Road Mapping Hydroxyethylcellulose Innovations in Biotechnological Patents

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEC Innovation Background and Objectives

Hydroxyethylcellulose (HEC) has emerged as a crucial component in various biotechnological applications, with its versatile properties driving innovation across multiple industries. The evolution of HEC technology can be traced back to the early 20th century when cellulose derivatives first gained attention for their unique characteristics. Over the decades, HEC has undergone significant advancements, particularly in its production methods and application scope.

The primary objective of this technical research report is to comprehensively examine the trajectory of HEC innovations within biotechnological patents. By analyzing the historical development and current state of HEC technology, we aim to identify key trends, breakthroughs, and potential future directions in this field. This analysis will provide valuable insights for strategic planning and product development in industries relying on HEC-based solutions.

Recent years have witnessed a surge in HEC-related patent activities, indicating a growing interest in leveraging this material for novel biotechnological applications. The increasing focus on sustainable and bio-based materials has further accelerated research and development efforts in HEC technology. As environmental concerns continue to shape industrial practices, HEC's biodegradability and renewable sourcing have positioned it as a promising alternative to synthetic polymers in various applications.

The biotechnology sector, in particular, has seen a rapid expansion in HEC utilization. From drug delivery systems to tissue engineering scaffolds, HEC's biocompatibility and tunable properties have opened up new possibilities for medical and pharmaceutical innovations. Additionally, the food and cosmetics industries have embraced HEC for its stabilizing and thickening properties, driving further patent activities in these areas.

As we delve into the patent landscape of HEC innovations, it is crucial to consider the interdisciplinary nature of this field. Advancements in HEC technology often involve collaborations between material scientists, chemists, and biotechnologists, resulting in cross-pollination of ideas and novel applications. This report aims to highlight these intersections and identify emerging trends that may shape the future of HEC in biotechnology.

Furthermore, this analysis will explore the geographical distribution of HEC-related patents, shedding light on the global centers of innovation in this field. By examining the key players and their patent portfolios, we can gain insights into the competitive landscape and potential collaboration opportunities. This information will be invaluable for companies seeking to position themselves strategically in the HEC market or looking to leverage this technology for their product development initiatives.

The primary objective of this technical research report is to comprehensively examine the trajectory of HEC innovations within biotechnological patents. By analyzing the historical development and current state of HEC technology, we aim to identify key trends, breakthroughs, and potential future directions in this field. This analysis will provide valuable insights for strategic planning and product development in industries relying on HEC-based solutions.

Recent years have witnessed a surge in HEC-related patent activities, indicating a growing interest in leveraging this material for novel biotechnological applications. The increasing focus on sustainable and bio-based materials has further accelerated research and development efforts in HEC technology. As environmental concerns continue to shape industrial practices, HEC's biodegradability and renewable sourcing have positioned it as a promising alternative to synthetic polymers in various applications.

The biotechnology sector, in particular, has seen a rapid expansion in HEC utilization. From drug delivery systems to tissue engineering scaffolds, HEC's biocompatibility and tunable properties have opened up new possibilities for medical and pharmaceutical innovations. Additionally, the food and cosmetics industries have embraced HEC for its stabilizing and thickening properties, driving further patent activities in these areas.

As we delve into the patent landscape of HEC innovations, it is crucial to consider the interdisciplinary nature of this field. Advancements in HEC technology often involve collaborations between material scientists, chemists, and biotechnologists, resulting in cross-pollination of ideas and novel applications. This report aims to highlight these intersections and identify emerging trends that may shape the future of HEC in biotechnology.

Furthermore, this analysis will explore the geographical distribution of HEC-related patents, shedding light on the global centers of innovation in this field. By examining the key players and their patent portfolios, we can gain insights into the competitive landscape and potential collaboration opportunities. This information will be invaluable for companies seeking to position themselves strategically in the HEC market or looking to leverage this technology for their product development initiatives.

Market Demand Analysis for HEC in Biotech

The market demand for Hydroxyethylcellulose (HEC) in biotechnology applications has been steadily growing, driven by its versatile properties and increasing adoption in various biotech processes. HEC, a non-ionic water-soluble polymer derived from cellulose, has found significant applications in biomedical, pharmaceutical, and tissue engineering fields.

