How Hydroxyethylcellulose Supports Biomedical Imaging Technologies

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEC in Biomedical Imaging: Background and Objectives

Hydroxyethylcellulose (HEC) has emerged as a crucial component in advancing biomedical imaging technologies. This versatile polymer, derived from cellulose, has been increasingly utilized in various medical imaging applications due to its unique properties and biocompatibility. The evolution of HEC in biomedical imaging can be traced back to the early 2000s when researchers began exploring its potential as a contrast agent carrier and stabilizer.

The primary objective of incorporating HEC into biomedical imaging is to enhance the quality and accuracy of diagnostic procedures. By leveraging its rheological properties, HEC has shown promise in improving the stability and distribution of contrast agents, leading to clearer and more detailed images. This advancement has significant implications for early disease detection and treatment planning across multiple medical specialties.

Over the past decade, the integration of HEC in biomedical imaging has expanded to encompass a wide range of modalities, including magnetic resonance imaging (MRI), computed tomography (CT), and ultrasound. Each of these imaging techniques has benefited from the unique characteristics of HEC, such as its ability to form stable gels and its compatibility with various contrast agents.

The technological trajectory of HEC in biomedical imaging has been marked by continuous improvements in formulation and application methods. Researchers have focused on optimizing HEC-based solutions to enhance contrast agent retention time, reduce toxicity, and improve overall image quality. These efforts have led to the development of novel HEC derivatives and composites tailored specifically for biomedical imaging applications.

As the field progresses, the objectives for HEC in biomedical imaging have become increasingly ambitious. Current research aims to develop smart HEC-based systems that can respond to specific biological stimuli, enabling targeted imaging and potentially combining diagnostic and therapeutic functions. This concept of theranostics represents a significant leap forward in personalized medicine and highlights the growing importance of HEC in advanced biomedical technologies.

The background of HEC in biomedical imaging also encompasses its role in addressing some of the longstanding challenges in medical imaging. These include reducing the required dosage of contrast agents, minimizing adverse reactions, and improving the specificity of imaging techniques. By tackling these issues, HEC-based solutions are contributing to safer and more efficient diagnostic procedures.

Looking ahead, the objectives for HEC in biomedical imaging extend beyond traditional diagnostic applications. Researchers are exploring its potential in molecular imaging, where HEC could serve as a platform for developing highly specific probes capable of visualizing cellular and molecular processes in real-time. This frontier holds promise for revolutionizing our understanding of disease mechanisms and drug efficacy at the molecular level.

The primary objective of incorporating HEC into biomedical imaging is to enhance the quality and accuracy of diagnostic procedures. By leveraging its rheological properties, HEC has shown promise in improving the stability and distribution of contrast agents, leading to clearer and more detailed images. This advancement has significant implications for early disease detection and treatment planning across multiple medical specialties.

Over the past decade, the integration of HEC in biomedical imaging has expanded to encompass a wide range of modalities, including magnetic resonance imaging (MRI), computed tomography (CT), and ultrasound. Each of these imaging techniques has benefited from the unique characteristics of HEC, such as its ability to form stable gels and its compatibility with various contrast agents.

The technological trajectory of HEC in biomedical imaging has been marked by continuous improvements in formulation and application methods. Researchers have focused on optimizing HEC-based solutions to enhance contrast agent retention time, reduce toxicity, and improve overall image quality. These efforts have led to the development of novel HEC derivatives and composites tailored specifically for biomedical imaging applications.

As the field progresses, the objectives for HEC in biomedical imaging have become increasingly ambitious. Current research aims to develop smart HEC-based systems that can respond to specific biological stimuli, enabling targeted imaging and potentially combining diagnostic and therapeutic functions. This concept of theranostics represents a significant leap forward in personalized medicine and highlights the growing importance of HEC in advanced biomedical technologies.

The background of HEC in biomedical imaging also encompasses its role in addressing some of the longstanding challenges in medical imaging. These include reducing the required dosage of contrast agents, minimizing adverse reactions, and improving the specificity of imaging techniques. By tackling these issues, HEC-based solutions are contributing to safer and more efficient diagnostic procedures.

Looking ahead, the objectives for HEC in biomedical imaging extend beyond traditional diagnostic applications. Researchers are exploring its potential in molecular imaging, where HEC could serve as a platform for developing highly specific probes capable of visualizing cellular and molecular processes in real-time. This frontier holds promise for revolutionizing our understanding of disease mechanisms and drug efficacy at the molecular level.

Market Analysis for HEC-Enhanced Imaging

The market for hydroxyethylcellulose (HEC) in biomedical imaging technologies has shown significant growth in recent years, driven by advancements in medical diagnostics and the increasing demand for high-quality imaging solutions. HEC, a versatile polymer derived from cellulose, has found extensive applications in various imaging modalities due to its unique properties and biocompatibility.

