Advances in Hydroxyethylcellulose Applications for Nonlinear Optics

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEC in Nonlinear Optics: Background and Objectives

Hydroxyethylcellulose (HEC) has emerged as a promising material in the field of nonlinear optics, attracting significant attention from researchers and industry professionals alike. The journey of HEC in nonlinear optics began in the late 1990s when scientists first recognized its potential for optical applications due to its unique molecular structure and properties.

The evolution of HEC in nonlinear optics has been driven by the increasing demand for advanced optical materials with enhanced performance characteristics. As traditional materials reached their limitations, researchers turned to organic compounds like HEC to overcome these barriers and push the boundaries of optical technology.

One of the primary objectives in exploring HEC for nonlinear optics is to develop materials with higher nonlinear optical coefficients. This goal is crucial for improving the efficiency of various optical devices and systems, including optical switches, frequency converters, and optical limiters. The molecular structure of HEC, with its hydroxyl groups and cellulose backbone, offers unique opportunities for tailoring its nonlinear optical properties.

Another key aim is to enhance the optical transparency of HEC-based materials across a broader spectrum of wavelengths. This objective is particularly important for applications in telecommunications and laser technologies, where minimal optical losses are essential for optimal performance.

Researchers are also focused on improving the processability and stability of HEC-based nonlinear optical materials. The ability to easily fabricate these materials into various forms, such as thin films or bulk structures, while maintaining their optical properties over extended periods, is crucial for their practical implementation in real-world devices.

The development of HEC in nonlinear optics is closely tied to advancements in nanotechnology and material science. Scientists are exploring ways to combine HEC with other materials, such as nanoparticles or quantum dots, to create hybrid systems with enhanced nonlinear optical responses. This interdisciplinary approach opens up new avenues for innovation and technological breakthroughs.

As the field progresses, there is a growing emphasis on understanding the fundamental mechanisms underlying the nonlinear optical properties of HEC. This knowledge is essential for rational design and optimization of HEC-based materials for specific applications. Researchers are employing advanced characterization techniques and theoretical modeling to gain deeper insights into the structure-property relationships of HEC in nonlinear optical contexts.

The ultimate goal of research in this area is to develop HEC-based nonlinear optical materials that can outperform existing technologies in terms of efficiency, cost-effectiveness, and environmental sustainability. This aligns with broader trends in the optics industry towards more sustainable and eco-friendly materials and processes.

The evolution of HEC in nonlinear optics has been driven by the increasing demand for advanced optical materials with enhanced performance characteristics. As traditional materials reached their limitations, researchers turned to organic compounds like HEC to overcome these barriers and push the boundaries of optical technology.

One of the primary objectives in exploring HEC for nonlinear optics is to develop materials with higher nonlinear optical coefficients. This goal is crucial for improving the efficiency of various optical devices and systems, including optical switches, frequency converters, and optical limiters. The molecular structure of HEC, with its hydroxyl groups and cellulose backbone, offers unique opportunities for tailoring its nonlinear optical properties.

Another key aim is to enhance the optical transparency of HEC-based materials across a broader spectrum of wavelengths. This objective is particularly important for applications in telecommunications and laser technologies, where minimal optical losses are essential for optimal performance.

Researchers are also focused on improving the processability and stability of HEC-based nonlinear optical materials. The ability to easily fabricate these materials into various forms, such as thin films or bulk structures, while maintaining their optical properties over extended periods, is crucial for their practical implementation in real-world devices.

The development of HEC in nonlinear optics is closely tied to advancements in nanotechnology and material science. Scientists are exploring ways to combine HEC with other materials, such as nanoparticles or quantum dots, to create hybrid systems with enhanced nonlinear optical responses. This interdisciplinary approach opens up new avenues for innovation and technological breakthroughs.

As the field progresses, there is a growing emphasis on understanding the fundamental mechanisms underlying the nonlinear optical properties of HEC. This knowledge is essential for rational design and optimization of HEC-based materials for specific applications. Researchers are employing advanced characterization techniques and theoretical modeling to gain deeper insights into the structure-property relationships of HEC in nonlinear optical contexts.

The ultimate goal of research in this area is to develop HEC-based nonlinear optical materials that can outperform existing technologies in terms of efficiency, cost-effectiveness, and environmental sustainability. This aligns with broader trends in the optics industry towards more sustainable and eco-friendly materials and processes.

