Role of Hydroxyethylcellulose in Reducing Greenhouse Gas Emissions

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEC and GHG Reduction: Background and Objectives

Hydroxyethylcellulose (HEC) has emerged as a promising material in the global effort to reduce greenhouse gas (GHG) emissions. This natural polymer, derived from cellulose, has garnered significant attention due to its versatile properties and potential applications in various industries. The development of HEC technology has been driven by the urgent need to address climate change and the increasing demand for sustainable materials.

The evolution of HEC in the context of GHG reduction can be traced back to the early 2000s when researchers began exploring its potential as a bio-based alternative to petroleum-derived products. Initially, HEC was primarily used in the pharmaceutical and personal care industries. However, its unique properties, such as water solubility, film-forming ability, and biodegradability, soon attracted attention from environmental scientists and engineers seeking innovative solutions to combat climate change.

Over the past two decades, the role of HEC in reducing GHG emissions has expanded significantly. Its applications now span across multiple sectors, including construction, agriculture, and energy production. In the construction industry, HEC has been incorporated into cement formulations to enhance the material's properties while reducing the carbon footprint of concrete production. In agriculture, HEC-based hydrogels have shown promise in improving water retention in soil, potentially reducing water consumption and associated energy use in irrigation systems.

The primary objective of utilizing HEC in GHG reduction efforts is to develop sustainable alternatives to carbon-intensive materials and processes. By leveraging the unique properties of HEC, researchers and industry professionals aim to create innovative solutions that can significantly lower carbon emissions across various sectors. These objectives align with global climate goals, such as those set forth in the Paris Agreement, which calls for limiting global temperature increase to well below 2 degrees Celsius above pre-industrial levels.

Current research and development efforts focus on optimizing HEC production processes to further reduce its environmental impact and enhance its effectiveness in GHG reduction applications. Scientists are exploring new methods of cellulose extraction and modification to improve the efficiency and sustainability of HEC production. Additionally, there is ongoing work to expand the range of HEC applications in emerging fields such as carbon capture and storage, where its unique properties could potentially play a crucial role in developing more effective and environmentally friendly technologies.

As the world continues to grapple with the challenges of climate change, the role of HEC in reducing GHG emissions is expected to grow. The technology's potential to replace carbon-intensive materials and improve the efficiency of various industrial processes positions it as a key player in the transition to a low-carbon economy. Future developments in HEC technology are likely to focus on enhancing its performance in existing applications while also exploring novel uses that could further contribute to global GHG reduction efforts.

The evolution of HEC in the context of GHG reduction can be traced back to the early 2000s when researchers began exploring its potential as a bio-based alternative to petroleum-derived products. Initially, HEC was primarily used in the pharmaceutical and personal care industries. However, its unique properties, such as water solubility, film-forming ability, and biodegradability, soon attracted attention from environmental scientists and engineers seeking innovative solutions to combat climate change.

Over the past two decades, the role of HEC in reducing GHG emissions has expanded significantly. Its applications now span across multiple sectors, including construction, agriculture, and energy production. In the construction industry, HEC has been incorporated into cement formulations to enhance the material's properties while reducing the carbon footprint of concrete production. In agriculture, HEC-based hydrogels have shown promise in improving water retention in soil, potentially reducing water consumption and associated energy use in irrigation systems.

The primary objective of utilizing HEC in GHG reduction efforts is to develop sustainable alternatives to carbon-intensive materials and processes. By leveraging the unique properties of HEC, researchers and industry professionals aim to create innovative solutions that can significantly lower carbon emissions across various sectors. These objectives align with global climate goals, such as those set forth in the Paris Agreement, which calls for limiting global temperature increase to well below 2 degrees Celsius above pre-industrial levels.

Current research and development efforts focus on optimizing HEC production processes to further reduce its environmental impact and enhance its effectiveness in GHG reduction applications. Scientists are exploring new methods of cellulose extraction and modification to improve the efficiency and sustainability of HEC production. Additionally, there is ongoing work to expand the range of HEC applications in emerging fields such as carbon capture and storage, where its unique properties could potentially play a crucial role in developing more effective and environmentally friendly technologies.

