Advances in Hydroxyethylcellulose-Based Flame Retardants

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEC Flame Retardants: Background and Objectives

Hydroxyethylcellulose (HEC) has emerged as a promising material in the development of flame retardants, addressing the growing concern for fire safety in various industries. The evolution of HEC-based flame retardants can be traced back to the early 2000s when researchers began exploring sustainable alternatives to traditional halogenated flame retardants. This shift was driven by increasing environmental awareness and stricter regulations on toxic substances.

The primary objective of HEC flame retardant technology is to enhance fire resistance in materials while maintaining eco-friendliness and cost-effectiveness. HEC, a cellulose derivative, offers unique properties that make it an attractive option for flame retardant applications. Its high thermal stability, biodegradability, and non-toxic nature align well with the current global push towards sustainable and safe materials.

Over the past decade, significant advancements have been made in understanding the flame retardant mechanisms of HEC. Research has focused on improving its efficiency through various modification techniques, such as chemical grafting and nanocomposite formation. These efforts aim to overcome the inherent limitations of HEC, including its hydrophilicity and relatively low flame retardant efficiency compared to some synthetic alternatives.

The technological trajectory of HEC flame retardants has been shaped by several key factors. Firstly, the increasing demand for fire-safe materials in construction, textiles, and electronics has driven continuous innovation. Secondly, stringent fire safety regulations across different regions have necessitated the development of more effective and environmentally benign flame retardants. Lastly, the growing emphasis on circular economy principles has further boosted interest in bio-based materials like HEC.

Recent trends in HEC flame retardant research include the exploration of synergistic effects with other flame retardant additives, the development of multifunctional coatings, and the integration of nanotechnology. These approaches aim to enhance the overall performance of HEC-based systems, addressing challenges such as durability, processing compatibility, and broad-spectrum effectiveness against different types of fires.

Looking ahead, the field of HEC flame retardants is poised for further growth and innovation. Key objectives for future research include improving the flame retardant efficiency to match or surpass that of conventional systems, enhancing the material's resistance to environmental degradation, and developing scalable production methods for commercial viability. Additionally, there is a growing interest in understanding the long-term environmental impact of HEC flame retardants and optimizing their end-of-life management.

The primary objective of HEC flame retardant technology is to enhance fire resistance in materials while maintaining eco-friendliness and cost-effectiveness. HEC, a cellulose derivative, offers unique properties that make it an attractive option for flame retardant applications. Its high thermal stability, biodegradability, and non-toxic nature align well with the current global push towards sustainable and safe materials.

Over the past decade, significant advancements have been made in understanding the flame retardant mechanisms of HEC. Research has focused on improving its efficiency through various modification techniques, such as chemical grafting and nanocomposite formation. These efforts aim to overcome the inherent limitations of HEC, including its hydrophilicity and relatively low flame retardant efficiency compared to some synthetic alternatives.

The technological trajectory of HEC flame retardants has been shaped by several key factors. Firstly, the increasing demand for fire-safe materials in construction, textiles, and electronics has driven continuous innovation. Secondly, stringent fire safety regulations across different regions have necessitated the development of more effective and environmentally benign flame retardants. Lastly, the growing emphasis on circular economy principles has further boosted interest in bio-based materials like HEC.

Recent trends in HEC flame retardant research include the exploration of synergistic effects with other flame retardant additives, the development of multifunctional coatings, and the integration of nanotechnology. These approaches aim to enhance the overall performance of HEC-based systems, addressing challenges such as durability, processing compatibility, and broad-spectrum effectiveness against different types of fires.

Looking ahead, the field of HEC flame retardants is poised for further growth and innovation. Key objectives for future research include improving the flame retardant efficiency to match or surpass that of conventional systems, enhancing the material's resistance to environmental degradation, and developing scalable production methods for commercial viability. Additionally, there is a growing interest in understanding the long-term environmental impact of HEC flame retardants and optimizing their end-of-life management.

Market Analysis for HEC-Based Fire Protection

The market for hydroxyethylcellulose (HEC)-based flame retardants has shown significant growth in recent years, driven by increasing safety regulations and a growing awareness of fire protection across various industries. The global flame retardant market, valued at approximately $7.4 billion in 2020, is expected to reach $10.2 billion by 2025, with HEC-based solutions playing an increasingly important role.

