Hydroxyethylcellulose Blends for Biodegradable Packaging

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEC Blends Background

Hydroxyethylcellulose (HEC) blends have emerged as a promising solution in the field of biodegradable packaging, addressing the growing environmental concerns associated with conventional plastic materials. The development of these blends stems from the urgent need to reduce plastic waste and its detrimental impact on ecosystems. HEC, a cellulose derivative, has gained significant attention due to its biodegradability, biocompatibility, and versatile properties.

The journey of HEC blends in packaging applications can be traced back to the early 2000s when researchers began exploring alternatives to petroleum-based plastics. Initially, the focus was on pure HEC films, which demonstrated excellent oxygen barrier properties but lacked the necessary mechanical strength for practical packaging applications. This limitation led to the exploration of HEC blends with other biodegradable polymers and additives to enhance their overall performance.

Over the past two decades, significant advancements have been made in the formulation and processing of HEC blends. Researchers have investigated various combinations of HEC with other biopolymers such as starch, chitosan, and poly(lactic acid) (PLA) to create synergistic blends with improved mechanical, barrier, and thermal properties. These efforts have resulted in the development of HEC-based materials that can potentially replace conventional plastics in certain packaging applications.

The evolution of HEC blends has been driven by several factors, including increasing environmental regulations, consumer demand for sustainable products, and technological advancements in material science. The European Union's ban on single-use plastics in 2021 has further accelerated research and development in this field, pushing for more innovative and eco-friendly packaging solutions.

Recent trends in HEC blend research focus on enhancing the material's properties through nanotechnology, such as incorporating nanocellulose or nanoclays to improve barrier properties and mechanical strength. Additionally, there is growing interest in developing active packaging systems using HEC blends, which can incorporate antimicrobial agents or antioxidants to extend the shelf life of packaged products.

The current technological landscape of HEC blends for biodegradable packaging is characterized by a multidisciplinary approach, combining polymer science, nanotechnology, and packaging engineering. Researchers are exploring various processing techniques, including solution casting, extrusion, and electrospinning, to optimize the production of HEC-based packaging materials. The ultimate goal is to develop cost-effective, high-performance biodegradable packaging that can compete with traditional plastics in terms of functionality and durability while offering superior environmental benefits.

The journey of HEC blends in packaging applications can be traced back to the early 2000s when researchers began exploring alternatives to petroleum-based plastics. Initially, the focus was on pure HEC films, which demonstrated excellent oxygen barrier properties but lacked the necessary mechanical strength for practical packaging applications. This limitation led to the exploration of HEC blends with other biodegradable polymers and additives to enhance their overall performance.

Over the past two decades, significant advancements have been made in the formulation and processing of HEC blends. Researchers have investigated various combinations of HEC with other biopolymers such as starch, chitosan, and poly(lactic acid) (PLA) to create synergistic blends with improved mechanical, barrier, and thermal properties. These efforts have resulted in the development of HEC-based materials that can potentially replace conventional plastics in certain packaging applications.

The evolution of HEC blends has been driven by several factors, including increasing environmental regulations, consumer demand for sustainable products, and technological advancements in material science. The European Union's ban on single-use plastics in 2021 has further accelerated research and development in this field, pushing for more innovative and eco-friendly packaging solutions.

Recent trends in HEC blend research focus on enhancing the material's properties through nanotechnology, such as incorporating nanocellulose or nanoclays to improve barrier properties and mechanical strength. Additionally, there is growing interest in developing active packaging systems using HEC blends, which can incorporate antimicrobial agents or antioxidants to extend the shelf life of packaged products.

The current technological landscape of HEC blends for biodegradable packaging is characterized by a multidisciplinary approach, combining polymer science, nanotechnology, and packaging engineering. Researchers are exploring various processing techniques, including solution casting, extrusion, and electrospinning, to optimize the production of HEC-based packaging materials. The ultimate goal is to develop cost-effective, high-performance biodegradable packaging that can compete with traditional plastics in terms of functionality and durability while offering superior environmental benefits.

Biodegradable Packaging Market Analysis

The biodegradable packaging market has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations on plastic waste. The global market for biodegradable packaging is projected to reach substantial value by 2025, with a compound annual growth rate (CAGR) exceeding industry averages. This growth is primarily attributed to the rising demand for sustainable packaging solutions across various sectors, including food and beverage, personal care, and healthcare industries.

