Integration of Hydroxyethylcellulose in Synthetic Biology Applications

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEC in Synthetic Biology: Background and Objectives

Hydroxyethylcellulose (HEC) has emerged as a promising biomaterial in the rapidly evolving field of synthetic biology. This natural polymer, derived from cellulose, has garnered significant attention due to its unique properties and potential applications in bioengineering. The integration of HEC in synthetic biology represents a convergence of traditional materials science with cutting-edge biological engineering, opening new avenues for innovation in biotechnology and medicine.

The development of HEC applications in synthetic biology can be traced back to the early 2000s when researchers began exploring its potential as a scaffold for tissue engineering and drug delivery systems. Since then, the field has witnessed a steady progression in understanding HEC's molecular structure, its interactions with biological systems, and its adaptability for various synthetic biology applications. This evolution has been driven by advancements in polymer chemistry, genetic engineering, and nanotechnology, which have collectively expanded the possibilities for HEC utilization.

The primary objective of integrating HEC into synthetic biology is to harness its biocompatibility, biodegradability, and versatile physicochemical properties to create novel biological systems and materials. Researchers aim to exploit HEC's ability to form hydrogels, its non-toxicity, and its capacity for chemical modification to develop advanced biomaterials for applications ranging from controlled drug release to artificial extracellular matrices for cell culture and tissue engineering.

One of the key goals in this field is to engineer HEC-based materials that can interface seamlessly with living systems, providing structural support, facilitating molecular transport, or serving as a platform for cellular interactions. This includes developing HEC derivatives that can respond to specific biological stimuli, creating "smart" materials capable of dynamic behavior in biological environments.

Another critical objective is to explore the potential of HEC in the design of synthetic biological circuits and systems. By incorporating HEC into the toolkit of synthetic biology, researchers seek to create new functional materials that can enhance the performance and capabilities of engineered biological systems. This could lead to innovations in biosensors, bioreactors, and even artificial organs.

The integration of HEC in synthetic biology also aims to address some of the limitations of current biomaterials, such as poor mechanical properties or limited functionality. By combining HEC with other biological or synthetic components, scientists hope to create hybrid materials with enhanced properties and functionalities that can better mimic or interact with natural biological systems.

As the field progresses, there is a growing focus on developing sustainable and eco-friendly processes for HEC production and modification, aligning with the broader goals of green chemistry and sustainable bioengineering. This includes exploring new sources of cellulose, optimizing enzymatic modification techniques, and developing more efficient methods for HEC functionalization.

The development of HEC applications in synthetic biology can be traced back to the early 2000s when researchers began exploring its potential as a scaffold for tissue engineering and drug delivery systems. Since then, the field has witnessed a steady progression in understanding HEC's molecular structure, its interactions with biological systems, and its adaptability for various synthetic biology applications. This evolution has been driven by advancements in polymer chemistry, genetic engineering, and nanotechnology, which have collectively expanded the possibilities for HEC utilization.

The primary objective of integrating HEC into synthetic biology is to harness its biocompatibility, biodegradability, and versatile physicochemical properties to create novel biological systems and materials. Researchers aim to exploit HEC's ability to form hydrogels, its non-toxicity, and its capacity for chemical modification to develop advanced biomaterials for applications ranging from controlled drug release to artificial extracellular matrices for cell culture and tissue engineering.

One of the key goals in this field is to engineer HEC-based materials that can interface seamlessly with living systems, providing structural support, facilitating molecular transport, or serving as a platform for cellular interactions. This includes developing HEC derivatives that can respond to specific biological stimuli, creating "smart" materials capable of dynamic behavior in biological environments.

Another critical objective is to explore the potential of HEC in the design of synthetic biological circuits and systems. By incorporating HEC into the toolkit of synthetic biology, researchers seek to create new functional materials that can enhance the performance and capabilities of engineered biological systems. This could lead to innovations in biosensors, bioreactors, and even artificial organs.

The integration of HEC in synthetic biology also aims to address some of the limitations of current biomaterials, such as poor mechanical properties or limited functionality. By combining HEC with other biological or synthetic components, scientists hope to create hybrid materials with enhanced properties and functionalities that can better mimic or interact with natural biological systems.

As the field progresses, there is a growing focus on developing sustainable and eco-friendly processes for HEC production and modification, aligning with the broader goals of green chemistry and sustainable bioengineering. This includes exploring new sources of cellulose, optimizing enzymatic modification techniques, and developing more efficient methods for HEC functionalization.

