Hydroxyethylcellulose's Contributions to the Development of Flexible Electronics

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEC in Flexible Electronics: Background and Objectives

Hydroxyethylcellulose (HEC) has emerged as a key material in the rapidly evolving field of flexible electronics. This versatile polymer, derived from cellulose, has been instrumental in addressing several challenges faced by the industry, particularly in the development of flexible and stretchable electronic devices. The journey of HEC in flexible electronics began in the early 2000s when researchers started exploring its potential as a substrate and encapsulation material.

The primary objective of incorporating HEC into flexible electronics is to enhance the mechanical properties and durability of devices while maintaining their electrical performance. HEC's unique characteristics, such as its high flexibility, excellent film-forming ability, and good adhesion to various surfaces, make it an ideal candidate for this purpose. Additionally, its biocompatibility and biodegradability align well with the growing demand for environmentally friendly electronic components.

Over the past two decades, the application of HEC in flexible electronics has expanded significantly. Initially used primarily as a substrate material, it has now found applications in various components of flexible devices, including electrodes, dielectrics, and protective layers. This evolution has been driven by the increasing demand for wearable technology, foldable displays, and soft robotics, all of which require materials that can withstand repeated bending and stretching without compromising functionality.

The development of HEC-based flexible electronics has been marked by several key milestones. Early research focused on optimizing the mechanical properties of HEC films, followed by efforts to improve their electrical conductivity through the incorporation of conductive fillers. More recent advancements have centered on enhancing the interface between HEC and other materials used in flexible devices, as well as developing novel processing techniques to create complex structures and patterns.

As the field of flexible electronics continues to advance, the role of HEC is expected to grow further. Current research is exploring its potential in areas such as self-healing electronics, biodegradable sensors, and energy storage devices. The ongoing efforts to modify and functionalize HEC are likely to unlock new possibilities, potentially revolutionizing the way we design and manufacture flexible electronic devices.

The technological evolution of HEC in flexible electronics aligns closely with broader industry trends, including the push for more sustainable materials, the miniaturization of devices, and the integration of electronics into everyday objects. As such, understanding the background and objectives of HEC's application in this field is crucial for predicting future developments and identifying potential breakthroughs in flexible electronics technology.

The primary objective of incorporating HEC into flexible electronics is to enhance the mechanical properties and durability of devices while maintaining their electrical performance. HEC's unique characteristics, such as its high flexibility, excellent film-forming ability, and good adhesion to various surfaces, make it an ideal candidate for this purpose. Additionally, its biocompatibility and biodegradability align well with the growing demand for environmentally friendly electronic components.

Over the past two decades, the application of HEC in flexible electronics has expanded significantly. Initially used primarily as a substrate material, it has now found applications in various components of flexible devices, including electrodes, dielectrics, and protective layers. This evolution has been driven by the increasing demand for wearable technology, foldable displays, and soft robotics, all of which require materials that can withstand repeated bending and stretching without compromising functionality.

The development of HEC-based flexible electronics has been marked by several key milestones. Early research focused on optimizing the mechanical properties of HEC films, followed by efforts to improve their electrical conductivity through the incorporation of conductive fillers. More recent advancements have centered on enhancing the interface between HEC and other materials used in flexible devices, as well as developing novel processing techniques to create complex structures and patterns.

As the field of flexible electronics continues to advance, the role of HEC is expected to grow further. Current research is exploring its potential in areas such as self-healing electronics, biodegradable sensors, and energy storage devices. The ongoing efforts to modify and functionalize HEC are likely to unlock new possibilities, potentially revolutionizing the way we design and manufacture flexible electronic devices.

The technological evolution of HEC in flexible electronics aligns closely with broader industry trends, including the push for more sustainable materials, the miniaturization of devices, and the integration of electronics into everyday objects. As such, understanding the background and objectives of HEC's application in this field is crucial for predicting future developments and identifying potential breakthroughs in flexible electronics technology.