In the biomedical sector, HEC is widely used as a thickening agent and stabilizer in drug formulations, particularly in topical and ophthalmic preparations. Its ability to form hydrogels and its biocompatibility make it an attractive choice for controlled drug delivery systems. The pharmaceutical industry's continuous efforts to develop novel drug delivery mechanisms have further fueled the demand for HEC.

The tissue engineering field has also witnessed a surge in HEC usage. Its ability to form scaffolds that mimic the extracellular matrix has made it valuable for cell culture and tissue regeneration applications. As regenerative medicine advances, the demand for HEC in this sector is expected to grow substantially.

In biotechnology research and development, HEC serves as a crucial component in various laboratory techniques. It is used in gel electrophoresis, a fundamental method for separating DNA, RNA, and proteins. The increasing focus on genomics and proteomics research has contributed to the rising demand for HEC in this application.

The cosmeceutical industry, which bridges cosmetics and pharmaceuticals, has also embraced HEC for its film-forming and moisturizing properties. As consumers seek more advanced and scientifically-backed skincare products, the demand for HEC in this sector continues to expand.

Environmental biotechnology is another emerging area driving HEC demand. Its use in wastewater treatment processes and as a soil stabilizer in bioremediation projects has opened new market opportunities. The growing emphasis on sustainable and eco-friendly solutions in industrial processes further supports this trend.

Market analysts project a compound annual growth rate (CAGR) for HEC in biotechnology applications to exceed the overall chemical industry average over the next five years. This growth is attributed to ongoing research and development activities, expanding applications in emerging biotech fields, and the increasing adoption of HEC-based products in established sectors.

However, the market faces challenges such as the availability of alternative materials and the need for sustainable production methods. Innovations in HEC production, focusing on green chemistry principles and improved functionalization, are expected to address these challenges and further drive market growth.

In the biomedical sector, HEC is widely used as a thickening agent and stabilizer in drug formulations, particularly in topical and ophthalmic preparations. Its ability to form hydrogels and its biocompatibility make it an attractive choice for controlled drug delivery systems. The pharmaceutical industry's continuous efforts to develop novel drug delivery mechanisms have further fueled the demand for HEC.

The tissue engineering field has also witnessed a surge in HEC usage. Its ability to form scaffolds that mimic the extracellular matrix has made it valuable for cell culture and tissue regeneration applications. As regenerative medicine advances, the demand for HEC in this sector is expected to grow substantially.

In biotechnology research and development, HEC serves as a crucial component in various laboratory techniques. It is used in gel electrophoresis, a fundamental method for separating DNA, RNA, and proteins. The increasing focus on genomics and proteomics research has contributed to the rising demand for HEC in this application.

The cosmeceutical industry, which bridges cosmetics and pharmaceuticals, has also embraced HEC for its film-forming and moisturizing properties. As consumers seek more advanced and scientifically-backed skincare products, the demand for HEC in this sector continues to expand.

Environmental biotechnology is another emerging area driving HEC demand. Its use in wastewater treatment processes and as a soil stabilizer in bioremediation projects has opened new market opportunities. The growing emphasis on sustainable and eco-friendly solutions in industrial processes further supports this trend.

Market analysts project a compound annual growth rate (CAGR) for HEC in biotechnology applications to exceed the overall chemical industry average over the next five years. This growth is attributed to ongoing research and development activities, expanding applications in emerging biotech fields, and the increasing adoption of HEC-based products in established sectors.

However, the market faces challenges such as the availability of alternative materials and the need for sustainable production methods. Innovations in HEC production, focusing on green chemistry principles and improved functionalization, are expected to address these challenges and further drive market growth.

Current HEC Tech Status and Challenges

Hydroxyethylcellulose (HEC) has emerged as a crucial component in various biotechnological applications, with its current technological status reflecting both significant advancements and persistent challenges. The global market for HEC has witnessed steady growth, driven by its versatile properties and increasing demand across multiple industries.

In terms of production, the current state-of-the-art involves the etherification of cellulose with ethylene oxide under alkaline conditions. This process has been optimized over the years, resulting in improved yield and quality of HEC. However, the reliance on petrochemical-derived ethylene oxide poses sustainability concerns, prompting research into bio-based alternatives.

One of the primary challenges in HEC technology lies in achieving precise control over its molecular weight distribution and degree of substitution. These parameters significantly influence the rheological properties of HEC solutions, which are critical for its performance in various applications. Current manufacturing processes struggle to maintain consistent quality across batches, necessitating advanced process control systems and in-line monitoring techniques.