Market Analysis for HEC-Based Synthetic Biology Products

The market for HEC-based synthetic biology products is experiencing significant growth, driven by the increasing demand for sustainable and bio-based materials across various industries. Hydroxyethylcellulose (HEC), a versatile biopolymer, has found applications in synthetic biology due to its unique properties and biocompatibility. The global synthetic biology market, which encompasses HEC-based products, is projected to reach $30.7 billion by 2026, with a compound annual growth rate (CAGR) of 23.9% from 2021 to 2026.

The pharmaceutical and healthcare sectors represent the largest market segments for HEC-based synthetic biology products. HEC's ability to form hydrogels and its biocompatibility make it an ideal candidate for drug delivery systems, tissue engineering scaffolds, and wound healing applications. The growing emphasis on personalized medicine and regenerative therapies is expected to further boost demand in these sectors.

In the cosmetics and personal care industry, HEC-based synthetic biology products are gaining traction due to their natural origin and skin-friendly properties. The rising consumer preference for eco-friendly and sustainable beauty products is driving the adoption of HEC-based ingredients in formulations such as moisturizers, hair care products, and sunscreens.

The food and beverage industry is another key market for HEC-based synthetic biology products. HEC's thickening and stabilizing properties make it valuable in food applications, particularly in plant-based and alternative protein products. As the demand for plant-based foods continues to grow, the market for HEC-based ingredients in this sector is expected to expand significantly.

Environmental applications represent an emerging market for HEC-based synthetic biology products. The polymer's biodegradability and ability to form hydrogels make it suitable for soil remediation, water treatment, and agricultural applications. As environmental concerns become more pressing, this market segment is anticipated to experience rapid growth in the coming years.

Geographically, North America and Europe currently dominate the market for HEC-based synthetic biology products, owing to their advanced research infrastructure and strong presence of biotechnology companies. However, the Asia-Pacific region is expected to witness the highest growth rate, driven by increasing investments in synthetic biology research and growing industrial applications in countries like China, Japan, and South Korea.

Key challenges in the market include regulatory hurdles, particularly in the pharmaceutical and food industries, and the need for scalable and cost-effective production methods. However, ongoing advancements in synthetic biology techniques and increasing collaborations between academia and industry are expected to address these challenges and drive further market growth.

The pharmaceutical and healthcare sectors represent the largest market segments for HEC-based synthetic biology products. HEC's ability to form hydrogels and its biocompatibility make it an ideal candidate for drug delivery systems, tissue engineering scaffolds, and wound healing applications. The growing emphasis on personalized medicine and regenerative therapies is expected to further boost demand in these sectors.

In the cosmetics and personal care industry, HEC-based synthetic biology products are gaining traction due to their natural origin and skin-friendly properties. The rising consumer preference for eco-friendly and sustainable beauty products is driving the adoption of HEC-based ingredients in formulations such as moisturizers, hair care products, and sunscreens.

The food and beverage industry is another key market for HEC-based synthetic biology products. HEC's thickening and stabilizing properties make it valuable in food applications, particularly in plant-based and alternative protein products. As the demand for plant-based foods continues to grow, the market for HEC-based ingredients in this sector is expected to expand significantly.

Environmental applications represent an emerging market for HEC-based synthetic biology products. The polymer's biodegradability and ability to form hydrogels make it suitable for soil remediation, water treatment, and agricultural applications. As environmental concerns become more pressing, this market segment is anticipated to experience rapid growth in the coming years.

Geographically, North America and Europe currently dominate the market for HEC-based synthetic biology products, owing to their advanced research infrastructure and strong presence of biotechnology companies. However, the Asia-Pacific region is expected to witness the highest growth rate, driven by increasing investments in synthetic biology research and growing industrial applications in countries like China, Japan, and South Korea.

Key challenges in the market include regulatory hurdles, particularly in the pharmaceutical and food industries, and the need for scalable and cost-effective production methods. However, ongoing advancements in synthetic biology techniques and increasing collaborations between academia and industry are expected to address these challenges and drive further market growth.

Current Challenges in HEC Integration for Synthetic Biology

The integration of Hydroxyethylcellulose (HEC) in synthetic biology applications faces several significant challenges that hinder its widespread adoption and optimal utilization. One of the primary obstacles is the complexity of incorporating HEC into existing biological systems without disrupting their natural functions. HEC, being a non-native molecule, can potentially interfere with cellular processes, leading to unexpected outcomes in engineered organisms.

