The Role of Hydroxyethylcellulose in Heavy Metal Ion Absorption

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEC Background and Objectives

Hydroxyethylcellulose (HEC) has emerged as a promising material in the field of heavy metal ion absorption, drawing significant attention from researchers and industry professionals alike. This cellulose derivative, known for its excellent water solubility and film-forming properties, has been increasingly explored for its potential in environmental remediation and water treatment applications.

The development of HEC can be traced back to the early 20th century when cellulose ethers were first synthesized. However, its application in heavy metal ion absorption is a more recent discovery, gaining traction in the past few decades as environmental concerns have grown. The evolution of HEC technology has been driven by the urgent need for effective and sustainable solutions to address water pollution, particularly in industrial wastewater treatment.

As global industrialization continues to accelerate, the release of heavy metal ions into water bodies has become a critical environmental issue. Traditional methods of heavy metal removal, such as chemical precipitation and ion exchange, often come with limitations in terms of efficiency, cost, and environmental impact. This has led to a surge in research focused on developing alternative, eco-friendly approaches, with HEC emerging as a promising candidate.

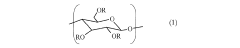

The primary objective of exploring HEC in heavy metal ion absorption is to harness its unique physicochemical properties to create more efficient and sustainable water treatment solutions. HEC's high molecular weight, abundant hydroxyl groups, and ability to form stable hydrogels make it an ideal candidate for metal ion chelation and adsorption. Researchers aim to optimize HEC-based materials to achieve higher absorption capacities, improved selectivity for specific metal ions, and enhanced reusability.

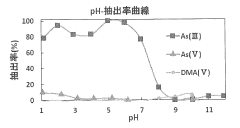

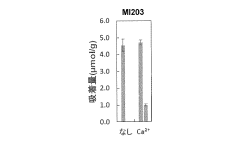

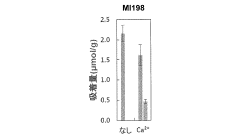

Another key goal is to understand the fundamental mechanisms underlying HEC's interaction with heavy metal ions. This includes investigating the role of functional groups, the impact of molecular weight and degree of substitution, and the influence of environmental factors such as pH and temperature on absorption efficiency. By gaining deeper insights into these aspects, scientists hope to tailor HEC-based materials for specific applications and improve their overall performance.

Furthermore, the research community is focused on developing innovative HEC-based composites and hybrid materials that combine the advantages of HEC with other adsorbents or functional materials. This approach aims to create synergistic effects, potentially leading to more versatile and effective heavy metal removal systems.

As environmental regulations become increasingly stringent worldwide, there is a growing emphasis on developing cost-effective and scalable HEC-based technologies that can be readily implemented in industrial settings. This includes exploring various forms of HEC, such as hydrogels, nanofibers, and membranes, to determine the most practical and efficient configurations for large-scale applications.

The development of HEC can be traced back to the early 20th century when cellulose ethers were first synthesized. However, its application in heavy metal ion absorption is a more recent discovery, gaining traction in the past few decades as environmental concerns have grown. The evolution of HEC technology has been driven by the urgent need for effective and sustainable solutions to address water pollution, particularly in industrial wastewater treatment.

As global industrialization continues to accelerate, the release of heavy metal ions into water bodies has become a critical environmental issue. Traditional methods of heavy metal removal, such as chemical precipitation and ion exchange, often come with limitations in terms of efficiency, cost, and environmental impact. This has led to a surge in research focused on developing alternative, eco-friendly approaches, with HEC emerging as a promising candidate.

The primary objective of exploring HEC in heavy metal ion absorption is to harness its unique physicochemical properties to create more efficient and sustainable water treatment solutions. HEC's high molecular weight, abundant hydroxyl groups, and ability to form stable hydrogels make it an ideal candidate for metal ion chelation and adsorption. Researchers aim to optimize HEC-based materials to achieve higher absorption capacities, improved selectivity for specific metal ions, and enhanced reusability.

Another key goal is to understand the fundamental mechanisms underlying HEC's interaction with heavy metal ions. This includes investigating the role of functional groups, the impact of molecular weight and degree of substitution, and the influence of environmental factors such as pH and temperature on absorption efficiency. By gaining deeper insights into these aspects, scientists hope to tailor HEC-based materials for specific applications and improve their overall performance.