As the world continues to grapple with the challenges of climate change, the role of HEC in reducing GHG emissions is expected to grow. The technology's potential to replace carbon-intensive materials and improve the efficiency of various industrial processes positions it as a key player in the transition to a low-carbon economy. Future developments in HEC technology are likely to focus on enhancing its performance in existing applications while also exploring novel uses that could further contribute to global GHG reduction efforts.

Market Analysis for HEC in Emission Reduction

The market for hydroxyethylcellulose (HEC) in emission reduction applications is experiencing significant growth, driven by increasing environmental regulations and a global push towards sustainability. As industries seek innovative solutions to reduce their carbon footprint, HEC has emerged as a promising material with diverse applications in emission control technologies.

In the construction sector, HEC is gaining traction as an additive in cement and concrete formulations. Its ability to enhance the rheological properties of these materials allows for improved workability and reduced water content, leading to stronger and more durable structures. This not only reduces the overall cement consumption but also decreases the associated carbon emissions from cement production, which is a major contributor to global greenhouse gas emissions.

The oil and gas industry is another key market for HEC in emission reduction. As a viscosifier in drilling fluids, HEC helps optimize drilling operations, reducing the energy required and minimizing waste. Moreover, its use in enhanced oil recovery techniques can improve the efficiency of oil extraction, potentially reducing the need for new drilling sites and associated emissions.

In the automotive sector, HEC is finding applications in the development of advanced catalytic converters and exhaust gas treatment systems. Its film-forming properties and thermal stability make it an excellent binder for catalyst coatings, enhancing the efficiency of emission control devices and helping vehicles meet increasingly stringent emission standards.

The water treatment industry is also adopting HEC-based solutions for reducing emissions indirectly. By improving the efficiency of water purification processes, HEC helps reduce the energy consumption and chemical usage in treatment plants, thereby lowering their overall carbon footprint.

Market analysts project a compound annual growth rate (CAGR) for HEC in emission reduction applications to exceed the overall HEC market growth rate over the next five years. This accelerated growth is attributed to the increasing adoption of green technologies across industries and the material's versatility in addressing various emission-related challenges.

Geographically, North America and Europe are currently the largest markets for HEC in emission reduction applications, owing to stringent environmental regulations and a strong focus on sustainable development. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing environmental awareness, and government initiatives to combat air pollution and climate change.

As the market expands, collaborations between HEC manufacturers and end-users are becoming more common, fostering innovation and the development of tailored solutions for specific emission reduction needs. This trend is expected to further drive market growth and technological advancements in the coming years.

In the construction sector, HEC is gaining traction as an additive in cement and concrete formulations. Its ability to enhance the rheological properties of these materials allows for improved workability and reduced water content, leading to stronger and more durable structures. This not only reduces the overall cement consumption but also decreases the associated carbon emissions from cement production, which is a major contributor to global greenhouse gas emissions.

The oil and gas industry is another key market for HEC in emission reduction. As a viscosifier in drilling fluids, HEC helps optimize drilling operations, reducing the energy required and minimizing waste. Moreover, its use in enhanced oil recovery techniques can improve the efficiency of oil extraction, potentially reducing the need for new drilling sites and associated emissions.

In the automotive sector, HEC is finding applications in the development of advanced catalytic converters and exhaust gas treatment systems. Its film-forming properties and thermal stability make it an excellent binder for catalyst coatings, enhancing the efficiency of emission control devices and helping vehicles meet increasingly stringent emission standards.

The water treatment industry is also adopting HEC-based solutions for reducing emissions indirectly. By improving the efficiency of water purification processes, HEC helps reduce the energy consumption and chemical usage in treatment plants, thereby lowering their overall carbon footprint.

Market analysts project a compound annual growth rate (CAGR) for HEC in emission reduction applications to exceed the overall HEC market growth rate over the next five years. This accelerated growth is attributed to the increasing adoption of green technologies across industries and the material's versatility in addressing various emission-related challenges.