Another major challenge lies in the precise control of HEC's properties within biological environments. The viscosity and gelation characteristics of HEC, which are crucial for many applications, can be highly sensitive to environmental factors such as pH, temperature, and ionic strength. This variability makes it difficult to maintain consistent performance across different synthetic biology platforms and applications.

The biocompatibility of HEC in various cellular systems presents another hurdle. While HEC is generally considered safe for many applications, its long-term effects on cellular health and genetic stability in engineered organisms are not fully understood. This uncertainty raises concerns about the potential unintended consequences of HEC integration in synthetic biology, particularly in applications involving long-term cellular cultures or in vivo systems.

Furthermore, the scalability of HEC-based synthetic biology solutions poses a significant challenge. Many promising applications demonstrated in laboratory settings face difficulties when scaled up to industrial levels. Issues such as maintaining uniform HEC distribution, preventing aggregation, and ensuring consistent biological performance across large volumes are yet to be fully resolved.

The lack of standardized protocols for HEC integration in synthetic biology is another impediment. The diverse range of potential applications for HEC in this field has led to a proliferation of custom approaches, making it challenging to compare results across different studies and replicate successful integrations. This absence of standardization also slows down the development of new applications and hinders collaborative efforts in the field.

Lastly, the regulatory landscape surrounding the use of HEC in synthetic biology applications remains complex and often unclear. As a relatively new area of research, the integration of HEC in engineered biological systems falls into a regulatory gray area in many jurisdictions. This uncertainty can deter investment and slow down the commercialization of promising HEC-based synthetic biology technologies.

Another major challenge lies in the precise control of HEC's properties within biological environments. The viscosity and gelation characteristics of HEC, which are crucial for many applications, can be highly sensitive to environmental factors such as pH, temperature, and ionic strength. This variability makes it difficult to maintain consistent performance across different synthetic biology platforms and applications.

The biocompatibility of HEC in various cellular systems presents another hurdle. While HEC is generally considered safe for many applications, its long-term effects on cellular health and genetic stability in engineered organisms are not fully understood. This uncertainty raises concerns about the potential unintended consequences of HEC integration in synthetic biology, particularly in applications involving long-term cellular cultures or in vivo systems.

Furthermore, the scalability of HEC-based synthetic biology solutions poses a significant challenge. Many promising applications demonstrated in laboratory settings face difficulties when scaled up to industrial levels. Issues such as maintaining uniform HEC distribution, preventing aggregation, and ensuring consistent biological performance across large volumes are yet to be fully resolved.

The lack of standardized protocols for HEC integration in synthetic biology is another impediment. The diverse range of potential applications for HEC in this field has led to a proliferation of custom approaches, making it challenging to compare results across different studies and replicate successful integrations. This absence of standardization also slows down the development of new applications and hinders collaborative efforts in the field.

Lastly, the regulatory landscape surrounding the use of HEC in synthetic biology applications remains complex and often unclear. As a relatively new area of research, the integration of HEC in engineered biological systems falls into a regulatory gray area in many jurisdictions. This uncertainty can deter investment and slow down the commercialization of promising HEC-based synthetic biology technologies.

Existing HEC Integration Methods in Synthetic Biology

01 Use as a thickening agent in various industries

Hydroxyethylcellulose is widely used as a thickening agent in various industries, including cosmetics, pharmaceuticals, and oil drilling. It helps to increase the viscosity of solutions and provides stability to formulations.- Use in drilling fluids and well treatment compositions: Hydroxyethylcellulose is utilized in drilling fluids and well treatment compositions to control viscosity and fluid loss. It acts as a thickening agent and helps maintain the stability of the fluid in various temperature and pressure conditions encountered during drilling operations.

- Application in personal care and cosmetic products: Hydroxyethylcellulose is employed in personal care and cosmetic formulations as a thickener, stabilizer, and emulsifier. It enhances the texture and consistency of products such as shampoos, lotions, and creams, while also providing moisturizing properties.

- Use in pharmaceutical formulations: Hydroxyethylcellulose is utilized in pharmaceutical formulations as a binder, thickener, and controlled-release agent. It helps in the preparation of tablets, capsules, and topical preparations, improving drug delivery and stability of the formulations.

