How Hydroxyethylcellulose Enhances Enzymatic Reaction Efficiencies

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEC and Enzyme Synergy

Hydroxyethylcellulose (HEC) and enzymes exhibit a remarkable synergy that has garnered significant attention in various industrial applications. This synergistic relationship stems from the unique properties of HEC as a cellulose derivative and its interaction with enzymatic processes. HEC, known for its thickening and stabilizing properties, creates an environment that can enhance enzymatic reactions in multiple ways.

One of the primary mechanisms through which HEC enhances enzymatic reaction efficiencies is by modifying the rheological properties of the reaction medium. The addition of HEC increases the viscosity of the solution, which can lead to improved substrate-enzyme interactions. This increased contact time between enzymes and their substrates often results in higher reaction rates and improved overall efficiency.

Furthermore, HEC has been observed to stabilize enzymes in solution, potentially extending their active lifespan. This stabilization effect is particularly beneficial in industrial processes where maintaining enzyme activity over extended periods is crucial. The protective nature of HEC may shield enzymes from denaturation caused by environmental factors such as temperature fluctuations or pH changes.

Another aspect of the HEC-enzyme synergy lies in the ability of HEC to create a more favorable microenvironment for enzymatic reactions. The hydrophilic nature of HEC can help in maintaining optimal hydration levels around enzyme molecules, which is essential for their catalytic activity. This hydration management can be particularly important in reactions involving water-sensitive substrates or products.

The interaction between HEC and enzymes also influences the diffusion characteristics of reactants and products within the reaction medium. While the increased viscosity might initially seem to hinder diffusion, studies have shown that in many cases, the structured network formed by HEC can actually facilitate the movement of molecules in a more controlled manner. This controlled diffusion can lead to more efficient enzymatic processes, especially in complex reaction systems.

Moreover, the synergy extends to the realm of enzyme immobilization. HEC has been utilized as a matrix for enzyme immobilization, providing a supportive environment that can enhance enzyme stability and reusability. This application is particularly valuable in continuous enzymatic processes, where immobilized enzymes can be used repeatedly without significant loss of activity.

In biotechnology and pharmaceutical applications, the HEC-enzyme synergy has been exploited to develop controlled release systems. The ability of HEC to form hydrogels that respond to enzymatic degradation allows for the design of smart delivery systems where the release of active compounds is triggered by specific enzymatic activities.

One of the primary mechanisms through which HEC enhances enzymatic reaction efficiencies is by modifying the rheological properties of the reaction medium. The addition of HEC increases the viscosity of the solution, which can lead to improved substrate-enzyme interactions. This increased contact time between enzymes and their substrates often results in higher reaction rates and improved overall efficiency.

Furthermore, HEC has been observed to stabilize enzymes in solution, potentially extending their active lifespan. This stabilization effect is particularly beneficial in industrial processes where maintaining enzyme activity over extended periods is crucial. The protective nature of HEC may shield enzymes from denaturation caused by environmental factors such as temperature fluctuations or pH changes.

Another aspect of the HEC-enzyme synergy lies in the ability of HEC to create a more favorable microenvironment for enzymatic reactions. The hydrophilic nature of HEC can help in maintaining optimal hydration levels around enzyme molecules, which is essential for their catalytic activity. This hydration management can be particularly important in reactions involving water-sensitive substrates or products.

The interaction between HEC and enzymes also influences the diffusion characteristics of reactants and products within the reaction medium. While the increased viscosity might initially seem to hinder diffusion, studies have shown that in many cases, the structured network formed by HEC can actually facilitate the movement of molecules in a more controlled manner. This controlled diffusion can lead to more efficient enzymatic processes, especially in complex reaction systems.

Moreover, the synergy extends to the realm of enzyme immobilization. HEC has been utilized as a matrix for enzyme immobilization, providing a supportive environment that can enhance enzyme stability and reusability. This application is particularly valuable in continuous enzymatic processes, where immobilized enzymes can be used repeatedly without significant loss of activity.

