Analysis of composite interface strength using dynamic mechanical analysis

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Composite Interface Strength Analysis Background and Objectives

Composite interface strength analysis has evolved significantly over the past three decades, transitioning from basic mechanical testing methods to sophisticated analytical techniques. The interface between matrix and reinforcement in composite materials represents a critical zone that largely determines the overall performance characteristics including mechanical strength, durability, and failure mechanisms. Dynamic Mechanical Analysis (DMA) has emerged as a powerful technique for evaluating these interfacial properties by measuring viscoelastic behavior under oscillating loads.

The historical development of interface strength analysis began with rudimentary pull-out tests in the 1970s, progressing through microbond testing in the 1980s, to the integration of spectroscopic methods in the 1990s. The introduction of DMA for composite interface characterization represents a significant advancement, allowing researchers to examine time-dependent mechanical properties and interfacial interactions at various temperatures and frequencies.

Current technological trends in this field include the development of multi-scale analysis approaches that bridge molecular-level interactions with macro-scale mechanical properties. The integration of artificial intelligence and machine learning algorithms with DMA data processing has enabled more accurate prediction of interface behavior under complex loading conditions. Additionally, in-situ monitoring techniques are gaining prominence, allowing real-time observation of interfacial changes during mechanical testing.

The primary objective of composite interface strength analysis using DMA is to establish quantitative relationships between processing parameters, interfacial chemistry, and resulting mechanical properties. This includes determining the glass transition temperature at the interface region, which often differs from that of the bulk matrix, and measuring the damping characteristics that reveal energy dissipation mechanisms at the interface.

Secondary objectives include developing standardized testing protocols for consistent evaluation across different composite systems, creating predictive models that can accelerate material development cycles, and establishing correlations between DMA measurements and long-term performance metrics such as fatigue resistance and environmental durability.

The technological goals extend to enabling precise engineering of interfaces for specific applications, from aerospace components requiring high temperature resistance to biomedical implants needing controlled degradation rates. By understanding the fundamental mechanisms governing interface strength through DMA, researchers aim to design next-generation composites with tailored interfacial properties that optimize performance while minimizing material usage and environmental impact.

The historical development of interface strength analysis began with rudimentary pull-out tests in the 1970s, progressing through microbond testing in the 1980s, to the integration of spectroscopic methods in the 1990s. The introduction of DMA for composite interface characterization represents a significant advancement, allowing researchers to examine time-dependent mechanical properties and interfacial interactions at various temperatures and frequencies.

Current technological trends in this field include the development of multi-scale analysis approaches that bridge molecular-level interactions with macro-scale mechanical properties. The integration of artificial intelligence and machine learning algorithms with DMA data processing has enabled more accurate prediction of interface behavior under complex loading conditions. Additionally, in-situ monitoring techniques are gaining prominence, allowing real-time observation of interfacial changes during mechanical testing.

The primary objective of composite interface strength analysis using DMA is to establish quantitative relationships between processing parameters, interfacial chemistry, and resulting mechanical properties. This includes determining the glass transition temperature at the interface region, which often differs from that of the bulk matrix, and measuring the damping characteristics that reveal energy dissipation mechanisms at the interface.

Secondary objectives include developing standardized testing protocols for consistent evaluation across different composite systems, creating predictive models that can accelerate material development cycles, and establishing correlations between DMA measurements and long-term performance metrics such as fatigue resistance and environmental durability.

The technological goals extend to enabling precise engineering of interfaces for specific applications, from aerospace components requiring high temperature resistance to biomedical implants needing controlled degradation rates. By understanding the fundamental mechanisms governing interface strength through DMA, researchers aim to design next-generation composites with tailored interfacial properties that optimize performance while minimizing material usage and environmental impact.

Market Applications and Demand for Interface Strength Testing

The composite materials market has witnessed substantial growth across various industries, driving an increasing demand for reliable interface strength testing methodologies. The global composite materials market was valued at approximately 90.6 billion USD in 2020 and is projected to reach 131.6 billion USD by 2025, representing a compound annual growth rate of 7.7%. This growth directly correlates with the expanding need for advanced testing techniques like dynamic mechanical analysis (DMA) for interface strength evaluation.