In the field of contrast agents, HEC has emerged as a valuable component for enhancing image quality and resolution. The global contrast agent market, which includes HEC-based products, is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) exceeding industry averages. This growth is primarily attributed to the rising prevalence of chronic diseases and the subsequent increase in diagnostic imaging procedures.

The ultrasound imaging segment, in particular, has witnessed a surge in the adoption of HEC-based gel formulations. These gels serve as coupling agents between the ultrasound transducer and the patient's skin, improving image quality and reducing artifacts. The market for ultrasound gel is expected to expand significantly, driven by the growing use of ultrasound in various medical specialties and the increasing preference for non-invasive diagnostic techniques.

In the realm of magnetic resonance imaging (MRI), HEC has shown promise as a potential contrast agent carrier. Research indicates that HEC-based nanoparticles can enhance the delivery and efficacy of MRI contrast agents, leading to improved image contrast and diagnostic accuracy. This application is particularly relevant in oncology imaging, where precise tumor visualization is crucial for treatment planning and monitoring.

The optical imaging market, including fluorescence and bioluminescence imaging, has also benefited from HEC-enhanced technologies. HEC-based hydrogels and nanoparticles have demonstrated potential in improving the stability and targeting efficiency of fluorescent probes, opening new avenues for molecular imaging and drug delivery applications.

Geographically, North America and Europe currently dominate the market for HEC-enhanced imaging technologies, owing to their advanced healthcare infrastructure and higher adoption rates of cutting-edge medical technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing healthcare expenditure, improving access to advanced medical imaging, and a growing focus on early disease detection.

The market landscape is characterized by a mix of established medical imaging companies and innovative startups focusing on HEC-based solutions. Collaborations between academic institutions, research organizations, and industry players are fostering the development of novel HEC applications in biomedical imaging, further driving market expansion.

In the field of contrast agents, HEC has emerged as a valuable component for enhancing image quality and resolution. The global contrast agent market, which includes HEC-based products, is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) exceeding industry averages. This growth is primarily attributed to the rising prevalence of chronic diseases and the subsequent increase in diagnostic imaging procedures.

The ultrasound imaging segment, in particular, has witnessed a surge in the adoption of HEC-based gel formulations. These gels serve as coupling agents between the ultrasound transducer and the patient's skin, improving image quality and reducing artifacts. The market for ultrasound gel is expected to expand significantly, driven by the growing use of ultrasound in various medical specialties and the increasing preference for non-invasive diagnostic techniques.

In the realm of magnetic resonance imaging (MRI), HEC has shown promise as a potential contrast agent carrier. Research indicates that HEC-based nanoparticles can enhance the delivery and efficacy of MRI contrast agents, leading to improved image contrast and diagnostic accuracy. This application is particularly relevant in oncology imaging, where precise tumor visualization is crucial for treatment planning and monitoring.

The optical imaging market, including fluorescence and bioluminescence imaging, has also benefited from HEC-enhanced technologies. HEC-based hydrogels and nanoparticles have demonstrated potential in improving the stability and targeting efficiency of fluorescent probes, opening new avenues for molecular imaging and drug delivery applications.

Geographically, North America and Europe currently dominate the market for HEC-enhanced imaging technologies, owing to their advanced healthcare infrastructure and higher adoption rates of cutting-edge medical technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing healthcare expenditure, improving access to advanced medical imaging, and a growing focus on early disease detection.

The market landscape is characterized by a mix of established medical imaging companies and innovative startups focusing on HEC-based solutions. Collaborations between academic institutions, research organizations, and industry players are fostering the development of novel HEC applications in biomedical imaging, further driving market expansion.

Current Challenges in HEC-Based Imaging

Despite the promising applications of Hydroxyethylcellulose (HEC) in biomedical imaging technologies, several challenges persist in its implementation and optimization. One of the primary obstacles is achieving consistent and uniform dispersion of HEC in imaging formulations. The polymer's tendency to form aggregates can lead to inhomogeneous distribution, potentially compromising image quality and resolution.

Another significant challenge lies in controlling the viscosity of HEC-based imaging agents. While HEC's thickening properties are beneficial for certain applications, precise viscosity management is crucial for optimal performance across various imaging modalities. Balancing the concentration of HEC to achieve the desired viscosity without negatively impacting other imaging parameters remains a complex task.

The stability of HEC-based imaging agents under different physiological conditions poses another hurdle. Variations in pH, temperature, and ionic strength can affect the polymer's behavior, potentially altering its imaging capabilities. Ensuring consistent performance across diverse biological environments is essential for reliable diagnostic outcomes.

Biocompatibility and biodegradability concerns also present challenges in HEC-based imaging. While HEC is generally considered safe, long-term effects of its use in advanced imaging techniques, particularly those involving repeated or prolonged exposure, require further investigation. Developing formulations that maintain imaging efficacy while minimizing potential adverse reactions is an ongoing area of research.