In biotechnology and pharmaceutical applications, the HEC-enzyme synergy has been exploited to develop controlled release systems. The ability of HEC to form hydrogels that respond to enzymatic degradation allows for the design of smart delivery systems where the release of active compounds is triggered by specific enzymatic activities.

Market Demand Analysis

The market demand for hydroxyethylcellulose (HEC) as an enzymatic reaction efficiency enhancer has been steadily growing across various industries. This versatile polymer, known for its thickening and stabilizing properties, has found increasing applications in sectors such as pharmaceuticals, cosmetics, food processing, and industrial biotechnology.

In the pharmaceutical industry, HEC's ability to improve enzymatic reaction efficiencies has led to its increased use in drug formulation and delivery systems. The demand for more efficient and targeted drug delivery mechanisms has driven the adoption of HEC in pharmaceutical processes, particularly in the development of controlled-release medications and enzyme-based therapies.

The cosmetics sector has also witnessed a surge in demand for HEC-enhanced enzymatic reactions. As consumers seek more natural and effective skincare products, manufacturers are turning to enzyme-based formulations. HEC's role in stabilizing these enzymatic reactions and improving their efficacy has made it a valuable ingredient in high-performance cosmetic products, including anti-aging creams, exfoliants, and hair care treatments.

In the food processing industry, HEC's potential to enhance enzymatic reactions has opened new avenues for product innovation. Its application in food enzymes has led to improved production processes, extended shelf life, and enhanced nutritional profiles of various food products. This has resulted in a growing demand from food manufacturers looking to optimize their production processes and meet consumer preferences for cleaner labels and natural ingredients.

The industrial biotechnology sector has emerged as a significant driver of HEC demand. As the industry moves towards more sustainable and eco-friendly processes, the use of enzymes in industrial applications has increased. HEC's ability to enhance the efficiency and stability of these enzymatic reactions has made it an essential component in various bioprocessing applications, including biofuel production, waste treatment, and the manufacturing of bio-based chemicals.

Market analysts project a compound annual growth rate (CAGR) for the global HEC market, driven largely by its applications in enhancing enzymatic reactions. This growth is expected to be particularly strong in emerging economies, where rapid industrialization and increasing adoption of biotechnology are creating new opportunities for HEC applications.

However, the market demand is not without challenges. Regulatory scrutiny of chemical additives in various industries may impact the adoption rate of HEC in certain applications. Additionally, the development of alternative materials that can enhance enzymatic reactions may pose competition to HEC in specific market segments.

In the pharmaceutical industry, HEC's ability to improve enzymatic reaction efficiencies has led to its increased use in drug formulation and delivery systems. The demand for more efficient and targeted drug delivery mechanisms has driven the adoption of HEC in pharmaceutical processes, particularly in the development of controlled-release medications and enzyme-based therapies.

The cosmetics sector has also witnessed a surge in demand for HEC-enhanced enzymatic reactions. As consumers seek more natural and effective skincare products, manufacturers are turning to enzyme-based formulations. HEC's role in stabilizing these enzymatic reactions and improving their efficacy has made it a valuable ingredient in high-performance cosmetic products, including anti-aging creams, exfoliants, and hair care treatments.

In the food processing industry, HEC's potential to enhance enzymatic reactions has opened new avenues for product innovation. Its application in food enzymes has led to improved production processes, extended shelf life, and enhanced nutritional profiles of various food products. This has resulted in a growing demand from food manufacturers looking to optimize their production processes and meet consumer preferences for cleaner labels and natural ingredients.

The industrial biotechnology sector has emerged as a significant driver of HEC demand. As the industry moves towards more sustainable and eco-friendly processes, the use of enzymes in industrial applications has increased. HEC's ability to enhance the efficiency and stability of these enzymatic reactions has made it an essential component in various bioprocessing applications, including biofuel production, waste treatment, and the manufacturing of bio-based chemicals.

Market analysts project a compound annual growth rate (CAGR) for the global HEC market, driven largely by its applications in enhancing enzymatic reactions. This growth is expected to be particularly strong in emerging economies, where rapid industrialization and increasing adoption of biotechnology are creating new opportunities for HEC applications.

