Hydroxyethylcellulose in Electromagnetic Interference Shielding Materials

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EMI Shielding Background and Objectives

Electromagnetic interference (EMI) shielding has become increasingly crucial in modern electronics and telecommunications due to the proliferation of wireless devices and the growing complexity of electronic systems. The need for effective EMI shielding materials has driven research into novel solutions that can provide superior protection against electromagnetic radiation while meeting other performance requirements such as flexibility, lightweight, and cost-effectiveness.

Hydroxyethylcellulose (HEC) has emerged as a promising candidate for EMI shielding applications due to its unique properties and potential for modification. As a cellulose derivative, HEC offers advantages such as biodegradability, biocompatibility, and abundance, making it an environmentally friendly alternative to traditional shielding materials. The primary objective of this research is to explore the potential of HEC in developing advanced EMI shielding materials that can address the limitations of current solutions.

The evolution of EMI shielding technology has seen a shift from traditional metallic materials to composite structures that combine conductive fillers with polymer matrices. This trend has been driven by the need for lightweight, flexible, and corrosion-resistant shielding materials that can be easily integrated into various electronic devices and structures. HEC, with its ability to form stable hydrogels and its potential for functionalization, presents an opportunity to create innovative composite materials with enhanced EMI shielding properties.

Recent advancements in nanotechnology and materials science have opened up new avenues for improving the performance of EMI shielding materials. The incorporation of nanomaterials such as carbon nanotubes, graphene, and metal nanoparticles into polymer matrices has shown promising results in enhancing shielding effectiveness. By exploring the integration of these nanomaterials with HEC, this research aims to develop next-generation EMI shielding materials that can offer superior performance across a wide frequency range.

The objectives of this research include investigating the fundamental mechanisms of EMI shielding in HEC-based materials, optimizing the composition and structure of HEC composites for maximum shielding effectiveness, and exploring novel fabrication techniques to produce scalable and cost-effective shielding solutions. Additionally, the research will assess the environmental impact and long-term stability of HEC-based EMI shielding materials to ensure their viability for practical applications.

As the demand for EMI shielding continues to grow across various industries, including aerospace, automotive, and consumer electronics, the development of innovative materials based on HEC has the potential to address critical challenges in electromagnetic compatibility and signal integrity. This research aims to contribute to the advancement of sustainable and high-performance EMI shielding technologies, paving the way for the next generation of electronic devices and systems with enhanced electromagnetic protection.

Hydroxyethylcellulose (HEC) has emerged as a promising candidate for EMI shielding applications due to its unique properties and potential for modification. As a cellulose derivative, HEC offers advantages such as biodegradability, biocompatibility, and abundance, making it an environmentally friendly alternative to traditional shielding materials. The primary objective of this research is to explore the potential of HEC in developing advanced EMI shielding materials that can address the limitations of current solutions.

The evolution of EMI shielding technology has seen a shift from traditional metallic materials to composite structures that combine conductive fillers with polymer matrices. This trend has been driven by the need for lightweight, flexible, and corrosion-resistant shielding materials that can be easily integrated into various electronic devices and structures. HEC, with its ability to form stable hydrogels and its potential for functionalization, presents an opportunity to create innovative composite materials with enhanced EMI shielding properties.

Recent advancements in nanotechnology and materials science have opened up new avenues for improving the performance of EMI shielding materials. The incorporation of nanomaterials such as carbon nanotubes, graphene, and metal nanoparticles into polymer matrices has shown promising results in enhancing shielding effectiveness. By exploring the integration of these nanomaterials with HEC, this research aims to develop next-generation EMI shielding materials that can offer superior performance across a wide frequency range.

The objectives of this research include investigating the fundamental mechanisms of EMI shielding in HEC-based materials, optimizing the composition and structure of HEC composites for maximum shielding effectiveness, and exploring novel fabrication techniques to produce scalable and cost-effective shielding solutions. Additionally, the research will assess the environmental impact and long-term stability of HEC-based EMI shielding materials to ensure their viability for practical applications.