Geographically, North America and Europe are currently the largest markets for HEC in emission reduction applications, owing to stringent environmental regulations and a strong focus on sustainable development. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing environmental awareness, and government initiatives to combat air pollution and climate change.

As the market expands, collaborations between HEC manufacturers and end-users are becoming more common, fostering innovation and the development of tailored solutions for specific emission reduction needs. This trend is expected to further drive market growth and technological advancements in the coming years.

Current Status and Challenges in HEC Application

Hydroxyethylcellulose (HEC) has gained significant attention in recent years for its potential role in reducing greenhouse gas emissions. Currently, HEC is widely used in various industries, including construction, pharmaceuticals, and personal care products, due to its excellent thickening, binding, and film-forming properties. In the context of greenhouse gas reduction, HEC is being explored for its applications in carbon capture and storage (CCS) technologies, as well as in the development of eco-friendly materials.

The current status of HEC application in greenhouse gas reduction is promising, yet still in its early stages. Research has shown that HEC can be effectively used as a rheology modifier in CO2 capture solvents, enhancing the efficiency of absorption processes. Additionally, HEC-based hydrogels have demonstrated potential for selective CO2 adsorption, offering a novel approach to carbon capture. In the construction industry, HEC is being incorporated into cement formulations to improve the carbon footprint of concrete production.

Despite these advancements, several challenges hinder the widespread adoption of HEC in greenhouse gas reduction strategies. One of the primary obstacles is the scalability of HEC-based solutions. While laboratory-scale experiments have shown promising results, translating these findings into large-scale industrial applications remains a significant challenge. The cost-effectiveness of HEC-based technologies compared to existing carbon capture methods is another crucial factor that needs to be addressed.

Furthermore, the environmental impact of HEC production itself needs careful consideration. The manufacturing process of HEC involves chemical modifications of cellulose, which may have its own carbon footprint. Striking a balance between the greenhouse gas reduction potential of HEC applications and the emissions associated with its production is a complex challenge that researchers and industry professionals are actively working to resolve.

Another hurdle in HEC application is the limited understanding of its long-term stability and performance under various environmental conditions. For instance, in CCS applications, the durability of HEC-based materials when exposed to high pressures and corrosive environments over extended periods needs further investigation. Additionally, the potential for biodegradation of HEC in certain applications may affect its long-term effectiveness in greenhouse gas reduction strategies.

Regulatory frameworks and standardization also pose challenges to the widespread adoption of HEC in greenhouse gas reduction technologies. The lack of specific guidelines and standards for HEC-based solutions in environmental applications creates uncertainty for both manufacturers and end-users. Developing comprehensive regulatory frameworks that address safety, efficacy, and environmental impact will be crucial for the future growth of HEC applications in this field.

The current status of HEC application in greenhouse gas reduction is promising, yet still in its early stages. Research has shown that HEC can be effectively used as a rheology modifier in CO2 capture solvents, enhancing the efficiency of absorption processes. Additionally, HEC-based hydrogels have demonstrated potential for selective CO2 adsorption, offering a novel approach to carbon capture. In the construction industry, HEC is being incorporated into cement formulations to improve the carbon footprint of concrete production.

Despite these advancements, several challenges hinder the widespread adoption of HEC in greenhouse gas reduction strategies. One of the primary obstacles is the scalability of HEC-based solutions. While laboratory-scale experiments have shown promising results, translating these findings into large-scale industrial applications remains a significant challenge. The cost-effectiveness of HEC-based technologies compared to existing carbon capture methods is another crucial factor that needs to be addressed.

Furthermore, the environmental impact of HEC production itself needs careful consideration. The manufacturing process of HEC involves chemical modifications of cellulose, which may have its own carbon footprint. Striking a balance between the greenhouse gas reduction potential of HEC applications and the emissions associated with its production is a complex challenge that researchers and industry professionals are actively working to resolve.