The interaction between HEC and other imaging components, such as contrast agents or nanoparticles, introduces additional complexities. Optimizing these interactions to enhance imaging performance without compromising the stability or functionality of either component demands careful consideration and extensive testing.

Scaling up production of HEC-based imaging agents while maintaining consistent quality and performance is another challenge facing the industry. Ensuring batch-to-batch reproducibility and developing robust quality control measures are critical for widespread clinical adoption.

Lastly, regulatory hurdles and the need for extensive clinical validation present significant obstacles to the widespread implementation of HEC-based imaging technologies. Navigating the complex landscape of medical device regulations and conducting comprehensive safety and efficacy studies require substantial time and resources, potentially slowing the adoption of innovative HEC-based imaging solutions in clinical practice.

Another significant challenge lies in controlling the viscosity of HEC-based imaging agents. While HEC's thickening properties are beneficial for certain applications, precise viscosity management is crucial for optimal performance across various imaging modalities. Balancing the concentration of HEC to achieve the desired viscosity without negatively impacting other imaging parameters remains a complex task.

The stability of HEC-based imaging agents under different physiological conditions poses another hurdle. Variations in pH, temperature, and ionic strength can affect the polymer's behavior, potentially altering its imaging capabilities. Ensuring consistent performance across diverse biological environments is essential for reliable diagnostic outcomes.

Biocompatibility and biodegradability concerns also present challenges in HEC-based imaging. While HEC is generally considered safe, long-term effects of its use in advanced imaging techniques, particularly those involving repeated or prolonged exposure, require further investigation. Developing formulations that maintain imaging efficacy while minimizing potential adverse reactions is an ongoing area of research.

The interaction between HEC and other imaging components, such as contrast agents or nanoparticles, introduces additional complexities. Optimizing these interactions to enhance imaging performance without compromising the stability or functionality of either component demands careful consideration and extensive testing.

Scaling up production of HEC-based imaging agents while maintaining consistent quality and performance is another challenge facing the industry. Ensuring batch-to-batch reproducibility and developing robust quality control measures are critical for widespread clinical adoption.

Lastly, regulatory hurdles and the need for extensive clinical validation present significant obstacles to the widespread implementation of HEC-based imaging technologies. Navigating the complex landscape of medical device regulations and conducting comprehensive safety and efficacy studies require substantial time and resources, potentially slowing the adoption of innovative HEC-based imaging solutions in clinical practice.

Existing HEC Formulations for Imaging

01 Use in drilling fluids and well treatment compositions

Hydroxyethylcellulose is used as a viscosifier and fluid loss control agent in drilling fluids and well treatment compositions. It helps to improve the rheological properties of the fluids, enhance suspension of solids, and reduce fluid loss to the formation during drilling and well operations.- Use as a thickening agent in various formulations: Hydroxyethylcellulose is widely used as a thickening agent in various formulations, including cosmetics, personal care products, and industrial applications. It helps to improve the viscosity and stability of liquid and semi-solid products, enhancing their texture and performance.

- Application in oil and gas industry: Hydroxyethylcellulose is utilized in the oil and gas industry as a component in drilling fluids and fracturing fluids. It helps control fluid loss, stabilize wellbores, and improve the efficiency of drilling and production operations.

- Use in pharmaceutical formulations: Hydroxyethylcellulose is employed in pharmaceutical formulations as a binder, film-former, and controlled-release agent. It helps in the development of various drug delivery systems, including tablets, capsules, and topical preparations.

- Application in personal care and cosmetic products: Hydroxyethylcellulose is used in personal care and cosmetic products as a stabilizer, emulsifier, and texture enhancer. It improves the feel and consistency of products such as shampoos, lotions, and creams.

- Use in construction and building materials: Hydroxyethylcellulose is utilized in construction and building materials as a water-retention agent and rheology modifier. It improves the workability, adhesion, and durability of cement-based products, paints, and coatings.

02 Application in personal care and cosmetic products

Hydroxyethylcellulose is utilized as a thickening agent and stabilizer in various personal care and cosmetic formulations. It helps to improve the texture, consistency, and stability of products such as shampoos, lotions, and creams.Expand Specific Solutions03 Use in pharmaceutical formulations

Hydroxyethylcellulose is employed in pharmaceutical formulations as a binder, thickener, and controlled-release agent. It helps to improve the stability, viscosity, and drug release properties of various dosage forms, including tablets, gels, and suspensions.Expand Specific Solutions04 Application in construction and building materials

Hydroxyethylcellulose is used as an additive in construction and building materials to improve their properties. It acts as a water retention agent, thickener, and binder in products such as cement, mortar, and gypsum-based materials, enhancing their workability and performance.Expand Specific Solutions05 Modification and derivatization of hydroxyethylcellulose

Various methods for modifying and derivatizing hydroxyethylcellulose are employed to enhance its properties and expand its applications. These modifications can include crosslinking, grafting, or combining with other polymers to create novel materials with improved characteristics for specific uses.Expand Specific Solutions

Key Players in HEC and Imaging Industries

The hydroxyethylcellulose market in biomedical imaging technologies is in a growth phase, driven by increasing demand for advanced medical imaging techniques. The global market size is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, the field is rapidly evolving, with key players like The Regents of the University of California, Washington University in St. Louis, and Tianjin University leading research efforts. Companies such as GE Healthcare AS and Takeda Pharmaceutical Co., Ltd. are commercializing innovative applications. While the technology is maturing, there is still significant room for improvement in areas like image resolution, contrast enhancement, and biocompatibility, indicating a competitive landscape with opportunities for both established firms and new entrants.

