Applications of Hydroxyethylcellulose in Food Safety Monitoring

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEC in Food Safety: Background and Objectives

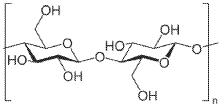

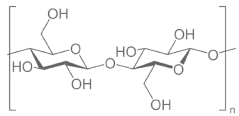

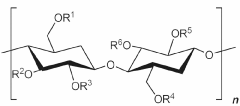

Hydroxyethylcellulose (HEC) has emerged as a promising material in the field of food safety monitoring, offering innovative solutions to address growing concerns about food quality and contamination. The evolution of HEC applications in this domain reflects the increasing demand for more effective and efficient methods to ensure the safety of food products throughout the supply chain.

The primary objective of utilizing HEC in food safety monitoring is to develop advanced sensing and detection systems that can rapidly and accurately identify potential hazards in food products. These hazards may include microbial contamination, chemical residues, allergens, and other harmful substances that pose risks to consumer health. By leveraging the unique properties of HEC, researchers and industry professionals aim to create more sensitive, reliable, and cost-effective monitoring tools.

The development of HEC-based food safety monitoring technologies is driven by several key factors. Firstly, the globalization of food supply chains has increased the complexity of ensuring food safety, necessitating more sophisticated monitoring methods. Secondly, regulatory bodies worldwide have implemented stricter food safety standards, compelling the food industry to adopt more advanced monitoring techniques. Lastly, consumer awareness and demand for safe, high-quality food products have intensified, pushing companies to invest in innovative safety measures.

HEC's versatility as a polymer makes it particularly suitable for various applications in food safety monitoring. Its ability to form stable gels, films, and coatings allows for the development of novel sensor platforms and packaging materials. These HEC-based materials can be engineered to respond to specific contaminants or environmental conditions, providing visual or measurable indicators of food quality and safety.

One of the primary goals in this field is to create rapid, on-site testing methods that can detect food contaminants in real-time. This would enable more efficient quality control processes and reduce the reliance on time-consuming laboratory tests. Additionally, researchers are exploring the potential of HEC-based smart packaging solutions that can actively monitor food quality throughout storage and transportation.

As the field progresses, there is a growing focus on integrating HEC-based monitoring systems with digital technologies. This convergence aims to create comprehensive food safety management systems that can track and analyze data from multiple points in the supply chain, enhancing traceability and enabling proactive risk management.

In conclusion, the application of HEC in food safety monitoring represents a significant technological advancement in ensuring food quality and consumer safety. The ongoing research and development in this area are expected to yield innovative solutions that will revolutionize how we monitor and maintain food safety standards in an increasingly complex global food system.

The primary objective of utilizing HEC in food safety monitoring is to develop advanced sensing and detection systems that can rapidly and accurately identify potential hazards in food products. These hazards may include microbial contamination, chemical residues, allergens, and other harmful substances that pose risks to consumer health. By leveraging the unique properties of HEC, researchers and industry professionals aim to create more sensitive, reliable, and cost-effective monitoring tools.

The development of HEC-based food safety monitoring technologies is driven by several key factors. Firstly, the globalization of food supply chains has increased the complexity of ensuring food safety, necessitating more sophisticated monitoring methods. Secondly, regulatory bodies worldwide have implemented stricter food safety standards, compelling the food industry to adopt more advanced monitoring techniques. Lastly, consumer awareness and demand for safe, high-quality food products have intensified, pushing companies to invest in innovative safety measures.

HEC's versatility as a polymer makes it particularly suitable for various applications in food safety monitoring. Its ability to form stable gels, films, and coatings allows for the development of novel sensor platforms and packaging materials. These HEC-based materials can be engineered to respond to specific contaminants or environmental conditions, providing visual or measurable indicators of food quality and safety.

One of the primary goals in this field is to create rapid, on-site testing methods that can detect food contaminants in real-time. This would enable more efficient quality control processes and reduce the reliance on time-consuming laboratory tests. Additionally, researchers are exploring the potential of HEC-based smart packaging solutions that can actively monitor food quality throughout storage and transportation.

As the field progresses, there is a growing focus on integrating HEC-based monitoring systems with digital technologies. This convergence aims to create comprehensive food safety management systems that can track and analyze data from multiple points in the supply chain, enhancing traceability and enabling proactive risk management.