Another hurdle in HEC application is the limited understanding of its long-term stability and performance under various environmental conditions. For instance, in CCS applications, the durability of HEC-based materials when exposed to high pressures and corrosive environments over extended periods needs further investigation. Additionally, the potential for biodegradation of HEC in certain applications may affect its long-term effectiveness in greenhouse gas reduction strategies.

Regulatory frameworks and standardization also pose challenges to the widespread adoption of HEC in greenhouse gas reduction technologies. The lack of specific guidelines and standards for HEC-based solutions in environmental applications creates uncertainty for both manufacturers and end-users. Developing comprehensive regulatory frameworks that address safety, efficacy, and environmental impact will be crucial for the future growth of HEC applications in this field.

Existing HEC-based GHG Reduction Solutions

01 Hydroxyethylcellulose in greenhouse gas reduction

Hydroxyethylcellulose (HEC) can be utilized in various applications to reduce greenhouse gas emissions. Its properties as a thickening agent and stabilizer make it useful in formulations that can help decrease carbon footprint in industrial processes and products.- Use of hydroxyethylcellulose in greenhouse gas reduction: Hydroxyethylcellulose can be utilized in various applications to help reduce greenhouse gas emissions. Its properties as a thickening agent and stabilizer make it useful in formulations designed to capture or sequester carbon dioxide and other greenhouse gases.

- Hydroxyethylcellulose in sustainable packaging: Hydroxyethylcellulose can be incorporated into biodegradable packaging materials, reducing the carbon footprint associated with traditional plastic packaging. This application helps decrease greenhouse gas emissions related to packaging production and disposal.

- Hydroxyethylcellulose in energy-efficient coatings: When used in coatings and films, hydroxyethylcellulose can enhance insulation properties, leading to improved energy efficiency in buildings and vehicles. This results in reduced energy consumption and lower greenhouse gas emissions from heating and cooling systems.

- Hydroxyethylcellulose in carbon capture technologies: Hydroxyethylcellulose can be used in the development of advanced carbon capture technologies, such as membranes or absorbents, to help remove greenhouse gases from industrial emissions or directly from the atmosphere.

- Hydroxyethylcellulose in biofuel production: The use of hydroxyethylcellulose in biofuel production processes can improve efficiency and yield, potentially reducing the overall carbon footprint of biofuel manufacturing. This contributes to the reduction of greenhouse gas emissions in the transportation sector.

02 HEC in sustainable packaging solutions

Hydroxyethylcellulose can be incorporated into eco-friendly packaging materials, contributing to the reduction of greenhouse gas emissions associated with traditional plastic packaging. Its biodegradable nature and ability to form films make it a promising alternative for sustainable packaging solutions.Expand Specific Solutions03 Use of HEC in carbon capture technologies

Hydroxyethylcellulose can be employed in the development of carbon capture and storage technologies. Its unique properties allow it to be used in formulations that enhance the efficiency of carbon dioxide absorption and sequestration processes, contributing to greenhouse gas reduction efforts.Expand Specific Solutions04 HEC in energy-efficient construction materials

Hydroxyethylcellulose can be utilized in the production of energy-efficient construction materials. Its inclusion in building products can improve insulation properties, reducing energy consumption and associated greenhouse gas emissions in the built environment.Expand Specific Solutions05 HEC-based solutions for renewable energy technologies

Hydroxyethylcellulose can be incorporated into various components of renewable energy technologies, such as solar panels and wind turbines. Its use in these applications can enhance performance and durability, contributing to the broader adoption of clean energy solutions and reduction of greenhouse gas emissions.Expand Specific Solutions

