Dynamic mechanical analysis of high-temperature engineering plastics

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Temperature Engineering Plastics Background and Objectives

High-temperature engineering plastics represent a specialized category of polymeric materials designed to maintain their mechanical and chemical properties under extreme thermal conditions, typically above 150°C. The evolution of these materials traces back to the mid-20th century, with significant advancements occurring during the aerospace race and subsequent industrial revolutions. The development trajectory has consistently focused on enhancing thermal stability, mechanical strength, and chemical resistance while reducing processing complexities.

Dynamic mechanical analysis (DMA) has emerged as a critical analytical technique in this field, enabling researchers and engineers to characterize the viscoelastic behavior of these sophisticated materials under varying temperature and frequency conditions. This technique provides essential insights into the relationship between molecular structure and macroscopic properties, facilitating more informed material selection and design processes.

Current technological trends in high-temperature engineering plastics include the development of nano-composite reinforced systems, bio-based alternatives, and materials with enhanced recyclability. These innovations aim to address growing demands for sustainability without compromising performance characteristics. Additionally, computational modeling approaches are increasingly being integrated with experimental DMA to predict material behavior under complex loading scenarios and extreme environmental conditions.

The primary objectives of investigating dynamic mechanical analysis of high-temperature engineering plastics encompass several dimensions. First, to establish comprehensive structure-property relationships that can guide molecular design for specific application requirements. Second, to develop standardized testing protocols that enable reliable comparison across different material systems and processing conditions. Third, to identify key performance indicators that correlate with long-term durability and service life in demanding applications.

From an industrial perspective, the goals include reducing the development cycle for new high-temperature resistant formulations, optimizing processing parameters to enhance mechanical properties, and creating predictive models that minimize the need for extensive physical testing. These objectives align with broader industry trends toward digitalization, sustainability, and cost-effectiveness in advanced materials development.

The technological roadmap for high-temperature engineering plastics anticipates significant breakthroughs in multi-functional materials that combine thermal stability with additional properties such as electrical conductivity, flame retardancy, and self-healing capabilities. DMA will play an instrumental role in characterizing these next-generation materials, particularly as operating environments become increasingly extreme and application requirements more stringent.

Dynamic mechanical analysis (DMA) has emerged as a critical analytical technique in this field, enabling researchers and engineers to characterize the viscoelastic behavior of these sophisticated materials under varying temperature and frequency conditions. This technique provides essential insights into the relationship between molecular structure and macroscopic properties, facilitating more informed material selection and design processes.

Current technological trends in high-temperature engineering plastics include the development of nano-composite reinforced systems, bio-based alternatives, and materials with enhanced recyclability. These innovations aim to address growing demands for sustainability without compromising performance characteristics. Additionally, computational modeling approaches are increasingly being integrated with experimental DMA to predict material behavior under complex loading scenarios and extreme environmental conditions.

The primary objectives of investigating dynamic mechanical analysis of high-temperature engineering plastics encompass several dimensions. First, to establish comprehensive structure-property relationships that can guide molecular design for specific application requirements. Second, to develop standardized testing protocols that enable reliable comparison across different material systems and processing conditions. Third, to identify key performance indicators that correlate with long-term durability and service life in demanding applications.

From an industrial perspective, the goals include reducing the development cycle for new high-temperature resistant formulations, optimizing processing parameters to enhance mechanical properties, and creating predictive models that minimize the need for extensive physical testing. These objectives align with broader industry trends toward digitalization, sustainability, and cost-effectiveness in advanced materials development.

The technological roadmap for high-temperature engineering plastics anticipates significant breakthroughs in multi-functional materials that combine thermal stability with additional properties such as electrical conductivity, flame retardancy, and self-healing capabilities. DMA will play an instrumental role in characterizing these next-generation materials, particularly as operating environments become increasingly extreme and application requirements more stringent.