Aerospace and automotive industries represent the largest market segments demanding interface strength testing solutions. In aerospace applications, where safety is paramount, the ability to accurately predict composite behavior under various loading conditions is critical. The aerospace composites market alone is expected to grow at 8.5% annually through 2026, with interface strength being a key performance parameter for certification requirements.

The automotive sector has similarly embraced composite materials to meet stringent fuel efficiency and emissions standards. As electric vehicle production increases, the demand for lightweight yet strong composite components has surged, necessitating more sophisticated interface strength testing protocols. Automotive manufacturers require testing methods that can simulate real-world conditions while providing quantitative data on interface durability.

Wind energy represents another rapidly expanding market for composite interface strength testing. With wind turbine blades growing larger to increase energy capture efficiency, the structural integrity of composite interfaces becomes increasingly critical. The wind energy sector's demand for reliable testing methods is expected to grow at 9.8% annually as blade designs become more complex and performance requirements more stringent.

Electronics and consumer products manufacturers have also emerged as significant markets for interface strength testing. As electronic devices become thinner and more integrated, the performance of composite interfaces in these applications directly impacts product reliability and consumer satisfaction. The miniaturization trend in electronics has created demand for testing methodologies capable of evaluating interface strength at increasingly smaller scales.

Medical device manufacturers represent a specialized but growing market segment. Composite materials in implantable devices, prosthetics, and medical equipment must maintain interface integrity under biological conditions. This sector demands testing protocols that can simulate physiological environments while providing predictive data on long-term interface performance.

The construction industry has begun adopting composite materials for infrastructure applications, creating new market opportunities for interface strength testing. As aging infrastructure requires replacement, composite solutions offer durability advantages that depend heavily on interface performance. This emerging market segment is expected to grow significantly as composite adoption in civil engineering applications increases.

Aerospace and automotive industries represent the largest market segments demanding interface strength testing solutions. In aerospace applications, where safety is paramount, the ability to accurately predict composite behavior under various loading conditions is critical. The aerospace composites market alone is expected to grow at 8.5% annually through 2026, with interface strength being a key performance parameter for certification requirements.

The automotive sector has similarly embraced composite materials to meet stringent fuel efficiency and emissions standards. As electric vehicle production increases, the demand for lightweight yet strong composite components has surged, necessitating more sophisticated interface strength testing protocols. Automotive manufacturers require testing methods that can simulate real-world conditions while providing quantitative data on interface durability.

Wind energy represents another rapidly expanding market for composite interface strength testing. With wind turbine blades growing larger to increase energy capture efficiency, the structural integrity of composite interfaces becomes increasingly critical. The wind energy sector's demand for reliable testing methods is expected to grow at 9.8% annually as blade designs become more complex and performance requirements more stringent.

Electronics and consumer products manufacturers have also emerged as significant markets for interface strength testing. As electronic devices become thinner and more integrated, the performance of composite interfaces in these applications directly impacts product reliability and consumer satisfaction. The miniaturization trend in electronics has created demand for testing methodologies capable of evaluating interface strength at increasingly smaller scales.

Medical device manufacturers represent a specialized but growing market segment. Composite materials in implantable devices, prosthetics, and medical equipment must maintain interface integrity under biological conditions. This sector demands testing protocols that can simulate physiological environments while providing predictive data on long-term interface performance.

The construction industry has begun adopting composite materials for infrastructure applications, creating new market opportunities for interface strength testing. As aging infrastructure requires replacement, composite solutions offer durability advantages that depend heavily on interface performance. This emerging market segment is expected to grow significantly as composite adoption in civil engineering applications increases.

Current DMA Technology Status and Challenges

Dynamic Mechanical Analysis (DMA) has evolved significantly over the past decades, becoming a crucial technique for evaluating composite interface strength. Currently, DMA technology operates by applying oscillating forces to materials and analyzing their viscoelastic response, providing valuable insights into the mechanical properties at interfaces between different components in composite materials.