Furthermore, the research community is focused on developing innovative HEC-based composites and hybrid materials that combine the advantages of HEC with other adsorbents or functional materials. This approach aims to create synergistic effects, potentially leading to more versatile and effective heavy metal removal systems.

As environmental regulations become increasingly stringent worldwide, there is a growing emphasis on developing cost-effective and scalable HEC-based technologies that can be readily implemented in industrial settings. This includes exploring various forms of HEC, such as hydrogels, nanofibers, and membranes, to determine the most practical and efficient configurations for large-scale applications.

Market Demand Analysis

The market demand for hydroxyethylcellulose (HEC) in heavy metal ion absorption applications has been steadily growing due to increasing environmental concerns and stricter regulations on water pollution. Industries such as mining, electroplating, and battery manufacturing are major contributors to heavy metal contamination in water sources, creating a significant need for effective and eco-friendly absorption solutions.

The global water treatment chemicals market, which includes heavy metal ion absorption technologies, is projected to expand substantially in the coming years. This growth is driven by the rising awareness of water scarcity and the need for clean water in both developed and developing countries. HEC, as a biodegradable and non-toxic polymer, has gained attention for its potential in addressing these environmental challenges.

In the industrial sector, there is a growing demand for cost-effective and efficient heavy metal removal techniques. HEC's ability to form stable complexes with metal ions makes it an attractive option for wastewater treatment in various industries. The mining industry, in particular, has shown increased interest in HEC-based solutions for treating acid mine drainage and recovering valuable metals from wastewater streams.

The pharmaceutical and food industries are also exploring HEC's potential in heavy metal ion absorption. With stricter regulations on product purity and safety, these sectors are seeking innovative methods to remove trace amounts of heavy metals from their processes and final products. HEC's biocompatibility and FDA approval for certain applications make it a promising candidate for these high-standard industries.

Environmental remediation projects have emerged as another significant market for HEC-based heavy metal absorption technologies. Governments and environmental agencies worldwide are investing in the cleanup of contaminated sites, creating opportunities for advanced absorption materials. HEC's ability to be modified and combined with other materials for enhanced performance aligns well with the requirements of these large-scale remediation efforts.

The agriculture sector presents a growing niche market for HEC in heavy metal ion absorption. As concerns about soil contamination and its impact on crop quality increase, farmers and agricultural companies are seeking solutions to mitigate heavy metal uptake by plants. HEC-based soil amendments and water treatment solutions for irrigation systems are gaining traction in this sector.

Consumer awareness of heavy metal contamination in drinking water has also fueled demand for home water purification systems. This trend has opened up opportunities for HEC-based filtration technologies in the residential market, particularly in regions with aging water infrastructure or known heavy metal contamination issues.

The global water treatment chemicals market, which includes heavy metal ion absorption technologies, is projected to expand substantially in the coming years. This growth is driven by the rising awareness of water scarcity and the need for clean water in both developed and developing countries. HEC, as a biodegradable and non-toxic polymer, has gained attention for its potential in addressing these environmental challenges.

In the industrial sector, there is a growing demand for cost-effective and efficient heavy metal removal techniques. HEC's ability to form stable complexes with metal ions makes it an attractive option for wastewater treatment in various industries. The mining industry, in particular, has shown increased interest in HEC-based solutions for treating acid mine drainage and recovering valuable metals from wastewater streams.

The pharmaceutical and food industries are also exploring HEC's potential in heavy metal ion absorption. With stricter regulations on product purity and safety, these sectors are seeking innovative methods to remove trace amounts of heavy metals from their processes and final products. HEC's biocompatibility and FDA approval for certain applications make it a promising candidate for these high-standard industries.

Environmental remediation projects have emerged as another significant market for HEC-based heavy metal absorption technologies. Governments and environmental agencies worldwide are investing in the cleanup of contaminated sites, creating opportunities for advanced absorption materials. HEC's ability to be modified and combined with other materials for enhanced performance aligns well with the requirements of these large-scale remediation efforts.

The agriculture sector presents a growing niche market for HEC in heavy metal ion absorption. As concerns about soil contamination and its impact on crop quality increase, farmers and agricultural companies are seeking solutions to mitigate heavy metal uptake by plants. HEC-based soil amendments and water treatment solutions for irrigation systems are gaining traction in this sector.