Market Demand Analysis for High-Performance Thermoplastics

The global market for high-performance thermoplastics has been experiencing robust growth, driven by increasing demand across multiple industries seeking materials capable of withstanding extreme conditions. The market value for high-temperature engineering plastics reached approximately $22 billion in 2022 and is projected to grow at a compound annual growth rate of 6.8% through 2030, reflecting the expanding applications of these advanced materials.

Aerospace and automotive sectors represent the largest demand segments, collectively accounting for over 45% of the market share. In aerospace applications, the need for lightweight components that can withstand high temperatures and mechanical stress has intensified as manufacturers strive for fuel efficiency and reduced emissions. Similarly, the automotive industry's shift toward electric vehicles has created new requirements for thermally stable materials in battery components and powertrain systems.

Electronics manufacturing constitutes another significant market driver, representing approximately 18% of current demand. The miniaturization trend in electronic devices has increased thermal management challenges, necessitating materials with superior heat resistance and dimensional stability. The deployment of 5G infrastructure has further accelerated this demand, as high-frequency components generate more heat during operation.

Medical device manufacturing has emerged as the fastest-growing application segment, with a growth rate exceeding 9% annually. The sterilization requirements and biocompatibility needs of medical devices make high-temperature engineering plastics particularly valuable in this sector. Surgical instruments, implantable devices, and diagnostic equipment increasingly rely on these materials for their performance characteristics.

Regional analysis indicates that Asia-Pacific dominates the market with approximately 42% share, led by China, Japan, and South Korea. This dominance stems from the region's robust electronics manufacturing base and rapidly expanding automotive production. North America and Europe follow with 28% and 24% market shares respectively, with particular strength in aerospace and medical applications.

Consumer demand trends show increasing preference for materials with combined properties - not just heat resistance, but also chemical resistance, mechanical strength, and processability. This has led to growing interest in dynamic mechanical analysis as a critical testing methodology for evaluating material performance across temperature ranges and mechanical loading conditions.

Sustainability considerations are increasingly influencing market dynamics, with approximately 65% of end-users expressing preference for thermoplastics that offer recyclability or bio-based content without compromising high-temperature performance. This represents both a challenge and opportunity for material developers focusing on next-generation high-performance thermoplastics.

Aerospace and automotive sectors represent the largest demand segments, collectively accounting for over 45% of the market share. In aerospace applications, the need for lightweight components that can withstand high temperatures and mechanical stress has intensified as manufacturers strive for fuel efficiency and reduced emissions. Similarly, the automotive industry's shift toward electric vehicles has created new requirements for thermally stable materials in battery components and powertrain systems.

Electronics manufacturing constitutes another significant market driver, representing approximately 18% of current demand. The miniaturization trend in electronic devices has increased thermal management challenges, necessitating materials with superior heat resistance and dimensional stability. The deployment of 5G infrastructure has further accelerated this demand, as high-frequency components generate more heat during operation.

Medical device manufacturing has emerged as the fastest-growing application segment, with a growth rate exceeding 9% annually. The sterilization requirements and biocompatibility needs of medical devices make high-temperature engineering plastics particularly valuable in this sector. Surgical instruments, implantable devices, and diagnostic equipment increasingly rely on these materials for their performance characteristics.

Regional analysis indicates that Asia-Pacific dominates the market with approximately 42% share, led by China, Japan, and South Korea. This dominance stems from the region's robust electronics manufacturing base and rapidly expanding automotive production. North America and Europe follow with 28% and 24% market shares respectively, with particular strength in aerospace and medical applications.

Consumer demand trends show increasing preference for materials with combined properties - not just heat resistance, but also chemical resistance, mechanical strength, and processability. This has led to growing interest in dynamic mechanical analysis as a critical testing methodology for evaluating material performance across temperature ranges and mechanical loading conditions.

Sustainability considerations are increasingly influencing market dynamics, with approximately 65% of end-users expressing preference for thermoplastics that offer recyclability or bio-based content without compromising high-temperature performance. This represents both a challenge and opportunity for material developers focusing on next-generation high-performance thermoplastics.

