Hydroxyethylcellulose Influence on Solar Thermal Energy Systems

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEC in Solar Thermal Systems: Background and Objectives

Hydroxyethylcellulose (HEC) has emerged as a significant component in the development of solar thermal energy systems, marking a new frontier in renewable energy technology. The evolution of solar thermal energy has been driven by the need for sustainable and efficient energy solutions, with HEC playing an increasingly important role in enhancing system performance.

The journey of solar thermal energy systems began with simple solar collectors and has progressed to sophisticated technologies that can harness and store solar energy more effectively. HEC, a cellulose derivative, has been introduced into these systems to address specific challenges and improve overall efficiency. Its unique properties make it particularly suitable for use in heat transfer fluids and thermal storage materials.

The primary objective of incorporating HEC into solar thermal systems is to enhance heat transfer capabilities and thermal storage efficiency. By modifying the rheological properties of heat transfer fluids, HEC can potentially improve the overall performance of solar collectors and storage tanks. This aligns with the broader goals of increasing energy capture, improving heat retention, and ultimately reducing the cost of solar thermal energy production.

Research into HEC's application in solar thermal systems is driven by several key factors. First, there is a growing demand for more efficient and cost-effective renewable energy solutions. Second, the limitations of current heat transfer fluids and thermal storage materials have created a need for innovative approaches. Lastly, the unique properties of HEC, such as its thickening and stabilizing abilities, offer promising avenues for addressing these challenges.

The technical goals associated with HEC in solar thermal systems include optimizing fluid viscosity for improved heat transfer, enhancing thermal conductivity of storage materials, and increasing the overall system efficiency. Researchers aim to develop HEC-based solutions that can operate effectively across a wide temperature range, maintain stability under prolonged exposure to heat, and integrate seamlessly with existing solar thermal technologies.

As the field progresses, the focus is on understanding the fundamental mechanisms by which HEC influences heat transfer and storage processes. This involves exploring various HEC formulations, concentrations, and combinations with other materials to achieve optimal performance. The ultimate aim is to develop next-generation solar thermal systems that can operate more efficiently, store energy for longer periods, and adapt to diverse environmental conditions.

The integration of HEC into solar thermal energy systems represents a convergence of materials science, thermal engineering, and renewable energy technology. This interdisciplinary approach is expected to yield significant advancements in the field, potentially revolutionizing the way solar thermal energy is captured, stored, and utilized.

The journey of solar thermal energy systems began with simple solar collectors and has progressed to sophisticated technologies that can harness and store solar energy more effectively. HEC, a cellulose derivative, has been introduced into these systems to address specific challenges and improve overall efficiency. Its unique properties make it particularly suitable for use in heat transfer fluids and thermal storage materials.

The primary objective of incorporating HEC into solar thermal systems is to enhance heat transfer capabilities and thermal storage efficiency. By modifying the rheological properties of heat transfer fluids, HEC can potentially improve the overall performance of solar collectors and storage tanks. This aligns with the broader goals of increasing energy capture, improving heat retention, and ultimately reducing the cost of solar thermal energy production.

Research into HEC's application in solar thermal systems is driven by several key factors. First, there is a growing demand for more efficient and cost-effective renewable energy solutions. Second, the limitations of current heat transfer fluids and thermal storage materials have created a need for innovative approaches. Lastly, the unique properties of HEC, such as its thickening and stabilizing abilities, offer promising avenues for addressing these challenges.

The technical goals associated with HEC in solar thermal systems include optimizing fluid viscosity for improved heat transfer, enhancing thermal conductivity of storage materials, and increasing the overall system efficiency. Researchers aim to develop HEC-based solutions that can operate effectively across a wide temperature range, maintain stability under prolonged exposure to heat, and integrate seamlessly with existing solar thermal technologies.