Consumer preferences are shifting towards eco-friendly products, with a growing number of individuals willing to pay a premium for sustainable packaging options. This trend is particularly evident in developed regions such as North America and Europe, where environmental concerns are more pronounced. However, emerging economies in Asia-Pacific and Latin America are also witnessing a surge in demand for biodegradable packaging, driven by urbanization and changing consumer lifestyles.

The food and beverage industry remains the largest end-user segment for biodegradable packaging, accounting for a significant share of the market. This is due to the increasing adoption of biodegradable materials in food service disposables, fresh produce packaging, and beverage containers. The personal care and cosmetics sector is also emerging as a key growth driver, with many brands transitioning to sustainable packaging solutions to appeal to environmentally conscious consumers.

Regulatory support has played a crucial role in market expansion, with several countries implementing bans or restrictions on single-use plastics. These policies have accelerated the adoption of biodegradable alternatives across industries. Additionally, government initiatives promoting the use of bio-based materials and circular economy principles have further stimulated market growth.

Despite the positive outlook, the biodegradable packaging market faces challenges such as higher production costs compared to conventional plastics and limited waste management infrastructure for proper disposal and composting. However, ongoing research and development efforts, including the exploration of hydroxyethylcellulose blends, are addressing these issues by improving material properties and reducing production costs.

The competitive landscape of the biodegradable packaging market is characterized by a mix of established players and innovative start-ups. Key market participants are investing heavily in research and development to enhance product performance and expand their product portfolios. Strategic partnerships and collaborations between material suppliers, packaging manufacturers, and end-users are becoming increasingly common to drive innovation and market penetration.

Looking ahead, the biodegradable packaging market is poised for continued growth, with opportunities emerging in new application areas and geographies. The development of novel materials, such as hydroxyethylcellulose blends, holds promise for addressing current limitations and expanding the market further. As sustainability becomes a core focus for businesses and consumers alike, the demand for biodegradable packaging solutions is expected to remain robust in the foreseeable future.

Consumer preferences are shifting towards eco-friendly products, with a growing number of individuals willing to pay a premium for sustainable packaging options. This trend is particularly evident in developed regions such as North America and Europe, where environmental concerns are more pronounced. However, emerging economies in Asia-Pacific and Latin America are also witnessing a surge in demand for biodegradable packaging, driven by urbanization and changing consumer lifestyles.

The food and beverage industry remains the largest end-user segment for biodegradable packaging, accounting for a significant share of the market. This is due to the increasing adoption of biodegradable materials in food service disposables, fresh produce packaging, and beverage containers. The personal care and cosmetics sector is also emerging as a key growth driver, with many brands transitioning to sustainable packaging solutions to appeal to environmentally conscious consumers.

Regulatory support has played a crucial role in market expansion, with several countries implementing bans or restrictions on single-use plastics. These policies have accelerated the adoption of biodegradable alternatives across industries. Additionally, government initiatives promoting the use of bio-based materials and circular economy principles have further stimulated market growth.

Despite the positive outlook, the biodegradable packaging market faces challenges such as higher production costs compared to conventional plastics and limited waste management infrastructure for proper disposal and composting. However, ongoing research and development efforts, including the exploration of hydroxyethylcellulose blends, are addressing these issues by improving material properties and reducing production costs.

The competitive landscape of the biodegradable packaging market is characterized by a mix of established players and innovative start-ups. Key market participants are investing heavily in research and development to enhance product performance and expand their product portfolios. Strategic partnerships and collaborations between material suppliers, packaging manufacturers, and end-users are becoming increasingly common to drive innovation and market penetration.

Looking ahead, the biodegradable packaging market is poised for continued growth, with opportunities emerging in new application areas and geographies. The development of novel materials, such as hydroxyethylcellulose blends, holds promise for addressing current limitations and expanding the market further. As sustainability becomes a core focus for businesses and consumers alike, the demand for biodegradable packaging solutions is expected to remain robust in the foreseeable future.

HEC Blend Challenges

The development of hydroxyethylcellulose (HEC) blends for biodegradable packaging faces several significant challenges that researchers and industry professionals must address. One of the primary obstacles is achieving the right balance between biodegradability and mechanical properties. While HEC itself is biodegradable, blending it with other materials to enhance its performance can sometimes compromise its eco-friendly nature.

Material compatibility is another crucial challenge in HEC blend research. Ensuring that HEC can be effectively combined with other biodegradable polymers or additives without phase separation or loss of desired properties requires extensive experimentation and formulation optimization. This process is often time-consuming and resource-intensive, as each combination may behave differently under various processing conditions.