However, the market demand is not without challenges. Regulatory scrutiny of chemical additives in various industries may impact the adoption rate of HEC in certain applications. Additionally, the development of alternative materials that can enhance enzymatic reactions may pose competition to HEC in specific market segments.

Current Challenges

Despite the promising potential of hydroxyethylcellulose (HEC) in enhancing enzymatic reaction efficiencies, several significant challenges persist in its widespread application and optimization. These challenges span across multiple domains, including molecular-level interactions, process engineering, and scalability issues.

One of the primary obstacles lies in fully understanding the complex interactions between HEC and various enzymes at the molecular level. While it is known that HEC can improve enzyme stability and activity, the exact mechanisms by which it achieves these effects are not yet fully elucidated. This lack of comprehensive understanding hampers the ability to predict and optimize HEC's performance across different enzymatic systems.

The heterogeneity of enzyme structures and reaction conditions presents another significant challenge. Different enzymes have unique structural characteristics and optimal operating conditions, making it difficult to develop a one-size-fits-all approach for HEC enhancement. Tailoring HEC properties to suit specific enzymes and reaction environments requires extensive research and experimentation, which can be time-consuming and resource-intensive.

Furthermore, the impact of HEC on enzyme kinetics and reaction rates is not uniform across all enzymatic systems. In some cases, while HEC may improve enzyme stability, it might simultaneously reduce reaction rates due to increased viscosity or altered substrate diffusion. Balancing these competing effects to achieve optimal overall reaction efficiency remains a significant challenge.

The scalability of HEC-enhanced enzymatic processes also presents hurdles in industrial applications. What works effectively at laboratory scale may not necessarily translate seamlessly to large-scale production environments. Issues such as mixing efficiency, heat transfer, and mass transfer can become more pronounced at industrial scales, potentially affecting the benefits provided by HEC.

Additionally, the long-term stability and recyclability of HEC-enzyme systems in continuous or repeated-batch processes are areas that require further investigation. The potential accumulation of HEC or its degradation products over multiple reaction cycles could impact enzyme performance and product purity, necessitating the development of effective regeneration or separation techniques.

Regulatory and safety considerations also pose challenges, particularly in applications involving food, pharmaceuticals, or other sensitive products. Ensuring that HEC and its potential breakdown products meet stringent safety and purity standards across various regulatory frameworks is crucial for widespread adoption.

Lastly, the economic viability of incorporating HEC into enzymatic processes on an industrial scale remains a challenge. While HEC can enhance reaction efficiencies, the additional cost of incorporating this material into existing processes must be justified by significant improvements in yield, product quality, or process economics. Developing cost-effective production methods for HEC and optimizing its use to maximize economic benefits are ongoing challenges in this field.

One of the primary obstacles lies in fully understanding the complex interactions between HEC and various enzymes at the molecular level. While it is known that HEC can improve enzyme stability and activity, the exact mechanisms by which it achieves these effects are not yet fully elucidated. This lack of comprehensive understanding hampers the ability to predict and optimize HEC's performance across different enzymatic systems.

The heterogeneity of enzyme structures and reaction conditions presents another significant challenge. Different enzymes have unique structural characteristics and optimal operating conditions, making it difficult to develop a one-size-fits-all approach for HEC enhancement. Tailoring HEC properties to suit specific enzymes and reaction environments requires extensive research and experimentation, which can be time-consuming and resource-intensive.

Furthermore, the impact of HEC on enzyme kinetics and reaction rates is not uniform across all enzymatic systems. In some cases, while HEC may improve enzyme stability, it might simultaneously reduce reaction rates due to increased viscosity or altered substrate diffusion. Balancing these competing effects to achieve optimal overall reaction efficiency remains a significant challenge.

The scalability of HEC-enhanced enzymatic processes also presents hurdles in industrial applications. What works effectively at laboratory scale may not necessarily translate seamlessly to large-scale production environments. Issues such as mixing efficiency, heat transfer, and mass transfer can become more pronounced at industrial scales, potentially affecting the benefits provided by HEC.