Consumer awareness of heavy metal contamination in drinking water has also fueled demand for home water purification systems. This trend has opened up opportunities for HEC-based filtration technologies in the residential market, particularly in regions with aging water infrastructure or known heavy metal contamination issues.

HEC Absorption Challenges

Despite the promising potential of hydroxyethylcellulose (HEC) in heavy metal ion absorption, several significant challenges hinder its widespread application and effectiveness. One of the primary obstacles is the limited absorption capacity of unmodified HEC. While the polymer demonstrates an affinity for metal ions, its natural form often falls short in competing with other established absorbents in terms of efficiency and capacity.

Another critical challenge lies in the selectivity of HEC towards specific heavy metal ions. In real-world applications, wastewater and contaminated environments often contain a complex mixture of various metal ions. The ability to selectively absorb target ions while leaving others untouched is crucial for effective remediation. However, unmodified HEC typically lacks this specificity, potentially leading to inefficient or incomplete treatment processes.

The stability of HEC in diverse environmental conditions poses another significant hurdle. Heavy metal contamination occurs in a wide range of pH levels, temperatures, and ionic strengths. The performance of HEC as an absorbent can be dramatically affected by these factors, potentially limiting its applicability across different scenarios. Ensuring consistent absorption efficiency under varying conditions remains a key challenge for researchers and engineers.

Regeneration and reusability of HEC-based absorbents present additional complications. For economic and environmental reasons, it is desirable to regenerate and reuse the absorbent material multiple times. However, the desorption process and subsequent regeneration of HEC can be complex, often resulting in reduced absorption capacity or structural degradation over repeated cycles.

The mechanical strength and physical form of HEC-based absorbents also present challenges in practical applications. While HEC can be processed into various forms such as hydrogels, beads, or membranes, each form comes with its own set of limitations. For instance, HEC hydrogels may suffer from poor mechanical stability in flow-through systems, while membranes might face issues with fouling or reduced permeability over time.

Lastly, the scalability of HEC-based absorption systems for industrial-scale applications remains a significant challenge. Translating laboratory successes to large-scale, cost-effective treatment solutions involves overcoming issues related to production, handling, and integration with existing water treatment infrastructure. The economic viability of HEC-based systems compared to conventional treatment methods is a crucial factor that requires careful consideration and optimization.

Another critical challenge lies in the selectivity of HEC towards specific heavy metal ions. In real-world applications, wastewater and contaminated environments often contain a complex mixture of various metal ions. The ability to selectively absorb target ions while leaving others untouched is crucial for effective remediation. However, unmodified HEC typically lacks this specificity, potentially leading to inefficient or incomplete treatment processes.

The stability of HEC in diverse environmental conditions poses another significant hurdle. Heavy metal contamination occurs in a wide range of pH levels, temperatures, and ionic strengths. The performance of HEC as an absorbent can be dramatically affected by these factors, potentially limiting its applicability across different scenarios. Ensuring consistent absorption efficiency under varying conditions remains a key challenge for researchers and engineers.

Regeneration and reusability of HEC-based absorbents present additional complications. For economic and environmental reasons, it is desirable to regenerate and reuse the absorbent material multiple times. However, the desorption process and subsequent regeneration of HEC can be complex, often resulting in reduced absorption capacity or structural degradation over repeated cycles.

The mechanical strength and physical form of HEC-based absorbents also present challenges in practical applications. While HEC can be processed into various forms such as hydrogels, beads, or membranes, each form comes with its own set of limitations. For instance, HEC hydrogels may suffer from poor mechanical stability in flow-through systems, while membranes might face issues with fouling or reduced permeability over time.

Lastly, the scalability of HEC-based absorption systems for industrial-scale applications remains a significant challenge. Translating laboratory successes to large-scale, cost-effective treatment solutions involves overcoming issues related to production, handling, and integration with existing water treatment infrastructure. The economic viability of HEC-based systems compared to conventional treatment methods is a crucial factor that requires careful consideration and optimization.