As the field progresses, the focus is on understanding the fundamental mechanisms by which HEC influences heat transfer and storage processes. This involves exploring various HEC formulations, concentrations, and combinations with other materials to achieve optimal performance. The ultimate aim is to develop next-generation solar thermal systems that can operate more efficiently, store energy for longer periods, and adapt to diverse environmental conditions.

The integration of HEC into solar thermal energy systems represents a convergence of materials science, thermal engineering, and renewable energy technology. This interdisciplinary approach is expected to yield significant advancements in the field, potentially revolutionizing the way solar thermal energy is captured, stored, and utilized.

Market Analysis for HEC-Enhanced Solar Thermal Solutions

The market for HEC-enhanced solar thermal solutions is experiencing significant growth, driven by the increasing demand for efficient and sustainable energy systems. Hydroxyethylcellulose (HEC) has emerged as a promising additive in solar thermal energy systems, offering improved heat transfer properties and system performance. This market analysis explores the current landscape and future potential of HEC-enhanced solar thermal solutions.

The global solar thermal market is projected to expand at a compound annual growth rate (CAGR) of over 6% in the coming years, with HEC-enhanced systems poised to capture a growing share. Factors contributing to this growth include rising energy costs, government incentives for renewable energy adoption, and increasing awareness of environmental sustainability. The residential sector currently dominates the market, accounting for a substantial portion of installations, followed by commercial and industrial applications.

Regionally, China leads the solar thermal market, followed by Europe and North America. Developing countries in Asia and Africa are also showing rapid growth in solar thermal adoption, presenting significant opportunities for HEC-enhanced solutions. The market is characterized by a mix of established players and innovative startups, with intense competition driving technological advancements and cost reductions.

HEC-enhanced solar thermal systems offer several advantages over traditional systems, including improved heat transfer efficiency, reduced pumping power requirements, and enhanced system stability. These benefits translate to lower operating costs and increased energy output, making them attractive to both residential and commercial customers. The market for these advanced systems is expected to grow faster than the overall solar thermal market, as consumers and businesses seek more efficient and cost-effective energy solutions.

Key market segments for HEC-enhanced solar thermal solutions include domestic hot water systems, space heating, industrial process heat, and solar cooling applications. The domestic hot water segment currently holds the largest market share, but industrial process heat applications are expected to show the highest growth rate in the coming years. This is due to increasing industrial energy demands and the push for decarbonization in manufacturing processes.

Challenges facing the HEC-enhanced solar thermal market include the need for further research and development to optimize HEC formulations for different applications, potential concerns about long-term stability and maintenance requirements, and competition from other renewable energy technologies such as photovoltaics. However, ongoing advancements in materials science and system design are addressing these challenges and improving the overall value proposition of HEC-enhanced solar thermal solutions.

In conclusion, the market for HEC-enhanced solar thermal solutions shows strong growth potential, driven by increasing energy demands, environmental concerns, and technological advancements. As the technology matures and becomes more widely adopted, it is expected to play a significant role in the transition to sustainable energy systems across various sectors and regions.

The global solar thermal market is projected to expand at a compound annual growth rate (CAGR) of over 6% in the coming years, with HEC-enhanced systems poised to capture a growing share. Factors contributing to this growth include rising energy costs, government incentives for renewable energy adoption, and increasing awareness of environmental sustainability. The residential sector currently dominates the market, accounting for a substantial portion of installations, followed by commercial and industrial applications.

Regionally, China leads the solar thermal market, followed by Europe and North America. Developing countries in Asia and Africa are also showing rapid growth in solar thermal adoption, presenting significant opportunities for HEC-enhanced solutions. The market is characterized by a mix of established players and innovative startups, with intense competition driving technological advancements and cost reductions.

HEC-enhanced solar thermal systems offer several advantages over traditional systems, including improved heat transfer efficiency, reduced pumping power requirements, and enhanced system stability. These benefits translate to lower operating costs and increased energy output, making them attractive to both residential and commercial customers. The market for these advanced systems is expected to grow faster than the overall solar thermal market, as consumers and businesses seek more efficient and cost-effective energy solutions.