Market Analysis for HEC-based Flexible Electronics

The market for HEC-based flexible electronics is experiencing rapid growth, driven by increasing demand for wearable devices, foldable displays, and soft robotics. Hydroxyethylcellulose (HEC) has emerged as a key material in this sector due to its unique properties, including flexibility, biocompatibility, and ease of processing. The global flexible electronics market is projected to reach significant value in the coming years, with HEC-based products playing a crucial role in this expansion.

One of the primary drivers of market growth is the rising consumer interest in wearable technology. HEC-based flexible sensors and circuits are being integrated into smartwatches, fitness trackers, and health monitoring devices. These applications benefit from HEC's ability to conform to body contours and withstand repeated bending and stretching, enhancing user comfort and device durability.

The healthcare sector represents another substantial market opportunity for HEC-based flexible electronics. Medical devices incorporating flexible sensors and electrodes made with HEC are gaining traction for applications such as continuous glucose monitoring, ECG recording, and wound healing monitoring. The biocompatibility of HEC makes it particularly suitable for these medical applications, addressing concerns about long-term skin contact and potential allergic reactions.

In the display technology sector, HEC is contributing to the development of foldable and rollable screens. Major electronics manufacturers are investing heavily in this technology, recognizing the potential for innovative form factors in smartphones, tablets, and laptops. HEC's transparency and flexibility make it an excellent candidate for substrate materials in these next-generation displays.

The automotive industry is also showing increased interest in HEC-based flexible electronics. Applications include touch-sensitive control panels, flexible lighting systems, and conformable sensors for various vehicle components. As vehicles become more electrified and autonomous, the demand for lightweight, flexible electronic components is expected to grow significantly.

Environmental sustainability is becoming a key factor in market dynamics. HEC, being a cellulose derivative, offers advantages in terms of biodegradability and renewable sourcing compared to petroleum-based polymers. This aligns well with the growing consumer preference for eco-friendly products and stricter environmental regulations in many regions.

Despite the promising outlook, challenges remain in scaling up production and reducing costs. Current manufacturing processes for HEC-based flexible electronics are often complex and expensive, limiting widespread adoption. However, ongoing research and development efforts are focused on improving production efficiency and exploring new applications, which are expected to drive down costs and expand market opportunities in the coming years.

One of the primary drivers of market growth is the rising consumer interest in wearable technology. HEC-based flexible sensors and circuits are being integrated into smartwatches, fitness trackers, and health monitoring devices. These applications benefit from HEC's ability to conform to body contours and withstand repeated bending and stretching, enhancing user comfort and device durability.

The healthcare sector represents another substantial market opportunity for HEC-based flexible electronics. Medical devices incorporating flexible sensors and electrodes made with HEC are gaining traction for applications such as continuous glucose monitoring, ECG recording, and wound healing monitoring. The biocompatibility of HEC makes it particularly suitable for these medical applications, addressing concerns about long-term skin contact and potential allergic reactions.

In the display technology sector, HEC is contributing to the development of foldable and rollable screens. Major electronics manufacturers are investing heavily in this technology, recognizing the potential for innovative form factors in smartphones, tablets, and laptops. HEC's transparency and flexibility make it an excellent candidate for substrate materials in these next-generation displays.

The automotive industry is also showing increased interest in HEC-based flexible electronics. Applications include touch-sensitive control panels, flexible lighting systems, and conformable sensors for various vehicle components. As vehicles become more electrified and autonomous, the demand for lightweight, flexible electronic components is expected to grow significantly.

Environmental sustainability is becoming a key factor in market dynamics. HEC, being a cellulose derivative, offers advantages in terms of biodegradability and renewable sourcing compared to petroleum-based polymers. This aligns well with the growing consumer preference for eco-friendly products and stricter environmental regulations in many regions.

Despite the promising outlook, challenges remain in scaling up production and reducing costs. Current manufacturing processes for HEC-based flexible electronics are often complex and expensive, limiting widespread adoption. However, ongoing research and development efforts are focused on improving production efficiency and exploring new applications, which are expected to drive down costs and expand market opportunities in the coming years.