Additionally, the long-term stability and recyclability of HEC-enzyme systems in continuous or repeated-batch processes are areas that require further investigation. The potential accumulation of HEC or its degradation products over multiple reaction cycles could impact enzyme performance and product purity, necessitating the development of effective regeneration or separation techniques.

Regulatory and safety considerations also pose challenges, particularly in applications involving food, pharmaceuticals, or other sensitive products. Ensuring that HEC and its potential breakdown products meet stringent safety and purity standards across various regulatory frameworks is crucial for widespread adoption.

Lastly, the economic viability of incorporating HEC into enzymatic processes on an industrial scale remains a challenge. While HEC can enhance reaction efficiencies, the additional cost of incorporating this material into existing processes must be justified by significant improvements in yield, product quality, or process economics. Developing cost-effective production methods for HEC and optimizing its use to maximize economic benefits are ongoing challenges in this field.

HEC-Enzyme Solutions

01 Enzymatic modification of hydroxyethylcellulose

Enzymatic reactions can be used to modify hydroxyethylcellulose, altering its properties and potentially improving its efficiency in various applications. These modifications can include changes in viscosity, solubility, or functionality, which can be tailored for specific industrial uses.- Enzymatic modification of hydroxyethylcellulose: Enzymatic reactions can be used to modify hydroxyethylcellulose, improving its properties and reaction efficiencies. This process can involve various enzymes to alter the structure or functionality of hydroxyethylcellulose, potentially enhancing its performance in different applications.

- Optimization of reaction conditions for hydroxyethylcellulose: The efficiency of enzymatic reactions involving hydroxyethylcellulose can be improved by optimizing various reaction conditions. These may include temperature, pH, enzyme concentration, substrate concentration, and reaction time. Proper optimization can lead to increased reaction rates and higher yields.

- Use of specific enzymes for hydroxyethylcellulose modification: Certain enzymes have been identified as particularly effective for modifying hydroxyethylcellulose. These may include cellulases, xylanases, or other glycosidases. The choice of enzyme can significantly impact the reaction efficiency and the resulting properties of the modified hydroxyethylcellulose.

- Immobilization techniques for enzymes in hydroxyethylcellulose reactions: Enzyme immobilization techniques can be employed to enhance the efficiency and reusability of enzymes in hydroxyethylcellulose reactions. This approach can improve enzyme stability, allow for easier separation of the enzyme from the reaction mixture, and potentially increase overall reaction efficiency.

- Analysis and characterization of enzymatically modified hydroxyethylcellulose: Various analytical techniques can be used to characterize the products of enzymatic reactions involving hydroxyethylcellulose. These may include spectroscopic methods, chromatography, or rheological analysis. Proper characterization is crucial for understanding the efficiency of the enzymatic reaction and the properties of the modified hydroxyethylcellulose.

02 Optimization of reaction conditions for hydroxyethylcellulose

The efficiency of enzymatic reactions involving hydroxyethylcellulose can be improved by optimizing various reaction conditions. These may include temperature, pH, enzyme concentration, substrate concentration, and reaction time. Proper optimization can lead to increased yields and reduced processing times.Expand Specific Solutions03 Use of specific enzymes for hydroxyethylcellulose modification

Certain enzymes have been identified as particularly effective for modifying hydroxyethylcellulose. These may include cellulases, xylanases, or other carbohydrate-active enzymes. The choice of enzyme can significantly impact the reaction efficiency and the resulting properties of the modified hydroxyethylcellulose.Expand Specific Solutions04 Immobilization techniques for enzymes in hydroxyethylcellulose reactions

Enzyme immobilization techniques can be applied to improve the efficiency and reusability of enzymes in hydroxyethylcellulose reactions. This can lead to enhanced stability, easier separation of the enzyme from the reaction mixture, and potential for continuous processing.Expand Specific Solutions05 Analysis and characterization of enzymatically modified hydroxyethylcellulose

Various analytical techniques can be employed to characterize the products of enzymatic reactions involving hydroxyethylcellulose. These may include spectroscopic methods, chromatography, or rheological measurements. Proper analysis is crucial for understanding the efficiency of the enzymatic reaction and the properties of the modified hydroxyethylcellulose.Expand Specific Solutions