HEC-based flame retardants have gained traction due to their eco-friendly nature and superior performance compared to traditional halogenated flame retardants. The construction industry represents the largest market segment for these products, accounting for nearly 30% of the total demand. This is primarily due to stringent building codes and regulations mandating the use of fire-resistant materials in residential and commercial structures.

The automotive sector is another key market for HEC-based flame retardants, driven by the need for enhanced safety features in vehicles. With the rise of electric vehicles and the associated fire risks of lithium-ion batteries, the demand for advanced flame retardant solutions in this sector is expected to grow at a CAGR of 7.5% over the next five years.

The electronics industry is also a significant consumer of HEC-based flame retardants, particularly in the production of consumer electronics, wiring, and cables. As the global demand for electronic devices continues to rise, this sector is projected to witness a CAGR of 6.8% in flame retardant consumption through 2025.

Geographically, Asia-Pacific dominates the market for HEC-based flame retardants, accounting for over 40% of the global demand. This is primarily due to rapid industrialization, urbanization, and the implementation of stringent fire safety regulations in countries like China and India. North America and Europe follow, with mature markets driven by advanced safety standards and ongoing research and development efforts.

The competitive landscape of the HEC-based flame retardant market is characterized by a mix of large multinational corporations and specialized chemical companies. Key players include BASF SE, Dow Chemical Company, and Clariant AG, who have invested heavily in research and development to improve the efficacy and sustainability of their products.

Looking ahead, the market for HEC-based flame retardants is poised for continued growth, with emerging applications in renewable energy infrastructure, such as wind turbines and solar panels, presenting new opportunities. Additionally, the ongoing shift towards sustainable and non-toxic flame retardant solutions is expected to further boost the adoption of HEC-based products across various industries.

HEC-based flame retardants have gained traction due to their eco-friendly nature and superior performance compared to traditional halogenated flame retardants. The construction industry represents the largest market segment for these products, accounting for nearly 30% of the total demand. This is primarily due to stringent building codes and regulations mandating the use of fire-resistant materials in residential and commercial structures.

The automotive sector is another key market for HEC-based flame retardants, driven by the need for enhanced safety features in vehicles. With the rise of electric vehicles and the associated fire risks of lithium-ion batteries, the demand for advanced flame retardant solutions in this sector is expected to grow at a CAGR of 7.5% over the next five years.

The electronics industry is also a significant consumer of HEC-based flame retardants, particularly in the production of consumer electronics, wiring, and cables. As the global demand for electronic devices continues to rise, this sector is projected to witness a CAGR of 6.8% in flame retardant consumption through 2025.

Geographically, Asia-Pacific dominates the market for HEC-based flame retardants, accounting for over 40% of the global demand. This is primarily due to rapid industrialization, urbanization, and the implementation of stringent fire safety regulations in countries like China and India. North America and Europe follow, with mature markets driven by advanced safety standards and ongoing research and development efforts.

The competitive landscape of the HEC-based flame retardant market is characterized by a mix of large multinational corporations and specialized chemical companies. Key players include BASF SE, Dow Chemical Company, and Clariant AG, who have invested heavily in research and development to improve the efficacy and sustainability of their products.

Looking ahead, the market for HEC-based flame retardants is poised for continued growth, with emerging applications in renewable energy infrastructure, such as wind turbines and solar panels, presenting new opportunities. Additionally, the ongoing shift towards sustainable and non-toxic flame retardant solutions is expected to further boost the adoption of HEC-based products across various industries.

Current Challenges in HEC Flame Retardant Technology

Despite the promising advancements in hydroxyethylcellulose (HEC) based flame retardants, several significant challenges persist in their development and application. One of the primary obstacles is achieving an optimal balance between flame retardancy and other material properties. While HEC-based flame retardants demonstrate excellent fire-resistant characteristics, they often compromise the mechanical strength and flexibility of the treated materials.

Another critical challenge lies in the environmental impact of HEC flame retardants. Although they are derived from renewable resources, concerns remain about their biodegradability and potential ecological effects when released into the environment. Researchers are grappling with the task of developing formulations that maintain high flame retardancy while ensuring minimal environmental footprint.

The durability of HEC-based flame retardants poses another significant hurdle. Current formulations may lose their effectiveness over time due to factors such as weathering, washing, or mechanical stress. This necessitates the development of more robust and long-lasting flame retardant solutions that can withstand various environmental conditions and maintain their protective properties throughout the product's lifecycle.