The state-of-the-art DMA equipment offers temperature ranges from -150°C to 600°C, with frequency capabilities spanning from 0.001 Hz to 200 Hz. Modern systems can achieve force resolutions down to 0.00001 N and displacement resolutions of 1 nanometer, enabling highly precise measurements of interfacial properties. However, these specifications vary significantly between manufacturers and models, creating challenges in standardization across the industry.

Despite technological advancements, several critical challenges persist in DMA application for composite interface strength analysis. Sample preparation remains a significant hurdle, as inconsistencies in specimen geometry and mounting can introduce substantial measurement errors. The interface region itself presents unique difficulties due to its heterogeneous nature and often microscopic dimensions, making it challenging to isolate interface-specific responses from bulk material behavior.

Data interpretation poses another major challenge. The complex viscoelastic responses obtained from DMA measurements require sophisticated mathematical models to extract meaningful interface strength parameters. Current models often make simplifying assumptions that may not fully capture the complex stress transfer mechanisms at composite interfaces, particularly in advanced multi-phase composites with engineered interphases.

Environmental factors significantly impact DMA measurements, with humidity and atmospheric conditions potentially altering interface properties during testing. This is particularly problematic for bio-based composites and those with hygroscopic components, where moisture absorption can dramatically change interfacial characteristics.

Geographically, DMA technology development shows distinct patterns. North American and European research institutions lead in theoretical advancements and modeling approaches, while Asian manufacturers, particularly in Japan and China, dominate equipment production with continuous improvements in hardware precision and automation. This geographical distribution creates challenges in standardization and knowledge transfer across different regions.

The miniaturization trend in materials science has pushed DMA technology toward nano-scale measurements, but current systems struggle with the spatial resolution required for next-generation nanocomposites. Additionally, high-throughput capabilities remain limited, with most DMA systems still requiring time-consuming individual sample testing rather than parallel processing methods needed for industrial-scale material development.

The state-of-the-art DMA equipment offers temperature ranges from -150°C to 600°C, with frequency capabilities spanning from 0.001 Hz to 200 Hz. Modern systems can achieve force resolutions down to 0.00001 N and displacement resolutions of 1 nanometer, enabling highly precise measurements of interfacial properties. However, these specifications vary significantly between manufacturers and models, creating challenges in standardization across the industry.

Despite technological advancements, several critical challenges persist in DMA application for composite interface strength analysis. Sample preparation remains a significant hurdle, as inconsistencies in specimen geometry and mounting can introduce substantial measurement errors. The interface region itself presents unique difficulties due to its heterogeneous nature and often microscopic dimensions, making it challenging to isolate interface-specific responses from bulk material behavior.

Data interpretation poses another major challenge. The complex viscoelastic responses obtained from DMA measurements require sophisticated mathematical models to extract meaningful interface strength parameters. Current models often make simplifying assumptions that may not fully capture the complex stress transfer mechanisms at composite interfaces, particularly in advanced multi-phase composites with engineered interphases.

Environmental factors significantly impact DMA measurements, with humidity and atmospheric conditions potentially altering interface properties during testing. This is particularly problematic for bio-based composites and those with hygroscopic components, where moisture absorption can dramatically change interfacial characteristics.

Geographically, DMA technology development shows distinct patterns. North American and European research institutions lead in theoretical advancements and modeling approaches, while Asian manufacturers, particularly in Japan and China, dominate equipment production with continuous improvements in hardware precision and automation. This geographical distribution creates challenges in standardization and knowledge transfer across different regions.

The miniaturization trend in materials science has pushed DMA technology toward nano-scale measurements, but current systems struggle with the spatial resolution required for next-generation nanocomposites. Additionally, high-throughput capabilities remain limited, with most DMA systems still requiring time-consuming individual sample testing rather than parallel processing methods needed for industrial-scale material development.