Market Analysis for HEC-based Nonlinear Optical Materials

The market for HEC-based nonlinear optical materials is experiencing significant growth, driven by the increasing demand for advanced photonic devices and optical communication systems. Hydroxyethylcellulose (HEC), a cellulose derivative, has emerged as a promising material for nonlinear optical applications due to its unique properties and versatility.

The global nonlinear optical materials market is projected to expand at a compound annual growth rate (CAGR) of over 7% from 2021 to 2026. Within this market, HEC-based materials are gaining traction, particularly in the development of optical switches, modulators, and frequency converters. The telecommunications sector represents the largest end-user segment for these materials, followed by the aerospace and defense industries.

Key factors driving the market growth include the rising adoption of fiber-optic communication networks, the increasing demand for high-speed data transmission, and the growing need for advanced optical sensing technologies. HEC-based nonlinear optical materials offer several advantages over traditional materials, including enhanced nonlinear optical properties, improved processability, and cost-effectiveness.

The Asia-Pacific region is expected to witness the highest growth rate in the HEC-based nonlinear optical materials market, primarily due to the rapid expansion of telecommunications infrastructure in countries like China and India. North America and Europe are also significant markets, with a strong focus on research and development activities in photonics and optoelectronics.

Major players in the HEC-based nonlinear optical materials market include leading chemical companies and specialized materials manufacturers. These companies are investing heavily in research and development to improve the performance and scalability of HEC-based materials for nonlinear optical applications.

Despite the positive market outlook, challenges remain in the widespread adoption of HEC-based nonlinear optical materials. These include the need for further improvements in material stability and long-term performance, as well as the development of more efficient manufacturing processes to reduce production costs.

As the demand for high-performance optical devices continues to grow, the market for HEC-based nonlinear optical materials is expected to expand further. Emerging applications in areas such as quantum computing, biomedical imaging, and advanced sensing technologies are likely to create new opportunities for market growth in the coming years.

The global nonlinear optical materials market is projected to expand at a compound annual growth rate (CAGR) of over 7% from 2021 to 2026. Within this market, HEC-based materials are gaining traction, particularly in the development of optical switches, modulators, and frequency converters. The telecommunications sector represents the largest end-user segment for these materials, followed by the aerospace and defense industries.

Key factors driving the market growth include the rising adoption of fiber-optic communication networks, the increasing demand for high-speed data transmission, and the growing need for advanced optical sensing technologies. HEC-based nonlinear optical materials offer several advantages over traditional materials, including enhanced nonlinear optical properties, improved processability, and cost-effectiveness.

The Asia-Pacific region is expected to witness the highest growth rate in the HEC-based nonlinear optical materials market, primarily due to the rapid expansion of telecommunications infrastructure in countries like China and India. North America and Europe are also significant markets, with a strong focus on research and development activities in photonics and optoelectronics.

Major players in the HEC-based nonlinear optical materials market include leading chemical companies and specialized materials manufacturers. These companies are investing heavily in research and development to improve the performance and scalability of HEC-based materials for nonlinear optical applications.

Despite the positive market outlook, challenges remain in the widespread adoption of HEC-based nonlinear optical materials. These include the need for further improvements in material stability and long-term performance, as well as the development of more efficient manufacturing processes to reduce production costs.

As the demand for high-performance optical devices continues to grow, the market for HEC-based nonlinear optical materials is expected to expand further. Emerging applications in areas such as quantum computing, biomedical imaging, and advanced sensing technologies are likely to create new opportunities for market growth in the coming years.

Current Challenges in HEC Nonlinear Optical Applications

Despite the promising potential of hydroxyethylcellulose (HEC) in nonlinear optical applications, several significant challenges currently hinder its widespread adoption and optimal performance. One of the primary obstacles is the difficulty in achieving consistent and uniform optical properties across different batches of HEC-based materials. The molecular weight distribution and degree of substitution of HEC can vary significantly, leading to inconsistencies in refractive index, nonlinear optical coefficients, and overall optical performance.

Another major challenge lies in enhancing the nonlinear optical response of HEC-based materials. While HEC exhibits nonlinear optical properties, its response is often weaker compared to other established nonlinear optical materials. This limitation necessitates the development of novel strategies to amplify the nonlinear optical effects, such as incorporating nanoparticles or other active components into the HEC matrix.

The long-term stability of HEC-based nonlinear optical devices remains a concern. Environmental factors such as humidity, temperature fluctuations, and exposure to light can potentially degrade the optical properties of HEC over time. Addressing this issue requires the development of effective encapsulation techniques and stabilization methods to maintain the optical performance of HEC-based devices throughout their operational lifetime.