Current Challenges in HEC Application for Flexible Electronics

Despite the promising potential of hydroxyethylcellulose (HEC) in flexible electronics, several challenges currently hinder its widespread application in this field. One of the primary obstacles is the optimization of HEC's mechanical properties for flexible electronic devices. While HEC exhibits good flexibility, achieving the right balance between flexibility and durability remains a significant challenge. Researchers are working to enhance HEC's tensile strength and elongation at break without compromising its flexibility, which is crucial for maintaining device performance under various bending and stretching conditions.

Another major challenge lies in improving the electrical conductivity of HEC-based materials. Although HEC serves as an excellent substrate and binder for conductive materials, its inherent non-conductive nature limits its direct use in electronic components. Current efforts focus on developing effective methods to incorporate conductive fillers or creating hybrid materials that combine HEC's flexibility with high electrical conductivity. This includes exploring nanocomposites with carbon nanotubes, graphene, or metallic nanoparticles, but achieving uniform dispersion and maintaining connectivity under deformation remains problematic.

The stability of HEC-based flexible electronics in various environmental conditions poses another significant challenge. HEC is hygroscopic, meaning it readily absorbs moisture from the environment. This property can lead to changes in the material's dimensions and electrical properties, potentially affecting device performance and longevity. Researchers are investigating ways to enhance the moisture resistance of HEC-based materials without compromising their flexibility or biocompatibility, such as through chemical modifications or protective coatings.

Scalability and manufacturing processes present additional hurdles in the application of HEC for flexible electronics. While HEC can be processed using various techniques, including solution casting and electrospinning, translating these methods to large-scale, cost-effective production remains challenging. Ensuring consistency in material properties, thickness control, and surface quality across large areas is critical for commercial viability but currently difficult to achieve.

Lastly, the integration of HEC-based components with other materials and electronic elements in flexible devices presents ongoing challenges. This includes developing effective bonding techniques, ensuring compatibility with existing manufacturing processes, and maintaining performance at the interfaces between different materials. Addressing these integration issues is crucial for realizing fully functional, reliable flexible electronic systems that can leverage the unique properties of HEC.

Another major challenge lies in improving the electrical conductivity of HEC-based materials. Although HEC serves as an excellent substrate and binder for conductive materials, its inherent non-conductive nature limits its direct use in electronic components. Current efforts focus on developing effective methods to incorporate conductive fillers or creating hybrid materials that combine HEC's flexibility with high electrical conductivity. This includes exploring nanocomposites with carbon nanotubes, graphene, or metallic nanoparticles, but achieving uniform dispersion and maintaining connectivity under deformation remains problematic.

The stability of HEC-based flexible electronics in various environmental conditions poses another significant challenge. HEC is hygroscopic, meaning it readily absorbs moisture from the environment. This property can lead to changes in the material's dimensions and electrical properties, potentially affecting device performance and longevity. Researchers are investigating ways to enhance the moisture resistance of HEC-based materials without compromising their flexibility or biocompatibility, such as through chemical modifications or protective coatings.

Scalability and manufacturing processes present additional hurdles in the application of HEC for flexible electronics. While HEC can be processed using various techniques, including solution casting and electrospinning, translating these methods to large-scale, cost-effective production remains challenging. Ensuring consistency in material properties, thickness control, and surface quality across large areas is critical for commercial viability but currently difficult to achieve.

Lastly, the integration of HEC-based components with other materials and electronic elements in flexible devices presents ongoing challenges. This includes developing effective bonding techniques, ensuring compatibility with existing manufacturing processes, and maintaining performance at the interfaces between different materials. Addressing these integration issues is crucial for realizing fully functional, reliable flexible electronic systems that can leverage the unique properties of HEC.