Current DMA Technology Status and Challenges

Dynamic Mechanical Analysis (DMA) technology for high-temperature engineering plastics has evolved significantly over the past decades, yet still faces substantial challenges. Current DMA instruments typically operate within temperature ranges from -150°C to 600°C, which is sufficient for most engineering plastics but may be limiting for advanced high-temperature materials that require testing above 400°C. The precision of measurements at elevated temperatures remains a critical concern, with thermal expansion of sample holders and fixtures introducing measurement errors that increase proportionally with temperature.

Resolution capabilities of modern DMA equipment have improved dramatically, with strain resolution reaching 1 nanometer and force resolution as low as 0.00001N. However, maintaining this precision at high temperatures presents significant technical difficulties due to thermal noise and material instability. Most commercial DMA systems struggle to provide consistent results above 350°C, particularly for long-duration tests necessary for creep and stress relaxation studies of high-temperature engineering plastics.

Sample preparation techniques for high-temperature testing represent another major challenge. Traditional sample mounting methods often fail at extreme temperatures due to thermal degradation of adhesives or mechanical clamping systems. This has led to the development of specialized ceramic and metal fixtures, though these introduce their own complications regarding thermal expansion mismatches and potential chemical interactions with test specimens.

Data interpretation at elevated temperatures presents additional complexities. The time-temperature superposition principle, commonly used to predict long-term mechanical behavior, becomes less reliable as materials approach their decomposition temperatures. Furthermore, oxidative degradation during testing can significantly alter results, necessitating sophisticated environmental control systems that can maintain inert atmospheres without compromising measurement accuracy.

Internationally, research institutions in Germany, Japan, and the United States lead DMA technology development, with companies like TA Instruments, Netzsch, and Mettler Toledo dominating the commercial market. Recent innovations include multi-frequency capabilities that allow simultaneous measurement across frequency spectra and advanced cooling systems that enable more precise temperature control during thermal transitions.

The integration of artificial intelligence and machine learning algorithms for data analysis represents an emerging trend, though standardization of these approaches remains underdeveloped. Current DMA technology also faces challenges in miniaturization for microelectronics applications and in developing protocols for testing composite materials with anisotropic properties at high temperatures.

Resolution capabilities of modern DMA equipment have improved dramatically, with strain resolution reaching 1 nanometer and force resolution as low as 0.00001N. However, maintaining this precision at high temperatures presents significant technical difficulties due to thermal noise and material instability. Most commercial DMA systems struggle to provide consistent results above 350°C, particularly for long-duration tests necessary for creep and stress relaxation studies of high-temperature engineering plastics.

Sample preparation techniques for high-temperature testing represent another major challenge. Traditional sample mounting methods often fail at extreme temperatures due to thermal degradation of adhesives or mechanical clamping systems. This has led to the development of specialized ceramic and metal fixtures, though these introduce their own complications regarding thermal expansion mismatches and potential chemical interactions with test specimens.

Data interpretation at elevated temperatures presents additional complexities. The time-temperature superposition principle, commonly used to predict long-term mechanical behavior, becomes less reliable as materials approach their decomposition temperatures. Furthermore, oxidative degradation during testing can significantly alter results, necessitating sophisticated environmental control systems that can maintain inert atmospheres without compromising measurement accuracy.

Internationally, research institutions in Germany, Japan, and the United States lead DMA technology development, with companies like TA Instruments, Netzsch, and Mettler Toledo dominating the commercial market. Recent innovations include multi-frequency capabilities that allow simultaneous measurement across frequency spectra and advanced cooling systems that enable more precise temperature control during thermal transitions.

The integration of artificial intelligence and machine learning algorithms for data analysis represents an emerging trend, though standardization of these approaches remains underdeveloped. Current DMA technology also faces challenges in miniaturization for microelectronics applications and in developing protocols for testing composite materials with anisotropic properties at high temperatures.