- Application in construction and building materials: Hydroxyethylcellulose is used in construction and building materials as a water-retention agent and rheology modifier. It improves the workability, adhesion, and stability of cement-based products, paints, and coatings, enhancing their overall performance.

- Use in textile processing and paper manufacturing: Hydroxyethylcellulose finds applications in textile processing and paper manufacturing as a sizing agent, binder, and surface treatment additive. It improves the strength, smoothness, and printability of paper products, and enhances the dyeing and finishing processes in textiles.

02 Application in personal care products

Hydroxyethylcellulose is commonly used in personal care products such as shampoos, lotions, and creams. It acts as a thickener, emulsifier, and stabilizer, improving the texture and consistency of these products.Expand Specific Solutions03 Use in pharmaceutical formulations

Hydroxyethylcellulose is utilized in pharmaceutical formulations as a binder, film-former, and controlled-release agent. It helps in the production of tablets, capsules, and topical medications, improving their stability and release characteristics.Expand Specific Solutions04 Application in oil and gas industry

Hydroxyethylcellulose is used in the oil and gas industry as a component of drilling fluids and fracturing fluids. It helps control fluid loss, improve viscosity, and enhance the overall performance of these fluids in well operations.Expand Specific Solutions05 Use in adhesives and coatings

Hydroxyethylcellulose is employed in the production of adhesives and coatings. It acts as a thickener, binder, and film-former, improving the performance and application properties of these products.Expand Specific Solutions

Key Players in HEC and Synthetic Biology Industries

The integration of Hydroxyethylcellulose in Synthetic Biology Applications is an emerging field with significant potential. The market is in its early growth stage, characterized by increasing research and development activities. While the market size is still relatively small, it is expected to expand rapidly as applications in biotechnology and materials science evolve. Technologically, the field is progressing, with companies like Hercules Corp. and LOTTE Fine Chemical Co., Ltd. leading in industrial applications. Academic institutions such as Wuhan University and the University of Washington are contributing to fundamental research, while organizations like the Centre National de la Recherche Scientifique are bridging the gap between academia and industry. The collaboration between these players is driving innovation and gradually increasing the technology's maturity level.

Cellectis SA

Technical Solution: Cellectis SA has innovatively integrated hydroxyethylcellulose (HEC) into their synthetic biology platform, particularly in the field of gene editing and cell therapy. Their approach leverages HEC as a biocompatible carrier for delivering gene-editing tools, such as CRISPR-Cas9, to target cells. By encapsulating gene-editing components in HEC-based nanoparticles, Cellectis has improved the efficiency and specificity of genetic modifications in therapeutic cells. This technology has shown promise in enhancing the production of CAR-T cells and other engineered cell therapies[8]. Additionally, Cellectis has developed HEC-based hydrogels that serve as 3D culture systems for maintaining and expanding genetically modified cells, providing a more physiologically relevant environment compared to traditional 2D cultures[9]. The company's integration of HEC in their synthetic biology workflow has led to improvements in cell viability and functionality in their therapeutic products.

Strengths: Enhanced gene editing efficiency, improved cell therapy production processes. Weaknesses: Potential immunogenicity concerns, challenges in large-scale manufacturing of complex biological products.

UPM-Kymmene Oyj

Technical Solution: UPM-Kymmene Oyj has pioneered the integration of hydroxyethylcellulose (HEC) in synthetic biology applications, particularly in the development of sustainable biomaterials. Their approach involves using HEC as a renewable and biodegradable platform for creating functional biocomposites. By combining HEC with engineered enzymes and microorganisms, UPM has developed a range of bio-based materials with tailored properties. These materials find applications in packaging, textiles, and biomedical fields. The company has successfully demonstrated the production of HEC-based hydrogels that can be programmed to respond to specific environmental stimuli, opening up possibilities for smart packaging and biosensors[4][5]. UPM's technology also includes the modification of HEC to improve its compatibility with various synthetic biology tools, enabling more efficient integration into complex biological systems.

Strengths: Expertise in sustainable biomaterials, innovative applications in packaging and biosensors. Weaknesses: May face competition from established petroleum-based materials, potential regulatory hurdles for novel biomaterials.