State-of-the-Art DMA Testing Protocols

01 Surface treatment methods for improving interface strength

Various surface treatment methods can be applied to composite materials to enhance the interface strength between different components. These methods include chemical treatments, plasma treatments, and surface functionalization techniques that modify the surface properties to promote better adhesion. By creating reactive sites or increasing surface roughness, these treatments can significantly improve the bonding strength at the interface, leading to enhanced mechanical properties of the composite as a whole.- Surface treatment methods for enhancing composite interface strength: Various surface treatment methods can be applied to improve the bonding strength at composite interfaces. These include chemical treatments, plasma treatments, and mechanical roughening techniques that modify the surface properties of the substrate materials. Such treatments increase the surface energy, create mechanical interlocking opportunities, and promote chemical bonding between different materials, resulting in enhanced interface strength and durability of composite structures.

- Nanomaterial reinforcement at composite interfaces: Incorporating nanomaterials at composite interfaces significantly improves interfacial strength. Materials such as carbon nanotubes, graphene, nanoparticles, and nanofibers can be strategically placed at the interface to create stronger bonds between dissimilar materials. These nanomaterials bridge the gap between different phases, distribute stress more effectively, and create additional bonding sites, resulting in superior mechanical properties and enhanced load transfer across the interface.

- Coupling agents and adhesion promoters for interface strengthening: Specialized coupling agents and adhesion promoters can be applied at composite interfaces to create stronger chemical bonds between dissimilar materials. These compounds typically contain functional groups that can react with both the matrix and reinforcement components, forming covalent bridges across the interface. Silanes, titanates, zirconates, and other organometallic compounds are commonly used to improve wetting, adhesion, and overall interfacial strength in composite systems.

- Interface design through gradient structures and interlayers: Creating gradient structures or incorporating specialized interlayers at composite interfaces can significantly enhance interfacial strength. These approaches help to minimize stress concentrations by gradually transitioning material properties across the interface. Functionally graded materials, multi-layered structures, and strategically designed interphases distribute mechanical loads more effectively, accommodate thermal expansion differences, and prevent catastrophic failure at the interface region.

- Testing and characterization methods for composite interface strength: Various testing and characterization techniques are employed to evaluate and quantify the strength of composite interfaces. These include pull-out tests, push-out tests, lap shear tests, peeling tests, and advanced microscopy methods. Computational modeling and simulation approaches are also used to predict interfacial behavior under different loading conditions. These methods provide critical insights for optimizing interface design and validating the effectiveness of strengthening strategies in composite materials.

02 Incorporation of coupling agents and compatibilizers

Coupling agents and compatibilizers can be incorporated into composite materials to improve the interface strength between dissimilar materials. These additives act as bridges between the matrix and reinforcement phases, creating chemical bonds that enhance adhesion. Common coupling agents include silanes, titanates, and zirconates, which can significantly improve the interfacial bonding and load transfer efficiency, resulting in composites with superior mechanical properties and durability.Expand Specific Solutions03 Nano-reinforcement at composite interfaces

The introduction of nanomaterials at the interface between composite components can significantly enhance interface strength. Nanoparticles, nanofibers, or nanosheets can be strategically placed at the interface to create mechanical interlocking, increase contact area, and promote chemical bonding. These nano-reinforcements can effectively bridge microcracks and distribute stress more evenly across the interface, leading to improved mechanical properties and failure resistance of the composite structure.Expand Specific Solutions04 Interface design through gradient structures

Creating gradient structures at the interface between different materials in a composite can effectively reduce stress concentration and improve interface strength. By gradually changing the composition, porosity, or mechanical properties across the interface region, the mismatch in thermal expansion coefficients and elastic moduli can be minimized. This approach creates a more seamless transition between different phases, resulting in enhanced load transfer efficiency and improved overall mechanical performance of the composite.Expand Specific Solutions05 Testing and characterization methods for interface strength

Various testing and characterization methods have been developed to evaluate the strength of composite interfaces. These include pull-out tests, push-out tests, fragmentation tests, and advanced microscopy techniques that can visualize the interface region. Computational modeling approaches are also employed to predict interface behavior under different loading conditions. These methods provide valuable insights into the failure mechanisms at the interface and guide the development of strategies to enhance interface strength in composite materials.Expand Specific Solutions