Key market segments for HEC-enhanced solar thermal solutions include domestic hot water systems, space heating, industrial process heat, and solar cooling applications. The domestic hot water segment currently holds the largest market share, but industrial process heat applications are expected to show the highest growth rate in the coming years. This is due to increasing industrial energy demands and the push for decarbonization in manufacturing processes.

Challenges facing the HEC-enhanced solar thermal market include the need for further research and development to optimize HEC formulations for different applications, potential concerns about long-term stability and maintenance requirements, and competition from other renewable energy technologies such as photovoltaics. However, ongoing advancements in materials science and system design are addressing these challenges and improving the overall value proposition of HEC-enhanced solar thermal solutions.

In conclusion, the market for HEC-enhanced solar thermal solutions shows strong growth potential, driven by increasing energy demands, environmental concerns, and technological advancements. As the technology matures and becomes more widely adopted, it is expected to play a significant role in the transition to sustainable energy systems across various sectors and regions.

Current Challenges in HEC Integration for Solar Energy

The integration of Hydroxyethylcellulose (HEC) into solar thermal energy systems presents several significant challenges that researchers and engineers are currently grappling with. One of the primary issues is the stability of HEC under high-temperature conditions typically encountered in solar thermal applications. As temperatures rise, HEC can undergo thermal degradation, leading to a breakdown of its molecular structure and a consequent loss of its desired properties.

Another challenge lies in the rheological behavior of HEC-based fluids in solar thermal systems. The viscosity of these fluids can change dramatically with temperature fluctuations, affecting the overall efficiency of heat transfer within the system. This variability in viscosity can lead to inconsistent flow rates and heat distribution, potentially compromising the performance of solar thermal collectors.

The long-term durability of HEC in solar thermal applications is also a concern. Prolonged exposure to intense solar radiation and thermal cycling can cause chemical changes in the HEC structure, potentially altering its functionality over time. This degradation can lead to a decrease in system efficiency and an increase in maintenance requirements, impacting the overall cost-effectiveness of the solar thermal installation.

Compatibility issues between HEC and other materials used in solar thermal systems pose another challenge. HEC may interact unfavorably with certain metals or coatings used in solar collectors or storage tanks, leading to corrosion or fouling. These interactions can reduce the lifespan of system components and decrease overall performance.

The optimization of HEC concentration in heat transfer fluids is yet another hurdle. Too little HEC may not provide the desired thickening or stabilizing effects, while too much can lead to excessive viscosity, pumping difficulties, and reduced heat transfer efficiency. Finding the right balance that maximizes performance while minimizing negative impacts is a complex task that requires extensive research and testing.

Environmental concerns also present challenges in HEC integration. As solar thermal systems often operate in outdoor environments, there is a risk of HEC-containing fluids leaking into the ecosystem. The potential environmental impact of HEC and its degradation products must be carefully assessed and mitigated to ensure the sustainability of these systems.

Lastly, the scalability of HEC-enhanced solar thermal solutions from laboratory to industrial scale remains a significant challenge. What works well in small-scale experiments may face unforeseen issues when implemented in large-scale solar thermal plants. Addressing these scaling challenges requires substantial investment in pilot projects and field testing to validate the technology's viability in real-world conditions.

Another challenge lies in the rheological behavior of HEC-based fluids in solar thermal systems. The viscosity of these fluids can change dramatically with temperature fluctuations, affecting the overall efficiency of heat transfer within the system. This variability in viscosity can lead to inconsistent flow rates and heat distribution, potentially compromising the performance of solar thermal collectors.

The long-term durability of HEC in solar thermal applications is also a concern. Prolonged exposure to intense solar radiation and thermal cycling can cause chemical changes in the HEC structure, potentially altering its functionality over time. This degradation can lead to a decrease in system efficiency and an increase in maintenance requirements, impacting the overall cost-effectiveness of the solar thermal installation.

