Novel Hydroxyethylcellulose Coatings for Aerospace Materials

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Coatings Evolution and Objectives

The aerospace industry has witnessed significant advancements in coating technologies over the past decades, driven by the need for enhanced performance, durability, and safety of aircraft and spacecraft. The evolution of aerospace coatings has been marked by a shift from traditional solvent-based systems to more environmentally friendly and efficient alternatives. This progression has been fueled by stringent regulations, increasing environmental concerns, and the demand for improved fuel efficiency.

In the early stages, aerospace coatings primarily focused on corrosion protection and aesthetic appearance. However, as the industry evolved, the requirements expanded to include thermal protection, ice resistance, and electromagnetic interference shielding. The introduction of composite materials in aerospace construction further necessitated the development of specialized coatings compatible with these new substrates.

The current landscape of aerospace coatings is characterized by multi-functional systems that offer a combination of properties such as UV resistance, erosion protection, and self-cleaning capabilities. Nanotechnology has played a crucial role in this evolution, enabling the creation of coatings with enhanced mechanical properties and reduced weight. Smart coatings capable of self-healing and real-time monitoring of structural integrity have also emerged as promising innovations.

The development of novel hydroxyethylcellulose coatings for aerospace materials represents a significant step forward in this evolutionary process. Hydroxyethylcellulose, a cellulose derivative, offers unique properties that align well with the demanding requirements of aerospace applications. Its biodegradability, excellent film-forming ability, and compatibility with various additives make it an attractive candidate for next-generation aerospace coatings.

The primary objectives of developing hydroxyethylcellulose coatings for aerospace materials are multifaceted. Firstly, there is a strong focus on improving the environmental profile of aerospace coatings by reducing volatile organic compound (VOC) emissions and enhancing biodegradability. Secondly, these coatings aim to provide superior protection against extreme environmental conditions, including temperature fluctuations, UV radiation, and chemical exposure.

Furthermore, the research into hydroxyethylcellulose coatings seeks to address the challenges of weight reduction and fuel efficiency in aerospace applications. By developing lightweight yet durable coatings, the industry aims to contribute to overall aircraft performance and operational cost reduction. Additionally, there is a growing interest in exploring the potential of these coatings to incorporate smart functionalities, such as self-healing properties or integrated sensors for structural health monitoring.

In the early stages, aerospace coatings primarily focused on corrosion protection and aesthetic appearance. However, as the industry evolved, the requirements expanded to include thermal protection, ice resistance, and electromagnetic interference shielding. The introduction of composite materials in aerospace construction further necessitated the development of specialized coatings compatible with these new substrates.

The current landscape of aerospace coatings is characterized by multi-functional systems that offer a combination of properties such as UV resistance, erosion protection, and self-cleaning capabilities. Nanotechnology has played a crucial role in this evolution, enabling the creation of coatings with enhanced mechanical properties and reduced weight. Smart coatings capable of self-healing and real-time monitoring of structural integrity have also emerged as promising innovations.

The development of novel hydroxyethylcellulose coatings for aerospace materials represents a significant step forward in this evolutionary process. Hydroxyethylcellulose, a cellulose derivative, offers unique properties that align well with the demanding requirements of aerospace applications. Its biodegradability, excellent film-forming ability, and compatibility with various additives make it an attractive candidate for next-generation aerospace coatings.

The primary objectives of developing hydroxyethylcellulose coatings for aerospace materials are multifaceted. Firstly, there is a strong focus on improving the environmental profile of aerospace coatings by reducing volatile organic compound (VOC) emissions and enhancing biodegradability. Secondly, these coatings aim to provide superior protection against extreme environmental conditions, including temperature fluctuations, UV radiation, and chemical exposure.