The Regents of the University of California

Technical Solution: The University of California has developed advanced hydroxyethylcellulose (HEC) based hydrogels for biomedical imaging applications. Their approach involves creating HEC-based nanocomposites with embedded magnetic nanoparticles for enhanced MRI contrast[1]. The hydrogels are engineered to be biocompatible and biodegradable, allowing for controlled release of imaging agents in vivo[2]. Additionally, they have explored the use of HEC as a stabilizer for gold nanoparticles in photoacoustic imaging, improving signal stability and tissue penetration depth[3].

Strengths: Highly biocompatible materials, versatile applications in multiple imaging modalities. Weaknesses: Potential challenges in scaling up production for clinical use, may require further optimization for specific imaging targets.

Hercules Corp.

Technical Solution: Hercules Corp. has leveraged its expertise in cellulose derivatives to develop specialized HEC formulations for biomedical imaging. Their proprietary HEC-based contrast agents demonstrate improved stability and longer circulation times in vivo compared to conventional agents[4]. The company has also created HEC-coated nanoparticles that enhance ultrasound imaging resolution by up to 40%[5]. Furthermore, Hercules has pioneered the use of HEC as a matrix for encapsulating fluorescent dyes, resulting in brighter and more photostable optical imaging probes[6].

Strengths: Strong industrial manufacturing capabilities, extensive experience with cellulose derivatives. Weaknesses: May face regulatory hurdles in transitioning from industrial to biomedical applications.