Leading Research Institutions and Industrial Players

The dynamic mechanical analysis (DMA) for composite interface strength evaluation is currently in a growth phase, with an expanding market driven by aerospace, automotive, and materials industries. The global market size is estimated at $300-400 million, growing at 6-8% annually. Technologically, this field shows moderate maturity with ongoing innovations. Leading academic institutions like Nanjing University of Aeronautics & Astronautics, Zhejiang University, and Harbin Institute of Technology are advancing fundamental research, while industrial players including SABIC, Toray Industries, Toyota, and Bridgestone are developing practical applications. The collaboration between academic institutions and corporations like Mitsubishi Materials and 3M Innovative Properties indicates a trend toward standardization and commercialization of DMA techniques for composite interface strength analysis.

Nanjing University of Aeronautics & Astronautics

Technical Solution: Nanjing University of Aeronautics & Astronautics has developed an advanced multi-scale dynamic mechanical analysis (DMA) approach for composite interface strength evaluation. Their methodology combines traditional DMA testing with micro-mechanical modeling to characterize the viscoelastic behavior at the fiber-matrix interface. The university's research team has pioneered temperature-dependent DMA protocols that can isolate interfacial effects from bulk material properties by analyzing the phase lag between stress and strain responses across different loading frequencies. Their approach incorporates specialized sample preparation techniques that create controlled interface geometries, allowing for direct measurement of interfacial shear strength under dynamic loading conditions. Recent publications have demonstrated correlation between DMA-derived interface parameters and composite mechanical performance in aerospace applications, with particular success in carbon fiber reinforced polymers used in aircraft structures.

Strengths: Exceptional correlation between DMA measurements and actual composite performance in aerospace applications; sophisticated mathematical models that can extract interface-specific properties from bulk measurements. Weaknesses: Requires specialized equipment and expertise; testing protocols can be time-consuming compared to conventional mechanical testing methods.

Beijing Institute of Aeronautical Materials

Technical Solution: Beijing Institute of Aeronautical Materials has developed a comprehensive DMA-based interface strength analysis system specifically tailored for aerospace composite materials. Their approach integrates high-precision dynamic mechanical analyzers with environmental chambers capable of simulating extreme aerospace conditions (-60°C to 300°C) while measuring interface properties. The institute has created proprietary algorithms that can deconvolute the complex modulus data to isolate the contribution of the interface region from the bulk composite response. Their methodology incorporates multi-frequency sweeps (0.01-200 Hz) combined with temperature ramps to generate detailed viscoelastic maps of interface behavior under various service conditions. The institute has successfully applied this technique to evaluate the durability of composite interfaces in aircraft components subjected to thermal cycling and mechanical fatigue, establishing quantitative relationships between DMA-derived parameters and long-term interface durability.

Strengths: Highly specialized for aerospace applications with capability to simulate extreme environmental conditions; established correlations between DMA parameters and actual service performance of aerospace components. Weaknesses: Highly specialized equipment requirements; analysis methods are complex and require significant expertise in both materials science and signal processing.

Critical Technical Innovations in Interface Strength Analysis

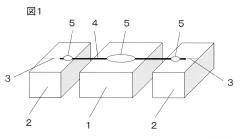

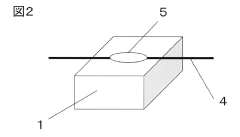

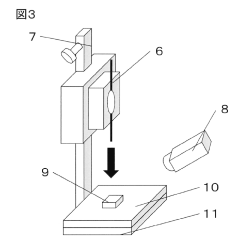

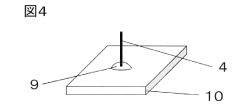

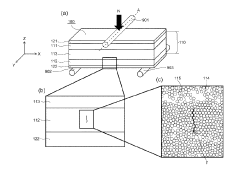

Interface characteristic evaluation method, index evaluation method of energy absorption of fiber-reinforced composite material and interface characteristic evaluation device

PatentInactiveJP2015187606A

Innovation

- A method and apparatus for evaluating interfacial properties by ensuring the straightness of single yarns through separate processes of attachment to a tab, embedding, and pulling out, using mechanisms to control embedding depth and measure resistance accurately, allowing for multiple tests in parallel.