Key Players in HEC and Emission Reduction

The role of hydroxyethylcellulose in reducing greenhouse gas emissions is an emerging field with growing market potential. The industry is in its early development stage, characterized by increasing research and pilot projects. Market size is expanding as more companies recognize the environmental benefits and regulatory pressures to reduce emissions. Technologically, it's still evolving, with companies like Dow Global Technologies, Hercules Corp., and Danisco US Inc. leading innovation. These firms are developing advanced formulations and applications, focusing on improving efficiency and scalability. While promising, the technology requires further refinement and large-scale implementation to fully realize its potential in combating climate change.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies LLC has developed innovative applications of hydroxyethylcellulose (HEC) in reducing greenhouse gas emissions. Their approach focuses on utilizing HEC as a key component in advanced carbon capture and storage (CCS) technologies. By incorporating HEC into specialized membranes, Dow has created highly efficient CO2 separation systems that can be integrated into industrial processes[1]. These membranes exhibit enhanced selectivity and permeability for CO2, allowing for more effective capture from flue gases. Additionally, Dow has explored the use of HEC-based hydrogels as a medium for CO2 absorption, which can be regenerated with lower energy input compared to traditional amine-based systems[3]. The company has also investigated the potential of HEC as a biodegradable alternative to petroleum-based plastics, indirectly contributing to emissions reduction through sustainable material production[5].

Strengths: Highly efficient CO2 separation, lower energy requirements for regeneration, potential for sustainable materials production. Weaknesses: May require significant initial investment for industrial implementation, performance in varied industrial conditions needs further validation.

Hercules Corp.

Technical Solution: Hercules Corp. has developed a novel approach using hydroxyethylcellulose (HEC) to reduce greenhouse gas emissions in the oil and gas industry. Their technology focuses on using HEC as a key ingredient in advanced drilling fluids that minimize methane leakage during extraction processes. By creating a more effective seal in wellbores, these HEC-based fluids can significantly reduce fugitive methane emissions, which are a major contributor to the industry's greenhouse gas footprint[2]. The company has also explored the use of HEC in enhanced oil recovery techniques, where it acts as a thickening agent for CO2 injection, improving the efficiency of carbon sequestration in depleted oil fields[4]. Furthermore, Hercules has investigated the potential of HEC-based coatings for pipelines to reduce corrosion and subsequent methane leaks, thereby indirectly contributing to emissions reduction[6].

Strengths: Directly addresses a major source of greenhouse gas emissions in the oil and gas industry, dual benefit of improved extraction efficiency and emissions reduction. Weaknesses: Limited to specific industry applications, may require changes to existing infrastructure and processes.

Core Innovations in HEC for Emission Control

Reduction of greenhouse gas emission

PatentActiveUS20180002262A1

Innovation

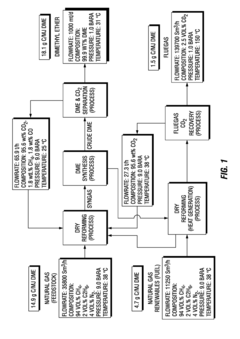

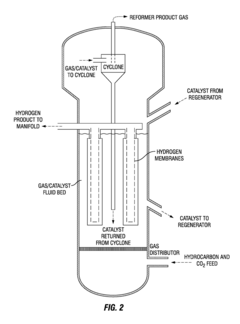

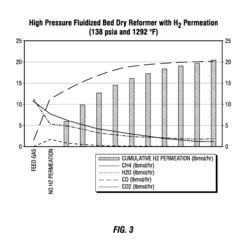

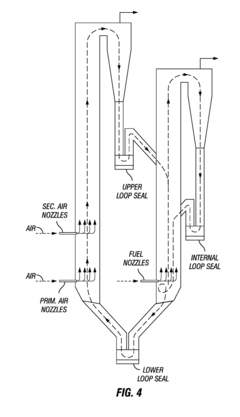

- A method involving a fluidized bed dry reforming reactor with a hydrogen membrane that converts natural gas to synthesis gas, which is then used to produce dimethyl ether (DME), utilizing renewable fuels in the regenerator and minimizing water and oxygen usage, allowing for lower GHG emissions and efficient production of a low-emission diesel fuel substitute.

Expression of an active carrier from xylose in genetically modified saccharomyces cerevisae

PatentInactiveUS20090053784A1

Innovation

- Isolation and cloning of a gene encoding an active xylose/glucose transporter from Candida intermedia with high affinity, which is then expressed in Saccharomyces cerevisiae, enabling efficient xylose consumption and fermentation by enhancing the xylose/proton symport mechanism.