Current HEC Solutions

01 Hydroxyethylcellulose as a thickening agent

Hydroxyethylcellulose is widely used as a thickening agent in various formulations. It can absorb water and swell, increasing the viscosity of solutions. This property makes it useful in cosmetics, pharmaceuticals, and industrial applications for controlling the consistency of products.- Hydroxyethylcellulose as a thickening agent: Hydroxyethylcellulose is widely used as a thickening agent in various industries, including cosmetics, pharmaceuticals, and oil drilling. It helps to increase the viscosity of solutions and improve their stability. The absorption properties of hydroxyethylcellulose contribute to its effectiveness as a thickener in different formulations.

- Hydroxyethylcellulose in drug delivery systems: Hydroxyethylcellulose is utilized in drug delivery systems due to its absorption and release properties. It can be formulated into various dosage forms, such as tablets, gels, and films, to control the release of active pharmaceutical ingredients. The polymer's ability to absorb and retain water influences its performance in drug delivery applications.

- Hydroxyethylcellulose in personal care products: In personal care products, hydroxyethylcellulose acts as a moisture-retaining agent and stabilizer. Its absorption properties help to improve the texture and feel of cosmetic formulations. The polymer can enhance the spreadability and skin adhesion of topical products, contributing to their overall performance and user experience.

- Hydroxyethylcellulose in oil and gas industry: Hydroxyethylcellulose is used in the oil and gas industry as a fluid loss control agent and viscosifier in drilling fluids. Its absorption properties help to maintain the stability of drilling muds and prevent fluid loss into the formation. The polymer's ability to form a protective film on wellbore walls contributes to improved drilling efficiency.

- Modification of hydroxyethylcellulose for enhanced absorption: Research has been conducted on modifying hydroxyethylcellulose to enhance its absorption properties. These modifications can include crosslinking, grafting, or combining with other polymers. The resulting materials may exhibit improved water absorption, retention, and release characteristics, expanding their potential applications in various fields.

02 Hydroxyethylcellulose in drug delivery systems

Hydroxyethylcellulose is utilized in drug delivery systems due to its absorption and release properties. It can form hydrogels that control the release of active ingredients, making it valuable in the development of sustained-release formulations for pharmaceuticals.Expand Specific Solutions03 Hydroxyethylcellulose in personal care products

In personal care products, hydroxyethylcellulose acts as a stabilizer and emulsifier. Its ability to absorb water and form a protective film on the skin or hair makes it useful in lotions, shampoos, and other cosmetic formulations.Expand Specific Solutions04 Hydroxyethylcellulose in oil field applications

Hydroxyethylcellulose is used in oil field applications, particularly in drilling fluids and fracturing fluids. Its absorption properties help control fluid loss and viscosity, improving the efficiency of drilling and extraction processes.Expand Specific Solutions05 Modification of hydroxyethylcellulose for enhanced properties

Research focuses on modifying hydroxyethylcellulose to enhance its absorption and other properties. This includes chemical modifications or combining it with other materials to create advanced composites with improved performance in various applications.Expand Specific Solutions

Key Industry Players

The field of hydroxyethylcellulose in heavy metal ion absorption is in a growth phase, with increasing market demand driven by environmental concerns and industrial applications. The global market size for this technology is expanding, particularly in water treatment and industrial waste management sectors. Technologically, the field is moderately mature, with ongoing research for improved efficiency and cost-effectiveness. Companies like Daicel Corp., BRAIN Biotech AG, and Dow Global Technologies LLC are at the forefront, leveraging their expertise in cellulose derivatives and biotech to advance the technology. Academic institutions such as Kanazawa University and MIT are also contributing significantly to research and development in this area.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies LLC has developed an advanced hydroxyethylcellulose (HEC) formulation specifically designed for heavy metal ion absorption. Their technology utilizes a modified HEC structure with enhanced chelating properties, allowing for more efficient binding of metal ions such as lead, cadmium, and mercury. The company has implemented a cross-linking process that increases the stability and porosity of the HEC matrix, resulting in a higher surface area for metal ion interaction[1]. Additionally, Dow's HEC-based absorbents demonstrate excellent regeneration capabilities, allowing for multiple use cycles without significant loss in absorption capacity[3].

Strengths: High absorption capacity, excellent regeneration capabilities, and versatility across various heavy metal ions. Weaknesses: Potentially higher production costs due to the modification process and limited effectiveness in highly acidic environments.