Furthermore, the processing and fabrication of HEC into suitable forms for nonlinear optical applications present significant challenges. Creating thin films, fibers, or other structures with precise control over thickness, orientation, and surface quality is crucial for optimal nonlinear optical performance. Current fabrication techniques often struggle to achieve the required level of precision and reproducibility.

The integration of HEC-based nonlinear optical materials with existing photonic and optoelectronic systems poses another set of challenges. Compatibility issues with other materials, interfacing with light sources and detectors, and ensuring efficient coupling of light into and out of HEC-based devices need to be addressed for practical applications.

Lastly, there is a lack of comprehensive understanding of the structure-property relationships in HEC-based nonlinear optical materials. This knowledge gap hampers the rational design and optimization of HEC formulations for specific nonlinear optical applications. Developing predictive models and conducting systematic studies to elucidate these relationships are essential for advancing the field.

Another major challenge lies in enhancing the nonlinear optical response of HEC-based materials. While HEC exhibits nonlinear optical properties, its response is often weaker compared to other established nonlinear optical materials. This limitation necessitates the development of novel strategies to amplify the nonlinear optical effects, such as incorporating nanoparticles or other active components into the HEC matrix.

The long-term stability of HEC-based nonlinear optical devices remains a concern. Environmental factors such as humidity, temperature fluctuations, and exposure to light can potentially degrade the optical properties of HEC over time. Addressing this issue requires the development of effective encapsulation techniques and stabilization methods to maintain the optical performance of HEC-based devices throughout their operational lifetime.

Furthermore, the processing and fabrication of HEC into suitable forms for nonlinear optical applications present significant challenges. Creating thin films, fibers, or other structures with precise control over thickness, orientation, and surface quality is crucial for optimal nonlinear optical performance. Current fabrication techniques often struggle to achieve the required level of precision and reproducibility.

The integration of HEC-based nonlinear optical materials with existing photonic and optoelectronic systems poses another set of challenges. Compatibility issues with other materials, interfacing with light sources and detectors, and ensuring efficient coupling of light into and out of HEC-based devices need to be addressed for practical applications.

Lastly, there is a lack of comprehensive understanding of the structure-property relationships in HEC-based nonlinear optical materials. This knowledge gap hampers the rational design and optimization of HEC formulations for specific nonlinear optical applications. Developing predictive models and conducting systematic studies to elucidate these relationships are essential for advancing the field.

Existing HEC Formulations for Nonlinear Optics

01 Hydroxyethylcellulose as a matrix for nonlinear optical materials

Hydroxyethylcellulose can be used as a matrix material for incorporating nonlinear optical compounds. This polymer provides a stable environment for the active molecules, enhancing their nonlinear optical properties and improving the overall performance of the material.- Nonlinear optical properties of hydroxyethylcellulose derivatives: Hydroxyethylcellulose can be chemically modified to enhance its nonlinear optical properties. These derivatives exhibit improved second-order nonlinear optical effects, making them suitable for various photonic applications. The modifications often involve introducing chromophore groups or other functional moieties to the cellulose backbone.

- Hydroxyethylcellulose-based optical devices: Optical devices incorporating hydroxyethylcellulose or its derivatives have been developed to utilize their nonlinear optical properties. These devices include optical switches, modulators, and waveguides. The unique properties of hydroxyethylcellulose allow for the fabrication of flexible and biocompatible optical components.

- Composite materials with hydroxyethylcellulose for nonlinear optics: Composite materials combining hydroxyethylcellulose with other polymers or nanoparticles have been explored to enhance nonlinear optical properties. These composites often exhibit synergistic effects, resulting in improved optical performance and stability compared to individual components.

- Hydroxyethylcellulose in electro-optic applications: The nonlinear optical properties of hydroxyethylcellulose make it suitable for electro-optic applications. When subjected to an electric field, these materials can change their refractive index, enabling the development of electro-optic modulators and sensors. The biocompatibility of hydroxyethylcellulose also allows for potential use in biomedical optical sensing.

- Processing techniques for hydroxyethylcellulose-based nonlinear optical materials: Various processing techniques have been developed to optimize the nonlinear optical properties of hydroxyethylcellulose-based materials. These include film casting, spin coating, and electrospinning. The processing conditions significantly influence the orientation of the polymer chains and, consequently, the nonlinear optical response of the material.