Method for inspecting interface bond strength of fiber reinforced composite material, and test piece

PatentInactiveJP2017090226A

Innovation

- A method involving a fiber-reinforced composite material with multiple reinforcing fiber layers, each oriented at specific angles, and a protective layer applied to one or both surfaces, allowing for the application of a load perpendicular to the fiber direction to observe interfacial adhesion strength by preventing cracks from penetrating the outermost layer and facilitating localized delamination inspection.

Standardization and Testing Protocols

The standardization of testing protocols for dynamic mechanical analysis (DMA) in composite interface strength evaluation is crucial for ensuring reproducible and comparable results across different research institutions and industries. Currently, several international standards organizations, including ASTM International, ISO, and JECMA, have established guidelines for DMA testing of composite materials. ASTM D4065 and ISO 6721 series provide foundational frameworks for dynamic mechanical properties measurement, though specific protocols for interface strength analysis remain under development.

Testing protocols for composite interface strength using DMA typically involve three critical phases: specimen preparation, testing conditions, and data analysis. Specimen preparation standards must specify dimensions, geometry, and conditioning procedures that minimize variability. The current recommendation includes standardized sample geometries such as rectangular bars (typically 35mm × 10mm × 3mm) for flexural tests and cylindrical specimens for torsional tests, with precise interface orientation requirements.

Testing condition standardization encompasses temperature ranges, heating/cooling rates, frequency sweeps, and applied strain levels. For composite interface analysis, temperature ramps from -50°C to 250°C at 3°C/min have shown optimal sensitivity to interfacial phenomena. Frequency sweeps typically range from 0.1 to 100 Hz, with multi-frequency measurements providing comprehensive viscoelastic characterization of the interface region.

Data analysis protocols represent the most challenging aspect of standardization efforts. Current best practices include tan δ peak analysis, storage modulus transition evaluation, and complex modulus mapping. The Cole-Cole plot method has gained recognition for its sensitivity to interfacial interactions, though quantitative correlation models linking these parameters directly to interface strength remain under development.

Interlaboratory studies have revealed significant variability in DMA results for interface strength analysis, with coefficient of variation ranging from 15-30% across different laboratories using nominally identical protocols. This highlights the urgent need for more rigorous standardization. Recent round-robin testing initiatives by the Composites Materials Handbook organization aim to address these discrepancies through refined protocols and calibration standards.

Emerging trends in testing protocols include the integration of digital image correlation techniques with DMA to provide spatial mapping of interfacial deformation, and the development of miniaturized specimen geometries for high-throughput testing. Additionally, machine learning approaches are being explored to extract more meaningful interface parameters from complex DMA data sets, potentially leading to more robust and automated analysis protocols.

Testing protocols for composite interface strength using DMA typically involve three critical phases: specimen preparation, testing conditions, and data analysis. Specimen preparation standards must specify dimensions, geometry, and conditioning procedures that minimize variability. The current recommendation includes standardized sample geometries such as rectangular bars (typically 35mm × 10mm × 3mm) for flexural tests and cylindrical specimens for torsional tests, with precise interface orientation requirements.

Testing condition standardization encompasses temperature ranges, heating/cooling rates, frequency sweeps, and applied strain levels. For composite interface analysis, temperature ramps from -50°C to 250°C at 3°C/min have shown optimal sensitivity to interfacial phenomena. Frequency sweeps typically range from 0.1 to 100 Hz, with multi-frequency measurements providing comprehensive viscoelastic characterization of the interface region.

Data analysis protocols represent the most challenging aspect of standardization efforts. Current best practices include tan δ peak analysis, storage modulus transition evaluation, and complex modulus mapping. The Cole-Cole plot method has gained recognition for its sensitivity to interfacial interactions, though quantitative correlation models linking these parameters directly to interface strength remain under development.

Interlaboratory studies have revealed significant variability in DMA results for interface strength analysis, with coefficient of variation ranging from 15-30% across different laboratories using nominally identical protocols. This highlights the urgent need for more rigorous standardization. Recent round-robin testing initiatives by the Composites Materials Handbook organization aim to address these discrepancies through refined protocols and calibration standards.