Innovative HEC Modifications for Synthetic Biology

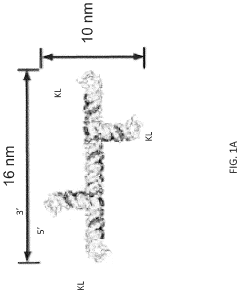

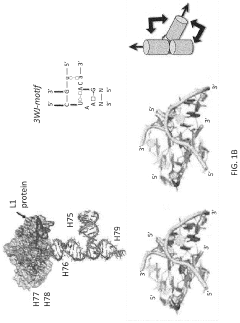

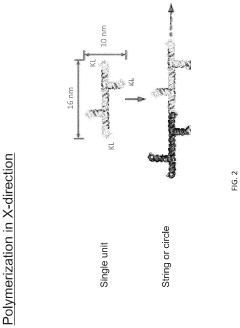

Building designer RNA nano-structures for synthetic biology applications

PatentPendingUS20230332161A1

Innovation

- Designing RNA molecules with specific sequences to form thermodynamically stable 2D and 3D structures through spontaneous self-assembly, utilizing three-way junctions and kissing loops, which can self-assemble into nanostructures like strings, ladders, and grids without the need for catalytic co-factors or specific conditions, allowing for precise control over structure formation.

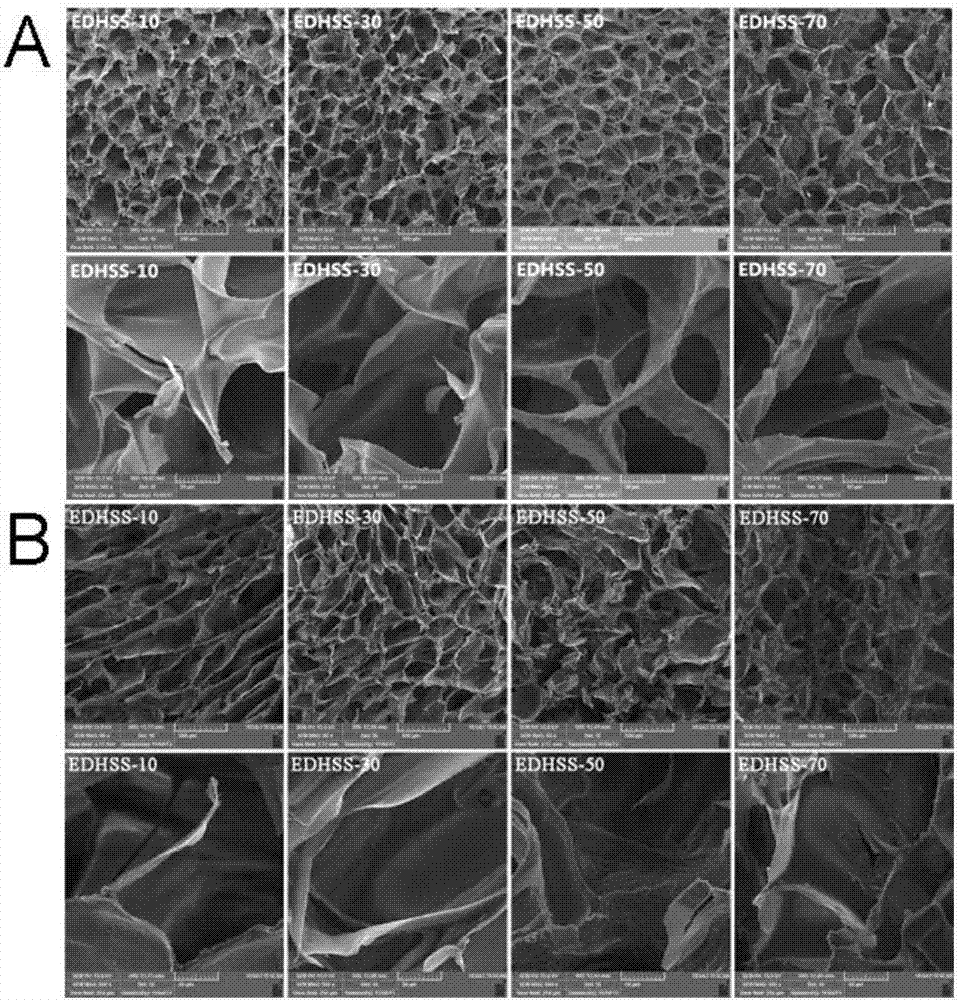

Hydroxyethyl cellulose/soybean protein composite sponge with water sensitive shape memory function and preparing method of composite sponge

PatentActiveCN107141817A

Innovation

- By dissolving hydroxyethyl cellulose and soy protein in deionized water, adding sodium hydroxide solution, blending in proportion, performing a cross-linking reaction at room temperature, and then freeze-drying, a composite with water-sensitive shape memory function was prepared. Sponge material. The method includes adding epichlorohydrin or ethylene glycol diglycidyl ether to the blending solution for cross-linking to control the structure and properties of the material.