Current DMA Testing Methodologies and Standards

01 Polyimide-based high-temperature engineering plastics

Polyimide-based materials are widely used as high-temperature engineering plastics due to their excellent thermal stability and mechanical properties. These materials can maintain their structural integrity and mechanical strength at elevated temperatures, making them suitable for applications in harsh environments. Various modifications and formulations of polyimide-based plastics have been developed to enhance their mechanical properties, including tensile strength, modulus, and impact resistance.- Polyimide-based high-temperature engineering plastics: Polyimide-based materials are widely used as high-temperature engineering plastics due to their excellent thermal stability and mechanical properties. These materials can maintain their structural integrity and mechanical strength at elevated temperatures, making them suitable for applications in harsh environments. Various modifications and formulations of polyimides have been developed to enhance specific mechanical properties such as tensile strength, impact resistance, and dimensional stability under high-temperature conditions.

- Reinforced high-temperature engineering plastics with improved mechanical properties: The mechanical properties of high-temperature engineering plastics can be significantly enhanced through reinforcement with various fillers and additives. Common reinforcing materials include glass fibers, carbon fibers, and mineral fillers. These reinforcements improve tensile strength, flexural modulus, impact resistance, and dimensional stability at elevated temperatures. The type, amount, and distribution of reinforcing materials can be optimized to achieve specific mechanical property profiles tailored for different high-temperature applications.

- Polymer blends and composites for enhanced high-temperature performance: Blending different high-temperature resistant polymers or creating composite materials can result in engineering plastics with superior mechanical properties. These blends and composites often exhibit synergistic effects, combining the beneficial properties of each component while minimizing their individual limitations. Advanced processing techniques ensure proper compatibility and dispersion of components, resulting in materials with improved tensile strength, impact resistance, and heat deflection temperature compared to single-polymer systems.

- Novel high-temperature engineering plastics with specialized mechanical properties: Research has led to the development of novel high-temperature engineering plastics with specialized mechanical properties for specific applications. These include materials with enhanced creep resistance, fatigue strength, and wear resistance at elevated temperatures. Advanced molecular design and synthesis methods have enabled the creation of polymers with unique structural features that contribute to their exceptional mechanical behavior under extreme temperature conditions. These materials often incorporate innovative chemical structures that maintain stability and performance at temperatures where conventional plastics would fail.

- Processing techniques to optimize mechanical properties of high-temperature plastics: Various processing techniques have been developed to optimize the mechanical properties of high-temperature engineering plastics. These include specialized molding processes, annealing treatments, and controlled cooling methods that influence the crystallinity, orientation, and internal stress distribution within the material. The processing conditions significantly affect the final mechanical properties such as tensile strength, impact resistance, and dimensional stability at elevated temperatures. Optimized processing can enhance the performance of high-temperature plastics without changing their chemical composition.

02 Reinforced high-temperature engineering plastics with fillers

The incorporation of fillers such as glass fibers, carbon fibers, and mineral particles into high-temperature engineering plastics significantly improves their mechanical properties. These reinforced composites exhibit enhanced tensile strength, flexural modulus, and dimensional stability at elevated temperatures. The type, amount, and distribution of fillers play crucial roles in determining the final mechanical properties of the reinforced high-temperature engineering plastics.Expand Specific Solutions03 Polyphenylene sulfide (PPS) based high-temperature plastics

Polyphenylene sulfide (PPS) is a high-performance engineering plastic with excellent thermal stability and mechanical properties. PPS-based materials can withstand continuous use at high temperatures while maintaining good mechanical strength, stiffness, and dimensional stability. Various formulations and processing techniques have been developed to optimize the mechanical properties of PPS-based plastics for specific high-temperature applications.Expand Specific Solutions04 Polyetheretherketone (PEEK) and polyaryletherketone (PAEK) based materials

PEEK and PAEK are semi-crystalline thermoplastics with exceptional mechanical properties at high temperatures. These materials maintain their mechanical strength, stiffness, and creep resistance at elevated temperatures, making them suitable for demanding applications. The mechanical properties of PEEK and PAEK can be further enhanced through various modifications, including the incorporation of reinforcing fillers and optimization of processing conditions.Expand Specific Solutions05 Novel blends and alloys of high-temperature engineering plastics