As the demand for EMI shielding continues to grow across various industries, including aerospace, automotive, and consumer electronics, the development of innovative materials based on HEC has the potential to address critical challenges in electromagnetic compatibility and signal integrity. This research aims to contribute to the advancement of sustainable and high-performance EMI shielding technologies, paving the way for the next generation of electronic devices and systems with enhanced electromagnetic protection.

Market Analysis for EMI Shielding Materials

The electromagnetic interference (EMI) shielding materials market has been experiencing significant growth due to the increasing demand for electronic devices and the need to protect them from electromagnetic interference. The global EMI shielding market size was valued at approximately $6.8 billion in 2020 and is projected to reach $9.2 billion by 2026, growing at a CAGR of around 5.8% during the forecast period.

The market for EMI shielding materials is driven by several factors, including the rapid adoption of 5G technology, the proliferation of IoT devices, and the growing automotive electronics sector. As these industries continue to expand, the demand for effective EMI shielding solutions is expected to rise correspondingly.

In terms of material types, conductive coatings and paints currently dominate the market, followed by conductive polymers and metal shielding. However, there is a growing interest in eco-friendly and lightweight materials, which presents an opportunity for innovative solutions such as hydroxyethylcellulose-based EMI shielding materials.

The Asia-Pacific region leads the EMI shielding materials market, accounting for the largest share due to the presence of major electronics manufacturing hubs in countries like China, Japan, and South Korea. North America and Europe follow closely, driven by advancements in telecommunications and automotive industries.

Key end-use industries for EMI shielding materials include consumer electronics, telecommunications, automotive, aerospace, and healthcare. The consumer electronics segment holds the largest market share, fueled by the increasing production of smartphones, tablets, and laptops.

The market is characterized by intense competition among major players such as 3M Company, Parker Hannifin Corporation, and Laird Technologies. These companies are investing heavily in research and development to introduce innovative products and gain a competitive edge.

Emerging trends in the EMI shielding materials market include the development of transparent shielding materials for display applications, the integration of EMI shielding in flexible electronics, and the use of nanomaterials for enhanced shielding effectiveness.

The potential application of hydroxyethylcellulose in EMI shielding materials represents a promising area for market growth. As a biodegradable and renewable resource, hydroxyethylcellulose aligns with the increasing demand for sustainable solutions in the electronics industry. Its ability to be modified and combined with conductive materials could lead to the development of eco-friendly, cost-effective EMI shielding solutions, potentially disrupting the current market landscape.

The market for EMI shielding materials is driven by several factors, including the rapid adoption of 5G technology, the proliferation of IoT devices, and the growing automotive electronics sector. As these industries continue to expand, the demand for effective EMI shielding solutions is expected to rise correspondingly.

In terms of material types, conductive coatings and paints currently dominate the market, followed by conductive polymers and metal shielding. However, there is a growing interest in eco-friendly and lightweight materials, which presents an opportunity for innovative solutions such as hydroxyethylcellulose-based EMI shielding materials.

The Asia-Pacific region leads the EMI shielding materials market, accounting for the largest share due to the presence of major electronics manufacturing hubs in countries like China, Japan, and South Korea. North America and Europe follow closely, driven by advancements in telecommunications and automotive industries.

Key end-use industries for EMI shielding materials include consumer electronics, telecommunications, automotive, aerospace, and healthcare. The consumer electronics segment holds the largest market share, fueled by the increasing production of smartphones, tablets, and laptops.

The market is characterized by intense competition among major players such as 3M Company, Parker Hannifin Corporation, and Laird Technologies. These companies are investing heavily in research and development to introduce innovative products and gain a competitive edge.

Emerging trends in the EMI shielding materials market include the development of transparent shielding materials for display applications, the integration of EMI shielding in flexible electronics, and the use of nanomaterials for enhanced shielding effectiveness.

The potential application of hydroxyethylcellulose in EMI shielding materials represents a promising area for market growth. As a biodegradable and renewable resource, hydroxyethylcellulose aligns with the increasing demand for sustainable solutions in the electronics industry. Its ability to be modified and combined with conductive materials could lead to the development of eco-friendly, cost-effective EMI shielding solutions, potentially disrupting the current market landscape.