Furthermore, the research into hydroxyethylcellulose coatings seeks to address the challenges of weight reduction and fuel efficiency in aerospace applications. By developing lightweight yet durable coatings, the industry aims to contribute to overall aircraft performance and operational cost reduction. Additionally, there is a growing interest in exploring the potential of these coatings to incorporate smart functionalities, such as self-healing properties or integrated sensors for structural health monitoring.

Market Analysis for Advanced Aerospace Materials

The market for advanced aerospace materials, particularly novel coatings like hydroxyethylcellulose (HEC) for aerospace applications, is experiencing significant growth and transformation. This sector is driven by the increasing demand for lightweight, durable, and high-performance materials in the aerospace industry. The global aerospace coatings market is projected to expand substantially in the coming years, with a focus on innovative solutions that can enhance aircraft performance, reduce fuel consumption, and improve overall efficiency.

The demand for advanced aerospace materials is primarily fueled by the growing commercial aviation sector, increased military spending, and the emergence of new players in the space industry. Commercial airlines are continuously seeking ways to reduce operational costs, with fuel efficiency being a top priority. This has led to a surge in demand for lightweight materials and coatings that can reduce aircraft weight without compromising structural integrity or safety.

In the military aerospace sector, there is a strong emphasis on developing materials that can withstand extreme conditions and provide enhanced stealth capabilities. This has created opportunities for novel coatings like HEC, which can offer improved thermal protection, radar absorption, and resistance to chemical and environmental factors.

The space industry, with its rapid commercialization and increased launch activities, is another key driver for advanced aerospace materials. Companies are investing in materials that can withstand the harsh conditions of space, including extreme temperatures, radiation, and micrometeoroid impacts. Novel coatings play a crucial role in protecting spacecraft and satellites, extending their operational lifespan and reliability.

Geographically, North America and Europe continue to dominate the aerospace materials market, owing to the presence of major aircraft manufacturers and defense contractors. However, the Asia-Pacific region is emerging as a significant market, driven by the growing aviation industry in countries like China and India, and increased defense spending across the region.

The market for advanced aerospace materials is characterized by intense competition and rapid technological advancements. Key players in this sector are investing heavily in research and development to gain a competitive edge. Collaborations between material manufacturers, aerospace companies, and research institutions are becoming increasingly common, fostering innovation and accelerating the development of novel solutions like HEC coatings.

Environmental regulations and sustainability concerns are also shaping the market landscape. There is a growing emphasis on developing eco-friendly coatings and materials that reduce the environmental impact of aerospace operations. This trend is likely to drive further innovation in bio-based and recyclable aerospace materials in the coming years.

The demand for advanced aerospace materials is primarily fueled by the growing commercial aviation sector, increased military spending, and the emergence of new players in the space industry. Commercial airlines are continuously seeking ways to reduce operational costs, with fuel efficiency being a top priority. This has led to a surge in demand for lightweight materials and coatings that can reduce aircraft weight without compromising structural integrity or safety.

In the military aerospace sector, there is a strong emphasis on developing materials that can withstand extreme conditions and provide enhanced stealth capabilities. This has created opportunities for novel coatings like HEC, which can offer improved thermal protection, radar absorption, and resistance to chemical and environmental factors.

The space industry, with its rapid commercialization and increased launch activities, is another key driver for advanced aerospace materials. Companies are investing in materials that can withstand the harsh conditions of space, including extreme temperatures, radiation, and micrometeoroid impacts. Novel coatings play a crucial role in protecting spacecraft and satellites, extending their operational lifespan and reliability.

Geographically, North America and Europe continue to dominate the aerospace materials market, owing to the presence of major aircraft manufacturers and defense contractors. However, the Asia-Pacific region is emerging as a significant market, driven by the growing aviation industry in countries like China and India, and increased defense spending across the region.

The market for advanced aerospace materials is characterized by intense competition and rapid technological advancements. Key players in this sector are investing heavily in research and development to gain a competitive edge. Collaborations between material manufacturers, aerospace companies, and research institutions are becoming increasingly common, fostering innovation and accelerating the development of novel solutions like HEC coatings.