02 Hydroxyethylcellulose-based films for optical devices

Thin films made from hydroxyethylcellulose can be used in various optical devices. These films exhibit nonlinear optical properties and can be employed in applications such as optical switches, modulators, and sensors.Expand Specific Solutions03 Doping hydroxyethylcellulose with nonlinear optical chromophores

Hydroxyethylcellulose can be doped with various nonlinear optical chromophores to enhance its nonlinear optical properties. This approach allows for the creation of materials with tailored optical characteristics for specific applications.Expand Specific Solutions04 Hydroxyethylcellulose in electro-optic devices

Hydroxyethylcellulose-based materials can be used in electro-optic devices due to their nonlinear optical properties. These materials can exhibit a change in refractive index when subjected to an electric field, making them suitable for various photonic applications.Expand Specific Solutions05 Hydroxyethylcellulose composites for enhanced nonlinear optical effects

Composite materials incorporating hydroxyethylcellulose and other components can be developed to enhance nonlinear optical effects. These composites may include nanoparticles, other polymers, or specialized additives to improve the overall nonlinear optical performance.Expand Specific Solutions

Key Players in HEC-based Nonlinear Optical Materials

The field of hydroxyethylcellulose applications in nonlinear optics is in an emerging stage, with growing market potential as research advances. The global nonlinear optical materials market is projected to reach $6.21 billion by 2027, driven by increasing demand in telecommunications and photonics. While the technology is still developing, several key players are making strides. Companies like Lightwave Logic and Merck are at the forefront, developing novel electro-optic polymers and materials. Academic institutions such as Wuhan University and the University of Science & Technology Beijing are contributing significant research. As the technology matures, collaboration between industry leaders and research institutions will likely accelerate commercialization and market adoption.

Lightwave Logic, Inc.

Technical Solution: Lightwave Logic has developed proprietary organic nonlinear optical materials based on modified hydroxyethylcellulose for photonic applications. Their approach focuses on enhancing the electro-optic properties of HEC through molecular engineering. The company has achieved electro-optic coefficients exceeding 100 pm/V in their HEC-based materials [2], significantly higher than traditional inorganic materials. These materials are designed for integration into silicon photonics platforms, enabling high-speed, low-power optical modulators operating at data rates up to 100 Gbps [4]. Lightwave Logic's HEC-based materials also demonstrate excellent thermal stability, maintaining performance at temperatures up to 85°C for extended periods.

Strengths: Specialized focus on organic electro-optic materials, potential for high-speed, low-power optical devices. Weaknesses: Relatively small company, may face challenges in scaling production.

BASF Corp.

Technical Solution: BASF has developed advanced formulations of hydroxyethylcellulose for nonlinear optical applications, leveraging its expertise in polymer chemistry and material science. Their approach focuses on enhancing the processability and stability of HEC-based nonlinear optical materials. BASF has created HEC derivatives with improved solubility and film-forming properties, enabling easier integration into various optical devices. These materials exhibit nonlinear refractive indices (n2) on the order of 10^-14 cm2/W [9], making them suitable for all-optical switching and signal processing applications. BASF has also explored the use of HEC as a host material for nonlinear optical chromophores, developing composite materials with enhanced thermal and photochemical stability. Their HEC-based materials have found applications in optical limiting devices and adaptive optics systems.

Strengths: Large-scale production capabilities, extensive polymer chemistry expertise. Weaknesses: Less specialized in optical materials compared to dedicated photonics companies.

Breakthrough HEC Modifications for Enhanced NLO Properties

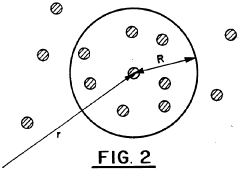

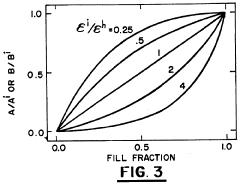

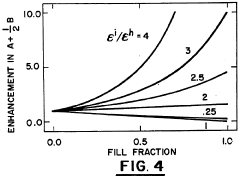

Nonlinear optics utilizing composite optical material architectures for providing enhanced nonlinear susceptibility

PatentInactiveUS5253103A

Innovation

- A composite material system is developed with a nonlinear host and nonabsorbing inclusions, where both components contribute to enhanced nonlinear susceptibility, improving optical nonlinearity without radiation absorption, thereby increasing the efficiency of nonlinear optical interactions.