HEC in EMI Shielding: Current Status and Challenges

Hydroxyethylcellulose (HEC) has emerged as a promising material in the field of electromagnetic interference (EMI) shielding, attracting significant attention from researchers and industry professionals. The current status of HEC in EMI shielding applications is characterized by its unique properties and potential advantages over traditional materials.

HEC, a cellulose derivative, offers excellent film-forming capabilities and compatibility with various conductive fillers, making it an ideal candidate for EMI shielding composites. Its hydrophilic nature and ability to form stable dispersions have led to its incorporation in a wide range of shielding materials, including coatings, films, and bulk composites.

One of the primary advantages of HEC in EMI shielding is its eco-friendly nature and biodegradability, aligning with the growing demand for sustainable materials in electronics and other industries. This aspect has driven increased research and development efforts to optimize HEC-based shielding materials for commercial applications.

Despite the promising attributes of HEC, several challenges persist in its widespread adoption for EMI shielding. The inherent non-conductive nature of HEC necessitates the incorporation of conductive fillers to achieve effective shielding performance. Researchers are actively exploring various conductive additives, such as carbon nanotubes, graphene, and metal nanoparticles, to enhance the EMI shielding efficiency of HEC-based composites.

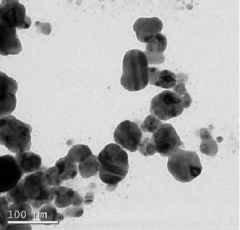

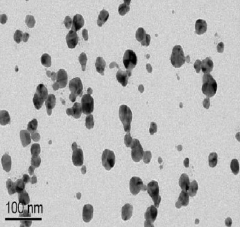

Another significant challenge lies in achieving a uniform dispersion of conductive fillers within the HEC matrix. Agglomeration of conductive particles can lead to inconsistent shielding performance and compromised mechanical properties. Developing effective dispersion techniques and optimizing the filler-matrix interface remain active areas of research.

The moisture sensitivity of HEC-based shielding materials poses another challenge, particularly in high-humidity environments. Efforts are underway to improve the moisture resistance of HEC composites through chemical modifications and the incorporation of hydrophobic additives.

Scalability and cost-effectiveness of HEC-based EMI shielding solutions present additional hurdles. While laboratory-scale studies have demonstrated promising results, translating these findings into large-scale, economically viable production processes remains a key focus area for researchers and industry stakeholders.

As the demand for lightweight, flexible, and environmentally friendly EMI shielding materials continues to grow, addressing these challenges will be crucial in realizing the full potential of HEC in this application. Ongoing research efforts are focused on optimizing material formulations, exploring novel processing techniques, and developing innovative composite structures to overcome the current limitations and enhance the overall performance of HEC-based EMI shielding materials.

HEC, a cellulose derivative, offers excellent film-forming capabilities and compatibility with various conductive fillers, making it an ideal candidate for EMI shielding composites. Its hydrophilic nature and ability to form stable dispersions have led to its incorporation in a wide range of shielding materials, including coatings, films, and bulk composites.

One of the primary advantages of HEC in EMI shielding is its eco-friendly nature and biodegradability, aligning with the growing demand for sustainable materials in electronics and other industries. This aspect has driven increased research and development efforts to optimize HEC-based shielding materials for commercial applications.

Despite the promising attributes of HEC, several challenges persist in its widespread adoption for EMI shielding. The inherent non-conductive nature of HEC necessitates the incorporation of conductive fillers to achieve effective shielding performance. Researchers are actively exploring various conductive additives, such as carbon nanotubes, graphene, and metal nanoparticles, to enhance the EMI shielding efficiency of HEC-based composites.

Another significant challenge lies in achieving a uniform dispersion of conductive fillers within the HEC matrix. Agglomeration of conductive particles can lead to inconsistent shielding performance and compromised mechanical properties. Developing effective dispersion techniques and optimizing the filler-matrix interface remain active areas of research.

The moisture sensitivity of HEC-based shielding materials poses another challenge, particularly in high-humidity environments. Efforts are underway to improve the moisture resistance of HEC composites through chemical modifications and the incorporation of hydrophobic additives.