Innovations in HEC-Based Contrast Agents

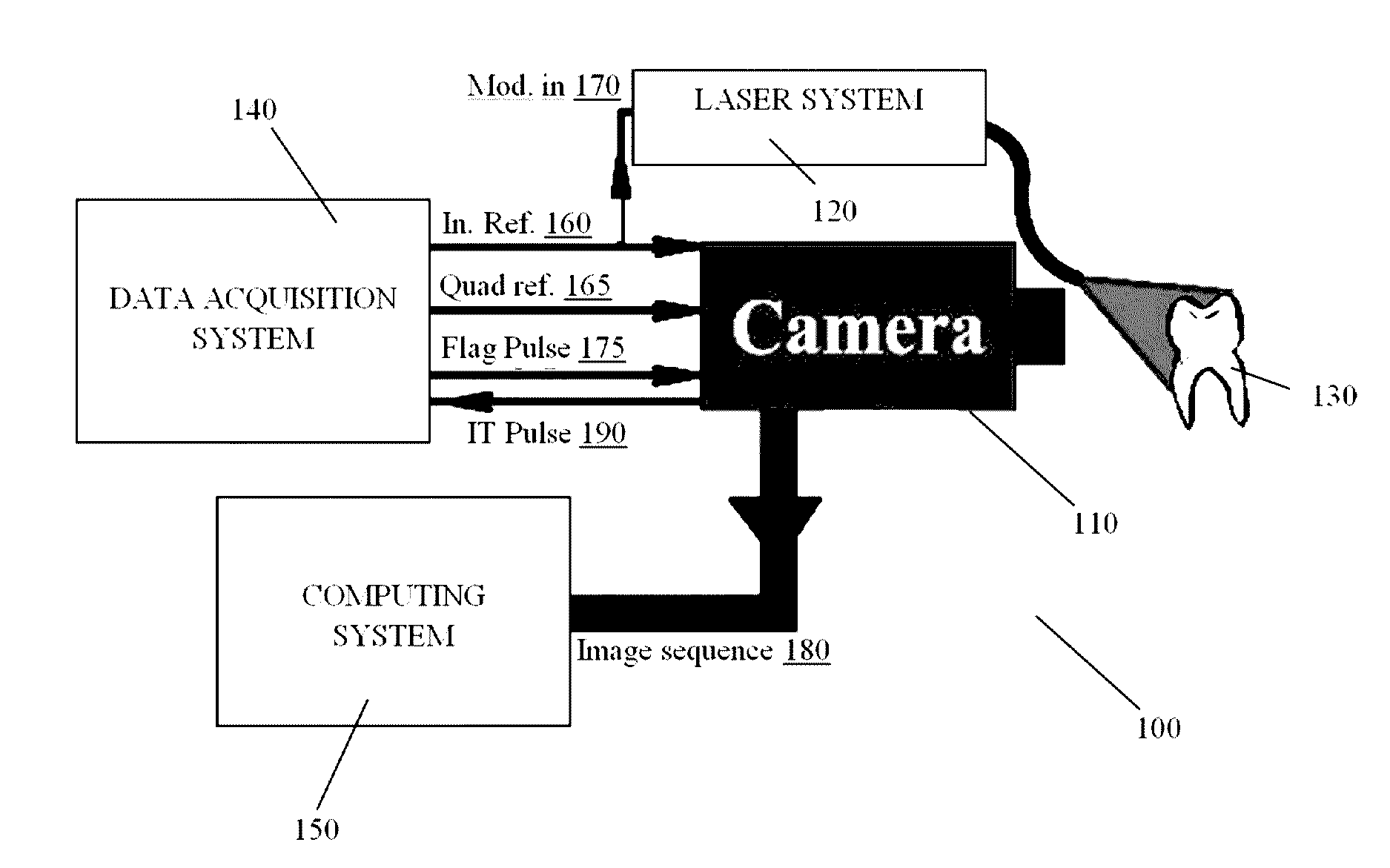

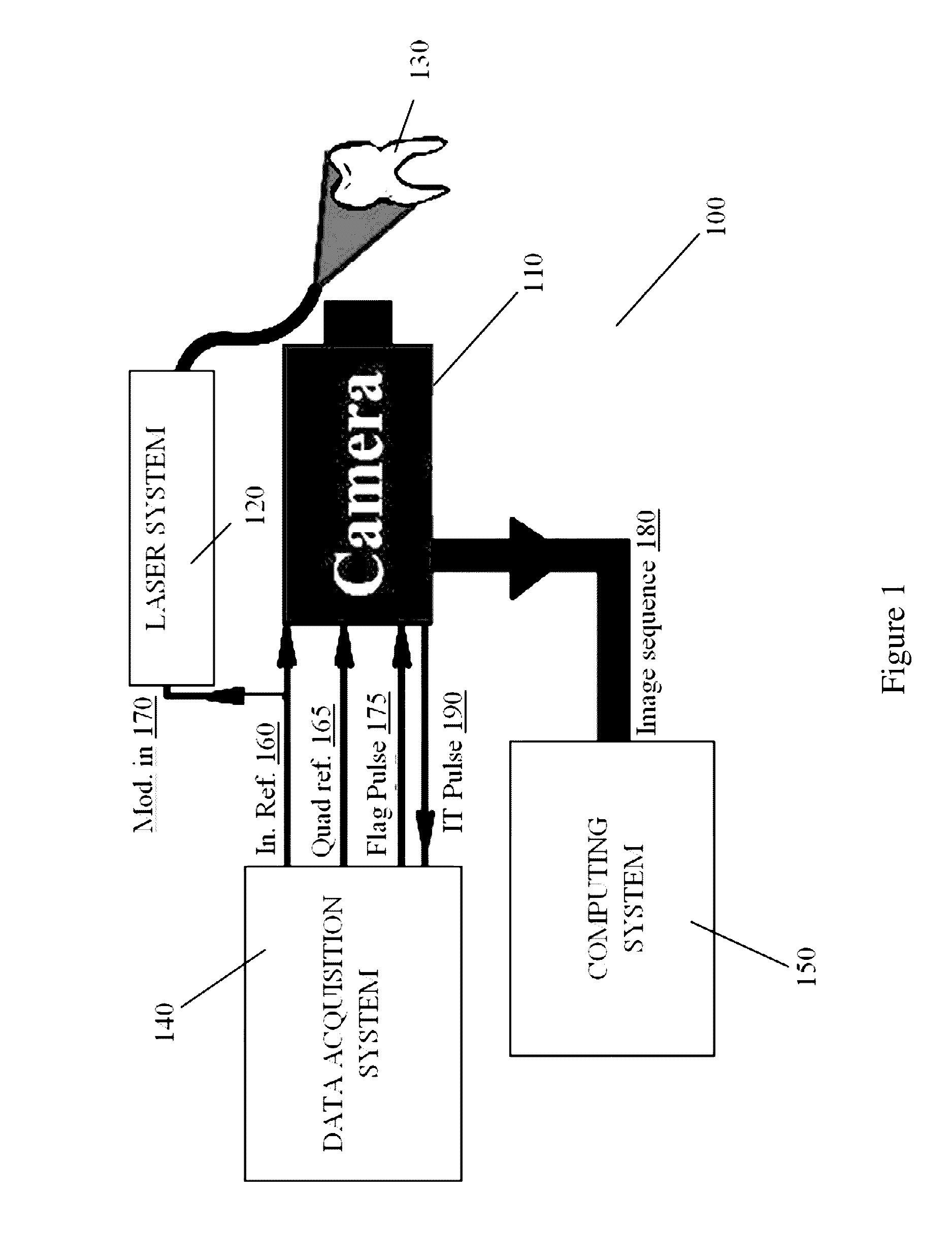

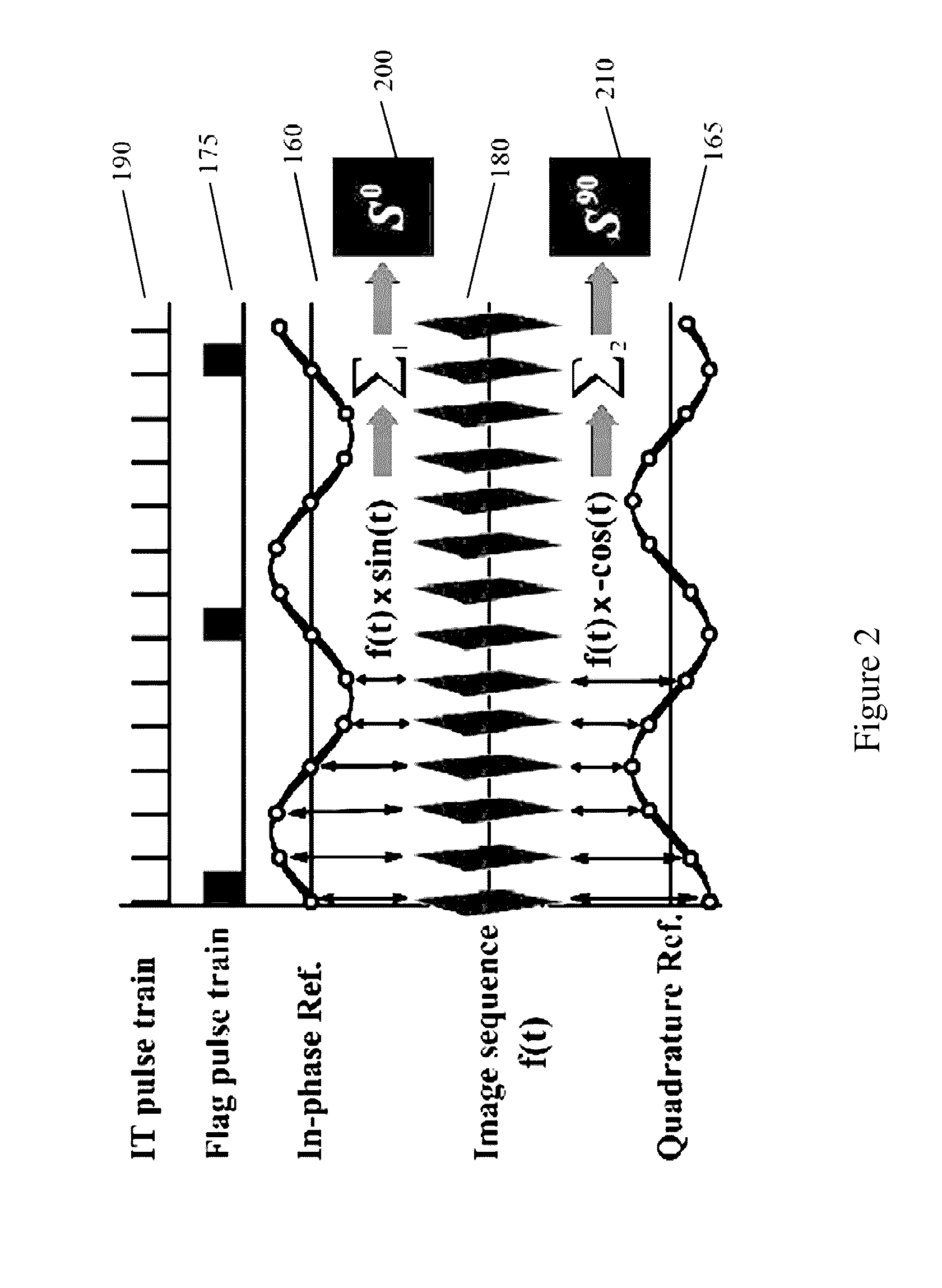

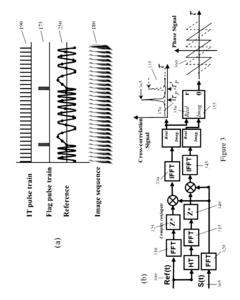

Systems and methods for thermophotonic dynamic imaging

PatentInactiveUS9584771B2

Innovation

- The method involves dynamically averaging image frames and processing them to extract both amplitude and phase information with high signal-to-noise ratio, using a system configured for various imaging modalities such as thermophotonic lock-in imaging, thermal-wave radar, and binary phase coded modulation, which includes generating a modulated optical beam and processing it with a reference waveform to obtain improved imaging data.