Dalian Polytechnic University

Technical Solution: Researchers at Dalian Polytechnic University have focused on developing eco-friendly and cost-effective hydroxyethylcellulose-based materials for heavy metal ion absorption. Their approach involves the chemical modification of HEC with various functional groups, such as carboxyl and amino groups, to enhance its metal-binding capabilities. The university has also explored the use of HEC in combination with other natural polymers, creating composite materials with synergistic absorption properties[5]. Their studies have shown particularly promising results in the removal of copper and lead ions from aqueous solutions, with absorption capacities comparable to commercial adsorbents[6].

Strengths: Environmentally friendly approach, cost-effective production, and good performance for specific metal ions. Weaknesses: Limited research on large-scale applications and potential variability in performance across different environmental conditions.

Core HEC Innovations

Cellulose derivative, heavy metal removal material containing the same, and heavy metal removing method using the same

PatentInactiveJP2020019845A

Innovation

- A cellulose derivative with a dithiocarbamate group introduced via a specific linker structure, allowing for efficient and cost-effective heavy metal adsorption, particularly for arsenic, cadmium, and lead, while maintaining selectivity even in the presence of other metal ions.

Environmental Regulations

Environmental regulations play a crucial role in shaping the use and application of hydroxyethylcellulose (HEC) in heavy metal ion absorption processes. These regulations are designed to protect human health and the environment from the harmful effects of heavy metal contamination in water and soil.

In many countries, strict limits have been set on the permissible levels of heavy metals in drinking water and wastewater discharges. For instance, the United States Environmental Protection Agency (EPA) has established Maximum Contaminant Levels (MCLs) for various heavy metals, including lead, mercury, and cadmium. These regulations drive the demand for effective heavy metal removal technologies, such as those utilizing HEC.

The European Union's Water Framework Directive (WFD) and its daughter directives also set stringent standards for water quality, including limits on heavy metal concentrations. This regulatory framework has spurred research and development in advanced water treatment technologies, including the use of HEC-based materials for heavy metal absorption.

In developing countries, where heavy metal pollution is often more severe due to rapid industrialization, environmental regulations are becoming increasingly stringent. This trend is creating new markets for HEC-based heavy metal absorption technologies, as industries seek cost-effective solutions to comply with tightening regulations.

The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal has implications for the disposal of heavy metal-contaminated materials, including spent HEC adsorbents. This international treaty influences the development of regeneration and disposal methods for HEC-based materials used in heavy metal absorption.

Regulations governing the use of chemicals in water treatment, such as the EU's Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation, also impact the development and application of HEC-based technologies. These regulations ensure that new materials and processes are safe for both human health and the environment.

As environmental awareness grows and regulations become more stringent, there is an increasing focus on sustainable and eco-friendly solutions for heavy metal removal. This trend is driving research into biodegradable and renewable materials, potentially enhancing the appeal of HEC-based technologies due to their natural origin and biodegradability.

The regulatory landscape also influences funding and research priorities in the field of heavy metal absorption. Government agencies and research institutions often align their funding programs with environmental policy objectives, potentially accelerating the development of HEC-based technologies that show promise in meeting regulatory standards.

In many countries, strict limits have been set on the permissible levels of heavy metals in drinking water and wastewater discharges. For instance, the United States Environmental Protection Agency (EPA) has established Maximum Contaminant Levels (MCLs) for various heavy metals, including lead, mercury, and cadmium. These regulations drive the demand for effective heavy metal removal technologies, such as those utilizing HEC.

The European Union's Water Framework Directive (WFD) and its daughter directives also set stringent standards for water quality, including limits on heavy metal concentrations. This regulatory framework has spurred research and development in advanced water treatment technologies, including the use of HEC-based materials for heavy metal absorption.

In developing countries, where heavy metal pollution is often more severe due to rapid industrialization, environmental regulations are becoming increasingly stringent. This trend is creating new markets for HEC-based heavy metal absorption technologies, as industries seek cost-effective solutions to comply with tightening regulations.

The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal has implications for the disposal of heavy metal-contaminated materials, including spent HEC adsorbents. This international treaty influences the development of regeneration and disposal methods for HEC-based materials used in heavy metal absorption.

Regulations governing the use of chemicals in water treatment, such as the EU's Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation, also impact the development and application of HEC-based technologies. These regulations ensure that new materials and processes are safe for both human health and the environment.