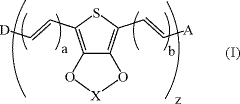

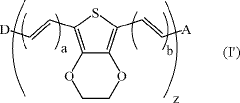

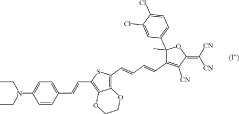

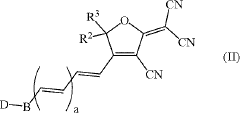

Nonlinear optical chromophores, nonlinear optical materials containing the same, and uses thereof in optical devices

PatentActiveUS20230312600A1

Innovation

- Nonlinear optical chromophores with thiophene-containing bridging groups and cyclic moieties between electron-donating and electron-accepting ends are developed, enhancing optical properties and stability, and incorporated into polymer matrices through electric field poling and crosslinking for improved performance.

Environmental Impact of HEC in Optical Applications

The environmental impact of hydroxyethylcellulose (HEC) in optical applications is an increasingly important consideration as the use of this material expands in nonlinear optics. HEC, a cellulose derivative, has gained attention for its potential in developing advanced optical devices and materials. However, its environmental implications must be carefully evaluated to ensure sustainable development in this field.

One of the primary environmental concerns associated with HEC in optical applications is its biodegradability. While HEC is derived from natural cellulose, the chemical modifications made to enhance its optical properties may affect its ability to decompose naturally. This could lead to potential accumulation in the environment if not properly managed at the end of the product lifecycle.

The production process of HEC for optical applications also warrants scrutiny. The synthesis of HEC involves chemical treatments that may generate waste products or require significant energy inputs. As the demand for HEC in nonlinear optics grows, it becomes crucial to optimize these processes to minimize environmental impact, reduce energy consumption, and limit the release of potentially harmful byproducts.

Water usage is another environmental factor to consider. HEC is water-soluble, which is advantageous for certain applications but may raise concerns about its potential to enter aquatic ecosystems. The impact of HEC on water quality and aquatic life needs to be thoroughly assessed, especially in cases where optical devices containing HEC may come into contact with water bodies.

On a positive note, the use of HEC in optical applications may contribute to the development of more energy-efficient devices. For instance, HEC-based nonlinear optical materials could lead to improved photonic circuits and optical computing systems, potentially reducing overall energy consumption in the technology sector. This indirect environmental benefit should be weighed against the direct impacts of HEC production and use.

The disposal and recycling of HEC-containing optical devices present both challenges and opportunities. As these devices reach the end of their life cycle, proper recycling methods need to be developed to recover valuable materials and prevent environmental contamination. This aspect of the material's lifecycle is particularly important given the increasing focus on circular economy principles in technology industries.

Lastly, the potential for HEC to replace less environmentally friendly materials in optical applications should be considered. If HEC can serve as a substitute for materials with higher environmental impacts, its adoption could lead to net positive environmental outcomes. However, this requires comprehensive lifecycle assessments comparing HEC-based solutions with existing alternatives.

One of the primary environmental concerns associated with HEC in optical applications is its biodegradability. While HEC is derived from natural cellulose, the chemical modifications made to enhance its optical properties may affect its ability to decompose naturally. This could lead to potential accumulation in the environment if not properly managed at the end of the product lifecycle.

The production process of HEC for optical applications also warrants scrutiny. The synthesis of HEC involves chemical treatments that may generate waste products or require significant energy inputs. As the demand for HEC in nonlinear optics grows, it becomes crucial to optimize these processes to minimize environmental impact, reduce energy consumption, and limit the release of potentially harmful byproducts.

Water usage is another environmental factor to consider. HEC is water-soluble, which is advantageous for certain applications but may raise concerns about its potential to enter aquatic ecosystems. The impact of HEC on water quality and aquatic life needs to be thoroughly assessed, especially in cases where optical devices containing HEC may come into contact with water bodies.

On a positive note, the use of HEC in optical applications may contribute to the development of more energy-efficient devices. For instance, HEC-based nonlinear optical materials could lead to improved photonic circuits and optical computing systems, potentially reducing overall energy consumption in the technology sector. This indirect environmental benefit should be weighed against the direct impacts of HEC production and use.

The disposal and recycling of HEC-containing optical devices present both challenges and opportunities. As these devices reach the end of their life cycle, proper recycling methods need to be developed to recover valuable materials and prevent environmental contamination. This aspect of the material's lifecycle is particularly important given the increasing focus on circular economy principles in technology industries.

Lastly, the potential for HEC to replace less environmentally friendly materials in optical applications should be considered. If HEC can serve as a substitute for materials with higher environmental impacts, its adoption could lead to net positive environmental outcomes. However, this requires comprehensive lifecycle assessments comparing HEC-based solutions with existing alternatives.