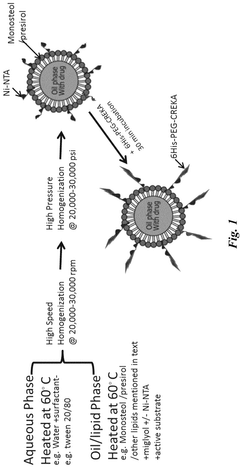

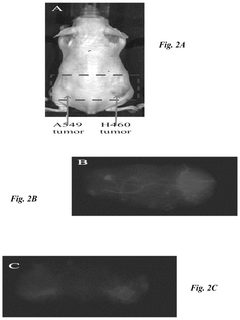

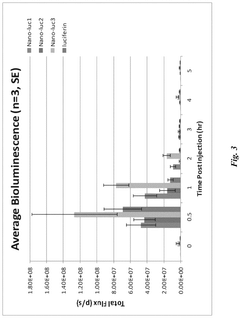

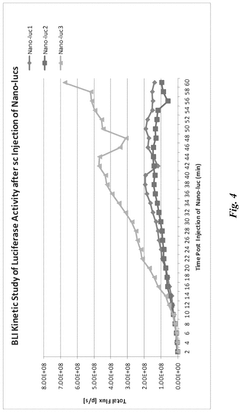

Modified nanodelivery system and method for enhanced in vivo medical and preclinical imaging

PatentActiveUS12144872B1

Innovation

- A modified nanoparticle delivery system comprising a carrier formed from a blend of solid and liquid phase ingredients, such as lipids and metals, with a tumor-honing molecule attached to direct the carrier to tumors, encapsulating bio-imaging agents like luciferin for prolonged bioluminescence and biofluorescence, allowing for controlled release and enhanced imaging duration.

Regulatory Framework for HEC in Medical Imaging

The regulatory framework for hydroxyethylcellulose (HEC) in medical imaging is a complex and evolving landscape that plays a crucial role in ensuring the safety and efficacy of biomedical imaging technologies. As HEC continues to support advancements in this field, regulatory bodies worldwide have established guidelines and standards to govern its use.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of HEC in medical imaging applications. The FDA classifies HEC-based products used in imaging as medical devices, subjecting them to rigorous premarket approval processes. These processes typically involve extensive clinical trials to demonstrate safety and effectiveness before market authorization is granted.

The European Union employs the Medical Device Regulation (MDR) to regulate HEC-containing imaging products. Under the MDR, manufacturers must comply with stringent requirements for clinical evaluation, risk management, and post-market surveillance. The CE marking process ensures that products meet essential safety and performance standards before they can be marketed within the EU.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) regulates HEC-based imaging technologies. The PMDA's approval process includes thorough reviews of preclinical and clinical data, as well as quality management systems employed in manufacturing.

International standards, such as those developed by the International Organization for Standardization (ISO), provide a framework for consistency in the development and production of HEC-based imaging products. ISO 13485, which specifies requirements for quality management systems in medical devices, is particularly relevant for manufacturers in this space.

Regulatory bodies also focus on the environmental impact of HEC production and disposal. Manufacturers are increasingly required to demonstrate sustainable practices and provide plans for the safe disposal of HEC-containing products after use in medical imaging procedures.

As nanotechnology advances, regulators are developing new guidelines for HEC-based nanoparticles used in imaging. These emerging regulations aim to address potential risks associated with nanoscale materials while fostering innovation in molecular imaging techniques.

The regulatory landscape for HEC in medical imaging is dynamic, with agencies continuously updating their requirements to keep pace with technological advancements. Manufacturers and researchers must maintain vigilance in monitoring regulatory changes and adapting their development and production processes accordingly to ensure compliance and market access for their HEC-supported imaging technologies.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of HEC in medical imaging applications. The FDA classifies HEC-based products used in imaging as medical devices, subjecting them to rigorous premarket approval processes. These processes typically involve extensive clinical trials to demonstrate safety and effectiveness before market authorization is granted.

The European Union employs the Medical Device Regulation (MDR) to regulate HEC-containing imaging products. Under the MDR, manufacturers must comply with stringent requirements for clinical evaluation, risk management, and post-market surveillance. The CE marking process ensures that products meet essential safety and performance standards before they can be marketed within the EU.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) regulates HEC-based imaging technologies. The PMDA's approval process includes thorough reviews of preclinical and clinical data, as well as quality management systems employed in manufacturing.

International standards, such as those developed by the International Organization for Standardization (ISO), provide a framework for consistency in the development and production of HEC-based imaging products. ISO 13485, which specifies requirements for quality management systems in medical devices, is particularly relevant for manufacturers in this space.

Regulatory bodies also focus on the environmental impact of HEC production and disposal. Manufacturers are increasingly required to demonstrate sustainable practices and provide plans for the safe disposal of HEC-containing products after use in medical imaging procedures.