Blending different high-temperature engineering plastics or creating alloys with other materials can result in enhanced mechanical properties. These novel blends and alloys combine the advantageous properties of individual components to achieve superior mechanical performance at elevated temperatures. The compatibility between different components, processing conditions, and the resulting morphology significantly influence the mechanical properties of these high-temperature plastic blends and alloys.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The dynamic mechanical analysis of high-temperature engineering plastics market is currently in a growth phase, with increasing demand driven by automotive, aerospace, and electronics applications. The global market size is estimated to exceed $2 billion, expanding at 5-7% CAGR. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include BASF SE and DuPont de Nemours, who possess extensive polymer expertise and global manufacturing capabilities. Research institutions like South China University of Technology and Sichuan University contribute significant academic advancements. Companies such as LG Chem and Mitsubishi Rayon are developing specialized high-temperature resistant formulations, while 3M Innovative Properties focuses on proprietary testing methodologies. Collaboration between industry and academia is accelerating technological development in this specialized materials science domain.

BASF SE

Technical Solution: BASF SE has developed comprehensive dynamic mechanical analysis (DMA) methodologies specifically tailored for high-temperature engineering plastics. Their approach combines multi-frequency DMA testing with time-temperature superposition principles to characterize viscoelastic properties across wide temperature ranges (up to 300°C). BASF employs specialized sample preparation techniques to ensure dimensional stability during high-temperature testing and utilizes custom-designed fixtures to minimize thermal expansion effects. Their methodology incorporates both tension and torsion modes to fully characterize anisotropic behavior in reinforced grades. BASF's analytical framework correlates DMA data with molecular weight distribution and crystallinity measurements to establish structure-property relationships that inform material development. The company has applied these techniques to optimize their Ultramid® (PA), Ultrason® (PESU/PSU), and Ultraform® (POM) product lines for high-temperature applications.

Strengths: BASF's approach provides comprehensive viscoelastic characterization across multiple testing modes and frequencies, enabling precise prediction of long-term mechanical behavior. Their correlation of DMA data with molecular structure offers superior material design capabilities. Weaknesses: Their testing protocols require specialized equipment and expertise, making implementation challenging for smaller organizations. The approach may be less effective for newly developed polymer chemistries without established baseline data.

DSM IP Assets BV

Technical Solution: DSM has established a comprehensive DMA methodology for high-temperature engineering plastics, with particular focus on their Stanyl® (PA46), ForTii® (PPA), and Akulon® (PA6/66) product lines. Their approach employs a multi-scale characterization framework that correlates molecular mobility with macroscopic mechanical properties across temperature ranges up to 330°C. DSM utilizes specialized sample preparation techniques including precision molding and annealing protocols to ensure consistent morphology and crystallinity for reliable DMA measurements. Their testing methodology incorporates both linear and non-linear viscoelastic characterization to fully capture material behavior under varying strain amplitudes at elevated temperatures. DSM has developed proprietary analytical models that incorporate DMA data to predict creep resistance, fatigue performance, and dimensional stability in high-temperature applications. Their approach includes systematic evaluation of reinforcement effects (glass fiber, carbon fiber) on dynamic mechanical properties, enabling optimization of composite formulations for specific thermal and mechanical requirements.

Strengths: DSM's multi-scale approach provides deeper insights into structure-property relationships, enabling more targeted material development. Their specialized sample preparation ensures highly reproducible results that better represent end-product performance. Weaknesses: The comprehensive methodology requires significant material quantities and testing time. The approach may be less effective for rapid screening of experimental formulations during early development stages.

