Dynamic mechanical analysis under cyclic thermal conditions

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DMA Technology Background and Objectives

Dynamic Mechanical Analysis (DMA) has evolved significantly since its inception in the mid-20th century as a fundamental technique for characterizing viscoelastic properties of materials. Initially developed for polymer characterization, DMA has expanded its application scope to encompass a wide range of materials including composites, ceramics, metals, and biological samples. The technique fundamentally measures how materials respond to applied oscillatory forces while monitoring deformation as a function of temperature, time, and frequency.

The integration of cyclic thermal conditions into DMA represents a critical advancement in materials testing methodology. This evolution addresses the growing industrial need to understand material behavior under real-world conditions where temperature fluctuations are common. Traditional isothermal or constant-rate temperature change tests often fail to capture the complex material responses that occur during thermal cycling, particularly in applications involving repeated heating and cooling cycles.

Current technological trends in DMA under cyclic thermal conditions focus on enhancing measurement precision, expanding temperature range capabilities, and developing more sophisticated data analysis algorithms. The miniaturization of testing equipment, integration with other analytical techniques, and automation of testing procedures represent significant directions in the field's development.

The primary objective of cyclic thermal DMA technology is to accurately predict and characterize material behavior under complex thermal environments that simulate actual service conditions. This includes understanding fatigue properties, thermal expansion coefficients, glass transition temperatures, and relaxation phenomena as they evolve through multiple thermal cycles.

For industries such as aerospace, automotive, and electronics manufacturing, where materials experience frequent temperature fluctuations, this technology aims to provide critical insights into material durability, reliability, and performance degradation over time. The ability to accelerate testing by simulating years of thermal cycling in laboratory conditions represents a particularly valuable aspect of this technology.

Another key objective is the development of standardized testing protocols that enable consistent comparison of materials across different laboratories and testing conditions. This standardization effort seeks to establish reliable correlations between accelerated laboratory tests and actual field performance, thereby improving material selection processes and design optimization.

The technology further aims to bridge the gap between theoretical models of viscoelastic behavior and practical engineering applications by providing empirical data that can validate and refine computational models. This synergy between experimental techniques and theoretical frameworks drives the continuous improvement of predictive capabilities in materials science and engineering.

The integration of cyclic thermal conditions into DMA represents a critical advancement in materials testing methodology. This evolution addresses the growing industrial need to understand material behavior under real-world conditions where temperature fluctuations are common. Traditional isothermal or constant-rate temperature change tests often fail to capture the complex material responses that occur during thermal cycling, particularly in applications involving repeated heating and cooling cycles.

Current technological trends in DMA under cyclic thermal conditions focus on enhancing measurement precision, expanding temperature range capabilities, and developing more sophisticated data analysis algorithms. The miniaturization of testing equipment, integration with other analytical techniques, and automation of testing procedures represent significant directions in the field's development.

The primary objective of cyclic thermal DMA technology is to accurately predict and characterize material behavior under complex thermal environments that simulate actual service conditions. This includes understanding fatigue properties, thermal expansion coefficients, glass transition temperatures, and relaxation phenomena as they evolve through multiple thermal cycles.

For industries such as aerospace, automotive, and electronics manufacturing, where materials experience frequent temperature fluctuations, this technology aims to provide critical insights into material durability, reliability, and performance degradation over time. The ability to accelerate testing by simulating years of thermal cycling in laboratory conditions represents a particularly valuable aspect of this technology.

Another key objective is the development of standardized testing protocols that enable consistent comparison of materials across different laboratories and testing conditions. This standardization effort seeks to establish reliable correlations between accelerated laboratory tests and actual field performance, thereby improving material selection processes and design optimization.

The technology further aims to bridge the gap between theoretical models of viscoelastic behavior and practical engineering applications by providing empirical data that can validate and refine computational models. This synergy between experimental techniques and theoretical frameworks drives the continuous improvement of predictive capabilities in materials science and engineering.

Market Applications and Demand Analysis

Dynamic mechanical analysis (DMA) under cyclic thermal conditions has witnessed significant market growth across multiple industries due to its ability to characterize material behavior under real-world temperature fluctuations. The global materials testing market, where DMA is a critical component, is currently valued at approximately $4.2 billion and projected to grow at a CAGR of 5.7% through 2028, with thermal analysis techniques representing a substantial segment of this expansion.