Biosafety and Regulatory Considerations for HEC Use

The integration of Hydroxyethylcellulose (HEC) in synthetic biology applications necessitates careful consideration of biosafety and regulatory aspects. As a non-toxic, biodegradable polymer derived from cellulose, HEC presents a relatively low environmental risk compared to many synthetic materials. However, its use in biological systems still requires thorough safety assessments and adherence to regulatory guidelines.

From a biosafety perspective, the primary concerns revolve around the potential interactions between HEC and living organisms. While HEC is generally considered safe for human consumption and environmental exposure, its effects when integrated into engineered biological systems must be carefully evaluated. This includes assessing potential impacts on cell viability, metabolic processes, and genetic stability in host organisms.

Regulatory considerations for HEC use in synthetic biology span multiple jurisdictions and frameworks. In the United States, the Food and Drug Administration (FDA) and Environmental Protection Agency (EPA) play crucial roles in overseeing the use of materials like HEC in biological applications. The FDA's guidance on the use of novel excipients in drug products and the EPA's regulations on new chemical substances under the Toxic Substances Control Act (TSCA) are particularly relevant.

Internationally, regulatory bodies such as the European Medicines Agency (EMA) and the European Chemicals Agency (ECHA) have established guidelines for the use of cellulose derivatives in various applications. These regulations often focus on purity standards, permissible levels of chemical modifications, and potential environmental impacts.

For synthetic biology applications specifically, researchers and companies must navigate the evolving landscape of regulations surrounding genetically modified organisms (GMOs) and engineered biological systems. This includes obtaining necessary permits for contained use or deliberate release of engineered organisms incorporating HEC.

Risk assessment protocols for HEC in synthetic biology should address both the inherent properties of the material and its potential interactions within engineered biological systems. This includes evaluating the stability of HEC-modified organisms, assessing horizontal gene transfer risks, and considering potential ecological impacts if released into the environment.

Standardization efforts are crucial for ensuring consistent safety and regulatory compliance across different applications of HEC in synthetic biology. Organizations such as the International Organization for Standardization (ISO) and the Synthetic Biology Standards Consortium are working to develop guidelines and best practices for the use of materials like HEC in bioengineering contexts.

From a biosafety perspective, the primary concerns revolve around the potential interactions between HEC and living organisms. While HEC is generally considered safe for human consumption and environmental exposure, its effects when integrated into engineered biological systems must be carefully evaluated. This includes assessing potential impacts on cell viability, metabolic processes, and genetic stability in host organisms.

Regulatory considerations for HEC use in synthetic biology span multiple jurisdictions and frameworks. In the United States, the Food and Drug Administration (FDA) and Environmental Protection Agency (EPA) play crucial roles in overseeing the use of materials like HEC in biological applications. The FDA's guidance on the use of novel excipients in drug products and the EPA's regulations on new chemical substances under the Toxic Substances Control Act (TSCA) are particularly relevant.

Internationally, regulatory bodies such as the European Medicines Agency (EMA) and the European Chemicals Agency (ECHA) have established guidelines for the use of cellulose derivatives in various applications. These regulations often focus on purity standards, permissible levels of chemical modifications, and potential environmental impacts.

For synthetic biology applications specifically, researchers and companies must navigate the evolving landscape of regulations surrounding genetically modified organisms (GMOs) and engineered biological systems. This includes obtaining necessary permits for contained use or deliberate release of engineered organisms incorporating HEC.

Risk assessment protocols for HEC in synthetic biology should address both the inherent properties of the material and its potential interactions within engineered biological systems. This includes evaluating the stability of HEC-modified organisms, assessing horizontal gene transfer risks, and considering potential ecological impacts if released into the environment.

Standardization efforts are crucial for ensuring consistent safety and regulatory compliance across different applications of HEC in synthetic biology. Organizations such as the International Organization for Standardization (ISO) and the Synthetic Biology Standards Consortium are working to develop guidelines and best practices for the use of materials like HEC in bioengineering contexts.