Cost-effectiveness remains a substantial challenge in the widespread adoption of HEC flame retardants. While they offer numerous advantages, the production costs are often higher compared to conventional flame retardants. This economic barrier hinders their integration into mass-market products, particularly in price-sensitive industries.

Compatibility issues with different substrate materials present another obstacle. HEC-based flame retardants may not adhere well to certain surfaces or may alter the appearance and texture of treated materials. Researchers are working to develop versatile formulations that can be effectively applied to a wide range of substrates without compromising their inherent properties.

Regulatory compliance and standardization pose additional challenges. As environmental and safety regulations become increasingly stringent, HEC flame retardants must meet evolving standards across different regions and industries. Developing formulations that consistently meet these diverse regulatory requirements while maintaining performance is a complex task for researchers and manufacturers.

Lastly, the scalability of production processes for HEC-based flame retardants remains a significant challenge. Transitioning from laboratory-scale synthesis to large-scale industrial production while maintaining consistent quality and performance is a complex undertaking that requires substantial investment in research and development.

Another critical challenge lies in the environmental impact of HEC flame retardants. Although they are derived from renewable resources, concerns remain about their biodegradability and potential ecological effects when released into the environment. Researchers are grappling with the task of developing formulations that maintain high flame retardancy while ensuring minimal environmental footprint.

The durability of HEC-based flame retardants poses another significant hurdle. Current formulations may lose their effectiveness over time due to factors such as weathering, washing, or mechanical stress. This necessitates the development of more robust and long-lasting flame retardant solutions that can withstand various environmental conditions and maintain their protective properties throughout the product's lifecycle.

Cost-effectiveness remains a substantial challenge in the widespread adoption of HEC flame retardants. While they offer numerous advantages, the production costs are often higher compared to conventional flame retardants. This economic barrier hinders their integration into mass-market products, particularly in price-sensitive industries.

Compatibility issues with different substrate materials present another obstacle. HEC-based flame retardants may not adhere well to certain surfaces or may alter the appearance and texture of treated materials. Researchers are working to develop versatile formulations that can be effectively applied to a wide range of substrates without compromising their inherent properties.

Regulatory compliance and standardization pose additional challenges. As environmental and safety regulations become increasingly stringent, HEC flame retardants must meet evolving standards across different regions and industries. Developing formulations that consistently meet these diverse regulatory requirements while maintaining performance is a complex task for researchers and manufacturers.

Lastly, the scalability of production processes for HEC-based flame retardants remains a significant challenge. Transitioning from laboratory-scale synthesis to large-scale industrial production while maintaining consistent quality and performance is a complex undertaking that requires substantial investment in research and development.

Existing HEC Flame Retardant Solutions

01 Hydroxyethylcellulose as a flame retardant component

Hydroxyethylcellulose (HEC) is utilized as a key component in flame retardant formulations. Its unique chemical structure and properties contribute to enhancing the flame retardancy of various materials. HEC can form a protective char layer when exposed to heat, which helps to inhibit the spread of flames and reduce heat release.- Hydroxyethylcellulose as a flame retardant component: Hydroxyethylcellulose (HEC) is utilized as a key component in flame retardant formulations. It acts as a char-forming agent, creating a protective barrier when exposed to heat. This cellulose derivative enhances the overall flame retardancy of materials by promoting char formation and reducing heat release during combustion.

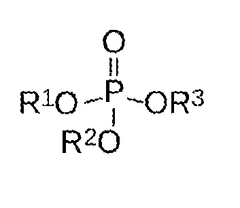

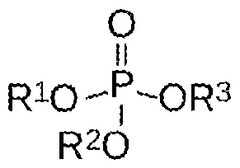

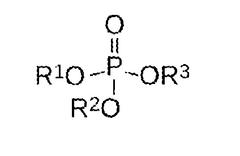

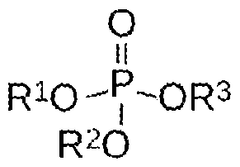

- Synergistic effects with other flame retardant additives: Hydroxyethylcellulose-based flame retardants are often combined with other additives to achieve synergistic effects. These combinations can include phosphorus-based compounds, nitrogen-containing substances, or inorganic fillers. The synergistic approach enhances flame retardancy performance while potentially reducing the overall additive loading in the material.