Emerging trends in testing protocols include the integration of digital image correlation techniques with DMA to provide spatial mapping of interfacial deformation, and the development of miniaturized specimen geometries for high-throughput testing. Additionally, machine learning approaches are being explored to extract more meaningful interface parameters from complex DMA data sets, potentially leading to more robust and automated analysis protocols.

Material-Specific Considerations and Limitations

Dynamic mechanical analysis (DMA) for composite interface strength assessment must account for material-specific considerations that significantly impact test results and interpretation. Fiber-reinforced composites exhibit distinct behaviors depending on the fiber type used; carbon fibers demonstrate higher stiffness and thermal stability compared to glass or aramid fibers, necessitating different DMA parameters for accurate interface characterization. The matrix material similarly influences testing protocols, with thermoset matrices like epoxy requiring different temperature ranges than thermoplastic matrices due to their distinct glass transition behaviors and crosslinking structures.

Specimen geometry presents another critical consideration, as the interface response varies significantly between unidirectional, woven, or randomly oriented fiber composites. The fiber volume fraction and orientation relative to the applied load direction fundamentally alter the stress transfer mechanisms at the interface, requiring careful standardization of specimen preparation to ensure reproducible results. Additionally, the interface region's thickness and composition, which may include sizing agents or coupling treatments, create unique viscoelastic responses that must be accounted for in analysis models.

Environmental sensitivity represents a substantial limitation in DMA testing of composite interfaces. Moisture absorption can dramatically alter the interface properties, particularly in hydrophilic matrix systems, potentially masking the true mechanical response. Temperature history during processing and testing similarly affects results, with residual thermal stresses potentially influencing measured interface strength values. These environmental factors necessitate careful conditioning and documentation of specimen history prior to testing.

Scale-dependent phenomena further complicate analysis, as microscale interface properties may not directly translate to macroscale composite performance. The heterogeneous nature of composite materials creates localized stress concentrations and non-uniform deformation patterns that standard DMA models may not fully capture. This limitation becomes particularly pronounced in multi-phase composites or those with complex interface architectures.

Aging and degradation mechanisms specific to certain material combinations must also be considered, as UV exposure, thermal cycling, or chemical environments can disproportionately affect the interface region compared to bulk materials. Time-dependent behaviors such as creep and stress relaxation vary significantly between material systems, requiring material-specific calibration of viscoelastic models used to interpret DMA data. These considerations necessitate careful selection of test parameters and interpretation frameworks tailored to the specific composite system under investigation.

Specimen geometry presents another critical consideration, as the interface response varies significantly between unidirectional, woven, or randomly oriented fiber composites. The fiber volume fraction and orientation relative to the applied load direction fundamentally alter the stress transfer mechanisms at the interface, requiring careful standardization of specimen preparation to ensure reproducible results. Additionally, the interface region's thickness and composition, which may include sizing agents or coupling treatments, create unique viscoelastic responses that must be accounted for in analysis models.

Environmental sensitivity represents a substantial limitation in DMA testing of composite interfaces. Moisture absorption can dramatically alter the interface properties, particularly in hydrophilic matrix systems, potentially masking the true mechanical response. Temperature history during processing and testing similarly affects results, with residual thermal stresses potentially influencing measured interface strength values. These environmental factors necessitate careful conditioning and documentation of specimen history prior to testing.

Scale-dependent phenomena further complicate analysis, as microscale interface properties may not directly translate to macroscale composite performance. The heterogeneous nature of composite materials creates localized stress concentrations and non-uniform deformation patterns that standard DMA models may not fully capture. This limitation becomes particularly pronounced in multi-phase composites or those with complex interface architectures.

Aging and degradation mechanisms specific to certain material combinations must also be considered, as UV exposure, thermal cycling, or chemical environments can disproportionately affect the interface region compared to bulk materials. Time-dependent behaviors such as creep and stress relaxation vary significantly between material systems, requiring material-specific calibration of viscoelastic models used to interpret DMA data. These considerations necessitate careful selection of test parameters and interpretation frameworks tailored to the specific composite system under investigation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!