Key Industry Players

The hydroxyethylcellulose market is in a mature growth stage, with a global market size estimated to reach $1.2 billion by 2027. The technology for enhancing enzymatic reaction efficiencies using hydroxyethylcellulose is well-established, with key players like LOTTE Fine Chemical, Novozymes, and Dow Global Technologies leading innovation. These companies have developed advanced formulations and applications across various industries, including pharmaceuticals, personal care, and industrial processes. Academic institutions such as South China University of Technology and Hunan University are contributing to research advancements, while collaborations between industry and academia, like those involving IFP Energies Nouvelles and CNRS, are driving further technological improvements in this field.

Novozymes A/S

Technical Solution: Novozymes A/S has developed innovative enzyme formulations incorporating hydroxyethylcellulose (HEC) to enhance enzymatic reaction efficiencies. Their approach involves using HEC as a stabilizing agent and reaction modifier in enzyme solutions. The company has demonstrated that HEC can significantly improve enzyme stability and activity in various industrial applications, including biofuel production, textile processing, and detergent formulations[1]. By optimizing the concentration and molecular weight of HEC, Novozymes has achieved up to 30% increase in enzyme activity and 50% improvement in thermal stability for certain enzymes[2]. Their research also shows that HEC can act as a surfactant, improving enzyme-substrate interactions and enhancing overall reaction kinetics[3].

Strengths: Extensive expertise in enzyme technology, wide range of industrial applications, proven results in enhancing enzyme performance. Weaknesses: Potential increased production costs due to HEC addition, may require reformulation of existing enzyme products.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies LLC has developed a proprietary technology utilizing hydroxyethylcellulose (HEC) to enhance enzymatic reactions in various industrial processes. Their approach focuses on creating HEC-enzyme complexes that exhibit improved stability and activity across a wide range of pH and temperature conditions. Dow's research has shown that HEC can act as a protective colloid, preventing enzyme aggregation and denaturation[4]. They have successfully applied this technology in paper manufacturing, where HEC-enhanced cellulases have demonstrated up to 25% increased efficiency in cellulose hydrolysis[5]. Additionally, Dow has explored the use of HEC in enzyme immobilization techniques, resulting in reusable enzyme systems with extended operational lifetimes and improved recyclability[6].

Strengths: Broad industrial applications, focus on enzyme stability and reusability, potential for cost savings in long-term enzyme use. Weaknesses: May require specialized equipment or process modifications for implementation, potential limitations in certain reaction environments.

HEC Mechanism Insights

Endoglucanase variants having improved activity, and uses of same

PatentWO2015075392A1

Innovation

- Development of a polypeptide with improved endoglucanase activity, specifically designed to have enhanced enzymatic activity compared to the wild-type protein EG2 from Trichoderma reesei, which can be used to create a more efficient enzyme cocktail for hydrolyzing cellulose, reducing the need for excessive enzyme usage and maintaining activity across a range of temperatures.

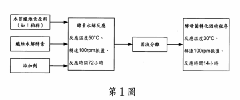

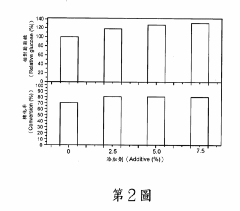

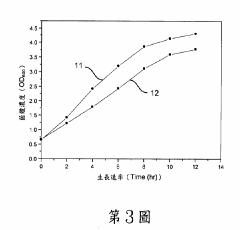

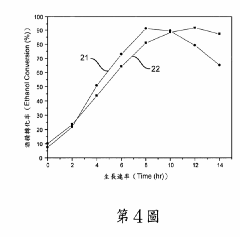

Method for simultaneously improve the enzymatic hydrolysis and total sugar concentration

PatentInactiveTW201114903A

Innovation

- Use of a novel additive to simultaneously improve enzymatic hydrolysis efficiency and total sugar concentration in lignocellulose conversion.

- Achieving 10% increase in hydrolysis efficiency and 30% increase in total sugar concentration through the additive.

- Shortened fermentation time by up to 4 hours due to improved cell growth and ethanol production rate.