Existing HEC-based Solutions for Flexible Electronics

01 Hydroxyethylcellulose as a viscosity modifier

Hydroxyethylcellulose is widely used as a viscosity modifier in various applications. It can be used to adjust the rheological properties of fluids, providing flexibility in formulation. The polymer's ability to thicken and stabilize solutions makes it valuable in industries such as personal care, pharmaceuticals, and oil drilling.- Hydroxyethylcellulose as a viscosity modifier: Hydroxyethylcellulose is widely used as a viscosity modifier in various applications. It can be used to adjust the rheological properties of fluids, providing flexibility in formulation. The polymer's ability to thicken and stabilize solutions makes it valuable in industries such as cosmetics, pharmaceuticals, and oil drilling.

- Hydroxyethylcellulose in personal care products: Hydroxyethylcellulose is utilized in personal care products due to its flexibility and compatibility with other ingredients. It can be used as a thickener, stabilizer, and film-forming agent in products such as shampoos, lotions, and gels. The polymer's ability to form clear solutions and its non-ionic nature contribute to its versatility in formulations.

- Hydroxyethylcellulose in pharmaceutical applications: The flexibility of hydroxyethylcellulose makes it suitable for various pharmaceutical applications. It can be used as a binder, film-forming agent, and controlled-release matrix in tablet formulations. The polymer's ability to form hydrogels allows for the development of drug delivery systems with tailored release profiles.

- Hydroxyethylcellulose in oil and gas industry: Hydroxyethylcellulose is used in the oil and gas industry due to its flexibility in adjusting fluid properties. It serves as a viscosifier and fluid loss control agent in drilling muds and fracturing fluids. The polymer's ability to withstand high temperatures and salinity makes it valuable in challenging downhole conditions.

- Modification of hydroxyethylcellulose for enhanced properties: Researchers have explored various modifications of hydroxyethylcellulose to enhance its flexibility and functionality. These modifications can include crosslinking, grafting, or combining with other polymers. Such modifications can lead to improved thermal stability, mechanical properties, or specific functionalities tailored for particular applications.

02 Hydroxyethylcellulose in drug delivery systems

Hydroxyethylcellulose is utilized in pharmaceutical formulations to enhance drug delivery. Its flexibility allows for the creation of controlled-release systems, improving the efficacy and bioavailability of active ingredients. The polymer can be used in various dosage forms, including tablets, gels, and transdermal patches.Expand Specific Solutions03 Hydroxyethylcellulose in personal care products

The flexibility of hydroxyethylcellulose makes it suitable for use in personal care products. It can act as a thickener, emulsifier, and stabilizer in formulations such as shampoos, lotions, and cosmetics. The polymer's ability to form films and its moisturizing properties contribute to its versatility in this field.Expand Specific Solutions04 Hydroxyethylcellulose in oil and gas applications

Hydroxyethylcellulose is used in the oil and gas industry due to its flexibility in adjusting fluid properties. It can be employed in drilling fluids, fracturing fluids, and enhanced oil recovery processes. The polymer's ability to control viscosity and provide fluid loss control makes it valuable in these applications.Expand Specific Solutions05 Modification of hydroxyethylcellulose for enhanced properties

Research has been conducted on modifying hydroxyethylcellulose to enhance its properties and expand its applications. These modifications can include crosslinking, grafting, or combining with other polymers to improve characteristics such as water resistance, mechanical strength, or thermal stability. This flexibility in modification allows for tailored solutions in various industries.Expand Specific Solutions

Key Players in HEC and Flexible Electronics Industry

The development of flexible electronics using hydroxyethylcellulose is in its early stages, with a growing market and increasing technological maturity. The field is attracting attention from both academic institutions and industry players, indicating a competitive landscape. Companies like Liquid Wire, Inc. and Innolux Corp. are exploring applications in stretchable sensors and display technologies, respectively. Research institutions such as MIT, KAIST, and Fuzhou University are contributing to fundamental advancements. The market is expected to expand as flexible electronics find applications in wearable devices, healthcare, and consumer electronics, driving further innovation and competition among key players.