- Application in polymer matrices: Hydroxyethylcellulose-based flame retardants are incorporated into various polymer matrices to improve their fire resistance. These can include thermoplastics, thermosets, and elastomers. The compatibility of HEC with different polymer systems allows for its widespread use in enhancing the flame retardancy of diverse materials.

- Modification of hydroxyethylcellulose for enhanced performance: Chemical modifications of hydroxyethylcellulose are explored to enhance its flame retardant properties. These modifications can include grafting with flame retardant moieties, crosslinking, or functionalization with reactive groups. Such modifications aim to improve the thermal stability, char formation, and overall flame retardancy efficiency of the HEC-based systems.

- Environmentally friendly flame retardant solution: Hydroxyethylcellulose-based flame retardants are considered as an environmentally friendly alternative to traditional halogenated flame retardants. Being derived from renewable resources, HEC offers a more sustainable approach to flame retardancy. Its biodegradability and low toxicity make it an attractive option for developing eco-friendly fire-resistant materials.

02 Synergistic effects with other flame retardant additives

Hydroxyethylcellulose-based flame retardants can be combined with other flame retardant additives to achieve synergistic effects. These combinations can improve overall flame retardancy performance, reduce the total amount of additives required, and potentially enhance other material properties such as mechanical strength or processability.Expand Specific Solutions03 Application in polymer composites

Hydroxyethylcellulose-based flame retardants are effectively incorporated into various polymer composites to enhance their fire resistance. These composites find applications in construction materials, electrical components, and transportation industries. The addition of HEC-based flame retardants can significantly improve the fire performance of these composites without compromising their mechanical properties.Expand Specific Solutions04 Modification of hydroxyethylcellulose for improved flame retardancy

Chemical modification of hydroxyethylcellulose can enhance its flame retardant properties. Techniques such as phosphorylation, grafting with flame retardant monomers, or incorporation of inorganic nanoparticles can be employed to improve the effectiveness of HEC-based flame retardants. These modifications can lead to better char formation, reduced heat release, and improved overall flame retardancy performance.Expand Specific Solutions05 Environmentally friendly and sustainable flame retardant solution

Hydroxyethylcellulose-based flame retardants offer an environmentally friendly and sustainable alternative to traditional halogenated flame retardants. Being derived from cellulose, a renewable resource, HEC-based flame retardants have lower environmental impact and reduced toxicity compared to some conventional flame retardants. This makes them particularly attractive for use in consumer products and applications where environmental concerns are paramount.Expand Specific Solutions

Key Players in HEC Flame Retardant Industry

The market for hydroxyethylcellulose-based flame retardants is in a growth phase, driven by increasing safety regulations and demand for eco-friendly solutions. The global flame retardant market is projected to reach $10 billion by 2025, with cellulose-based products gaining traction. While the technology is advancing, it's not yet fully mature. Key players like Albemarle Corp., ICL-IP America, and J.M. Huber Corp. are investing in R&D to improve performance and cost-effectiveness. Academic institutions such as Kunming University of Science & Technology and Soochow University are also contributing to technological advancements. The competitive landscape is characterized by a mix of established chemical companies and innovative startups, with a focus on developing sustainable and efficient flame retardant solutions.

Albemarle Corp.

Technical Solution: Albemarle Corp. has developed advanced hydroxyethylcellulose-based flame retardants that incorporate novel synergistic additives to enhance flame retardancy. Their proprietary formulation includes a combination of hydroxyethylcellulose with phosphorus-based compounds and metal hydroxides, creating a multi-functional flame retardant system. This system forms an intumescent char layer upon exposure to heat, effectively insulating the underlying material and reducing heat transfer[1]. The company has also implemented a unique cross-linking process that improves the thermal stability of the hydroxyethylcellulose, resulting in better flame retardant performance at higher temperatures[3]. Albemarle's solution is particularly effective in textile applications, where it can be applied as a coating or incorporated into the fiber structure during manufacturing[5].

Strengths: Excellent flame retardancy, versatile application methods, and improved thermal stability. Weaknesses: Potentially higher cost due to complex formulation and may affect some material properties like flexibility.

ICL-IP America, Inc.

Technical Solution: ICL-IP America has pioneered a novel approach to hydroxyethylcellulose-based flame retardants by incorporating halogen-free, phosphorus-nitrogen synergistic compounds. Their technology focuses on creating a sustainable and environmentally friendly solution that meets stringent fire safety standards. The company's formulation includes a unique blend of hydroxyethylcellulose with ammonium polyphosphate and melamine derivatives, which work synergistically to provide both char formation and gas-phase flame inhibition[2]. This dual-action mechanism significantly improves the overall flame retardant performance. ICL-IP America has also developed a proprietary surface treatment process for the hydroxyethylcellulose particles, enhancing their dispersion in various polymer matrices and improving the long-term stability of the flame retardant system[4].