The aerospace and automotive sectors demonstrate the highest demand for cyclic thermal DMA, driven by stringent safety requirements and the need to understand material fatigue under temperature variations. These industries require materials that maintain structural integrity during repeated heating and cooling cycles, particularly for components exposed to extreme temperature fluctuations such as jet engine parts and automotive powertrain systems.

Electronics manufacturing represents another rapidly growing application area, with the semiconductor industry increasingly relying on cyclic thermal DMA to evaluate packaging materials, adhesives, and substrates. As electronic devices continue to miniaturize while generating more heat, understanding thermal cycling effects on material properties has become essential for reliability engineering and failure prevention.

The polymer and composite materials industry constitutes a significant market segment, utilizing cyclic thermal DMA to develop advanced materials with tailored thermal-mechanical properties. This demand is particularly evident in high-performance applications where materials must withstand repeated thermal stresses without degradation.

Regionally, North America and Europe currently lead the market adoption of advanced DMA techniques, though Asia-Pacific shows the fastest growth rate, primarily driven by expanding manufacturing capabilities in China, Japan, and South Korea. The region's electronics and automotive sectors are increasingly investing in sophisticated materials testing equipment.

Market research indicates a growing preference for integrated testing systems that combine DMA with other analytical techniques, allowing for comprehensive material characterization. This trend reflects the industry's movement toward more efficient testing protocols and holistic understanding of material behavior under complex environmental conditions.

Customer demand increasingly focuses on systems offering higher temperature ranges, faster cycling capabilities, and improved data analytics. The ability to simulate real-world thermal cycling conditions with greater precision and efficiency represents a key purchasing factor across industries, highlighting the need for continued innovation in this technology space.

The aerospace and automotive sectors demonstrate the highest demand for cyclic thermal DMA, driven by stringent safety requirements and the need to understand material fatigue under temperature variations. These industries require materials that maintain structural integrity during repeated heating and cooling cycles, particularly for components exposed to extreme temperature fluctuations such as jet engine parts and automotive powertrain systems.

Electronics manufacturing represents another rapidly growing application area, with the semiconductor industry increasingly relying on cyclic thermal DMA to evaluate packaging materials, adhesives, and substrates. As electronic devices continue to miniaturize while generating more heat, understanding thermal cycling effects on material properties has become essential for reliability engineering and failure prevention.

The polymer and composite materials industry constitutes a significant market segment, utilizing cyclic thermal DMA to develop advanced materials with tailored thermal-mechanical properties. This demand is particularly evident in high-performance applications where materials must withstand repeated thermal stresses without degradation.

Regionally, North America and Europe currently lead the market adoption of advanced DMA techniques, though Asia-Pacific shows the fastest growth rate, primarily driven by expanding manufacturing capabilities in China, Japan, and South Korea. The region's electronics and automotive sectors are increasingly investing in sophisticated materials testing equipment.

Market research indicates a growing preference for integrated testing systems that combine DMA with other analytical techniques, allowing for comprehensive material characterization. This trend reflects the industry's movement toward more efficient testing protocols and holistic understanding of material behavior under complex environmental conditions.

Customer demand increasingly focuses on systems offering higher temperature ranges, faster cycling capabilities, and improved data analytics. The ability to simulate real-world thermal cycling conditions with greater precision and efficiency represents a key purchasing factor across industries, highlighting the need for continued innovation in this technology space.

Current Challenges in Cyclic Thermal DMA

Despite significant advancements in Dynamic Mechanical Analysis (DMA) technology, conducting tests under cyclic thermal conditions presents several persistent challenges that limit both accuracy and applicability. The primary difficulty lies in maintaining precise temperature control during rapid thermal cycling, where temperature gradients within samples can lead to non-uniform mechanical responses and compromised data integrity. Even state-of-the-art DMA equipment struggles to achieve truly homogeneous temperature distribution throughout specimens during dynamic thermal transitions.