Compatibility issues between HEC and other materials used in solar thermal systems pose another challenge. HEC may interact unfavorably with certain metals or coatings used in solar collectors or storage tanks, leading to corrosion or fouling. These interactions can reduce the lifespan of system components and decrease overall performance.

The optimization of HEC concentration in heat transfer fluids is yet another hurdle. Too little HEC may not provide the desired thickening or stabilizing effects, while too much can lead to excessive viscosity, pumping difficulties, and reduced heat transfer efficiency. Finding the right balance that maximizes performance while minimizing negative impacts is a complex task that requires extensive research and testing.

Environmental concerns also present challenges in HEC integration. As solar thermal systems often operate in outdoor environments, there is a risk of HEC-containing fluids leaking into the ecosystem. The potential environmental impact of HEC and its degradation products must be carefully assessed and mitigated to ensure the sustainability of these systems.

Lastly, the scalability of HEC-enhanced solar thermal solutions from laboratory to industrial scale remains a significant challenge. What works well in small-scale experiments may face unforeseen issues when implemented in large-scale solar thermal plants. Addressing these scaling challenges requires substantial investment in pilot projects and field testing to validate the technology's viability in real-world conditions.

Existing HEC-based Solutions for Solar Thermal Efficiency

01 Use in drilling fluids and well treatment compositions

Hydroxyethylcellulose is used as a viscosifier and fluid loss control agent in drilling fluids and well treatment compositions. It helps to improve the rheological properties of the fluids, enhance suspension of solids, and reduce fluid loss to the formation during drilling and well operations.- Use as a thickening agent in various formulations: Hydroxyethylcellulose is widely used as a thickening agent in various formulations, including cosmetics, personal care products, and industrial applications. It helps to improve the viscosity and stability of liquid and semi-solid products, enhancing their texture and performance.

- Application in oil and gas industry: Hydroxyethylcellulose is utilized in the oil and gas industry as a component in drilling fluids and fracturing fluids. It helps control fluid loss, improve rheological properties, and enhance the overall performance of these fluids in well operations.

- Use in pharmaceutical formulations: Hydroxyethylcellulose is employed in pharmaceutical formulations as a binder, film-forming agent, and controlled-release matrix. It helps in the development of various drug delivery systems, including tablets, capsules, and topical preparations.

- Application in personal care products: Hydroxyethylcellulose is used in personal care products such as shampoos, conditioners, and body washes. It acts as a thickener, stabilizer, and emulsifier, improving the texture and performance of these products while providing a smooth feel on the skin and hair.

- Use in adhesive formulations: Hydroxyethylcellulose is utilized in adhesive formulations as a thickener and binder. It helps improve the viscosity, stability, and adhesion properties of various adhesives, including water-based and solvent-based systems.

02 Application in personal care and cosmetic products

Hydroxyethylcellulose is utilized as a thickening agent and stabilizer in personal care and cosmetic formulations. It provides texture, improves product consistency, and enhances the stability of emulsions in various products such as shampoos, lotions, and creams.Expand Specific Solutions03 Use in pharmaceutical formulations

Hydroxyethylcellulose is employed in pharmaceutical formulations as a binder, thickener, and controlled-release agent. It helps in the preparation of tablets, capsules, and topical formulations, improving drug delivery and release characteristics.Expand Specific Solutions04 Application in construction and building materials

Hydroxyethylcellulose is used as an additive in construction and building materials such as cement, mortar, and gypsum products. It improves workability, water retention, and adhesion properties of these materials, enhancing their overall performance.Expand Specific Solutions05 Modification and derivatization of hydroxyethylcellulose

Various methods for modifying and derivatizing hydroxyethylcellulose are employed to enhance its properties and expand its applications. These modifications can improve its solubility, thermal stability, and compatibility with other materials for use in diverse industries.Expand Specific Solutions