Strengths: Environmentally friendly, high-performance flame retardancy, and improved dispersion in polymers. Weaknesses: May require higher loading levels compared to some halogenated alternatives, potentially affecting mechanical properties.

Innovative HEC Flame Retardant Patents

Flame retardant cellulose-based products

PatentWO2025088612A1

Innovation

- An aqueous flame retardant composition (BPFR co-formulation) is applied to cellulose-based materials, comprising a brominated phosphate ester of Formula I and a melamine resin with a molecular weight above 150 g/mole, which bond chemically and/or physically to the cellulose, enhancing flame retardancy.

flame retardants based on amine compounds containing siloxane groups

PatentPendingDE102021110402A1

Innovation

- A flame retardant system using siloxane groups and amine compounds, synthesized via the sol-gel process, forms a crosslinked coating on textiles, releasing nitrogen and phosphorus residues to suppress combustion.

Environmental Impact of HEC Flame Retardants

The environmental impact of hydroxyethylcellulose (HEC) based flame retardants is a critical consideration in their development and application. These flame retardants offer significant advantages in terms of fire safety, but their potential effects on ecosystems and human health must be carefully evaluated.

HEC-based flame retardants are generally considered to have a lower environmental impact compared to traditional halogenated flame retardants. This is primarily due to their biodegradability and reduced toxicity. HEC, being a cellulose derivative, is inherently more environmentally friendly than many synthetic alternatives.

One of the key environmental benefits of HEC flame retardants is their potential for biodegradation. Unlike persistent organic pollutants often associated with conventional flame retardants, HEC-based materials can be broken down by natural processes over time. This reduces the long-term accumulation of these substances in the environment, minimizing their impact on ecosystems.

Water solubility is another important factor to consider. HEC is highly soluble in water, which can be both an advantage and a potential concern. On one hand, this property facilitates easier removal and treatment in wastewater systems. On the other hand, it may lead to increased mobility in aquatic environments, potentially affecting a wider range of organisms.

The production process of HEC flame retardants also contributes to their environmental profile. Compared to the synthesis of many halogenated flame retardants, the production of HEC-based alternatives typically involves less toxic chemicals and generates fewer harmful byproducts. This results in a reduced environmental footprint during the manufacturing stage.

However, the environmental impact of HEC flame retardants is not entirely benign. The increased use of these materials may lead to higher concentrations in wastewater and natural water bodies. While less toxic than traditional flame retardants, high concentrations of HEC could still affect aquatic ecosystems, potentially altering water quality and impacting sensitive species.

Furthermore, the end-of-life disposal of products containing HEC flame retardants must be considered. While biodegradable, these materials may not break down quickly in landfill conditions. Proper waste management and recycling strategies are crucial to minimize environmental accumulation.

Research into the long-term environmental effects of HEC flame retardants is ongoing. Studies are needed to fully understand their behavior in various ecosystems, their potential for bioaccumulation, and any unforeseen impacts on wildlife or plant life. As with any new technology, continuous monitoring and assessment are essential to ensure that the environmental benefits of HEC flame retardants outweigh any potential risks.

HEC-based flame retardants are generally considered to have a lower environmental impact compared to traditional halogenated flame retardants. This is primarily due to their biodegradability and reduced toxicity. HEC, being a cellulose derivative, is inherently more environmentally friendly than many synthetic alternatives.

One of the key environmental benefits of HEC flame retardants is their potential for biodegradation. Unlike persistent organic pollutants often associated with conventional flame retardants, HEC-based materials can be broken down by natural processes over time. This reduces the long-term accumulation of these substances in the environment, minimizing their impact on ecosystems.

Water solubility is another important factor to consider. HEC is highly soluble in water, which can be both an advantage and a potential concern. On one hand, this property facilitates easier removal and treatment in wastewater systems. On the other hand, it may lead to increased mobility in aquatic environments, potentially affecting a wider range of organisms.

The production process of HEC flame retardants also contributes to their environmental profile. Compared to the synthesis of many halogenated flame retardants, the production of HEC-based alternatives typically involves less toxic chemicals and generates fewer harmful byproducts. This results in a reduced environmental footprint during the manufacturing stage.

