pipes are enabling more efficient heat transfer, potentially reducing overall energy consumption in buildings.

Lastly, innovations in HDPE pipe production processes are focusing on reducing the environmental footprint of manufacturing. This includes the development of more energy-efficient extrusion techniques, water-saving cooling systems, and the use of renewable energy sources in production facilities. These improvements are helping to minimize the carbon footprint associated with HDPE pipe production.

As the industry continues to innovate, the environmental benefits of HDPE pipes are likely to expand further, cementing their role as a sustainable solution for various piping applications.

Regulatory Framework

The regulatory framework surrounding HDPE pipe innovations plays a crucial role in shaping the industry's development and adoption of new technologies. As advancements in HDPE pipe manufacturing and applications continue to emerge, regulatory bodies worldwide are adapting their standards and guidelines to ensure safety, quality, and environmental compliance.

In the United States, the American Society for Testing and Materials (ASTM) and the American Water Works Association (AWWA) have established comprehensive standards for HDPE pipes. These standards cover various aspects, including material properties, performance requirements, and testing methods. The ASTM D3350 standard, for instance, specifies the minimum requirements for polyethylene plastics pipe and fittings materials.

The European Union has implemented the EN 12201 standard for polyethylene piping systems for water supply and drainage. This standard provides guidelines for the production, installation, and testing of HDPE pipes, ensuring consistency across member states. Additionally, the EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts the materials used in HDPE pipe manufacturing, promoting the use of safer and more environmentally friendly additives.

In recent years, there has been a growing focus on sustainability and environmental impact within the regulatory framework. Many countries are introducing regulations that encourage the use of recycled materials in HDPE pipe production. For example, the UK's Water Industry Specification 4-32-19 allows for the inclusion of recycled content in HDPE pipes for water supply, provided they meet specific performance criteria.

The regulatory landscape is also evolving to accommodate innovative HDPE pipe technologies. Smart pipe systems, which incorporate sensors and monitoring capabilities, are being addressed in new standards and guidelines. The International Organization for Standardization (ISO) is developing standards for smart water networks, which will include provisions for intelligent HDPE pipe systems.

As HDPE pipes find new applications in challenging environments, such as deep-sea installations or extreme temperature conditions, regulatory bodies are updating their frameworks to address these specific use cases. For instance, the American Petroleum Institute (API) has developed standards for offshore polyethylene piping systems, considering the unique demands of subsea environments.

The global nature of the HDPE pipe industry necessitates international collaboration in regulatory development. Organizations like the International Standards Organization (ISO) are working to harmonize standards across different regions, facilitating global trade and ensuring consistent quality worldwide. This harmonization effort is particularly important as HDPE pipe innovations continue to cross borders and find applications in diverse markets.