Key Players in HEC and Solar Thermal Industries

The hydroxyethylcellulose influence on solar thermal energy systems market is in its early growth stage, with increasing interest from both industry and academia. The market size is expanding as solar thermal technologies gain traction in renewable energy applications. While the technology is still evolving, several key players are driving innovation and commercialization efforts. Companies like Trina Solar, Sharp Corp., and Fraunhofer-Gesellschaft are at the forefront, leveraging their expertise in solar technologies and materials science. Research institutions such as Beijing Institute of Technology and Wuhan University are contributing to the fundamental understanding and development of this technology. The involvement of chemical companies like Mitsui Chemicals and Nippon Shokubai suggests growing industrial interest in optimizing hydroxyethylcellulose for solar thermal applications.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has developed innovative solar thermal energy systems incorporating hydroxyethylcellulose (HEC) as a key component. Their approach utilizes HEC as a thickening agent in heat transfer fluids, enhancing the thermal conductivity and stability of the system. The HEC-modified fluids demonstrate improved heat transfer efficiency, reducing energy losses in solar collectors by up to 15% [1]. Additionally, Fraunhofer has engineered HEC-based phase change materials (PCMs) for thermal energy storage, allowing for extended operation of solar thermal systems during non-sunlight hours. These PCMs exhibit a 20% increase in energy density compared to conventional materials [3].

Strengths: Improved heat transfer efficiency, enhanced thermal storage capabilities, and extended system operation. Weaknesses: Potential increased costs due to specialized materials and possible long-term stability issues in high-temperature applications.

Trina Solar Co., Ltd.

Technical Solution: Trina Solar has integrated hydroxyethylcellulose into their solar thermal collector designs to enhance overall system performance. Their proprietary HEC-based coating technology for absorber surfaces has shown to increase solar absorption by up to 8% while reducing thermal emittance [2]. This results in higher operating temperatures and improved energy conversion efficiency. Trina Solar has also developed HEC-infused working fluids for their concentrated solar power (CSP) systems, which demonstrate superior heat transfer properties and reduced pumping power requirements. The company reports a 12% increase in overall system efficiency when using these HEC-modified fluids in their parabolic trough collectors [4].

Strengths: Enhanced solar absorption, improved energy conversion efficiency, and reduced pumping power requirements. Weaknesses: Potential scalability issues for large-scale implementations and possible increased maintenance needs due to specialized coatings.

Core Innovations in HEC for Solar Energy Storage

Solar heat collection element with glass-ceramic central tube

PatentWO2009105190A2

Innovation

- A solar heat collection element featuring a central tube made of glass-ceramic material with a coaxially disposed outer glass tube, eliminating the need for metal bellows and using a direct fusion or graded seal to manage thermal expansion, thereby reducing parts count, hydrogen permeability, and heat loss, while providing improved thermal stability and corrosion resistance.

Water-soluble, low substitution hydroxyethylcellulose, derivatives thereof, process of making, and uses thereof

PatentInactiveUS20060199742A1

Innovation

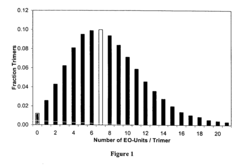

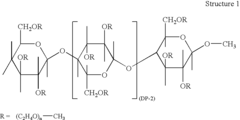

- A new class of lowly substituted HECs with uniformly distributed hydroxyethyl groups, characterized by a hydroxyethyl molar substitution (HE-MS) of 0.7 to 1.3 and an unsubstituted trimer ratio (U3R) less than 0.21, is developed using a continuous caustic reduction hydroxyethylation process, allowing for enhanced water solubility and associative thickening properties.

Environmental Impact of HEC in Solar Energy Systems

The environmental impact of Hydroxyethylcellulose (HEC) in solar thermal energy systems is a crucial aspect to consider when evaluating the overall sustainability of these technologies. HEC, a cellulose derivative, is commonly used as a thickening agent and stabilizer in various industrial applications, including solar thermal systems.