However, the environmental impact of HEC flame retardants is not entirely benign. The increased use of these materials may lead to higher concentrations in wastewater and natural water bodies. While less toxic than traditional flame retardants, high concentrations of HEC could still affect aquatic ecosystems, potentially altering water quality and impacting sensitive species.

Furthermore, the end-of-life disposal of products containing HEC flame retardants must be considered. While biodegradable, these materials may not break down quickly in landfill conditions. Proper waste management and recycling strategies are crucial to minimize environmental accumulation.

Research into the long-term environmental effects of HEC flame retardants is ongoing. Studies are needed to fully understand their behavior in various ecosystems, their potential for bioaccumulation, and any unforeseen impacts on wildlife or plant life. As with any new technology, continuous monitoring and assessment are essential to ensure that the environmental benefits of HEC flame retardants outweigh any potential risks.

Regulatory Framework for Flame Retardant Materials

The regulatory framework for flame retardant materials has become increasingly stringent and complex in recent years, reflecting growing concerns about fire safety and environmental impact. In the United States, the primary regulatory body overseeing flame retardants is the Consumer Product Safety Commission (CPSC), which enforces standards set by organizations such as the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL).

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of flame retardants. Under REACH, manufacturers must register chemicals and provide safety data, with some flame retardants subject to authorization or restriction due to potential health or environmental concerns.

Many countries have adopted or are in the process of adopting similar regulations to those in the US and EU. For instance, China has implemented the Measures for Environmental Management of New Chemical Substances, which includes provisions for flame retardants.

Specific to hydroxyethylcellulose-based flame retardants, regulations typically focus on their performance in standardized fire tests, such as the UL 94 vertical burning test or the cone calorimeter test. These tests evaluate factors like flame spread, heat release rate, and smoke production.

Environmental regulations are also becoming increasingly relevant for flame retardants. The Stockholm Convention on Persistent Organic Pollutants has led to the phase-out of certain halogenated flame retardants, prompting a shift towards more environmentally friendly alternatives like hydroxyethylcellulose-based solutions.

In the building and construction sector, regulations such as the International Building Code (IBC) and the European Construction Products Regulation (CPR) set specific requirements for flame retardant materials used in various applications. These regulations often reference standards like ASTM E84 for surface burning characteristics.

The textile industry faces regulations such as the US Flammable Fabrics Act and the EU's General Product Safety Directive, which mandate specific flame retardant properties for certain types of fabrics and clothing.

As research advances in hydroxyethylcellulose-based flame retardants, regulatory bodies are likely to update their frameworks to accommodate these new materials. This may include developing new testing methodologies and performance criteria specifically tailored to cellulose-based flame retardants, as well as reassessing environmental impact assessments in light of their potentially more sustainable nature.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of flame retardants. Under REACH, manufacturers must register chemicals and provide safety data, with some flame retardants subject to authorization or restriction due to potential health or environmental concerns.

Many countries have adopted or are in the process of adopting similar regulations to those in the US and EU. For instance, China has implemented the Measures for Environmental Management of New Chemical Substances, which includes provisions for flame retardants.

Specific to hydroxyethylcellulose-based flame retardants, regulations typically focus on their performance in standardized fire tests, such as the UL 94 vertical burning test or the cone calorimeter test. These tests evaluate factors like flame spread, heat release rate, and smoke production.

Environmental regulations are also becoming increasingly relevant for flame retardants. The Stockholm Convention on Persistent Organic Pollutants has led to the phase-out of certain halogenated flame retardants, prompting a shift towards more environmentally friendly alternatives like hydroxyethylcellulose-based solutions.

In the building and construction sector, regulations such as the International Building Code (IBC) and the European Construction Products Regulation (CPR) set specific requirements for flame retardant materials used in various applications. These regulations often reference standards like ASTM E84 for surface burning characteristics.

The textile industry faces regulations such as the US Flammable Fabrics Act and the EU's General Product Safety Directive, which mandate specific flame retardant properties for certain types of fabrics and clothing.

As research advances in hydroxyethylcellulose-based flame retardants, regulatory bodies are likely to update their frameworks to accommodate these new materials. This may include developing new testing methodologies and performance criteria specifically tailored to cellulose-based flame retardants, as well as reassessing environmental impact assessments in light of their potentially more sustainable nature.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!