As environmental awareness grows and regulations become more stringent, there is an increasing focus on sustainable and eco-friendly solutions for heavy metal removal. This trend is driving research into biodegradable and renewable materials, potentially enhancing the appeal of HEC-based technologies due to their natural origin and biodegradability.

The regulatory landscape also influences funding and research priorities in the field of heavy metal absorption. Government agencies and research institutions often align their funding programs with environmental policy objectives, potentially accelerating the development of HEC-based technologies that show promise in meeting regulatory standards.

Scalability and Cost Analysis

The scalability and cost analysis of hydroxyethylcellulose (HEC) in heavy metal ion absorption is crucial for determining its viability in large-scale applications. HEC's ability to absorb heavy metal ions has shown promise in laboratory settings, but transitioning this technology to industrial-scale operations requires careful consideration of several factors.

Scalability of HEC-based heavy metal absorption systems depends largely on the production capacity of HEC and the efficiency of the absorption process. Current manufacturing methods for HEC are well-established, with global production capacities in the range of hundreds of thousands of tons annually. This suggests that raw material availability is unlikely to be a limiting factor for scaling up HEC-based absorption systems.

However, the absorption process itself may present challenges when scaled up. Factors such as contact time, pH, temperature, and the concentration of heavy metal ions can all affect the efficiency of absorption. Large-scale systems would need to maintain optimal conditions across much larger volumes, which may require significant engineering solutions and process control mechanisms.

Cost analysis of HEC-based heavy metal absorption systems must consider both capital and operational expenditures. Initial investment costs include equipment for HEC modification (if required), absorption columns or reactors, and associated infrastructure. Operational costs encompass raw materials (HEC and any additives), energy consumption, labor, and waste management.

The cost-effectiveness of HEC-based systems compared to alternative heavy metal removal technologies is a critical consideration. While HEC is relatively inexpensive as a raw material, its performance in terms of absorption capacity and selectivity must justify its use over other adsorbents or treatment methods. Additionally, the potential for regeneration and reuse of HEC after absorption could significantly impact long-term operational costs.

Environmental and regulatory factors also play a role in scalability and cost analysis. The disposal or regeneration of HEC after heavy metal absorption must comply with environmental regulations, which can vary by region. The cost of proper disposal or the implementation of regeneration processes should be factored into the overall economic assessment.

In conclusion, while HEC shows promise for heavy metal ion absorption, its scalability and cost-effectiveness at industrial scales require further investigation. Pilot studies and techno-economic analyses would be necessary to accurately assess the viability of large-scale implementation and to optimize process parameters for maximum efficiency and minimum cost.

Scalability of HEC-based heavy metal absorption systems depends largely on the production capacity of HEC and the efficiency of the absorption process. Current manufacturing methods for HEC are well-established, with global production capacities in the range of hundreds of thousands of tons annually. This suggests that raw material availability is unlikely to be a limiting factor for scaling up HEC-based absorption systems.

However, the absorption process itself may present challenges when scaled up. Factors such as contact time, pH, temperature, and the concentration of heavy metal ions can all affect the efficiency of absorption. Large-scale systems would need to maintain optimal conditions across much larger volumes, which may require significant engineering solutions and process control mechanisms.

Cost analysis of HEC-based heavy metal absorption systems must consider both capital and operational expenditures. Initial investment costs include equipment for HEC modification (if required), absorption columns or reactors, and associated infrastructure. Operational costs encompass raw materials (HEC and any additives), energy consumption, labor, and waste management.

The cost-effectiveness of HEC-based systems compared to alternative heavy metal removal technologies is a critical consideration. While HEC is relatively inexpensive as a raw material, its performance in terms of absorption capacity and selectivity must justify its use over other adsorbents or treatment methods. Additionally, the potential for regeneration and reuse of HEC after absorption could significantly impact long-term operational costs.

Environmental and regulatory factors also play a role in scalability and cost analysis. The disposal or regeneration of HEC after heavy metal absorption must comply with environmental regulations, which can vary by region. The cost of proper disposal or the implementation of regeneration processes should be factored into the overall economic assessment.

In conclusion, while HEC shows promise for heavy metal ion absorption, its scalability and cost-effectiveness at industrial scales require further investigation. Pilot studies and techno-economic analyses would be necessary to accurately assess the viability of large-scale implementation and to optimize process parameters for maximum efficiency and minimum cost.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!