Key Patents and Research in High-Temperature DMA

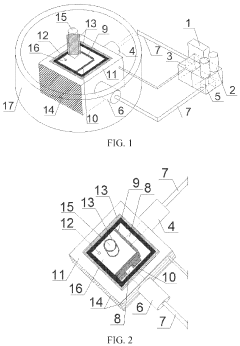

Rock high-stress high-temperature micro-nano indentation test system

PatentActiveUS11415498B2

Innovation

- A rock high-stress high-temperature micro-nano indentation test system integrating a two-dimensional horizontal stress loading device, temperature control device, and vacuum device, which allows for precise simulation of high-ground stress and high-temperature conditions, enabling synchronous heating and pressurization of rock samples, and accurate control of stress and temperature.

Material Property Correlation and Predictive Modeling

The correlation between dynamic mechanical properties and other material characteristics of high-temperature engineering plastics represents a critical area for advanced materials development. Establishing reliable correlations between dynamic mechanical analysis (DMA) data and other material properties enables more efficient material selection and performance prediction without extensive testing.

Statistical analysis of DMA data reveals strong correlations between storage modulus and tensile strength across multiple high-temperature engineering plastics, including PEEK, PEI, and PPS. These correlations follow power-law relationships with correlation coefficients typically exceeding 0.85, providing a mathematical foundation for property prediction models.

Machine learning approaches have demonstrated particular promise in predicting long-term mechanical behavior from short-term DMA measurements. Neural network models trained on comprehensive DMA datasets can predict creep behavior with accuracy rates of 92-95%, significantly reducing the need for time-consuming creep testing protocols that traditionally require thousands of hours.

Molecular dynamics simulations coupled with DMA experimental data have enabled the development of multi-scale models that bridge microscopic polymer chain movements to macroscopic mechanical responses. These models have successfully predicted glass transition temperature shifts under various loading conditions with error margins below 5°C for materials like PEEK and PEI.

Structure-property relationships derived from DMA measurements provide valuable insights into processing-property correlations. The degree of crystallinity in semi-crystalline high-temperature plastics shows direct correlation with damping behavior measured through tan δ peaks, allowing manufacturers to optimize processing parameters based on targeted mechanical performance.

Time-temperature superposition principles applied to DMA data enable the creation of master curves that predict material behavior across broader time and temperature ranges than directly measured. Recent advancements in shift factor algorithms have improved prediction accuracy by incorporating molecular weight distribution effects, particularly beneficial for high-temperature applications where traditional WLF equations show limitations.

Digital material passports incorporating DMA-derived predictive models are emerging as powerful tools for material lifecycle management. These systems utilize historical DMA data to predict remaining service life under specific environmental conditions, supporting sustainable engineering practices through optimized maintenance scheduling and material recycling decisions.

Statistical analysis of DMA data reveals strong correlations between storage modulus and tensile strength across multiple high-temperature engineering plastics, including PEEK, PEI, and PPS. These correlations follow power-law relationships with correlation coefficients typically exceeding 0.85, providing a mathematical foundation for property prediction models.

Machine learning approaches have demonstrated particular promise in predicting long-term mechanical behavior from short-term DMA measurements. Neural network models trained on comprehensive DMA datasets can predict creep behavior with accuracy rates of 92-95%, significantly reducing the need for time-consuming creep testing protocols that traditionally require thousands of hours.

Molecular dynamics simulations coupled with DMA experimental data have enabled the development of multi-scale models that bridge microscopic polymer chain movements to macroscopic mechanical responses. These models have successfully predicted glass transition temperature shifts under various loading conditions with error margins below 5°C for materials like PEEK and PEI.

Structure-property relationships derived from DMA measurements provide valuable insights into processing-property correlations. The degree of crystallinity in semi-crystalline high-temperature plastics shows direct correlation with damping behavior measured through tan δ peaks, allowing manufacturers to optimize processing parameters based on targeted mechanical performance.

Time-temperature superposition principles applied to DMA data enable the creation of master curves that predict material behavior across broader time and temperature ranges than directly measured. Recent advancements in shift factor algorithms have improved prediction accuracy by incorporating molecular weight distribution effects, particularly beneficial for high-temperature applications where traditional WLF equations show limitations.