Scalability and cost-effectiveness of HEC-based EMI shielding solutions present additional hurdles. While laboratory-scale studies have demonstrated promising results, translating these findings into large-scale, economically viable production processes remains a key focus area for researchers and industry stakeholders.

As the demand for lightweight, flexible, and environmentally friendly EMI shielding materials continues to grow, addressing these challenges will be crucial in realizing the full potential of HEC in this application. Ongoing research efforts are focused on optimizing material formulations, exploring novel processing techniques, and developing innovative composite structures to overcome the current limitations and enhance the overall performance of HEC-based EMI shielding materials.

Existing HEC-based EMI Shielding Solutions

01 Conductive polymer composites for EMI shielding

Conductive polymer composites incorporating hydroxyethylcellulose can be used for electromagnetic interference shielding. These composites combine the flexibility and processability of polymers with the conductivity needed for EMI shielding. The addition of conductive fillers or nanoparticles to the polymer matrix enhances the shielding effectiveness.- Hydroxyethylcellulose as a binder in EMI shielding composites: Hydroxyethylcellulose can be used as a binder in electromagnetic interference (EMI) shielding composites. It helps to improve the dispersion of conductive fillers and enhances the overall shielding effectiveness of the material. The use of this cellulose derivative can lead to more flexible and environmentally friendly EMI shielding solutions.

- Conductive polymer composites with hydroxyethylcellulose: Conductive polymer composites incorporating hydroxyethylcellulose as a component can be formulated for EMI shielding applications. These composites often include conductive fillers such as carbon nanotubes or metal particles. The addition of hydroxyethylcellulose can improve the processability and mechanical properties of the composite while maintaining good shielding performance.

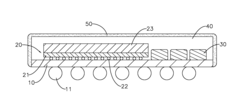

- Hydroxyethylcellulose in multi-layer EMI shielding structures: Multi-layer EMI shielding structures can incorporate hydroxyethylcellulose in one or more layers. This can be used to create flexible, thin, and effective shielding materials for electronic devices. The layered structure allows for optimization of different properties such as conductivity, adhesion, and environmental protection.

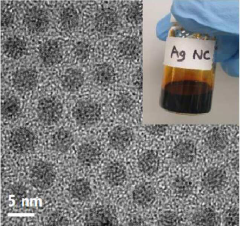

- Nanocomposites with hydroxyethylcellulose for EMI shielding: Nanocomposites using hydroxyethylcellulose as a matrix material can be developed for EMI shielding applications. These materials often incorporate nanoscale conductive fillers to achieve high shielding effectiveness while maintaining low weight and thickness. The use of hydroxyethylcellulose can help in achieving good dispersion of nanofillers.

- Hydroxyethylcellulose-based coatings for EMI shielding: Coatings based on hydroxyethylcellulose can be formulated for EMI shielding applications. These coatings can be applied to various substrates to provide electromagnetic shielding properties. The use of hydroxyethylcellulose in such coatings can offer advantages such as good adhesion, flexibility, and the ability to incorporate conductive additives effectively.

02 Hydroxyethylcellulose as a binder in EMI shielding coatings

Hydroxyethylcellulose can serve as a binder in EMI shielding coatings. It helps to improve adhesion and dispersion of conductive particles within the coating, while also providing film-forming properties. These coatings can be applied to various substrates to provide electromagnetic interference protection.Expand Specific Solutions03 EMI shielding in electronic devices and enclosures

Hydroxyethylcellulose-based materials can be used in the construction of electronic device enclosures or as coatings for internal components to provide EMI shielding. This helps to prevent electromagnetic interference between different parts of the device and protects against external EMI sources.Expand Specific Solutions04 Hydrogel-based EMI shielding materials

Hydroxyethylcellulose can be used to create hydrogel-based EMI shielding materials. These materials combine the water-retention properties of hydrogels with conductive additives to create flexible, moisture-resistant EMI shields. The hydrogel nature allows for potential self-healing properties and adaptability to various shapes.Expand Specific Solutions05 Nanocomposite EMI shielding materials