Environmental regulations and sustainability concerns are also shaping the market landscape. There is a growing emphasis on developing eco-friendly coatings and materials that reduce the environmental impact of aerospace operations. This trend is likely to drive further innovation in bio-based and recyclable aerospace materials in the coming years.

HEC Coating Technology: Current Status and Challenges

Hydroxyethylcellulose (HEC) coatings have emerged as a promising solution for aerospace materials, offering a unique combination of properties that address the demanding requirements of the industry. The current status of HEC coating technology reflects significant advancements in material science and engineering, yet it also faces several challenges that require further research and development.

One of the primary advantages of HEC coatings is their excellent film-forming ability, which allows for the creation of uniform and continuous protective layers on various aerospace substrates. This characteristic is crucial for ensuring consistent performance across different components and structures. Additionally, HEC coatings exhibit good adhesion to a wide range of materials commonly used in aerospace applications, including metals, composites, and ceramics.

The environmental resistance of HEC coatings has been a focal point of recent developments. These coatings have demonstrated improved resistance to UV radiation, thermal cycling, and moisture, which are critical factors in the harsh operating conditions encountered by aerospace materials. However, further enhancements are needed to meet the increasingly stringent requirements of next-generation aerospace systems.

A significant challenge in the current state of HEC coating technology is achieving optimal mechanical properties. While HEC coatings offer good flexibility, their scratch and abrasion resistance still lag behind some traditional coating systems. This limitation is particularly problematic for components subjected to high wear and tear during operation.

Another area of ongoing research is the incorporation of functional additives into HEC coatings. Scientists and engineers are exploring ways to integrate nanomaterials, self-healing agents, and smart sensors into the coating matrix to enhance performance and introduce new functionalities. However, ensuring uniform dispersion and maintaining the overall integrity of the coating system remain challenging.

The scalability of HEC coating production and application processes presents another hurdle. While laboratory-scale results have been promising, translating these successes to industrial-scale manufacturing requires further optimization. Issues such as coating thickness control, curing time reduction, and process repeatability need to be addressed to make HEC coatings commercially viable for large-scale aerospace applications.

Regulatory compliance and environmental considerations also pose challenges for the widespread adoption of HEC coatings. As aerospace industries face increasing pressure to reduce their environmental footprint, there is a growing need for eco-friendly coating solutions. While HEC itself is a biodegradable polymer, the additives and processing methods used in coating formulations may not always meet stringent environmental standards.

In conclusion, HEC coating technology for aerospace materials has made significant strides but still faces several challenges. Overcoming these obstacles will require collaborative efforts between material scientists, aerospace engineers, and industry partners to develop innovative solutions that meet the complex demands of modern aerospace applications.

One of the primary advantages of HEC coatings is their excellent film-forming ability, which allows for the creation of uniform and continuous protective layers on various aerospace substrates. This characteristic is crucial for ensuring consistent performance across different components and structures. Additionally, HEC coatings exhibit good adhesion to a wide range of materials commonly used in aerospace applications, including metals, composites, and ceramics.

The environmental resistance of HEC coatings has been a focal point of recent developments. These coatings have demonstrated improved resistance to UV radiation, thermal cycling, and moisture, which are critical factors in the harsh operating conditions encountered by aerospace materials. However, further enhancements are needed to meet the increasingly stringent requirements of next-generation aerospace systems.

A significant challenge in the current state of HEC coating technology is achieving optimal mechanical properties. While HEC coatings offer good flexibility, their scratch and abrasion resistance still lag behind some traditional coating systems. This limitation is particularly problematic for components subjected to high wear and tear during operation.

Another area of ongoing research is the incorporation of functional additives into HEC coatings. Scientists and engineers are exploring ways to integrate nanomaterials, self-healing agents, and smart sensors into the coating matrix to enhance performance and introduce new functionalities. However, ensuring uniform dispersion and maintaining the overall integrity of the coating system remain challenging.