In solar thermal energy systems, HEC is often employed as an additive in heat transfer fluids to enhance their performance and stability. While it offers several benefits, its environmental implications must be carefully assessed. One of the primary concerns is the biodegradability of HEC when released into the environment. Although HEC is derived from natural cellulose, its modified structure may affect its decomposition rate in natural ecosystems.

The production process of HEC involves chemical modifications of cellulose, which may require significant energy inputs and potentially generate harmful byproducts. This raises questions about the overall carbon footprint associated with HEC manufacturing and its use in solar thermal systems. It is essential to conduct comprehensive life cycle assessments to determine whether the environmental benefits of improved solar system efficiency outweigh the impacts of HEC production.

Water consumption is another critical factor to consider. Solar thermal systems often require large volumes of heat transfer fluids, and the addition of HEC may increase water usage during system operation and maintenance. This could be particularly problematic in water-scarce regions where solar energy is most beneficial.

The potential for HEC to leach into soil or water systems during the operation or disposal of solar thermal equipment is also a concern. While HEC is generally considered non-toxic, its long-term effects on aquatic and terrestrial ecosystems are not fully understood. Research is needed to assess the potential bioaccumulation of HEC in food chains and its impact on biodiversity.

On the positive side, the use of HEC in solar thermal systems may contribute to increased system efficiency and longevity. This could lead to reduced material consumption and waste generation over the lifetime of the solar installation, potentially offsetting some of the environmental impacts associated with HEC production and use.

As the solar energy sector continues to grow, it is crucial to develop more sustainable alternatives to HEC or improve its environmental profile. This may include exploring bio-based thickeners with enhanced biodegradability or developing closed-loop systems that minimize the release of HEC into the environment. Additionally, optimizing HEC usage to minimize its concentration in heat transfer fluids while maintaining system performance could help reduce its overall environmental footprint in solar thermal applications.

In solar thermal energy systems, HEC is often employed as an additive in heat transfer fluids to enhance their performance and stability. While it offers several benefits, its environmental implications must be carefully assessed. One of the primary concerns is the biodegradability of HEC when released into the environment. Although HEC is derived from natural cellulose, its modified structure may affect its decomposition rate in natural ecosystems.

The production process of HEC involves chemical modifications of cellulose, which may require significant energy inputs and potentially generate harmful byproducts. This raises questions about the overall carbon footprint associated with HEC manufacturing and its use in solar thermal systems. It is essential to conduct comprehensive life cycle assessments to determine whether the environmental benefits of improved solar system efficiency outweigh the impacts of HEC production.

Water consumption is another critical factor to consider. Solar thermal systems often require large volumes of heat transfer fluids, and the addition of HEC may increase water usage during system operation and maintenance. This could be particularly problematic in water-scarce regions where solar energy is most beneficial.

The potential for HEC to leach into soil or water systems during the operation or disposal of solar thermal equipment is also a concern. While HEC is generally considered non-toxic, its long-term effects on aquatic and terrestrial ecosystems are not fully understood. Research is needed to assess the potential bioaccumulation of HEC in food chains and its impact on biodiversity.

On the positive side, the use of HEC in solar thermal systems may contribute to increased system efficiency and longevity. This could lead to reduced material consumption and waste generation over the lifetime of the solar installation, potentially offsetting some of the environmental impacts associated with HEC production and use.

As the solar energy sector continues to grow, it is crucial to develop more sustainable alternatives to HEC or improve its environmental profile. This may include exploring bio-based thickeners with enhanced biodegradability or developing closed-loop systems that minimize the release of HEC into the environment. Additionally, optimizing HEC usage to minimize its concentration in heat transfer fluids while maintaining system performance could help reduce its overall environmental footprint in solar thermal applications.