The biocompatibility of HEC has led to its widespread use in pharmaceutical and biomedical applications. However, concerns regarding potential immunogenicity and long-term effects of HEC-based materials in the human body persist. This has spurred research into developing modified HEC derivatives with enhanced biocompatibility and reduced immunogenic potential.

In the field of drug delivery, HEC-based hydrogels have shown promise for controlled release applications. The current challenge lies in fine-tuning the release kinetics and improving the loading efficiency of various therapeutic agents. Researchers are exploring novel crosslinking methods and composite formulations to address these issues.

The application of HEC in tissue engineering scaffolds represents another frontier. While HEC provides excellent biocompatibility and tunable mechanical properties, challenges remain in enhancing cell adhesion and promoting tissue regeneration. Current efforts focus on developing HEC-based composite materials incorporating bioactive molecules and nanoparticles to improve scaffold functionality.

Environmental concerns have also shaped the current HEC technology landscape. The biodegradability of HEC, while generally considered favorable, can be problematic in certain applications requiring long-term stability. Conversely, in environmental remediation applications, there is a need for HEC derivatives with enhanced biodegradability and pollutant-binding capabilities.

Geographically, HEC production and research are concentrated in North America, Europe, and Asia, with China emerging as a significant player in recent years. This distribution has led to challenges in supply chain management and technology transfer, particularly in light of recent global disruptions.

In conclusion, while HEC technology has made significant strides, it faces multifaceted challenges ranging from production sustainability to application-specific performance optimization. Addressing these challenges will require interdisciplinary approaches and continued innovation in both fundamental research and applied technologies.

In terms of production, the current state-of-the-art involves the etherification of cellulose with ethylene oxide under alkaline conditions. This process has been optimized over the years, resulting in improved yield and quality of HEC. However, the reliance on petrochemical-derived ethylene oxide poses sustainability concerns, prompting research into bio-based alternatives.

One of the primary challenges in HEC technology lies in achieving precise control over its molecular weight distribution and degree of substitution. These parameters significantly influence the rheological properties of HEC solutions, which are critical for its performance in various applications. Current manufacturing processes struggle to maintain consistent quality across batches, necessitating advanced process control systems and in-line monitoring techniques.

The biocompatibility of HEC has led to its widespread use in pharmaceutical and biomedical applications. However, concerns regarding potential immunogenicity and long-term effects of HEC-based materials in the human body persist. This has spurred research into developing modified HEC derivatives with enhanced biocompatibility and reduced immunogenic potential.

In the field of drug delivery, HEC-based hydrogels have shown promise for controlled release applications. The current challenge lies in fine-tuning the release kinetics and improving the loading efficiency of various therapeutic agents. Researchers are exploring novel crosslinking methods and composite formulations to address these issues.

The application of HEC in tissue engineering scaffolds represents another frontier. While HEC provides excellent biocompatibility and tunable mechanical properties, challenges remain in enhancing cell adhesion and promoting tissue regeneration. Current efforts focus on developing HEC-based composite materials incorporating bioactive molecules and nanoparticles to improve scaffold functionality.

Environmental concerns have also shaped the current HEC technology landscape. The biodegradability of HEC, while generally considered favorable, can be problematic in certain applications requiring long-term stability. Conversely, in environmental remediation applications, there is a need for HEC derivatives with enhanced biodegradability and pollutant-binding capabilities.

Geographically, HEC production and research are concentrated in North America, Europe, and Asia, with China emerging as a significant player in recent years. This distribution has led to challenges in supply chain management and technology transfer, particularly in light of recent global disruptions.

In conclusion, while HEC technology has made significant strides, it faces multifaceted challenges ranging from production sustainability to application-specific performance optimization. Addressing these challenges will require interdisciplinary approaches and continued innovation in both fundamental research and applied technologies.

Current HEC Biotech Patent Solutions

01 Use in drilling fluids and well treatment compositions

Hydroxyethylcellulose is used as a viscosifier and fluid loss control agent in drilling fluids and well treatment compositions. It helps to improve the rheological properties of the fluids, control fluid loss, and enhance the stability of the wellbore during drilling operations.- Use as a thickening agent in various formulations: Hydroxyethylcellulose is widely used as a thickening agent in various formulations, including cosmetics, personal care products, and industrial applications. It helps to improve the viscosity and stability of liquid and semi-solid products, enhancing their texture and performance.