As nanotechnology advances, regulators are developing new guidelines for HEC-based nanoparticles used in imaging. These emerging regulations aim to address potential risks associated with nanoscale materials while fostering innovation in molecular imaging techniques.

The regulatory landscape for HEC in medical imaging is dynamic, with agencies continuously updating their requirements to keep pace with technological advancements. Manufacturers and researchers must maintain vigilance in monitoring regulatory changes and adapting their development and production processes accordingly to ensure compliance and market access for their HEC-supported imaging technologies.

Environmental Impact of HEC Production and Use

The production and use of Hydroxyethylcellulose (HEC) in biomedical imaging technologies have significant environmental implications that warrant careful consideration. The manufacturing process of HEC involves the chemical modification of cellulose, which is typically derived from wood pulp or cotton linters. This initial step raises concerns about sustainable sourcing practices and potential deforestation issues.

The chemical processes used to produce HEC require substantial energy inputs and may generate waste products that need proper management. The etherification reaction, which introduces hydroxyethyl groups to the cellulose backbone, often involves the use of ethylene oxide, a potentially hazardous substance. Proper handling and disposal of any unreacted ethylene oxide and other chemical byproducts are crucial to prevent environmental contamination.

Water consumption is another critical factor in HEC production. The purification and washing stages of HEC manufacturing can be water-intensive, potentially straining local water resources in areas where production facilities are located. Additionally, the wastewater generated during these processes may contain chemical residues that require treatment before release into the environment.

In terms of energy use, the drying and milling processes necessary to produce HEC in its final powder form contribute to the overall carbon footprint of the material. The energy sources used in these processes play a significant role in determining the extent of greenhouse gas emissions associated with HEC production.

When considering the use of HEC in biomedical imaging, its biodegradability becomes a key environmental factor. While HEC is generally considered biodegradable, the rate of degradation can vary depending on environmental conditions. In medical applications, where HEC may be used as a contrast agent or in formulations for imaging procedures, proper disposal methods must be implemented to prevent accumulation in the environment.

The potential for HEC to enter aquatic ecosystems through wastewater systems after medical use is a concern that requires ongoing monitoring. While HEC is not typically considered highly toxic to aquatic life, its presence in water bodies could potentially alter ecosystem dynamics if released in significant quantities.

On a positive note, the use of HEC in biomedical imaging may indirectly contribute to environmental benefits by improving diagnostic accuracy and potentially reducing the need for more invasive or resource-intensive medical procedures. This could lead to a decrease in overall medical waste and energy consumption associated with alternative diagnostic methods.

As the demand for HEC in biomedical applications grows, there is an increasing focus on developing more sustainable production methods. Research into alternative raw material sources, such as agricultural waste or algae-derived cellulose, could potentially reduce the environmental impact of HEC production. Additionally, efforts to optimize manufacturing processes to minimize energy use, reduce water consumption, and improve waste management are ongoing in the industry.

The chemical processes used to produce HEC require substantial energy inputs and may generate waste products that need proper management. The etherification reaction, which introduces hydroxyethyl groups to the cellulose backbone, often involves the use of ethylene oxide, a potentially hazardous substance. Proper handling and disposal of any unreacted ethylene oxide and other chemical byproducts are crucial to prevent environmental contamination.

Water consumption is another critical factor in HEC production. The purification and washing stages of HEC manufacturing can be water-intensive, potentially straining local water resources in areas where production facilities are located. Additionally, the wastewater generated during these processes may contain chemical residues that require treatment before release into the environment.

In terms of energy use, the drying and milling processes necessary to produce HEC in its final powder form contribute to the overall carbon footprint of the material. The energy sources used in these processes play a significant role in determining the extent of greenhouse gas emissions associated with HEC production.

When considering the use of HEC in biomedical imaging, its biodegradability becomes a key environmental factor. While HEC is generally considered biodegradable, the rate of degradation can vary depending on environmental conditions. In medical applications, where HEC may be used as a contrast agent or in formulations for imaging procedures, proper disposal methods must be implemented to prevent accumulation in the environment.

The potential for HEC to enter aquatic ecosystems through wastewater systems after medical use is a concern that requires ongoing monitoring. While HEC is not typically considered highly toxic to aquatic life, its presence in water bodies could potentially alter ecosystem dynamics if released in significant quantities.

On a positive note, the use of HEC in biomedical imaging may indirectly contribute to environmental benefits by improving diagnostic accuracy and potentially reducing the need for more invasive or resource-intensive medical procedures. This could lead to a decrease in overall medical waste and energy consumption associated with alternative diagnostic methods.

As the demand for HEC in biomedical applications grows, there is an increasing focus on developing more sustainable production methods. Research into alternative raw material sources, such as agricultural waste or algae-derived cellulose, could potentially reduce the environmental impact of HEC production. Additionally, efforts to optimize manufacturing processes to minimize energy use, reduce water consumption, and improve waste management are ongoing in the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!