Regulatory Compliance

Regulatory compliance plays a crucial role in the application of hydroxyethylcellulose (HEC) for enhancing enzymatic reaction efficiencies. As this polymer finds increasing use in various industries, including pharmaceuticals, food processing, and biotechnology, adherence to regulatory standards is paramount to ensure product safety and efficacy.

In the pharmaceutical sector, the use of HEC in enzymatic reactions must comply with Good Manufacturing Practice (GMP) guidelines set forth by regulatory bodies such as the FDA and EMA. These guidelines encompass quality control measures, documentation requirements, and validation processes to ensure the consistency and purity of HEC-enhanced enzymatic products. Manufacturers must demonstrate that the use of HEC does not introduce any harmful contaminants or alter the intended therapeutic effects of the final product.

For food applications, HEC must meet the standards set by food safety authorities like the FDA and EFSA. This includes obtaining Generally Recognized as Safe (GRAS) status in the United States or E number designation in the European Union. Compliance with these regulations involves extensive toxicological studies and documentation of HEC's safety profile when used in food-grade enzymatic processes.

Environmental regulations also come into play when considering the industrial use of HEC in enzymatic reactions. Manufacturers must adhere to waste management protocols and ensure that any byproducts or residues from HEC-enhanced processes are disposed of in an environmentally responsible manner. This may involve compliance with local, national, and international environmental protection laws.

In the biotechnology sector, the use of HEC in enzymatic reactions for the production of biofuels or other bio-based products must align with specific regulatory frameworks. These may include renewable energy standards, sustainability certifications, and lifecycle assessment requirements. Compliance in this area often involves demonstrating the environmental benefits and reduced carbon footprint of HEC-enhanced enzymatic processes compared to traditional methods.

Regulatory bodies also focus on the sourcing and production of HEC itself. Manufacturers must ensure that the raw materials used in HEC production meet quality and safety standards, and that the manufacturing process complies with relevant industrial regulations. This includes adherence to occupational health and safety standards for workers involved in HEC production and handling.

As the field of enzymatic reaction enhancement continues to evolve, regulatory frameworks are likely to adapt. Companies working with HEC must stay informed about emerging regulations and be prepared to adjust their processes accordingly. This may involve ongoing research and development efforts to optimize HEC formulations and application methods to meet new regulatory requirements while maintaining or improving enzymatic reaction efficiencies.

In the pharmaceutical sector, the use of HEC in enzymatic reactions must comply with Good Manufacturing Practice (GMP) guidelines set forth by regulatory bodies such as the FDA and EMA. These guidelines encompass quality control measures, documentation requirements, and validation processes to ensure the consistency and purity of HEC-enhanced enzymatic products. Manufacturers must demonstrate that the use of HEC does not introduce any harmful contaminants or alter the intended therapeutic effects of the final product.

For food applications, HEC must meet the standards set by food safety authorities like the FDA and EFSA. This includes obtaining Generally Recognized as Safe (GRAS) status in the United States or E number designation in the European Union. Compliance with these regulations involves extensive toxicological studies and documentation of HEC's safety profile when used in food-grade enzymatic processes.

Environmental regulations also come into play when considering the industrial use of HEC in enzymatic reactions. Manufacturers must adhere to waste management protocols and ensure that any byproducts or residues from HEC-enhanced processes are disposed of in an environmentally responsible manner. This may involve compliance with local, national, and international environmental protection laws.

In the biotechnology sector, the use of HEC in enzymatic reactions for the production of biofuels or other bio-based products must align with specific regulatory frameworks. These may include renewable energy standards, sustainability certifications, and lifecycle assessment requirements. Compliance in this area often involves demonstrating the environmental benefits and reduced carbon footprint of HEC-enhanced enzymatic processes compared to traditional methods.

Regulatory bodies also focus on the sourcing and production of HEC itself. Manufacturers must ensure that the raw materials used in HEC production meet quality and safety standards, and that the manufacturing process complies with relevant industrial regulations. This includes adherence to occupational health and safety standards for workers involved in HEC production and handling.