In conclusion, the application of HEC in food safety monitoring represents a significant technological advancement in ensuring food quality and consumer safety. The ongoing research and development in this area are expected to yield innovative solutions that will revolutionize how we monitor and maintain food safety standards in an increasingly complex global food system.

Market Analysis for HEC-based Food Safety Solutions

The market for HEC-based food safety solutions is experiencing significant growth, driven by increasing consumer awareness of food safety issues and stringent regulatory requirements. The global food safety testing market, which includes HEC-based solutions, is projected to reach substantial value in the coming years. This growth is attributed to the rising incidence of foodborne illnesses, globalization of food supply chains, and the need for rapid and accurate testing methods.

Hydroxyethylcellulose (HEC) has emerged as a versatile compound in food safety monitoring applications due to its unique properties. Its ability to form stable gels and films makes it particularly useful in developing advanced food packaging materials with antimicrobial properties. These HEC-based packaging solutions can extend shelf life and prevent contamination, addressing key concerns in the food industry.

The demand for HEC in food safety monitoring is also driven by its potential in developing biosensors and rapid testing kits. These applications allow for quick and efficient detection of pathogens, toxins, and other contaminants in food products. The market for such rapid testing solutions is expanding rapidly, as food producers and regulatory bodies seek faster and more cost-effective methods for ensuring food safety.

Geographically, North America and Europe currently dominate the market for HEC-based food safety solutions, owing to their stringent food safety regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing food safety concerns, rapid industrialization of the food sector, and growing export opportunities.

The market is characterized by a mix of established players and innovative startups. Large chemical companies are investing in research and development to expand their HEC product portfolios for food safety applications. Simultaneously, biotechnology firms are leveraging HEC in developing novel detection and monitoring technologies.

Challenges in the market include the need for continuous innovation to improve sensitivity and specificity of HEC-based detection methods, as well as addressing cost concerns for widespread adoption. Additionally, regulatory approval processes for new HEC-based food safety solutions can be time-consuming, potentially slowing market growth.

Despite these challenges, the future outlook for HEC-based food safety solutions remains positive. The increasing focus on preventive approaches to food safety, coupled with advancements in nanotechnology and biotechnology, is expected to create new opportunities for HEC applications in food safety monitoring.

Hydroxyethylcellulose (HEC) has emerged as a versatile compound in food safety monitoring applications due to its unique properties. Its ability to form stable gels and films makes it particularly useful in developing advanced food packaging materials with antimicrobial properties. These HEC-based packaging solutions can extend shelf life and prevent contamination, addressing key concerns in the food industry.

The demand for HEC in food safety monitoring is also driven by its potential in developing biosensors and rapid testing kits. These applications allow for quick and efficient detection of pathogens, toxins, and other contaminants in food products. The market for such rapid testing solutions is expanding rapidly, as food producers and regulatory bodies seek faster and more cost-effective methods for ensuring food safety.

Geographically, North America and Europe currently dominate the market for HEC-based food safety solutions, owing to their stringent food safety regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing food safety concerns, rapid industrialization of the food sector, and growing export opportunities.

The market is characterized by a mix of established players and innovative startups. Large chemical companies are investing in research and development to expand their HEC product portfolios for food safety applications. Simultaneously, biotechnology firms are leveraging HEC in developing novel detection and monitoring technologies.

Challenges in the market include the need for continuous innovation to improve sensitivity and specificity of HEC-based detection methods, as well as addressing cost concerns for widespread adoption. Additionally, regulatory approval processes for new HEC-based food safety solutions can be time-consuming, potentially slowing market growth.

Despite these challenges, the future outlook for HEC-based food safety solutions remains positive. The increasing focus on preventive approaches to food safety, coupled with advancements in nanotechnology and biotechnology, is expected to create new opportunities for HEC applications in food safety monitoring.

Current Challenges in HEC Food Safety Applications

The application of Hydroxyethylcellulose (HEC) in food safety monitoring faces several significant challenges that hinder its widespread adoption and effectiveness. One of the primary obstacles is the lack of standardized protocols for incorporating HEC into food safety testing methods. This absence of uniformity makes it difficult to compare results across different laboratories and regulatory bodies, potentially leading to inconsistencies in food safety assessments.

Another challenge lies in the sensitivity and specificity of HEC-based detection systems. While HEC has shown promise in enhancing the performance of certain biosensors and analytical techniques, there is still room for improvement in terms of detecting low concentrations of contaminants and distinguishing between closely related compounds. This limitation can result in false positives or negatives, compromising the reliability of food safety monitoring processes.