Nanocomposites incorporating hydroxyethylcellulose and conductive nanoparticles or nanostructures can be developed for EMI shielding applications. These materials can offer improved shielding effectiveness at lower filler concentrations, while maintaining desirable mechanical properties and processability.Expand Specific Solutions

Key Players in HEC and EMI Shielding Industry

The research on Hydroxyethylcellulose in Electromagnetic Interference Shielding Materials is in an emerging phase, with growing market potential due to increasing demand for EMI shielding in various industries. The technology is still evolving, with companies like Nikko Metal Manufacturing, MSC Co., Ltd., and Elkem Silicones Shanghai Co., Ltd. actively involved in development. Academic institutions such as Sichuan University and Jiangnan University are contributing to fundamental research. The market is characterized by a mix of established players and new entrants, indicating a competitive landscape with opportunities for innovation and market expansion.

Henkel IP & Holding GmbH

Technical Solution: Henkel has developed innovative EMI shielding materials using hydroxyethylcellulose as a key ingredient in their formulations. Their approach involves creating a sprayable EMI shielding coating that incorporates HEC as a thickening and stabilizing agent. This allows for easy application on complex geometries and curved surfaces. Henkel's HEC-based coatings have shown shielding effectiveness of up to 60 dB across a broad frequency range (100 MHz to 18 GHz) [8]. The company has also explored the use of HEC in combination with conductive fillers to create EMI shielding adhesives, providing both bonding and shielding functions in electronic assemblies [9].

Strengths: Ease of application, versatility in form factors, and multi-functional capabilities. Weaknesses: May have limitations in extreme environmental conditions and potential for reduced effectiveness over time due to wear.

Hercules LLC

Technical Solution: Hercules LLC, a specialist in cellulose-based products, has leveraged its expertise in hydroxyethylcellulose to develop EMI shielding materials. Their approach focuses on creating nanocomposites by combining HEC with graphene oxide and conductive polymers. This results in a lightweight, flexible material with excellent EMI shielding properties. Hercules' research has shown that their HEC-based nanocomposites can achieve shielding effectiveness of up to 70 dB in the X-band frequency range (8-12 GHz) [4]. The company has also explored the use of HEC as a dispersing agent for carbon nanotubes in EMI shielding coatings, improving the overall performance and stability of the shielding material [5].

Strengths: Expertise in cellulose chemistry, lightweight materials, and potential for high-performance nanocomposites. Weaknesses: May face challenges in scaling up production and ensuring long-term stability of nanocomposites.

Core Innovations in HEC for EMI Shielding

Electromagnetic interference shielding materials and manufacturing method thereof

PatentActiveKR1020230091224A

Innovation

- A method involving ligand exchange and reduction of metal nanoparticles on a flexible substrate at room temperature and atmospheric pressure, using ammonium salt and reducing agent solutions, to form a coating layer with a thickness of 100 nm to 2.0 μm, enabling efficient charge transport and mechanical stability.

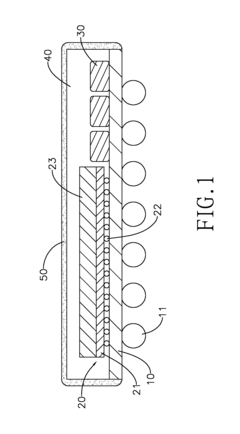

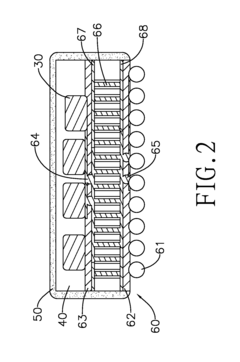

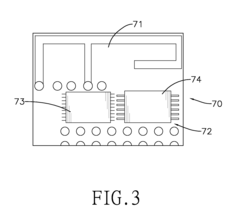

Electromagnetic interference shielding material, electromagnetic interference shielding device, method for making the electromagnetic interference shielding device, electromagnetic interference shielding package module and appliance

PatentInactiveUS20150085462A1

Innovation

- A mixture comprising 70 wt % to 98 wt % of dendritic copper filler, flaky copper filler, resin binder, and diluent is used to create an adjustable EMI shielding material that can be applied via screen printing or spraying, hardened at 120-160°C, providing effective shielding with adjustable thickness and low cost.