Liquid Wire, Inc.

Technical Solution: Liquid Wire has developed a proprietary technology utilizing hydroxyethylcellulose (HEC) to create stretchable and flexible electronic circuits. Their approach involves incorporating HEC into a conductive gel matrix, which can be printed or molded into various shapes. This gel-based circuit maintains conductivity even when stretched or bent, making it ideal for wearable electronics and soft robotics applications. The company has demonstrated prototypes with stretchability up to 500% while maintaining electrical performance[1]. Their technology also allows for integration with traditional rigid electronic components, creating hybrid flexible-rigid systems[2].

Strengths: Exceptional stretchability, compatibility with existing manufacturing processes, and potential for mass production. Weaknesses: May have limitations in high-temperature environments and potential long-term durability concerns in extreme conditions.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have pioneered the use of hydroxyethylcellulose in the development of biodegradable electronics. They have created a cellulose-based substrate infused with HEC that can host electronic components and circuits. This substrate is not only flexible but also dissolves in water after a predetermined period, addressing e-waste concerns. The team has successfully demonstrated functional electronic devices, including sensors and simple logic circuits, that can operate for weeks before degrading[3]. Additionally, they have explored the use of HEC as a component in ionic gels for creating soft, biocompatible actuators for medical devices[4].

Strengths: Environmentally friendly approach, potential for transient electronics in medical and environmental monitoring. Weaknesses: Limited lifespan may restrict applications, and performance may not match traditional electronics in all scenarios.

Innovative HEC Applications in Flexible Electronics

Stretchable composite conductors for flexible electronics, stretchable plasmonic devices, optical filters, and implantable devices and methods for manufacture thereof

PatentInactiveUS10629324B2

Innovation

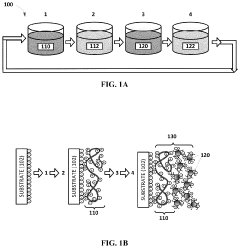

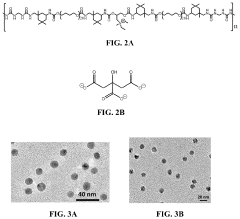

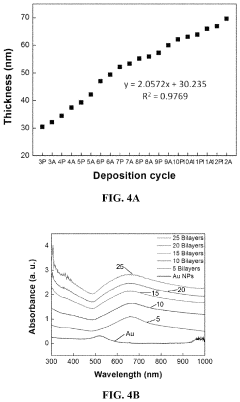

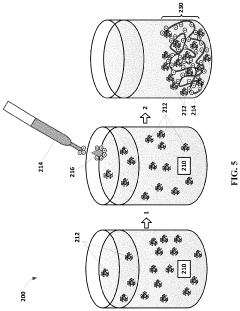

- Development of stretchable electrically conductive composite materials comprising an elastic polymer with a plurality of conductive nanoparticles, such as gold nanoparticles, which exhibit high conductivity even at significant tensile strains through layer-by-layer assembly or vacuum-assisted flocculation processes, allowing for the creation of materials with conductivities exceeding 500 S/cm at strains up to 75%.

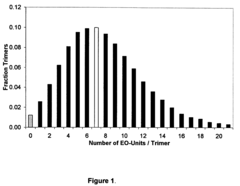

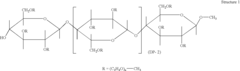

Blocky hydroxyethylcellulose, derivatives thereof, process of making, and uses thereof

PatentActiveUS20060182703A1

Innovation

- Development of 'blocky' HECs with non-uniform hydroxyethyl group distribution, characterized by an unsubstituted trimer ratio greater than 0.21 and hydroxyethyl molar substitution between 1.3 and 5.0, which are produced through a specific two-step alkalization and hydroxyethylation process, enhancing their associative behavior and solution viscosity.

Environmental Impact of HEC in Electronics Manufacturing

The environmental impact of hydroxyethylcellulose (HEC) in electronics manufacturing is a critical consideration as the flexible electronics industry continues to grow. HEC, a key component in the development of flexible electronic devices, offers both advantages and challenges from an environmental perspective.