The stability of HEC-based materials in various food matrices presents another hurdle. Different food products have diverse chemical compositions and physical properties, which can interfere with the functionality of HEC-modified sensors or analytical tools. Ensuring consistent performance across a wide range of food types remains a significant challenge for researchers and food safety professionals.

Cost-effectiveness is also a concern in the application of HEC for food safety monitoring. While HEC itself is relatively inexpensive, the development and implementation of HEC-based detection systems can be costly, particularly when considering the need for specialized equipment and trained personnel. This financial barrier may limit the adoption of HEC-based technologies, especially in smaller food production facilities or developing regions.

Environmental factors, such as temperature and pH variations, can affect the performance of HEC-based monitoring systems. Maintaining the integrity and reliability of these systems under diverse environmental conditions encountered in food processing and storage facilities is crucial but challenging. This issue is particularly relevant in global food supply chains where products may be subjected to varying conditions during transportation and storage.

Regulatory approval and standardization of HEC-based food safety monitoring methods pose additional challenges. The process of validating new technologies and integrating them into existing regulatory frameworks can be time-consuming and complex. This delay in regulatory acceptance can slow down the adoption of potentially beneficial HEC applications in the food industry.

Lastly, there is a need for more comprehensive research on the long-term effects of HEC exposure through food products. While HEC is generally recognized as safe, its increased use in food safety applications may lead to higher levels of human exposure. Ensuring that these elevated exposure levels do not pose any unforeseen health risks requires ongoing toxicological studies and risk assessments.

Another challenge lies in the sensitivity and specificity of HEC-based detection systems. While HEC has shown promise in enhancing the performance of certain biosensors and analytical techniques, there is still room for improvement in terms of detecting low concentrations of contaminants and distinguishing between closely related compounds. This limitation can result in false positives or negatives, compromising the reliability of food safety monitoring processes.

The stability of HEC-based materials in various food matrices presents another hurdle. Different food products have diverse chemical compositions and physical properties, which can interfere with the functionality of HEC-modified sensors or analytical tools. Ensuring consistent performance across a wide range of food types remains a significant challenge for researchers and food safety professionals.

Cost-effectiveness is also a concern in the application of HEC for food safety monitoring. While HEC itself is relatively inexpensive, the development and implementation of HEC-based detection systems can be costly, particularly when considering the need for specialized equipment and trained personnel. This financial barrier may limit the adoption of HEC-based technologies, especially in smaller food production facilities or developing regions.

Environmental factors, such as temperature and pH variations, can affect the performance of HEC-based monitoring systems. Maintaining the integrity and reliability of these systems under diverse environmental conditions encountered in food processing and storage facilities is crucial but challenging. This issue is particularly relevant in global food supply chains where products may be subjected to varying conditions during transportation and storage.

Regulatory approval and standardization of HEC-based food safety monitoring methods pose additional challenges. The process of validating new technologies and integrating them into existing regulatory frameworks can be time-consuming and complex. This delay in regulatory acceptance can slow down the adoption of potentially beneficial HEC applications in the food industry.

Lastly, there is a need for more comprehensive research on the long-term effects of HEC exposure through food products. While HEC is generally recognized as safe, its increased use in food safety applications may lead to higher levels of human exposure. Ensuring that these elevated exposure levels do not pose any unforeseen health risks requires ongoing toxicological studies and risk assessments.

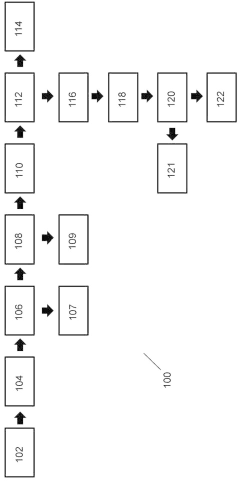

Existing HEC-based Food Safety Monitoring Methods

01 Use in drilling fluids and well treatment compositions

Hydroxyethylcellulose is utilized in drilling fluids and well treatment compositions to control viscosity and fluid loss. It acts as a thickening agent and helps maintain the stability of the fluid in various temperature and pressure conditions encountered during drilling operations.- Use in drilling fluids and well treatment compositions: Hydroxyethylcellulose is used as a viscosifier and fluid loss control agent in drilling fluids and well treatment compositions. It helps to improve the rheological properties of the fluids, enhance suspension of solids, and reduce fluid loss to the formation during drilling and well operations.