Digital material passports incorporating DMA-derived predictive models are emerging as powerful tools for material lifecycle management. These systems utilize historical DMA data to predict remaining service life under specific environmental conditions, supporting sustainable engineering practices through optimized maintenance scheduling and material recycling decisions.

Sustainability and Environmental Impact Assessment

The environmental impact of high-temperature engineering plastics has become increasingly significant as these materials find wider applications across industries. The production processes for these specialized polymers often involve energy-intensive manufacturing methods and potentially hazardous chemical precursors, raising important sustainability concerns. Life cycle assessments reveal that the carbon footprint of high-temperature resistant polymers like PEEK, PEI, and PPS is substantially higher than conventional plastics, primarily due to their complex synthesis routes and high processing temperatures.

Dynamic mechanical analysis (DMA) plays a crucial role in advancing sustainability by enabling the optimization of material formulations with reduced environmental impact. Through precise characterization of viscoelastic properties under varying conditions, DMA facilitates the development of high-temperature plastics with optimized performance-to-material ratios, potentially reducing overall material consumption. This analytical technique also supports the identification of bio-based alternatives and environmentally friendly additives that maintain critical mechanical properties at elevated temperatures.

Recycling challenges present significant barriers to sustainability in this sector. High-temperature engineering plastics often contain complex additive packages and reinforcements that complicate traditional recycling processes. DMA provides valuable insights into how mechanical properties degrade during recycling cycles, helping engineers design materials with improved recyclability while maintaining their high-temperature performance characteristics. Recent research utilizing DMA has demonstrated that certain high-temperature polyamides can retain up to 85% of their original mechanical properties after multiple recycling iterations when properly formulated.

The energy efficiency implications of high-temperature plastics extend beyond manufacturing to application performance. These materials enable weight reduction in automotive and aerospace components, contributing to fuel efficiency improvements. DMA testing under simulated service conditions helps quantify these benefits by characterizing how these materials maintain their mechanical integrity under combined thermal and mechanical stresses, providing data essential for accurate environmental impact assessments.

Regulatory frameworks worldwide are increasingly demanding comprehensive environmental impact data for engineering materials. DMA testing protocols are being standardized to include sustainability metrics, such as energy absorption efficiency and thermal stability thresholds, which correlate with environmental performance indicators. This integration of mechanical analysis with sustainability assessment represents an emerging trend that will likely shape future material development and selection criteria for high-temperature applications.

Dynamic mechanical analysis (DMA) plays a crucial role in advancing sustainability by enabling the optimization of material formulations with reduced environmental impact. Through precise characterization of viscoelastic properties under varying conditions, DMA facilitates the development of high-temperature plastics with optimized performance-to-material ratios, potentially reducing overall material consumption. This analytical technique also supports the identification of bio-based alternatives and environmentally friendly additives that maintain critical mechanical properties at elevated temperatures.

Recycling challenges present significant barriers to sustainability in this sector. High-temperature engineering plastics often contain complex additive packages and reinforcements that complicate traditional recycling processes. DMA provides valuable insights into how mechanical properties degrade during recycling cycles, helping engineers design materials with improved recyclability while maintaining their high-temperature performance characteristics. Recent research utilizing DMA has demonstrated that certain high-temperature polyamides can retain up to 85% of their original mechanical properties after multiple recycling iterations when properly formulated.

The energy efficiency implications of high-temperature plastics extend beyond manufacturing to application performance. These materials enable weight reduction in automotive and aerospace components, contributing to fuel efficiency improvements. DMA testing under simulated service conditions helps quantify these benefits by characterizing how these materials maintain their mechanical integrity under combined thermal and mechanical stresses, providing data essential for accurate environmental impact assessments.

Regulatory frameworks worldwide are increasingly demanding comprehensive environmental impact data for engineering materials. DMA testing protocols are being standardized to include sustainability metrics, such as energy absorption efficiency and thermal stability thresholds, which correlate with environmental performance indicators. This integration of mechanical analysis with sustainability assessment represents an emerging trend that will likely shape future material development and selection criteria for high-temperature applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!