One of the primary environmental benefits of HEC in electronics manufacturing is its biodegradability. As a cellulose-based polymer, HEC can naturally decompose over time, potentially reducing the long-term environmental impact of electronic waste. This characteristic aligns with the growing demand for more sustainable and eco-friendly materials in the electronics industry.

However, the production process of HEC does have some environmental implications. The manufacturing of HEC involves chemical modifications of cellulose, which can require significant energy inputs and potentially generate chemical waste. Manufacturers must implement proper waste management and treatment protocols to mitigate these environmental risks.

In terms of resource consumption, HEC production relies on cellulose, which is derived from renewable plant sources. This aspect contributes to the material's sustainability profile, especially when compared to petroleum-based alternatives. However, the increasing demand for HEC in flexible electronics could potentially lead to increased pressure on forestry resources if not managed responsibly.

The use of HEC in flexible electronics may also contribute to reduced electronic waste. Flexible devices tend to be more durable and less prone to physical damage compared to rigid electronics, potentially extending product lifespans. Additionally, the flexibility of HEC-based components may allow for more efficient use of materials, reducing overall waste in the manufacturing process.

Water usage is another environmental factor to consider in HEC production and application. The material's water-soluble nature means that water is often used in processing and cleaning stages. Manufacturers must implement water conservation and recycling measures to minimize the environmental impact of these processes.

As the flexible electronics industry expands, there is a growing focus on developing more environmentally friendly formulations of HEC and optimizing its production processes. Research is being conducted to explore greener synthesis methods, reduce energy consumption, and enhance the material's end-of-life recyclability.

The environmental impact of HEC in electronics manufacturing also extends to the disposal and recycling of flexible electronic devices. While HEC itself is biodegradable, its integration with other electronic components can complicate the recycling process. Developing effective separation and recycling techniques for HEC-based flexible electronics is an ongoing challenge that the industry must address to fully realize the material's environmental potential.

One of the primary environmental benefits of HEC in electronics manufacturing is its biodegradability. As a cellulose-based polymer, HEC can naturally decompose over time, potentially reducing the long-term environmental impact of electronic waste. This characteristic aligns with the growing demand for more sustainable and eco-friendly materials in the electronics industry.

However, the production process of HEC does have some environmental implications. The manufacturing of HEC involves chemical modifications of cellulose, which can require significant energy inputs and potentially generate chemical waste. Manufacturers must implement proper waste management and treatment protocols to mitigate these environmental risks.

In terms of resource consumption, HEC production relies on cellulose, which is derived from renewable plant sources. This aspect contributes to the material's sustainability profile, especially when compared to petroleum-based alternatives. However, the increasing demand for HEC in flexible electronics could potentially lead to increased pressure on forestry resources if not managed responsibly.

The use of HEC in flexible electronics may also contribute to reduced electronic waste. Flexible devices tend to be more durable and less prone to physical damage compared to rigid electronics, potentially extending product lifespans. Additionally, the flexibility of HEC-based components may allow for more efficient use of materials, reducing overall waste in the manufacturing process.

Water usage is another environmental factor to consider in HEC production and application. The material's water-soluble nature means that water is often used in processing and cleaning stages. Manufacturers must implement water conservation and recycling measures to minimize the environmental impact of these processes.

As the flexible electronics industry expands, there is a growing focus on developing more environmentally friendly formulations of HEC and optimizing its production processes. Research is being conducted to explore greener synthesis methods, reduce energy consumption, and enhance the material's end-of-life recyclability.

The environmental impact of HEC in electronics manufacturing also extends to the disposal and recycling of flexible electronic devices. While HEC itself is biodegradable, its integration with other electronic components can complicate the recycling process. Developing effective separation and recycling techniques for HEC-based flexible electronics is an ongoing challenge that the industry must address to fully realize the material's environmental potential.