The moisture sensitivity of HEC poses a significant hurdle in developing packaging materials. HEC's hydrophilic nature can lead to poor barrier properties against water vapor, potentially limiting its use in certain packaging applications. Researchers must find ways to modify HEC or incorporate other materials that can improve its moisture resistance without sacrificing biodegradability.

Processing challenges also emerge when working with HEC blends. The high viscosity of HEC solutions can make it difficult to process using conventional plastic processing techniques. This may require the development of new processing methods or the modification of existing equipment, which can be costly and time-consuming for manufacturers.

Scalability and cost-effectiveness present additional challenges. While HEC blends may show promise in laboratory settings, translating these formulations to large-scale production while maintaining consistent quality and performance is a complex task. Moreover, the cost of HEC and potential additives must be carefully considered to ensure that the final packaging solution is economically viable for widespread adoption.

Regulatory compliance and standardization pose further challenges. As biodegradable packaging is a relatively new field, there is a lack of universally accepted standards for biodegradability and compostability. Researchers must navigate varying regulations across different regions and ensure that their HEC blends meet the required criteria for biodegradable packaging.

Lastly, the long-term stability and shelf life of HEC blends in packaging applications remain areas of concern. Ensuring that the packaging maintains its integrity and protective properties throughout the product's intended lifespan, while still being able to biodegrade after disposal, requires careful formulation and extensive testing under various environmental conditions.

Material compatibility is another crucial challenge in HEC blend research. Ensuring that HEC can be effectively combined with other biodegradable polymers or additives without phase separation or loss of desired properties requires extensive experimentation and formulation optimization. This process is often time-consuming and resource-intensive, as each combination may behave differently under various processing conditions.

The moisture sensitivity of HEC poses a significant hurdle in developing packaging materials. HEC's hydrophilic nature can lead to poor barrier properties against water vapor, potentially limiting its use in certain packaging applications. Researchers must find ways to modify HEC or incorporate other materials that can improve its moisture resistance without sacrificing biodegradability.

Processing challenges also emerge when working with HEC blends. The high viscosity of HEC solutions can make it difficult to process using conventional plastic processing techniques. This may require the development of new processing methods or the modification of existing equipment, which can be costly and time-consuming for manufacturers.

Scalability and cost-effectiveness present additional challenges. While HEC blends may show promise in laboratory settings, translating these formulations to large-scale production while maintaining consistent quality and performance is a complex task. Moreover, the cost of HEC and potential additives must be carefully considered to ensure that the final packaging solution is economically viable for widespread adoption.

Regulatory compliance and standardization pose further challenges. As biodegradable packaging is a relatively new field, there is a lack of universally accepted standards for biodegradability and compostability. Researchers must navigate varying regulations across different regions and ensure that their HEC blends meet the required criteria for biodegradable packaging.

Lastly, the long-term stability and shelf life of HEC blends in packaging applications remain areas of concern. Ensuring that the packaging maintains its integrity and protective properties throughout the product's intended lifespan, while still being able to biodegrade after disposal, requires careful formulation and extensive testing under various environmental conditions.

Current HEC Solutions

01 Hydroxyethylcellulose blends in drilling fluids

Hydroxyethylcellulose is used in blends for drilling fluids to improve viscosity and fluid loss control. These blends can include other polymers or additives to enhance performance in various drilling conditions.- Hydroxyethylcellulose blends in drilling fluids: Hydroxyethylcellulose is used in blends for drilling fluids to improve viscosity and fluid loss control. These blends can include other polymers or additives to enhance performance in various drilling conditions.

- Hydroxyethylcellulose blends in personal care products: Hydroxyethylcellulose is combined with other ingredients in personal care formulations such as shampoos, conditioners, and skincare products. These blends provide thickening, stabilizing, and moisturizing properties.

- Hydroxyethylcellulose blends in pharmaceutical compositions: Hydroxyethylcellulose is used in blends for pharmaceutical formulations, particularly in controlled release drug delivery systems. These blends can modify drug release rates and improve bioavailability.

- Hydroxyethylcellulose blends in adhesive formulations: Hydroxyethylcellulose is incorporated into adhesive blends to improve bonding strength, viscosity, and water resistance. These blends find applications in various industries including construction and packaging.

- Hydroxyethylcellulose blends in textile processing: Hydroxyethylcellulose is used in blends for textile processing, particularly in sizing and finishing operations. These blends can improve fabric strength, appearance, and handling properties.