The scalability of HEC coating production and application processes presents another hurdle. While laboratory-scale results have been promising, translating these successes to industrial-scale manufacturing requires further optimization. Issues such as coating thickness control, curing time reduction, and process repeatability need to be addressed to make HEC coatings commercially viable for large-scale aerospace applications.

Regulatory compliance and environmental considerations also pose challenges for the widespread adoption of HEC coatings. As aerospace industries face increasing pressure to reduce their environmental footprint, there is a growing need for eco-friendly coating solutions. While HEC itself is a biodegradable polymer, the additives and processing methods used in coating formulations may not always meet stringent environmental standards.

In conclusion, HEC coating technology for aerospace materials has made significant strides but still faces several challenges. Overcoming these obstacles will require collaborative efforts between material scientists, aerospace engineers, and industry partners to develop innovative solutions that meet the complex demands of modern aerospace applications.

Existing HEC-based Coating Solutions for Aerospace

01 Use of hydroxyethylcellulose in coating compositions

Hydroxyethylcellulose is utilized as a key component in various coating formulations. It serves as a thickening agent, improving the viscosity and stability of the coating. This polymer enhances the application properties and film-forming characteristics of the coating, resulting in improved surface coverage and adhesion.- Use of hydroxyethylcellulose in coating compositions: Hydroxyethylcellulose is utilized as a key component in various coating formulations. It serves as a thickening agent, improving the viscosity and stability of the coating. This polymer enhances the application properties and film-forming characteristics of the coating, resulting in improved surface coverage and adhesion.

- Hydroxyethylcellulose in pharmaceutical coatings: In pharmaceutical applications, hydroxyethylcellulose is employed in coating formulations for tablets and other dosage forms. It acts as a film-forming agent, providing a protective barrier and controlling drug release. The polymer's properties allow for the development of modified release formulations and improved stability of pharmaceutical products.

- Hydroxyethylcellulose in personal care product coatings: Hydroxyethylcellulose is utilized in coatings for personal care products such as cosmetics and hair care items. It functions as a film-former and thickener, enhancing the texture and stability of the products. The polymer contributes to improved spreadability, moisture retention, and overall product performance in various personal care applications.

- Hydroxyethylcellulose in industrial coatings: In industrial coating applications, hydroxyethylcellulose is used to modify the rheological properties of the coating formulations. It helps in controlling the flow and leveling characteristics, resulting in improved application and film formation. The polymer enhances the stability and performance of coatings used in various industrial sectors.

- Modifications and combinations of hydroxyethylcellulose for coating applications: Research has been conducted on modifying hydroxyethylcellulose or combining it with other materials to enhance its properties for coating applications. These modifications aim to improve specific characteristics such as water resistance, adhesion, or compatibility with other coating components. The resulting modified polymers offer enhanced performance in various coating formulations.

02 Hydroxyethylcellulose in pharmaceutical coatings

In pharmaceutical applications, hydroxyethylcellulose is employed in coating formulations for tablets and other dosage forms. It acts as a film-forming agent, providing a protective barrier and controlling drug release. The polymer's properties allow for the development of modified release formulations and improved stability of pharmaceutical products.Expand Specific Solutions03 Hydroxyethylcellulose in personal care product coatings

Hydroxyethylcellulose is utilized in coatings for personal care products such as cosmetics and hair care items. It functions as a film-former and thickener, enhancing the texture and stability of the products. The polymer also contributes to improved moisture retention and sensory properties in these applications.Expand Specific Solutions04 Hydroxyethylcellulose in industrial coatings

In industrial coating applications, hydroxyethylcellulose is used to modify the rheological properties of the coating formulations. It helps in controlling the flow and leveling characteristics, resulting in improved application and film formation. The polymer also enhances the stability and storage properties of industrial coatings.Expand Specific Solutions05 Modifications and combinations of hydroxyethylcellulose for coating applications