Environmental Regulations and HEC Applications

The role of Hydroxyethylcellulose (HEC) in reducing greenhouse gas emissions is increasingly influenced by environmental regulations across various industries. As governments worldwide implement stricter policies to combat climate change, the applications of HEC have come under scrutiny for their potential to contribute to sustainability efforts.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for the use of chemicals in industrial processes, including those involving HEC. These regulations aim to minimize the environmental impact of manufacturing and encourage the adoption of eco-friendly alternatives. As a result, industries utilizing HEC are required to assess and report their emissions, driving innovation in HEC applications to meet compliance standards.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has also impacted HEC usage. Under REACH, manufacturers and importers must provide detailed information on the environmental and health impacts of chemicals, including HEC. This has led to increased transparency in the supply chain and prompted research into the lifecycle assessment of HEC-based products.

In the construction sector, green building certifications such as LEED (Leadership in Energy and Environmental Design) have created incentives for using materials with lower environmental footprints. HEC's role in cement and concrete admixtures has been reevaluated to ensure compliance with these standards, leading to the development of more sustainable formulations.

The personal care and cosmetics industry has seen a shift towards natural and biodegradable ingredients, influenced by regulations like the EU Cosmetics Regulation. This has spurred research into plant-based alternatives to synthetic HEC, as well as improvements in the production processes of HEC to reduce its environmental impact.

In the oil and gas sector, regulations on hydraulic fracturing have led to increased scrutiny of the chemicals used in fracking fluids, including HEC. Companies are now required to disclose the composition of these fluids and demonstrate their environmental safety, driving innovation in HEC formulations that are both effective and environmentally responsible.

The textile industry, another significant user of HEC, has been affected by regulations on wastewater treatment and chemical management. Initiatives like the Zero Discharge of Hazardous Chemicals (ZDHC) programme have pushed for the development of HEC-based products that minimize water pollution and reduce the carbon footprint of textile processing.

As environmental regulations continue to evolve, the applications of HEC are likely to undergo further refinement and innovation. The focus will be on developing HEC-based solutions that not only meet regulatory requirements but also actively contribute to reducing greenhouse gas emissions across various industries.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for the use of chemicals in industrial processes, including those involving HEC. These regulations aim to minimize the environmental impact of manufacturing and encourage the adoption of eco-friendly alternatives. As a result, industries utilizing HEC are required to assess and report their emissions, driving innovation in HEC applications to meet compliance standards.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has also impacted HEC usage. Under REACH, manufacturers and importers must provide detailed information on the environmental and health impacts of chemicals, including HEC. This has led to increased transparency in the supply chain and prompted research into the lifecycle assessment of HEC-based products.

In the construction sector, green building certifications such as LEED (Leadership in Energy and Environmental Design) have created incentives for using materials with lower environmental footprints. HEC's role in cement and concrete admixtures has been reevaluated to ensure compliance with these standards, leading to the development of more sustainable formulations.

The personal care and cosmetics industry has seen a shift towards natural and biodegradable ingredients, influenced by regulations like the EU Cosmetics Regulation. This has spurred research into plant-based alternatives to synthetic HEC, as well as improvements in the production processes of HEC to reduce its environmental impact.

In the oil and gas sector, regulations on hydraulic fracturing have led to increased scrutiny of the chemicals used in fracking fluids, including HEC. Companies are now required to disclose the composition of these fluids and demonstrate their environmental safety, driving innovation in HEC formulations that are both effective and environmentally responsible.

The textile industry, another significant user of HEC, has been affected by regulations on wastewater treatment and chemical management. Initiatives like the Zero Discharge of Hazardous Chemicals (ZDHC) programme have pushed for the development of HEC-based products that minimize water pollution and reduce the carbon footprint of textile processing.

As environmental regulations continue to evolve, the applications of HEC are likely to undergo further refinement and innovation. The focus will be on developing HEC-based solutions that not only meet regulatory requirements but also actively contribute to reducing greenhouse gas emissions across various industries.