02 Hydroxyethylcellulose in personal care products

Hydroxyethylcellulose is utilized in blends for personal care products such as cosmetics and hair care formulations. It acts as a thickener, stabilizer, and film-forming agent, improving product texture and performance.Expand Specific Solutions03 Hydroxyethylcellulose blends in pharmaceutical formulations

Blends containing hydroxyethylcellulose are used in pharmaceutical formulations as binders, disintegrants, and controlled-release agents. These blends can modify drug release profiles and improve tablet properties.Expand Specific Solutions04 Hydroxyethylcellulose in adhesive compositions

Hydroxyethylcellulose is incorporated into adhesive blends to enhance bonding strength, viscosity, and water retention. These blends find applications in various industries, including construction and packaging.Expand Specific Solutions05 Hydroxyethylcellulose blends in oil field applications

Hydroxyethylcellulose is used in blends for oil field applications, such as fracturing fluids and enhanced oil recovery. These blends help control fluid properties, reduce friction, and improve oil displacement efficiency.Expand Specific Solutions

Key Industry Players

The research on hydroxyethylcellulose blends for biodegradable packaging is in a growth phase, with increasing market demand driven by environmental concerns and regulatory pressures. The global biodegradable packaging market is expanding rapidly, expected to reach significant value in the coming years. Technologically, the field is advancing, with companies like Bayer AG, Kolon Industries, and Novamont SpA leading innovation. These firms are developing proprietary blends and processes to enhance the performance and cost-effectiveness of biodegradable packaging materials. However, the technology is still evolving, with ongoing research at institutions like South China University of Technology and Tongji University to improve material properties and production efficiency.

Bayer AG

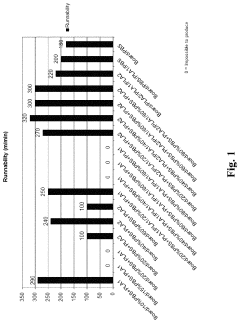

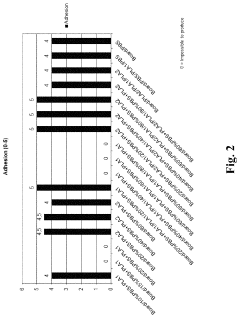

Technical Solution: Bayer AG has developed a novel approach to biodegradable packaging using hydroxyethylcellulose (HEC) blends. Their research focuses on optimizing the blend composition to enhance mechanical properties and biodegradability. The company has successfully created a formulation that combines HEC with other biodegradable polymers, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), to achieve a balance between strength and environmental friendliness. Bayer's technology incorporates a proprietary cross-linking agent that improves the water resistance of the packaging while maintaining its biodegradability[1]. The company has also implemented a unique processing technique that allows for the production of thin films with excellent barrier properties, making it suitable for food packaging applications[3].

Strengths: Strong R&D capabilities, extensive polymer expertise, and global market presence. Weaknesses: Higher production costs compared to traditional plastics, limited scalability of the technology.

World Centric

Technical Solution: World Centric has developed an innovative approach to biodegradable packaging using hydroxyethylcellulose blends. Their research focuses on creating sustainable, compostable packaging solutions for the food service industry. World Centric's technology involves blending HEC with other plant-based materials, such as bagasse and bamboo fibers, to create a robust and environmentally friendly packaging material[10]. The company has implemented a unique molding process that allows for the production of various shapes and sizes of packaging products, from plates and bowls to utensils. World Centric's HEC blends are designed to biodegrade completely in commercial composting facilities within 2-4 months, addressing the growing demand for truly compostable food packaging options[11].

Strengths: Strong focus on sustainability, diverse product range, and established presence in the eco-friendly packaging market. Weaknesses: Limited to specific market segments, potential challenges in scaling production to meet growing demand.

HEC Blend Innovations

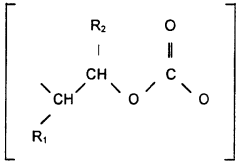

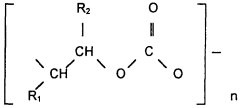

Biodegradable thermoplastically deformable materials for food packaging

PatentWO1998007782A1

Innovation

- Blends of starch esters with a degree of substitution between 1.5-2.6 and aliphatic polycarbonates, using biologically compatible secondary plasticizers and oxydicarboxylic acids, which enhance water stability and heat resistance while reducing migration values, allowing for transparent and mechanically robust products.