- Application in oil and gas industry: Hydroxyethylcellulose is utilized in the oil and gas industry as a component in drilling fluids and fracturing fluids. It helps control fluid loss, improve viscosity, and enhance the overall performance of these fluids in well operations.

- Use in pharmaceutical formulations: Hydroxyethylcellulose is employed in pharmaceutical formulations as a binder, film-forming agent, and controlled-release matrix. It helps in the development of various drug delivery systems, including tablets, capsules, and topical preparations.

- Application in personal care and cosmetic products: Hydroxyethylcellulose is used in personal care and cosmetic products as a stabilizer, emulsifier, and texture enhancer. It helps improve the feel and consistency of products such as shampoos, lotions, and creams.

- Use in adhesive and coating formulations: Hydroxyethylcellulose is utilized in adhesive and coating formulations to improve their properties. It acts as a thickener, binder, and film-forming agent, enhancing the performance and durability of various adhesives and coatings.

02 Application in personal care and cosmetic products

Hydroxyethylcellulose is utilized as a thickening agent and stabilizer in various personal care and cosmetic formulations. It helps to improve the texture, consistency, and stability of products such as shampoos, lotions, and creams.Expand Specific Solutions03 Use in pharmaceutical formulations

Hydroxyethylcellulose is employed in pharmaceutical formulations as a binder, thickener, and controlled release agent. It helps to improve the stability, viscosity, and drug release properties of various dosage forms, including tablets, gels, and suspensions.Expand Specific Solutions04 Application in adhesive compositions

Hydroxyethylcellulose is used in adhesive formulations to improve their rheological properties, water retention, and bonding strength. It is particularly useful in water-based adhesives and helps to enhance their performance in various applications.Expand Specific Solutions05 Use in textile processing and finishing

Hydroxyethylcellulose is utilized in textile processing and finishing applications as a thickener, sizing agent, and binder. It helps to improve the printability, dimensional stability, and surface properties of textiles during various treatment processes.Expand Specific Solutions

Key Players in HEC Biotech Patents

The road mapping of hydroxyethylcellulose innovations in biotechnological patents reveals a competitive landscape in its early to mid-stage development. The market size is growing, driven by increasing applications in pharmaceuticals, cosmetics, and food industries. Technologically, it's progressing from basic research to more advanced applications. Key players like The Regents of the University of California, Wuhan University, and Genentech, Inc. are leading in patent filings, indicating their strong R&D focus. Companies such as Exelixis, Inc. and Infinity Pharmaceuticals, Inc. are also making significant contributions, suggesting a diverse and dynamic competitive environment.

Hercules Corp.

Technical Solution: Hercules Corp. has developed innovative approaches in hydroxyethylcellulose (HEC) applications for biotechnology. Their patented technology focuses on enhancing the properties of HEC for use in drug delivery systems and tissue engineering scaffolds. The company has engineered HEC derivatives with improved biocompatibility and controlled degradation rates[1]. Their method involves chemical modification of HEC to introduce functional groups that allow for better cell adhesion and proliferation[2]. Additionally, Hercules has developed a novel cross-linking technique that enables the creation of HEC-based hydrogels with tunable mechanical properties, suitable for various biomedical applications[3].

Strengths: Customizable HEC derivatives for specific biomedical needs; improved biocompatibility and controlled degradation. Weaknesses: Potential complexity in large-scale production; may require additional regulatory approvals for novel modifications.

Jiangxi Qingyuan Hanben Biotechnology Co., Ltd.

Technical Solution: Jiangxi Qingyuan Hanben Biotechnology Co., Ltd. has made significant strides in the development of eco-friendly HEC production methods for biotechnological applications. Their patented process utilizes enzymatic modification of cellulose to produce HEC with high purity and consistent quality[4]. The company has also developed a green chemistry approach that reduces the use of harmful solvents in HEC synthesis, resulting in a more environmentally sustainable product[5]. Furthermore, they have innovated in the area of HEC functionalization, creating derivatives with enhanced properties for use in drug encapsulation and controlled release systems[6].

Strengths: Eco-friendly production methods; high-purity HEC suitable for pharmaceutical applications. Weaknesses: Potentially higher production costs compared to traditional methods; limited track record in global markets.