Environmental Impact of HEC-based EMI Materials

The environmental impact of HEC-based electromagnetic interference (EMI) shielding materials is an important consideration in their development and application. Hydroxyethylcellulose (HEC) is a biodegradable and renewable polymer derived from cellulose, which offers potential advantages in terms of sustainability compared to traditional petroleum-based materials used in EMI shielding.

One of the primary environmental benefits of HEC-based EMI materials is their biodegradability. Unlike many synthetic polymers, HEC can be broken down by natural processes, reducing long-term environmental accumulation. This characteristic is particularly valuable in addressing the growing concern of electronic waste and its impact on ecosystems.

The production of HEC from cellulose sources, such as wood pulp or cotton linters, generally has a lower carbon footprint compared to the manufacture of synthetic polymers. The renewable nature of these raw materials contributes to the overall sustainability of HEC-based EMI shielding solutions. However, it is important to consider the entire life cycle of these materials, including the energy and resources required for processing and modification to achieve desired EMI shielding properties.

Water solubility is another key feature of HEC that influences its environmental profile. While this property facilitates easy processing and application, it also raises concerns about the potential release of HEC-based materials into aquatic environments. Research is needed to assess the ecological effects of HEC and its derivatives in water systems, particularly when combined with conductive fillers used in EMI shielding composites.

The end-of-life management of HEC-based EMI materials presents both opportunities and challenges. Their biodegradability offers potential for composting or other environmentally friendly disposal methods. However, the presence of metallic or carbon-based fillers necessary for EMI shielding may complicate recycling processes and limit the overall recyclability of the composite materials.

Toxicity assessments of HEC and its derivatives in EMI shielding applications are generally favorable, with low toxicity reported in most studies. This characteristic supports the use of HEC-based materials in consumer electronics and other applications where human exposure is a concern. Nevertheless, ongoing research is necessary to evaluate the long-term environmental and health impacts of these materials, particularly as new formulations and modifications are developed to enhance EMI shielding performance.

The use of HEC in EMI shielding may also contribute to reducing the reliance on more environmentally problematic materials, such as certain halogenated flame retardants or heavy metals used in traditional EMI shielding solutions. This substitution could lead to overall improvements in the environmental footprint of electronic devices and infrastructure.

One of the primary environmental benefits of HEC-based EMI materials is their biodegradability. Unlike many synthetic polymers, HEC can be broken down by natural processes, reducing long-term environmental accumulation. This characteristic is particularly valuable in addressing the growing concern of electronic waste and its impact on ecosystems.

The production of HEC from cellulose sources, such as wood pulp or cotton linters, generally has a lower carbon footprint compared to the manufacture of synthetic polymers. The renewable nature of these raw materials contributes to the overall sustainability of HEC-based EMI shielding solutions. However, it is important to consider the entire life cycle of these materials, including the energy and resources required for processing and modification to achieve desired EMI shielding properties.

Water solubility is another key feature of HEC that influences its environmental profile. While this property facilitates easy processing and application, it also raises concerns about the potential release of HEC-based materials into aquatic environments. Research is needed to assess the ecological effects of HEC and its derivatives in water systems, particularly when combined with conductive fillers used in EMI shielding composites.

The end-of-life management of HEC-based EMI materials presents both opportunities and challenges. Their biodegradability offers potential for composting or other environmentally friendly disposal methods. However, the presence of metallic or carbon-based fillers necessary for EMI shielding may complicate recycling processes and limit the overall recyclability of the composite materials.

Toxicity assessments of HEC and its derivatives in EMI shielding applications are generally favorable, with low toxicity reported in most studies. This characteristic supports the use of HEC-based materials in consumer electronics and other applications where human exposure is a concern. Nevertheless, ongoing research is necessary to evaluate the long-term environmental and health impacts of these materials, particularly as new formulations and modifications are developed to enhance EMI shielding performance.