Research has been conducted on modifying hydroxyethylcellulose or combining it with other materials to enhance its performance in coating applications. These modifications can include chemical treatments or blending with other polymers to improve specific properties such as water resistance, adhesion, or durability of the resulting coatings.Expand Specific Solutions

Key Players in Aerospace Coating Industry

The development of novel hydroxyethylcellulose coatings for aerospace materials is in an emerging phase, with significant potential for growth. The market size is expanding as aerospace companies seek advanced materials to enhance performance and durability. While the technology is still evolving, several key players are driving innovation. Companies like Dow Global Technologies, BASF Coatings, and Henkel AG & Co. KGaA are leveraging their expertise in chemical engineering to develop cutting-edge solutions. Research institutions such as Purdue Research Foundation and NASA are also contributing to advancements in this field. The competitive landscape is characterized by a mix of established chemical companies and specialized aerospace material developers, indicating a growing interest in this niche but promising market.

Dow Global Technologies LLC

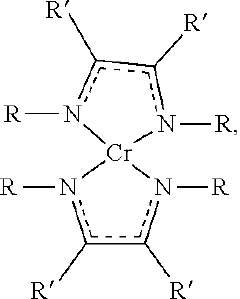

Technical Solution: Dow Global Technologies LLC has developed advanced hydroxyethylcellulose (HEC) coatings for aerospace materials, focusing on improving thermal stability and mechanical properties. Their approach involves modifying HEC with silane coupling agents to enhance adhesion to metal substrates [1]. The company has also incorporated nanoparticles into the HEC matrix to improve barrier properties and UV resistance [3]. Dow's formulation includes a cross-linking agent to increase the coating's durability in extreme aerospace environments [5]. They have optimized the viscosity and rheological properties of the HEC coating to ensure uniform application on complex aerospace structures [7].

Strengths: Excellent adhesion to metal substrates, improved thermal stability, and enhanced barrier properties. Weaknesses: Potential higher cost due to specialized additives and nanoparticles.

BASF Coatings GmbH

Technical Solution: BASF Coatings GmbH has developed a novel HEC-based coating system for aerospace materials that focuses on sustainability and performance. Their approach incorporates bio-based additives to enhance the renewable content of the coating [2]. BASF's formulation includes specially designed HEC derivatives that improve flexibility and impact resistance, crucial for aerospace applications [4]. The company has also integrated self-healing properties into their HEC coatings by incorporating microcapsules containing reactive agents [6]. BASF's coating system features a multi-layer approach, with each layer optimized for specific functions such as corrosion resistance, thermal insulation, and surface finish [8].

Strengths: Sustainable formulation, self-healing properties, and multi-functional coating system. Weaknesses: Complexity of the multi-layer system may increase application time and cost.

Innovations in HEC Coating Formulations

Flame-retardant epoxy composition and method of using the same

PatentWO2020131946A1

Innovation

- A halogen-free, low-density flame-retardant epoxy composition incorporating an epoxy component, curative, accelerator, nano-sized core-shell rubber particles, and a halogen-free fire-retardant component, along with a low-density filler, to prevent micro-cracking and enhance moisture resistance, processed as a one-part system for ease of use.

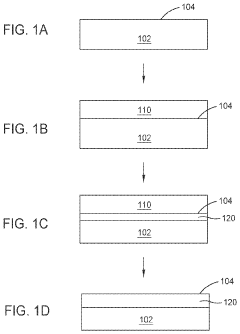

Methods for depositing sacrificial coatings on aerospace components

PatentPendingUS20230313380A1

Innovation

- A method involving the deposition of a metal oxide template layer on aerospace components, followed by a thermal process that diffuses aluminum to form an aluminum oxide layer, which is then oxidized and the template layer is removed, creating a protective coating with improved adhesion and reduced weight.