Key HEC Biotech Patent Innovations

Blocky hydroxyethylcellulose, derivatives thereof, process of making, and uses thereof

PatentActiveUS20060182703A1

Innovation

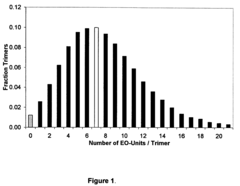

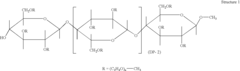

- Development of 'blocky' HECs with non-uniform hydroxyethyl group distribution, characterized by an unsubstituted trimer ratio greater than 0.21 and hydroxyethyl molar substitution between 1.3 and 5.0, which are produced through a specific two-step alkalization and hydroxyethylation process, enhancing their associative behavior and solution viscosity.

Variant hhip1 protein and methods and uses thereof

PatentWO2009146463A8

Innovation

- Determination of the crystal structure of a truncated form of the Hhipl ectodomain both alone and in complex with Shh, revealing critical interactions that allow for the design of polypeptide agonists, antagonists, antibodies, and small molecule inhibitors to modulate Hedgehog signaling.

HEC Regulatory Landscape in Biotech

The regulatory landscape for hydroxyethylcellulose (HEC) in biotechnology is complex and evolving, reflecting the increasing importance of this versatile polymer in various biotech applications. Regulatory bodies worldwide have established guidelines and standards for the use of HEC in biotech products, particularly in pharmaceuticals, medical devices, and cosmetics.

In the pharmaceutical sector, the U.S. Food and Drug Administration (FDA) has approved HEC for use in various drug formulations, including oral, topical, and ophthalmic preparations. The European Medicines Agency (EMA) has also recognized HEC as a safe excipient for pharmaceutical use. Both agencies require manufacturers to adhere to Good Manufacturing Practices (GMP) and provide detailed documentation on the sourcing, production, and quality control of HEC used in drug products.

For medical devices, regulatory frameworks such as the EU Medical Device Regulation (MDR) and the FDA's 510(k) process apply to products incorporating HEC. Manufacturers must demonstrate the safety and efficacy of HEC-containing devices through rigorous testing and clinical trials, where applicable.

In the cosmetics industry, HEC is generally recognized as safe (GRAS) by regulatory authorities. However, its use is subject to concentration limits and specific labeling requirements in some jurisdictions. The EU Cosmetics Regulation, for instance, mandates that HEC be listed in the ingredients using its INCI name (Hydroxyethylcellulose) when used in cosmetic products.

Environmental regulations also play a role in the HEC regulatory landscape. As a biodegradable polymer, HEC is viewed favorably in terms of environmental impact. However, manufacturers must still comply with waste management and disposal regulations, particularly in the production process.

Intellectual property considerations are crucial in the biotech industry's use of HEC. Patent offices worldwide have seen an increase in patent applications related to novel HEC formulations and applications in biotechnology. This trend underscores the importance of thorough patent searches and strategic IP management for companies innovating with HEC in the biotech space.

As the biotech industry continues to evolve, regulatory bodies are likely to refine their approaches to HEC oversight. This may include more specific guidelines for emerging applications, such as in tissue engineering or drug delivery systems. Companies working with HEC in biotech must stay abreast of these regulatory developments to ensure compliance and maintain their competitive edge in the market.

In the pharmaceutical sector, the U.S. Food and Drug Administration (FDA) has approved HEC for use in various drug formulations, including oral, topical, and ophthalmic preparations. The European Medicines Agency (EMA) has also recognized HEC as a safe excipient for pharmaceutical use. Both agencies require manufacturers to adhere to Good Manufacturing Practices (GMP) and provide detailed documentation on the sourcing, production, and quality control of HEC used in drug products.

For medical devices, regulatory frameworks such as the EU Medical Device Regulation (MDR) and the FDA's 510(k) process apply to products incorporating HEC. Manufacturers must demonstrate the safety and efficacy of HEC-containing devices through rigorous testing and clinical trials, where applicable.

In the cosmetics industry, HEC is generally recognized as safe (GRAS) by regulatory authorities. However, its use is subject to concentration limits and specific labeling requirements in some jurisdictions. The EU Cosmetics Regulation, for instance, mandates that HEC be listed in the ingredients using its INCI name (Hydroxyethylcellulose) when used in cosmetic products.

Environmental regulations also play a role in the HEC regulatory landscape. As a biodegradable polymer, HEC is viewed favorably in terms of environmental impact. However, manufacturers must still comply with waste management and disposal regulations, particularly in the production process.