- Application in personal care and cosmetic products: Hydroxyethylcellulose is utilized as a thickening agent and stabilizer in personal care and cosmetic formulations. It provides texture, improves product consistency, and enhances the stability of emulsions in various products such as shampoos, lotions, and creams.

- Use in pharmaceutical formulations: Hydroxyethylcellulose is employed in pharmaceutical formulations as a binder, thickener, and controlled-release agent. It helps to improve the stability, viscosity, and release characteristics of various drug delivery systems, including tablets, gels, and topical preparations.

- Application in construction and building materials: Hydroxyethylcellulose is used as an additive in construction and building materials to improve workability, water retention, and adhesion properties. It is particularly useful in cement-based products, mortars, and plasters to enhance their performance and durability.

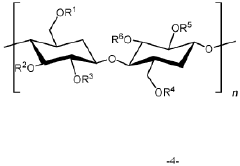

- Modification and derivatization of hydroxyethylcellulose: Various methods for modifying and derivatizing hydroxyethylcellulose are developed to enhance its properties and expand its applications. These modifications can improve its solubility, thermal stability, and compatibility with other materials, leading to novel functionalities in different industries.

02 Application in personal care and cosmetic products

Hydroxyethylcellulose serves as a thickener, stabilizer, and emulsifier in personal care and cosmetic formulations. It enhances the texture and consistency of products such as shampoos, lotions, and creams, while also providing moisturizing properties.Expand Specific Solutions03 Use in pharmaceutical formulations

Hydroxyethylcellulose is employed in pharmaceutical formulations as a binder, thickener, and controlled-release agent. It helps in the preparation of tablets, capsules, and topical medications, improving their stability and release characteristics.Expand Specific Solutions04 Application in construction and building materials

Hydroxyethylcellulose is used in construction and building materials as a water-retention agent and rheology modifier. It improves the workability of cement-based products, enhances adhesion, and helps control setting time in various applications.Expand Specific Solutions05 Use in textile and paper industries

Hydroxyethylcellulose finds applications in textile and paper industries as a sizing agent, binder, and surface treatment additive. It improves the strength and printability of paper products and enhances the dyeing and finishing processes in textiles.Expand Specific Solutions

Key Players in HEC Food Safety Technology

The applications of Hydroxyethylcellulose in food safety monitoring represent an emerging field with significant growth potential. The market is in its early stages, characterized by ongoing research and development efforts. Key players like Dow Global Technologies LLC, Shin-Etsu Chemical Co., Ltd., and Hercules Corp. are driving innovation in this sector. The technology's maturity is still evolving, with universities such as Wuhan University and South China University of Technology contributing to advancements. As food safety concerns grow globally, the market for Hydroxyethylcellulose-based monitoring solutions is expected to expand, attracting more industry participants and fostering collaborations between academic institutions and commercial entities.

Dow Global Technologies LLC

Technical Solution: Dow has developed advanced hydroxyethylcellulose (HEC) formulations for food safety monitoring applications. Their technology utilizes HEC's unique properties to create sensitive and selective biosensors for detecting foodborne pathogens and contaminants. The HEC-based sensors incorporate nanoparticles and specific antibodies to enhance detection capabilities[1]. Dow's approach allows for rapid, on-site testing of food products, with results available in minutes rather than hours or days required for traditional laboratory methods[2]. The company has also explored the use of HEC in smart packaging materials that can change color or provide visual indicators when food spoilage or contamination occurs[3].

Strengths: Rapid detection, on-site testing capability, and potential for integration into smart packaging. Weaknesses: May require specialized equipment for analysis and interpretation of results.

Hercules Corp.

Technical Solution: Hercules Corp. has developed a novel HEC-based film technology for food safety monitoring. Their approach involves creating thin, transparent films infused with HEC and specific reagents that react to the presence of harmful bacteria or toxins in food. These films can be applied directly to food packaging or used as separate testing strips. When exposed to contaminants, the films undergo a visible color change, providing a clear visual indicator of food safety issues[4]. Hercules has also incorporated nanotechnology to enhance the sensitivity and specificity of their HEC films, allowing for detection of even trace amounts of pathogens or chemicals[5].

Strengths: Easy-to-use visual detection system, potential for widespread application in food packaging. Weaknesses: May have limitations in detecting a wide range of contaminants simultaneously.