Intellectual Property Landscape for HEC in Flexible Electronics

The intellectual property landscape for hydroxyethylcellulose (HEC) in flexible electronics is characterized by a growing number of patents and innovations, reflecting the increasing importance of this material in the field. HEC, a cellulose derivative, has gained significant attention due to its unique properties that make it suitable for various applications in flexible electronics.

Patent analysis reveals a steady increase in HEC-related patents for flexible electronics over the past decade. Major technology companies and research institutions have been actively filing patents, with a focus on improving the material's properties and exploring novel applications. The patent landscape is diverse, covering areas such as flexible displays, sensors, and wearable devices.

Key patent holders in this domain include multinational corporations with strong research and development capabilities in materials science and electronics. These companies have been strategically building their patent portfolios to secure their positions in the emerging flexible electronics market. Additionally, several universities and research institutes have also made significant contributions to the patent landscape, often focusing on fundamental research and novel applications of HEC in flexible electronics.

The geographical distribution of patents shows a concentration in countries with advanced technology sectors, such as the United States, Japan, South Korea, and China. This distribution aligns with the global centers of electronics manufacturing and research, indicating the strategic importance of HEC in these regions' technological development plans.

Patent classifications related to HEC in flexible electronics primarily fall under categories such as conductive polymers, flexible substrates, and electronic component fabrication methods. This diverse range of classifications highlights the versatility of HEC and its potential applications across various aspects of flexible electronics manufacturing.

Recent patent trends indicate a growing interest in combining HEC with other materials to enhance performance characteristics such as flexibility, conductivity, and durability. Patents focusing on novel processing techniques for HEC, aimed at improving its integration into flexible electronic devices, have also seen an uptick.

The intellectual property landscape also reveals emerging application areas for HEC in flexible electronics, including biocompatible sensors, energy storage devices, and smart textiles. These areas represent potential growth opportunities for companies investing in HEC-related technologies.

Overall, the intellectual property landscape for HEC in flexible electronics is dynamic and competitive, with continuous innovations driving the field forward. As the technology matures, it is likely that patent activities will further intensify, potentially leading to increased collaborations and licensing agreements among key players in the industry.

Patent analysis reveals a steady increase in HEC-related patents for flexible electronics over the past decade. Major technology companies and research institutions have been actively filing patents, with a focus on improving the material's properties and exploring novel applications. The patent landscape is diverse, covering areas such as flexible displays, sensors, and wearable devices.

Key patent holders in this domain include multinational corporations with strong research and development capabilities in materials science and electronics. These companies have been strategically building their patent portfolios to secure their positions in the emerging flexible electronics market. Additionally, several universities and research institutes have also made significant contributions to the patent landscape, often focusing on fundamental research and novel applications of HEC in flexible electronics.

The geographical distribution of patents shows a concentration in countries with advanced technology sectors, such as the United States, Japan, South Korea, and China. This distribution aligns with the global centers of electronics manufacturing and research, indicating the strategic importance of HEC in these regions' technological development plans.

Patent classifications related to HEC in flexible electronics primarily fall under categories such as conductive polymers, flexible substrates, and electronic component fabrication methods. This diverse range of classifications highlights the versatility of HEC and its potential applications across various aspects of flexible electronics manufacturing.

Recent patent trends indicate a growing interest in combining HEC with other materials to enhance performance characteristics such as flexibility, conductivity, and durability. Patents focusing on novel processing techniques for HEC, aimed at improving its integration into flexible electronic devices, have also seen an uptick.

The intellectual property landscape also reveals emerging application areas for HEC in flexible electronics, including biocompatible sensors, energy storage devices, and smart textiles. These areas represent potential growth opportunities for companies investing in HEC-related technologies.

Overall, the intellectual property landscape for HEC in flexible electronics is dynamic and competitive, with continuous innovations driving the field forward. As the technology matures, it is likely that patent activities will further intensify, potentially leading to increased collaborations and licensing agreements among key players in the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!