As the field of enzymatic reaction enhancement continues to evolve, regulatory frameworks are likely to adapt. Companies working with HEC must stay informed about emerging regulations and be prepared to adjust their processes accordingly. This may involve ongoing research and development efforts to optimize HEC formulations and application methods to meet new regulatory requirements while maintaining or improving enzymatic reaction efficiencies.

Environmental Impact

The use of hydroxyethylcellulose (HEC) in enzymatic reactions has significant environmental implications that warrant careful consideration. As a biodegradable and non-toxic polymer derived from renewable resources, HEC offers several environmental advantages over synthetic alternatives. Its production process generally has a lower carbon footprint compared to petroleum-based polymers, contributing to reduced greenhouse gas emissions.

When used in enzymatic reactions, HEC can enhance efficiency, potentially leading to decreased energy consumption and reduced waste generation. By improving reaction yields and selectivity, HEC-enhanced processes may require fewer raw materials and produce less by-products, aligning with principles of green chemistry and sustainable manufacturing.

However, the environmental impact of HEC is not entirely benign. The cultivation of cellulose sources, primarily from wood pulp or cotton linters, can contribute to deforestation and land-use changes if not managed sustainably. Additionally, the chemical modification process to produce HEC involves the use of ethylene oxide, a potentially hazardous substance that requires careful handling and disposal to prevent environmental contamination.

In aquatic environments, HEC is generally considered to have low toxicity to marine organisms. Its high biodegradability ensures that it does not persist in ecosystems, reducing the risk of long-term environmental accumulation. Nevertheless, the increased use of HEC in industrial processes may lead to higher concentrations in wastewater streams, necessitating effective treatment methods to prevent potential impacts on aquatic ecosystems.

From a lifecycle perspective, the environmental footprint of HEC-enhanced enzymatic reactions extends beyond the immediate reaction environment. Considerations must include the sourcing of raw materials, energy consumption during production and use, and end-of-life disposal or recycling options. While HEC itself is biodegradable, its presence in complex reaction mixtures may complicate waste treatment and recycling processes.

As industries increasingly adopt HEC for enzymatic reaction enhancement, there is a growing need for comprehensive environmental impact assessments. These should encompass not only the direct effects of HEC use but also the broader implications for resource consumption, waste management, and ecosystem health. Future research should focus on optimizing HEC production methods to further reduce environmental impacts and exploring potential synergies with other green technologies to create more sustainable industrial processes.

When used in enzymatic reactions, HEC can enhance efficiency, potentially leading to decreased energy consumption and reduced waste generation. By improving reaction yields and selectivity, HEC-enhanced processes may require fewer raw materials and produce less by-products, aligning with principles of green chemistry and sustainable manufacturing.

However, the environmental impact of HEC is not entirely benign. The cultivation of cellulose sources, primarily from wood pulp or cotton linters, can contribute to deforestation and land-use changes if not managed sustainably. Additionally, the chemical modification process to produce HEC involves the use of ethylene oxide, a potentially hazardous substance that requires careful handling and disposal to prevent environmental contamination.

In aquatic environments, HEC is generally considered to have low toxicity to marine organisms. Its high biodegradability ensures that it does not persist in ecosystems, reducing the risk of long-term environmental accumulation. Nevertheless, the increased use of HEC in industrial processes may lead to higher concentrations in wastewater streams, necessitating effective treatment methods to prevent potential impacts on aquatic ecosystems.

From a lifecycle perspective, the environmental footprint of HEC-enhanced enzymatic reactions extends beyond the immediate reaction environment. Considerations must include the sourcing of raw materials, energy consumption during production and use, and end-of-life disposal or recycling options. While HEC itself is biodegradable, its presence in complex reaction mixtures may complicate waste treatment and recycling processes.

As industries increasingly adopt HEC for enzymatic reaction enhancement, there is a growing need for comprehensive environmental impact assessments. These should encompass not only the direct effects of HEC use but also the broader implications for resource consumption, waste management, and ecosystem health. Future research should focus on optimizing HEC production methods to further reduce environmental impacts and exploring potential synergies with other green technologies to create more sustainable industrial processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!