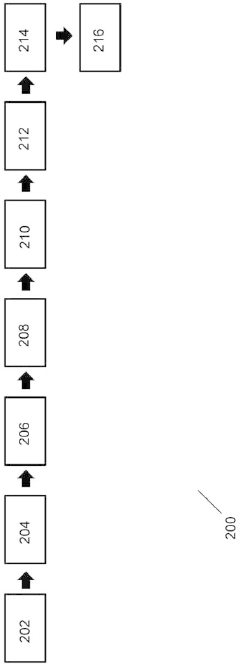

Innovative HEC Applications in Food Safety

Hydroxyethyl cellulose derivative foam control agents and methods of processing foodstuffs

PatentWO2020068484A1

Innovation

- The use of hydroxyethyl cellulose derivatives as foam control agents, which are biodegradable and can be used in various food processing stages to prevent or reduce foam formation without affecting the processing equipment or the final product, including the incorporation of hydroxyethyl methyl cellulose (HEMC) with specific viscosity ranges and degrees of substitution.

Hydroxyethyl cellulose derivative foam control agent and food processing method

PatentActiveJP2022502237A

Innovation

- The use of hydroxyethyl cellulose derivatives, such as hydroxyethylmethylcellulose (HEMC), which are biodegradable and effective in controlling foam during various food processing stages without forming films, by being added to aqueous compositions and applied at multiple processing points.

Regulatory Framework for HEC in Food Industry

The regulatory framework for hydroxyethylcellulose (HEC) in the food industry is complex and multifaceted, reflecting the importance of ensuring food safety while allowing for technological innovation. In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating HEC as a food additive. Under the Federal Food, Drug, and Cosmetic Act, HEC is classified as a Generally Recognized as Safe (GRAS) substance, which allows its use in food products without premarket approval, provided it meets certain criteria.

The European Union, through the European Food Safety Authority (EFSA), has also established regulations for HEC in food applications. EFSA has evaluated HEC and included it in the list of approved food additives under the E number E415. This designation indicates that HEC has been assessed for safety and is permitted for use in food products within the EU, subject to specific conditions and limitations.

In Asia, regulatory approaches vary by country. Japan's Ministry of Health, Labour and Welfare has approved HEC as a food additive, listing it in the Japan's Specifications and Standards for Food Additives. China's National Health Commission has similar provisions, allowing HEC in certain food categories with specified maximum levels.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards that many countries use as a basis for their national regulations. The Codex General Standard for Food Additives (GSFA) includes provisions for HEC, providing guidance on its use in various food categories.

Regulatory bodies typically focus on several key aspects when assessing HEC for food applications. These include purity specifications, acceptable daily intake levels, and potential interactions with other food components. Manufacturers must adhere to Good Manufacturing Practices (GMP) to ensure the quality and safety of HEC used in food products.

The regulatory landscape for HEC is not static. Ongoing research and technological advancements in food safety monitoring may lead to updates in regulations. For instance, improved analytical methods for detecting and quantifying HEC in food products could result in more precise regulatory limits or monitoring requirements.

As the use of HEC in food safety monitoring applications evolves, regulatory frameworks may need to adapt. This could involve developing new guidelines for novel applications, such as HEC-based smart packaging or biosensors for food contaminant detection. Regulatory bodies will likely continue to assess the safety and efficacy of these innovative uses, potentially leading to new standards or modifications to existing regulations.

The European Union, through the European Food Safety Authority (EFSA), has also established regulations for HEC in food applications. EFSA has evaluated HEC and included it in the list of approved food additives under the E number E415. This designation indicates that HEC has been assessed for safety and is permitted for use in food products within the EU, subject to specific conditions and limitations.

In Asia, regulatory approaches vary by country. Japan's Ministry of Health, Labour and Welfare has approved HEC as a food additive, listing it in the Japan's Specifications and Standards for Food Additives. China's National Health Commission has similar provisions, allowing HEC in certain food categories with specified maximum levels.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards that many countries use as a basis for their national regulations. The Codex General Standard for Food Additives (GSFA) includes provisions for HEC, providing guidance on its use in various food categories.

Regulatory bodies typically focus on several key aspects when assessing HEC for food applications. These include purity specifications, acceptable daily intake levels, and potential interactions with other food components. Manufacturers must adhere to Good Manufacturing Practices (GMP) to ensure the quality and safety of HEC used in food products.