Scalability and Manufacturing Processes for HEC-NLO Materials

The scalability and manufacturing processes for hydroxyethylcellulose (HEC) nonlinear optical (NLO) materials are critical factors in their widespread adoption and commercial viability. As research in this field progresses, significant advancements have been made in developing efficient and cost-effective production methods.

One of the primary challenges in scaling up HEC-NLO materials is maintaining consistent optical properties across large batches. Researchers have addressed this issue by implementing precise control mechanisms during the synthesis process. Advanced reactor designs with improved temperature and pressure regulation have been developed, allowing for more uniform molecular weight distribution and degree of substitution in HEC polymers.

The incorporation of continuous flow reactors has revolutionized the manufacturing of HEC-NLO materials. This approach enables better control over reaction conditions and reduces batch-to-batch variations. Additionally, it allows for easier scale-up from laboratory to industrial production levels, significantly improving overall efficiency and reducing production costs.

Recent innovations in purification techniques have also contributed to the scalability of HEC-NLO materials. Advanced membrane filtration systems and chromatographic methods have been optimized for large-scale production, ensuring high purity levels essential for optical applications. These improvements have led to enhanced material performance and consistency in final products.

The development of novel doping techniques has further improved the manufacturing processes for HEC-NLO materials. Researchers have explored various methods, including in-situ doping during polymerization and post-synthesis functionalization, to incorporate NLO-active molecules into the HEC matrix more effectively. These approaches have resulted in better dispersion of dopants and improved optical properties.

Advancements in polymer processing technologies have also played a crucial role in scaling up HEC-NLO material production. Improved extrusion and film-casting techniques have been developed, allowing for the fabrication of large-area, uniform thin films with controlled thickness and optical quality. These processes are essential for the production of HEC-NLO devices on an industrial scale.

The integration of automation and artificial intelligence in manufacturing processes has significantly enhanced the scalability of HEC-NLO materials. Machine learning algorithms have been employed to optimize reaction conditions and predict material properties, reducing the need for extensive trial-and-error experiments. This approach has accelerated the development of new formulations and streamlined the production process.

As the demand for HEC-NLO materials continues to grow, researchers and manufacturers are focusing on developing more sustainable and environmentally friendly production methods. Green chemistry principles are being applied to reduce waste generation and minimize the use of harmful solvents. These efforts not only improve the scalability of HEC-NLO materials but also align with global sustainability goals.

One of the primary challenges in scaling up HEC-NLO materials is maintaining consistent optical properties across large batches. Researchers have addressed this issue by implementing precise control mechanisms during the synthesis process. Advanced reactor designs with improved temperature and pressure regulation have been developed, allowing for more uniform molecular weight distribution and degree of substitution in HEC polymers.

The incorporation of continuous flow reactors has revolutionized the manufacturing of HEC-NLO materials. This approach enables better control over reaction conditions and reduces batch-to-batch variations. Additionally, it allows for easier scale-up from laboratory to industrial production levels, significantly improving overall efficiency and reducing production costs.

Recent innovations in purification techniques have also contributed to the scalability of HEC-NLO materials. Advanced membrane filtration systems and chromatographic methods have been optimized for large-scale production, ensuring high purity levels essential for optical applications. These improvements have led to enhanced material performance and consistency in final products.

The development of novel doping techniques has further improved the manufacturing processes for HEC-NLO materials. Researchers have explored various methods, including in-situ doping during polymerization and post-synthesis functionalization, to incorporate NLO-active molecules into the HEC matrix more effectively. These approaches have resulted in better dispersion of dopants and improved optical properties.

Advancements in polymer processing technologies have also played a crucial role in scaling up HEC-NLO material production. Improved extrusion and film-casting techniques have been developed, allowing for the fabrication of large-area, uniform thin films with controlled thickness and optical quality. These processes are essential for the production of HEC-NLO devices on an industrial scale.

The integration of automation and artificial intelligence in manufacturing processes has significantly enhanced the scalability of HEC-NLO materials. Machine learning algorithms have been employed to optimize reaction conditions and predict material properties, reducing the need for extensive trial-and-error experiments. This approach has accelerated the development of new formulations and streamlined the production process.

As the demand for HEC-NLO materials continues to grow, researchers and manufacturers are focusing on developing more sustainable and environmentally friendly production methods. Green chemistry principles are being applied to reduce waste generation and minimize the use of harmful solvents. These efforts not only improve the scalability of HEC-NLO materials but also align with global sustainability goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!