Life Cycle Assessment of HEC in GHG Reduction

Life Cycle Assessment (LCA) of Hydroxyethylcellulose (HEC) in greenhouse gas (GHG) reduction provides a comprehensive evaluation of the environmental impacts associated with HEC production, use, and disposal. This assessment is crucial for understanding the net effect of HEC on GHG emissions throughout its entire lifecycle.

The production phase of HEC involves the chemical modification of cellulose, typically derived from wood or cotton. This process requires energy inputs and chemical reagents, which contribute to the overall carbon footprint. However, the renewable nature of the cellulose source partially offsets these emissions. The manufacturing process also involves water consumption and potential chemical waste, which must be factored into the overall environmental impact.

During the use phase, HEC's role in reducing GHG emissions becomes more apparent. As a thickening agent and stabilizer in various applications, HEC can improve the efficiency of products and processes. For instance, in the construction industry, HEC enhances the performance of cement-based materials, potentially leading to reduced material consumption and improved durability. This, in turn, can result in lower GHG emissions associated with construction and maintenance activities.

In water treatment applications, HEC's flocculating properties can improve the efficiency of wastewater treatment processes. This leads to reduced energy consumption in treatment plants and potentially lower methane emissions from inadequately treated wastewater. Similarly, in the oil and gas industry, HEC's use in drilling fluids can optimize drilling operations, potentially reducing the overall energy consumption and associated GHG emissions.

The end-of-life phase of HEC presents both challenges and opportunities for GHG reduction. As a biodegradable polymer, HEC can decompose naturally, avoiding the long-term GHG emissions associated with non-biodegradable materials in landfills. However, the decomposition process itself may release some GHGs, particularly if not managed properly.

Comparative LCA studies have shown that the use of HEC in various applications generally results in a net reduction of GHG emissions when compared to alternative materials or processes. However, the magnitude of this reduction varies depending on the specific application and the alternatives considered.

It is important to note that the LCA of HEC must also consider indirect effects on GHG emissions. For example, the increased use of HEC in certain industries may lead to changes in supply chains or manufacturing processes that have their own GHG implications. These broader systemic effects should be included in a comprehensive LCA to provide a holistic view of HEC's role in GHG reduction.

The production phase of HEC involves the chemical modification of cellulose, typically derived from wood or cotton. This process requires energy inputs and chemical reagents, which contribute to the overall carbon footprint. However, the renewable nature of the cellulose source partially offsets these emissions. The manufacturing process also involves water consumption and potential chemical waste, which must be factored into the overall environmental impact.

During the use phase, HEC's role in reducing GHG emissions becomes more apparent. As a thickening agent and stabilizer in various applications, HEC can improve the efficiency of products and processes. For instance, in the construction industry, HEC enhances the performance of cement-based materials, potentially leading to reduced material consumption and improved durability. This, in turn, can result in lower GHG emissions associated with construction and maintenance activities.

In water treatment applications, HEC's flocculating properties can improve the efficiency of wastewater treatment processes. This leads to reduced energy consumption in treatment plants and potentially lower methane emissions from inadequately treated wastewater. Similarly, in the oil and gas industry, HEC's use in drilling fluids can optimize drilling operations, potentially reducing the overall energy consumption and associated GHG emissions.

The end-of-life phase of HEC presents both challenges and opportunities for GHG reduction. As a biodegradable polymer, HEC can decompose naturally, avoiding the long-term GHG emissions associated with non-biodegradable materials in landfills. However, the decomposition process itself may release some GHGs, particularly if not managed properly.

Comparative LCA studies have shown that the use of HEC in various applications generally results in a net reduction of GHG emissions when compared to alternative materials or processes. However, the magnitude of this reduction varies depending on the specific application and the alternatives considered.

It is important to note that the LCA of HEC must also consider indirect effects on GHG emissions. For example, the increased use of HEC in certain industries may lead to changes in supply chains or manufacturing processes that have their own GHG implications. These broader systemic effects should be included in a comprehensive LCA to provide a holistic view of HEC's role in GHG reduction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!