The regulatory landscape for HEC is not static. Ongoing research and technological advancements in food safety monitoring may lead to updates in regulations. For instance, improved analytical methods for detecting and quantifying HEC in food products could result in more precise regulatory limits or monitoring requirements.

As the use of HEC in food safety monitoring applications evolves, regulatory frameworks may need to adapt. This could involve developing new guidelines for novel applications, such as HEC-based smart packaging or biosensors for food contaminant detection. Regulatory bodies will likely continue to assess the safety and efficacy of these innovative uses, potentially leading to new standards or modifications to existing regulations.

Environmental Impact of HEC in Food Safety

The environmental impact of hydroxyethylcellulose (HEC) in food safety monitoring is a critical aspect to consider as its applications continue to expand. HEC, a cellulose derivative, is widely used in various industries, including food safety, due to its unique properties. However, its increasing use raises concerns about potential environmental consequences.

One of the primary environmental considerations is the biodegradability of HEC. As a modified natural polymer, HEC is generally considered biodegradable, which is advantageous compared to synthetic alternatives. This characteristic reduces the long-term accumulation of the substance in ecosystems. However, the rate of biodegradation can vary depending on environmental conditions and the specific formulation of HEC used in food safety applications.

The production process of HEC also warrants attention from an environmental perspective. The manufacturing of HEC involves chemical modifications of cellulose, which may require significant energy inputs and potentially generate chemical waste. Efforts to optimize these processes and implement cleaner production techniques are essential to mitigate the environmental footprint associated with HEC production.

Water pollution is another concern related to the use of HEC in food safety monitoring. While HEC itself is not considered toxic to aquatic life, its high solubility in water can lead to increased organic load in water bodies if improperly disposed of. This can potentially affect water quality and aquatic ecosystems, especially in areas with high concentrations of food processing facilities utilizing HEC-based monitoring systems.

The disposal of HEC-containing materials after use in food safety applications is an important consideration. Proper waste management practices are crucial to prevent the accumulation of HEC in landfills or its release into the environment. Recycling and reuse strategies for HEC-based products could help minimize waste and reduce the overall environmental impact.

On a positive note, the use of HEC in food safety monitoring can indirectly contribute to environmental protection by improving the efficiency and accuracy of food safety tests. This can lead to reduced food waste and more targeted use of resources in the food industry, potentially offsetting some of the environmental costs associated with HEC production and use.

As the demand for HEC in food safety applications grows, there is an increasing need for comprehensive life cycle assessments to fully understand its environmental implications. Such studies would help identify areas for improvement in the production, use, and disposal of HEC, guiding the development of more sustainable practices in the food safety monitoring sector.

One of the primary environmental considerations is the biodegradability of HEC. As a modified natural polymer, HEC is generally considered biodegradable, which is advantageous compared to synthetic alternatives. This characteristic reduces the long-term accumulation of the substance in ecosystems. However, the rate of biodegradation can vary depending on environmental conditions and the specific formulation of HEC used in food safety applications.

The production process of HEC also warrants attention from an environmental perspective. The manufacturing of HEC involves chemical modifications of cellulose, which may require significant energy inputs and potentially generate chemical waste. Efforts to optimize these processes and implement cleaner production techniques are essential to mitigate the environmental footprint associated with HEC production.

Water pollution is another concern related to the use of HEC in food safety monitoring. While HEC itself is not considered toxic to aquatic life, its high solubility in water can lead to increased organic load in water bodies if improperly disposed of. This can potentially affect water quality and aquatic ecosystems, especially in areas with high concentrations of food processing facilities utilizing HEC-based monitoring systems.

The disposal of HEC-containing materials after use in food safety applications is an important consideration. Proper waste management practices are crucial to prevent the accumulation of HEC in landfills or its release into the environment. Recycling and reuse strategies for HEC-based products could help minimize waste and reduce the overall environmental impact.

On a positive note, the use of HEC in food safety monitoring can indirectly contribute to environmental protection by improving the efficiency and accuracy of food safety tests. This can lead to reduced food waste and more targeted use of resources in the food industry, potentially offsetting some of the environmental costs associated with HEC production and use.

As the demand for HEC in food safety applications grows, there is an increasing need for comprehensive life cycle assessments to fully understand its environmental implications. Such studies would help identify areas for improvement in the production, use, and disposal of HEC, guiding the development of more sustainable practices in the food safety monitoring sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!