Method for manufacturing biodegradable packaging material, biodegradable packaging material and a package or a container made thereof

PatentActiveUS11434605B2

Innovation

- A method involving the extrusion of polymer coating layers onto fibrous substrates using a blend of high melt index polylactide (20-95 wt-%) and polybutylene succinate (5-80 wt-%) with optional polymeric additives, allowing for improved adhesion and heat-sealability while maintaining machine speed and biodegradability.

Environmental Impact

The environmental impact of hydroxyethylcellulose (HEC) blends for biodegradable packaging is a critical aspect to consider in the development and adoption of these materials. As the global focus on sustainability intensifies, the use of biodegradable packaging solutions has gained significant traction across various industries.

HEC blends offer a promising alternative to conventional plastic packaging, primarily due to their biodegradability and renewable sourcing. These materials are derived from cellulose, a naturally occurring polymer found in plant cell walls, making them inherently more environmentally friendly than petroleum-based plastics. The biodegradation process of HEC blends results in the breakdown of the material into harmless components, significantly reducing the long-term environmental impact associated with traditional plastic waste.

One of the key environmental benefits of HEC blends is their potential to mitigate plastic pollution in marine and terrestrial ecosystems. Unlike conventional plastics that persist in the environment for hundreds of years, HEC-based packaging can decompose within months to a few years, depending on environmental conditions. This rapid biodegradation helps to reduce the accumulation of plastic waste in landfills and natural habitats, thereby protecting wildlife and preserving ecosystem balance.

Furthermore, the production of HEC blends generally has a lower carbon footprint compared to traditional plastic manufacturing processes. The renewable nature of cellulose sources contributes to a more sustainable production cycle, potentially reducing greenhouse gas emissions associated with packaging materials. However, it is essential to consider the entire life cycle of HEC blends, including cultivation, processing, and end-of-life management, to accurately assess their overall environmental impact.

Water consumption and land use are additional factors to evaluate when considering the environmental impact of HEC blends. The production of cellulose-based materials may require significant water resources and agricultural land, which could potentially compete with food production or natural habitats. Sustainable sourcing practices and efficient production methods are crucial to minimizing these impacts and ensuring the overall environmental benefits of HEC-based packaging solutions.

The end-of-life management of HEC blends also plays a vital role in their environmental impact. While these materials are biodegradable, proper disposal and composting infrastructure are necessary to fully realize their environmental benefits. Educating consumers and implementing effective waste management systems are essential steps in maximizing the positive environmental impact of HEC-based packaging.

In conclusion, the environmental impact of hydroxyethylcellulose blends for biodegradable packaging is generally positive when compared to traditional plastic alternatives. Their biodegradability, renewable sourcing, and potential for reduced carbon emissions offer significant environmental advantages. However, ongoing research and development are crucial to further optimize these materials, address potential drawbacks, and ensure their sustainable integration into the global packaging industry.

HEC blends offer a promising alternative to conventional plastic packaging, primarily due to their biodegradability and renewable sourcing. These materials are derived from cellulose, a naturally occurring polymer found in plant cell walls, making them inherently more environmentally friendly than petroleum-based plastics. The biodegradation process of HEC blends results in the breakdown of the material into harmless components, significantly reducing the long-term environmental impact associated with traditional plastic waste.

One of the key environmental benefits of HEC blends is their potential to mitigate plastic pollution in marine and terrestrial ecosystems. Unlike conventional plastics that persist in the environment for hundreds of years, HEC-based packaging can decompose within months to a few years, depending on environmental conditions. This rapid biodegradation helps to reduce the accumulation of plastic waste in landfills and natural habitats, thereby protecting wildlife and preserving ecosystem balance.

Furthermore, the production of HEC blends generally has a lower carbon footprint compared to traditional plastic manufacturing processes. The renewable nature of cellulose sources contributes to a more sustainable production cycle, potentially reducing greenhouse gas emissions associated with packaging materials. However, it is essential to consider the entire life cycle of HEC blends, including cultivation, processing, and end-of-life management, to accurately assess their overall environmental impact.

Water consumption and land use are additional factors to evaluate when considering the environmental impact of HEC blends. The production of cellulose-based materials may require significant water resources and agricultural land, which could potentially compete with food production or natural habitats. Sustainable sourcing practices and efficient production methods are crucial to minimizing these impacts and ensuring the overall environmental benefits of HEC-based packaging solutions.