Environmental Impact of HEC in Synthetic Biology

The integration of Hydroxyethylcellulose (HEC) in synthetic biology applications has raised important questions about its environmental impact. As a biodegradable and renewable polymer, HEC offers potential advantages over synthetic alternatives. However, its widespread use in bioengineering processes necessitates a thorough examination of its ecological footprint.

HEC's biodegradability is a key factor in its environmental profile. When released into natural ecosystems, HEC can be broken down by microorganisms, reducing long-term accumulation in the environment. This characteristic sets it apart from many synthetic polymers that persist for extended periods. However, the rate and completeness of HEC biodegradation can vary depending on environmental conditions, potentially leading to temporary accumulation in certain ecosystems.

The production of HEC from cellulose, a renewable resource, contributes to its sustainability credentials. Cellulose can be sourced from various plant materials, including wood pulp and cotton linters. This renewable sourcing reduces dependence on fossil fuel-derived materials, potentially lowering the carbon footprint associated with HEC production. However, the environmental impact of cellulose extraction and processing must be considered, including land use, water consumption, and energy requirements.

In synthetic biology applications, HEC's use as a thickening agent, stabilizer, or encapsulation material may have both positive and negative environmental implications. On the positive side, HEC can enhance the efficiency of bioprocesses, potentially reducing overall resource consumption and waste generation. It may also improve the stability and efficacy of engineered biological systems, leading to more sustainable biotechnology applications.

However, the release of HEC-containing products or waste from synthetic biology processes into the environment requires careful management. While biodegradable, high concentrations of HEC could potentially alter local ecosystems, affecting water quality or soil properties. The interaction between HEC and engineered biological components in the environment is an area that demands further research to ensure no unintended ecological consequences.

The scalability of HEC production to meet growing demands in synthetic biology also raises environmental considerations. Increased cultivation of cellulose-producing crops or expansion of forestry operations could impact land use patterns and biodiversity. Balancing the benefits of HEC as a renewable resource with potential land-use changes is crucial for sustainable implementation.

In conclusion, while HEC offers promising environmental benefits in synthetic biology applications, its widespread adoption necessitates ongoing assessment and mitigation of potential ecological impacts. Future research should focus on optimizing HEC production methods, improving its biodegradation profile, and understanding its long-term effects on diverse ecosystems to ensure its sustainable integration in bioengineering processes.

HEC's biodegradability is a key factor in its environmental profile. When released into natural ecosystems, HEC can be broken down by microorganisms, reducing long-term accumulation in the environment. This characteristic sets it apart from many synthetic polymers that persist for extended periods. However, the rate and completeness of HEC biodegradation can vary depending on environmental conditions, potentially leading to temporary accumulation in certain ecosystems.

The production of HEC from cellulose, a renewable resource, contributes to its sustainability credentials. Cellulose can be sourced from various plant materials, including wood pulp and cotton linters. This renewable sourcing reduces dependence on fossil fuel-derived materials, potentially lowering the carbon footprint associated with HEC production. However, the environmental impact of cellulose extraction and processing must be considered, including land use, water consumption, and energy requirements.

In synthetic biology applications, HEC's use as a thickening agent, stabilizer, or encapsulation material may have both positive and negative environmental implications. On the positive side, HEC can enhance the efficiency of bioprocesses, potentially reducing overall resource consumption and waste generation. It may also improve the stability and efficacy of engineered biological systems, leading to more sustainable biotechnology applications.

However, the release of HEC-containing products or waste from synthetic biology processes into the environment requires careful management. While biodegradable, high concentrations of HEC could potentially alter local ecosystems, affecting water quality or soil properties. The interaction between HEC and engineered biological components in the environment is an area that demands further research to ensure no unintended ecological consequences.

The scalability of HEC production to meet growing demands in synthetic biology also raises environmental considerations. Increased cultivation of cellulose-producing crops or expansion of forestry operations could impact land use patterns and biodiversity. Balancing the benefits of HEC as a renewable resource with potential land-use changes is crucial for sustainable implementation.

In conclusion, while HEC offers promising environmental benefits in synthetic biology applications, its widespread adoption necessitates ongoing assessment and mitigation of potential ecological impacts. Future research should focus on optimizing HEC production methods, improving its biodegradation profile, and understanding its long-term effects on diverse ecosystems to ensure its sustainable integration in bioengineering processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!