The use of HEC in EMI shielding may also contribute to reducing the reliance on more environmentally problematic materials, such as certain halogenated flame retardants or heavy metals used in traditional EMI shielding solutions. This substitution could lead to overall improvements in the environmental footprint of electronic devices and infrastructure.

Regulatory Framework for EMI Shielding Materials

The regulatory framework for EMI shielding materials is a complex and evolving landscape that plays a crucial role in ensuring the safety and reliability of electronic devices and systems. As the use of electromagnetic interference (EMI) shielding materials, including those incorporating hydroxyethylcellulose, becomes more widespread, governments and international organizations have established various standards and regulations to govern their production, testing, and application.

In the United States, the Federal Communications Commission (FCC) sets the primary standards for EMI shielding materials through its electromagnetic compatibility (EMC) regulations. These regulations are outlined in Title 47 of the Code of Federal Regulations, specifically in Parts 15 and 18. The FCC requires that electronic devices meet certain emission limits and immunity standards to prevent interference with other devices and ensure proper functionality.

The European Union has implemented the Electromagnetic Compatibility Directive (2014/30/EU), which sets harmonized standards for EMI shielding materials and electronic products across member states. This directive mandates that all electronic equipment sold in the EU must comply with essential requirements for EMC, including both emissions and immunity standards.

International standards organizations, such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO), have developed a series of standards that address EMI shielding materials. These include IEC 61000 series for electromagnetic compatibility and ISO 11452 for vehicle component EMC testing. These standards provide guidelines for testing methods, performance criteria, and material specifications.

In the aerospace and defense sectors, more stringent regulations apply. The US Department of Defense has established MIL-STD-461 for EMI characteristics of equipment and subsystems, which includes specific requirements for shielding materials. Similarly, the European Aviation Safety Agency (EASA) and the Federal Aviation Administration (FAA) have regulations governing EMI shielding in aircraft systems.

As research on hydroxyethylcellulose in EMI shielding materials progresses, regulatory bodies are likely to update their frameworks to accommodate new materials and technologies. This may include the development of specific standards for bio-based or sustainable EMI shielding materials, as well as guidelines for their environmental impact and disposal.

Manufacturers and researchers working with hydroxyethylcellulose-based EMI shielding materials must stay informed about these regulations and ensure compliance throughout the development and production processes. This includes conducting appropriate EMC testing, obtaining necessary certifications, and maintaining documentation of compliance with relevant standards.

In the United States, the Federal Communications Commission (FCC) sets the primary standards for EMI shielding materials through its electromagnetic compatibility (EMC) regulations. These regulations are outlined in Title 47 of the Code of Federal Regulations, specifically in Parts 15 and 18. The FCC requires that electronic devices meet certain emission limits and immunity standards to prevent interference with other devices and ensure proper functionality.

The European Union has implemented the Electromagnetic Compatibility Directive (2014/30/EU), which sets harmonized standards for EMI shielding materials and electronic products across member states. This directive mandates that all electronic equipment sold in the EU must comply with essential requirements for EMC, including both emissions and immunity standards.

International standards organizations, such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO), have developed a series of standards that address EMI shielding materials. These include IEC 61000 series for electromagnetic compatibility and ISO 11452 for vehicle component EMC testing. These standards provide guidelines for testing methods, performance criteria, and material specifications.

In the aerospace and defense sectors, more stringent regulations apply. The US Department of Defense has established MIL-STD-461 for EMI characteristics of equipment and subsystems, which includes specific requirements for shielding materials. Similarly, the European Aviation Safety Agency (EASA) and the Federal Aviation Administration (FAA) have regulations governing EMI shielding in aircraft systems.

As research on hydroxyethylcellulose in EMI shielding materials progresses, regulatory bodies are likely to update their frameworks to accommodate new materials and technologies. This may include the development of specific standards for bio-based or sustainable EMI shielding materials, as well as guidelines for their environmental impact and disposal.

Manufacturers and researchers working with hydroxyethylcellulose-based EMI shielding materials must stay informed about these regulations and ensure compliance throughout the development and production processes. This includes conducting appropriate EMC testing, obtaining necessary certifications, and maintaining documentation of compliance with relevant standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!