The end-of-life management of HEC blends also plays a vital role in their environmental impact. While these materials are biodegradable, proper disposal and composting infrastructure are necessary to fully realize their environmental benefits. Educating consumers and implementing effective waste management systems are essential steps in maximizing the positive environmental impact of HEC-based packaging.

In conclusion, the environmental impact of hydroxyethylcellulose blends for biodegradable packaging is generally positive when compared to traditional plastic alternatives. Their biodegradability, renewable sourcing, and potential for reduced carbon emissions offer significant environmental advantages. However, ongoing research and development are crucial to further optimize these materials, address potential drawbacks, and ensure their sustainable integration into the global packaging industry.

Regulatory Compliance

Regulatory compliance is a critical aspect of developing and marketing biodegradable packaging materials, including those based on hydroxyethylcellulose (HEC) blends. As these materials are intended for food contact applications, they must adhere to strict regulations set by various governing bodies worldwide.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of food contact materials. HEC and its blends must comply with the FDA's Food Contact Substance Notification (FCN) program or be listed in the Code of Federal Regulations (CFR) Title 21. Manufacturers must demonstrate that their HEC-based packaging materials are safe for intended use and do not impart harmful substances to food.

The European Union has established comprehensive regulations for food contact materials through the Framework Regulation (EC) No 1935/2004. This regulation sets out general principles of safety and inertness for all food contact materials. Additionally, the Plastics Regulation (EU) No 10/2011 provides specific requirements for plastic food contact materials, which may apply to certain HEC blends depending on their composition.

Biodegradability claims for HEC-based packaging must be substantiated according to established standards. In the EU, the EN 13432 standard for compostable and biodegradable packaging is widely recognized. In the US, ASTM D6400 provides similar guidelines for compostable plastics. Manufacturers must conduct thorough testing to ensure their products meet these standards before making biodegradability claims.

Environmental regulations also play a significant role in the development of biodegradable packaging. The EU's Single-Use Plastics Directive aims to reduce the impact of certain plastic products on the environment, which may influence the adoption of HEC-based alternatives. Similarly, various states in the US have implemented or are considering bans on single-use plastics, potentially creating opportunities for biodegradable options.

Compliance with these regulations requires extensive documentation, testing, and certification processes. Manufacturers must maintain detailed records of raw materials, production processes, and quality control measures. Third-party certification bodies often play a crucial role in verifying compliance with biodegradability standards and food contact regulations.

As regulations continue to evolve in response to environmental concerns and scientific advancements, companies developing HEC blends for biodegradable packaging must stay informed of regulatory changes and adapt their products accordingly. This may involve ongoing research and development efforts to ensure continued compliance and market relevance.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of food contact materials. HEC and its blends must comply with the FDA's Food Contact Substance Notification (FCN) program or be listed in the Code of Federal Regulations (CFR) Title 21. Manufacturers must demonstrate that their HEC-based packaging materials are safe for intended use and do not impart harmful substances to food.

The European Union has established comprehensive regulations for food contact materials through the Framework Regulation (EC) No 1935/2004. This regulation sets out general principles of safety and inertness for all food contact materials. Additionally, the Plastics Regulation (EU) No 10/2011 provides specific requirements for plastic food contact materials, which may apply to certain HEC blends depending on their composition.

Biodegradability claims for HEC-based packaging must be substantiated according to established standards. In the EU, the EN 13432 standard for compostable and biodegradable packaging is widely recognized. In the US, ASTM D6400 provides similar guidelines for compostable plastics. Manufacturers must conduct thorough testing to ensure their products meet these standards before making biodegradability claims.

Environmental regulations also play a significant role in the development of biodegradable packaging. The EU's Single-Use Plastics Directive aims to reduce the impact of certain plastic products on the environment, which may influence the adoption of HEC-based alternatives. Similarly, various states in the US have implemented or are considering bans on single-use plastics, potentially creating opportunities for biodegradable options.

Compliance with these regulations requires extensive documentation, testing, and certification processes. Manufacturers must maintain detailed records of raw materials, production processes, and quality control measures. Third-party certification bodies often play a crucial role in verifying compliance with biodegradability standards and food contact regulations.

As regulations continue to evolve in response to environmental concerns and scientific advancements, companies developing HEC blends for biodegradable packaging must stay informed of regulatory changes and adapt their products accordingly. This may involve ongoing research and development efforts to ensure continued compliance and market relevance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!