Intellectual property considerations are crucial in the biotech industry's use of HEC. Patent offices worldwide have seen an increase in patent applications related to novel HEC formulations and applications in biotechnology. This trend underscores the importance of thorough patent searches and strategic IP management for companies innovating with HEC in the biotech space.

As the biotech industry continues to evolve, regulatory bodies are likely to refine their approaches to HEC oversight. This may include more specific guidelines for emerging applications, such as in tissue engineering or drug delivery systems. Companies working with HEC in biotech must stay abreast of these regulatory developments to ensure compliance and maintain their competitive edge in the market.

Environmental Impact of HEC Production

The production of Hydroxyethylcellulose (HEC) has significant environmental implications that warrant careful consideration. The manufacturing process involves the reaction of cellulose with ethylene oxide, which can lead to various environmental concerns if not properly managed.

One of the primary environmental impacts of HEC production is the potential for air pollution. The use of ethylene oxide, a volatile organic compound, can result in emissions that contribute to smog formation and air quality degradation. Stringent emission control measures are necessary to mitigate these effects, including the implementation of advanced scrubbing technologies and closed-loop production systems.

Water pollution is another critical concern in HEC manufacturing. The process generates wastewater containing organic compounds and potentially harmful chemicals. Proper treatment and disposal of this wastewater are essential to prevent contamination of local water bodies and groundwater resources. Many facilities have implemented advanced water treatment systems to address this issue, including biological treatment processes and membrane filtration technologies.

Energy consumption in HEC production is substantial, contributing to greenhouse gas emissions and climate change. The energy-intensive nature of the manufacturing process, particularly in the reaction and purification stages, necessitates the exploration of more energy-efficient technologies and the adoption of renewable energy sources to reduce the carbon footprint of production facilities.

The sourcing of raw materials, primarily cellulose, also has environmental implications. Sustainable forestry practices and the use of alternative cellulose sources, such as agricultural waste or recycled materials, are being explored to minimize the impact on natural ecosystems and reduce deforestation.

Waste management is a crucial aspect of HEC production's environmental impact. The process generates various by-products and waste materials that require proper handling and disposal. Innovations in waste reduction, recycling, and upcycling of by-products are being developed to move towards a more circular economy model in HEC manufacturing.

Biotechnological innovations are playing an increasingly important role in addressing these environmental challenges. Enzymatic processes for cellulose modification are being researched as a more environmentally friendly alternative to traditional chemical methods. These bio-based approaches have the potential to reduce chemical usage, lower energy requirements, and minimize waste generation in HEC production.

One of the primary environmental impacts of HEC production is the potential for air pollution. The use of ethylene oxide, a volatile organic compound, can result in emissions that contribute to smog formation and air quality degradation. Stringent emission control measures are necessary to mitigate these effects, including the implementation of advanced scrubbing technologies and closed-loop production systems.

Water pollution is another critical concern in HEC manufacturing. The process generates wastewater containing organic compounds and potentially harmful chemicals. Proper treatment and disposal of this wastewater are essential to prevent contamination of local water bodies and groundwater resources. Many facilities have implemented advanced water treatment systems to address this issue, including biological treatment processes and membrane filtration technologies.

Energy consumption in HEC production is substantial, contributing to greenhouse gas emissions and climate change. The energy-intensive nature of the manufacturing process, particularly in the reaction and purification stages, necessitates the exploration of more energy-efficient technologies and the adoption of renewable energy sources to reduce the carbon footprint of production facilities.

The sourcing of raw materials, primarily cellulose, also has environmental implications. Sustainable forestry practices and the use of alternative cellulose sources, such as agricultural waste or recycled materials, are being explored to minimize the impact on natural ecosystems and reduce deforestation.

Waste management is a crucial aspect of HEC production's environmental impact. The process generates various by-products and waste materials that require proper handling and disposal. Innovations in waste reduction, recycling, and upcycling of by-products are being developed to move towards a more circular economy model in HEC manufacturing.

Biotechnological innovations are playing an increasingly important role in addressing these environmental challenges. Enzymatic processes for cellulose modification are being researched as a more environmentally friendly alternative to traditional chemical methods. These bio-based approaches have the potential to reduce chemical usage, lower energy requirements, and minimize waste generation in HEC production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!