Environmental Impact of HEC Coatings in Aerospace

The environmental impact of Hydroxyethylcellulose (HEC) coatings in aerospace applications is a critical consideration as the industry strives for more sustainable practices. HEC coatings offer several environmental advantages over traditional aerospace coatings, primarily due to their biodegradable nature and reduced toxicity.

One of the most significant environmental benefits of HEC coatings is their biodegradability. Unlike many conventional aerospace coatings that persist in the environment for extended periods, HEC-based coatings can naturally decompose over time. This characteristic significantly reduces the long-term environmental footprint of aerospace materials, particularly at the end of their lifecycle.

The production process of HEC coatings also tends to have a lower environmental impact compared to traditional alternatives. HEC is derived from renewable resources, primarily cellulose from wood or cotton, which contributes to a more sustainable supply chain. The manufacturing process typically requires less energy and produces fewer harmful byproducts, resulting in reduced greenhouse gas emissions and air pollution.

In terms of application and use, HEC coatings present fewer health and environmental risks to workers and surrounding ecosystems. They generally contain lower levels of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) compared to solvent-based coatings. This reduction in harmful emissions not only improves air quality in manufacturing and maintenance facilities but also minimizes the potential for atmospheric pollution during the operational life of aerospace components.

Water-based HEC coatings further enhance environmental benefits by eliminating the need for organic solvents, which are often associated with air and water pollution. The use of water as a carrier reduces the risk of soil and groundwater contamination in case of spills or improper disposal.

However, it is important to note that the environmental impact of HEC coatings is not entirely benign. The production of HEC still requires chemical processing, which can have associated environmental costs. Additionally, while biodegradable, the breakdown products of HEC coatings in the environment need to be carefully studied to ensure they do not pose unforeseen ecological risks.

The aerospace industry's adoption of HEC coatings aligns with broader sustainability goals and regulatory trends. As environmental regulations become more stringent, particularly regarding emissions and waste management, HEC coatings offer a pathway for compliance while maintaining high performance standards required in aerospace applications.

In conclusion, while HEC coatings represent a significant improvement in terms of environmental impact compared to traditional aerospace coatings, ongoing research and development are crucial to further optimize their ecological profile and ensure their long-term sustainability in aerospace applications.

One of the most significant environmental benefits of HEC coatings is their biodegradability. Unlike many conventional aerospace coatings that persist in the environment for extended periods, HEC-based coatings can naturally decompose over time. This characteristic significantly reduces the long-term environmental footprint of aerospace materials, particularly at the end of their lifecycle.

The production process of HEC coatings also tends to have a lower environmental impact compared to traditional alternatives. HEC is derived from renewable resources, primarily cellulose from wood or cotton, which contributes to a more sustainable supply chain. The manufacturing process typically requires less energy and produces fewer harmful byproducts, resulting in reduced greenhouse gas emissions and air pollution.

In terms of application and use, HEC coatings present fewer health and environmental risks to workers and surrounding ecosystems. They generally contain lower levels of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) compared to solvent-based coatings. This reduction in harmful emissions not only improves air quality in manufacturing and maintenance facilities but also minimizes the potential for atmospheric pollution during the operational life of aerospace components.

Water-based HEC coatings further enhance environmental benefits by eliminating the need for organic solvents, which are often associated with air and water pollution. The use of water as a carrier reduces the risk of soil and groundwater contamination in case of spills or improper disposal.

However, it is important to note that the environmental impact of HEC coatings is not entirely benign. The production of HEC still requires chemical processing, which can have associated environmental costs. Additionally, while biodegradable, the breakdown products of HEC coatings in the environment need to be carefully studied to ensure they do not pose unforeseen ecological risks.

The aerospace industry's adoption of HEC coatings aligns with broader sustainability goals and regulatory trends. As environmental regulations become more stringent, particularly regarding emissions and waste management, HEC coatings offer a pathway for compliance while maintaining high performance standards required in aerospace applications.