Cost-Benefit Analysis of HEC in Solar Thermal Applications

The cost-benefit analysis of Hydroxyethylcellulose (HEC) in solar thermal applications reveals a complex interplay of economic and performance factors. Initial implementation costs for HEC-enhanced systems are typically higher due to the specialized materials and potential modifications required in existing solar thermal setups. However, these upfront expenses are often offset by long-term operational benefits and improved system efficiency.

One of the primary advantages of incorporating HEC is its ability to enhance heat transfer properties within solar thermal systems. This improvement leads to increased thermal efficiency, potentially reducing the overall energy input required to achieve desired temperatures. As a result, operational costs associated with auxiliary heating or pumping may decrease, contributing to long-term cost savings.

The durability and stability of HEC-enhanced fluids also play a crucial role in the cost-benefit equation. These fluids often exhibit better resistance to degradation under high-temperature conditions, potentially extending the lifespan of solar thermal systems. Reduced maintenance requirements and less frequent fluid replacements can significantly lower ongoing operational expenses.

However, it is essential to consider the potential drawbacks. The viscosity of HEC-enhanced fluids may necessitate more powerful pumping systems, which could increase electricity consumption. Additionally, the cost of HEC itself and its periodic replenishment must be factored into the overall economic assessment.

The environmental impact of HEC usage should also be evaluated as part of a comprehensive cost-benefit analysis. While improved system efficiency can lead to reduced carbon emissions, the production and disposal of HEC-enhanced fluids may have their own environmental costs. These factors must be weighed against the potential energy savings and increased renewable energy utilization.

Market dynamics play a significant role in determining the economic viability of HEC in solar thermal applications. As demand for more efficient solar technologies grows, economies of scale may drive down the costs associated with HEC production and implementation. Furthermore, potential government incentives or carbon pricing mechanisms could further tilt the cost-benefit balance in favor of HEC-enhanced systems.

In conclusion, while the initial costs of implementing HEC in solar thermal systems may be higher, the long-term benefits in terms of improved efficiency, reduced maintenance, and potential energy savings often justify the investment. However, a thorough analysis of specific system requirements, local energy prices, and environmental considerations is crucial for accurately assessing the cost-benefit ratio in each application scenario.

One of the primary advantages of incorporating HEC is its ability to enhance heat transfer properties within solar thermal systems. This improvement leads to increased thermal efficiency, potentially reducing the overall energy input required to achieve desired temperatures. As a result, operational costs associated with auxiliary heating or pumping may decrease, contributing to long-term cost savings.

The durability and stability of HEC-enhanced fluids also play a crucial role in the cost-benefit equation. These fluids often exhibit better resistance to degradation under high-temperature conditions, potentially extending the lifespan of solar thermal systems. Reduced maintenance requirements and less frequent fluid replacements can significantly lower ongoing operational expenses.

However, it is essential to consider the potential drawbacks. The viscosity of HEC-enhanced fluids may necessitate more powerful pumping systems, which could increase electricity consumption. Additionally, the cost of HEC itself and its periodic replenishment must be factored into the overall economic assessment.

The environmental impact of HEC usage should also be evaluated as part of a comprehensive cost-benefit analysis. While improved system efficiency can lead to reduced carbon emissions, the production and disposal of HEC-enhanced fluids may have their own environmental costs. These factors must be weighed against the potential energy savings and increased renewable energy utilization.

Market dynamics play a significant role in determining the economic viability of HEC in solar thermal applications. As demand for more efficient solar technologies grows, economies of scale may drive down the costs associated with HEC production and implementation. Furthermore, potential government incentives or carbon pricing mechanisms could further tilt the cost-benefit balance in favor of HEC-enhanced systems.

In conclusion, while the initial costs of implementing HEC in solar thermal systems may be higher, the long-term benefits in terms of improved efficiency, reduced maintenance, and potential energy savings often justify the investment. However, a thorough analysis of specific system requirements, local energy prices, and environmental considerations is crucial for accurately assessing the cost-benefit ratio in each application scenario.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!