In conclusion, while HEC coatings represent a significant improvement in terms of environmental impact compared to traditional aerospace coatings, ongoing research and development are crucial to further optimize their ecological profile and ensure their long-term sustainability in aerospace applications.

Certification and Testing Standards for Aerospace Coatings

Certification and testing standards play a crucial role in ensuring the safety, reliability, and performance of aerospace coatings, including novel hydroxyethylcellulose coatings for aerospace materials. These standards are developed and maintained by various organizations, such as the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and industry bodies like SAE International.

The primary certification standards for aerospace coatings focus on several key aspects. Firstly, they address the coating's ability to withstand extreme environmental conditions, including temperature fluctuations, humidity, and exposure to UV radiation. Standards such as ASTM D2247 and ASTM G154 are commonly used to evaluate these properties.

Secondly, the standards assess the coating's resistance to various chemicals and fluids encountered in aerospace applications. This includes resistance to hydraulic fluids, jet fuels, and de-icing agents. Tests like ASTM F502 and ASTM F1110 are employed to evaluate chemical resistance.

Adhesion properties are another critical aspect covered by certification standards. Tests like ASTM D3359 and ASTM D4541 are used to measure the coating's ability to adhere to different aerospace substrates under various conditions.

Fire resistance is a paramount concern in aerospace applications. Standards such as FAR 25.853 and ASTM E84 are used to evaluate the flame spread and smoke development characteristics of coatings.

Durability and wear resistance are also key factors addressed in certification standards. Tests like ASTM D4060 and ASTM D2794 are used to assess the coating's resistance to abrasion and impact.

For novel hydroxyethylcellulose coatings, additional testing may be required to evaluate their unique properties. This could include assessing their biodegradability, moisture absorption characteristics, and potential for microbial growth.

The certification process typically involves rigorous testing by accredited laboratories, followed by a comprehensive review of test results and manufacturing processes. Manufacturers must demonstrate compliance with all relevant standards and regulations before their coatings can be approved for use in aerospace applications.

It's important to note that certification standards are continually evolving to keep pace with technological advancements and emerging safety concerns. As such, manufacturers and researchers working on novel coatings must stay informed about the latest standards and testing requirements in the aerospace industry.

The primary certification standards for aerospace coatings focus on several key aspects. Firstly, they address the coating's ability to withstand extreme environmental conditions, including temperature fluctuations, humidity, and exposure to UV radiation. Standards such as ASTM D2247 and ASTM G154 are commonly used to evaluate these properties.

Secondly, the standards assess the coating's resistance to various chemicals and fluids encountered in aerospace applications. This includes resistance to hydraulic fluids, jet fuels, and de-icing agents. Tests like ASTM F502 and ASTM F1110 are employed to evaluate chemical resistance.

Adhesion properties are another critical aspect covered by certification standards. Tests like ASTM D3359 and ASTM D4541 are used to measure the coating's ability to adhere to different aerospace substrates under various conditions.

Fire resistance is a paramount concern in aerospace applications. Standards such as FAR 25.853 and ASTM E84 are used to evaluate the flame spread and smoke development characteristics of coatings.

Durability and wear resistance are also key factors addressed in certification standards. Tests like ASTM D4060 and ASTM D2794 are used to assess the coating's resistance to abrasion and impact.

For novel hydroxyethylcellulose coatings, additional testing may be required to evaluate their unique properties. This could include assessing their biodegradability, moisture absorption characteristics, and potential for microbial growth.

The certification process typically involves rigorous testing by accredited laboratories, followed by a comprehensive review of test results and manufacturing processes. Manufacturers must demonstrate compliance with all relevant standards and regulations before their coatings can be approved for use in aerospace applications.

It's important to note that certification standards are continually evolving to keep pace with technological advancements and emerging safety concerns. As such, manufacturers and researchers working on novel coatings must stay informed about the latest standards and testing requirements in the aerospace industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!