Material response lag represents another critical challenge, as the thermal and mechanical responses of polymers and composites often exhibit phase differences during cyclic temperature changes. This temporal misalignment between applied thermal conditions and measured mechanical properties creates interpretation complexities that current analytical models inadequately address. The viscoelastic nature of many materials further complicates analysis, as their properties demonstrate strong temperature-history dependence that traditional DMA methodologies fail to fully characterize.

Instrumentation limitations constitute a significant barrier, particularly regarding sensor response times and calibration stability across wide temperature ranges. Thermal expansion of both the sample and instrument components introduces measurement artifacts that can obscure genuine material behavior. Current compensation algorithms remain insufficient for completely eliminating these systematic errors, especially during rapid thermal transitions where thermal equilibrium is never fully achieved.

Data analysis frameworks for cyclic thermal DMA remain underdeveloped compared to isothermal testing protocols. The complex interplay between frequency, temperature rate, and mechanical response creates multidimensional datasets that challenge conventional analytical approaches. Current software solutions typically employ oversimplified models that fail to capture the full complexity of material behavior under these dynamic conditions.

Long-term testing reliability presents additional challenges, as repeated thermal cycling can induce cumulative changes in both the test equipment and sample fixtures. Thermal fatigue of components and gradual calibration drift compromise measurement consistency, particularly for extended durability studies requiring hundreds or thousands of thermal cycles. The lack of standardized protocols for cyclic thermal DMA further complicates cross-laboratory comparisons and validation of results.

Sample preparation techniques also require refinement for cyclic thermal testing, as conventional sample geometries optimized for isothermal testing may perform poorly under thermal cycling conditions. Edge effects and thermal gradient sensitivity become more pronounced during thermal transitions, necessitating specialized sample designs that few laboratories have systematically developed or validated.

Material response lag represents another critical challenge, as the thermal and mechanical responses of polymers and composites often exhibit phase differences during cyclic temperature changes. This temporal misalignment between applied thermal conditions and measured mechanical properties creates interpretation complexities that current analytical models inadequately address. The viscoelastic nature of many materials further complicates analysis, as their properties demonstrate strong temperature-history dependence that traditional DMA methodologies fail to fully characterize.

Instrumentation limitations constitute a significant barrier, particularly regarding sensor response times and calibration stability across wide temperature ranges. Thermal expansion of both the sample and instrument components introduces measurement artifacts that can obscure genuine material behavior. Current compensation algorithms remain insufficient for completely eliminating these systematic errors, especially during rapid thermal transitions where thermal equilibrium is never fully achieved.

Data analysis frameworks for cyclic thermal DMA remain underdeveloped compared to isothermal testing protocols. The complex interplay between frequency, temperature rate, and mechanical response creates multidimensional datasets that challenge conventional analytical approaches. Current software solutions typically employ oversimplified models that fail to capture the full complexity of material behavior under these dynamic conditions.

Long-term testing reliability presents additional challenges, as repeated thermal cycling can induce cumulative changes in both the test equipment and sample fixtures. Thermal fatigue of components and gradual calibration drift compromise measurement consistency, particularly for extended durability studies requiring hundreds or thousands of thermal cycles. The lack of standardized protocols for cyclic thermal DMA further complicates cross-laboratory comparisons and validation of results.

Sample preparation techniques also require refinement for cyclic thermal testing, as conventional sample geometries optimized for isothermal testing may perform poorly under thermal cycling conditions. Edge effects and thermal gradient sensitivity become more pronounced during thermal transitions, necessitating specialized sample designs that few laboratories have systematically developed or validated.

State-of-the-Art DMA Testing Solutions

01 DMA testing equipment and methods

Dynamic Mechanical Analysis (DMA) equipment and methodologies are used to characterize the mechanical properties of materials under oscillating loads. These systems typically include temperature control chambers, force transducers, and displacement sensors to measure properties such as storage modulus, loss modulus, and tan delta. Advanced DMA equipment allows for testing under various conditions including different frequencies, temperatures, and strain rates to comprehensively evaluate material behavior.- DMA testing equipment and methods: Dynamic mechanical analysis (DMA) equipment and methodologies are used to characterize the mechanical properties of materials under oscillatory loads. These systems typically include temperature control chambers, force transducers, and displacement sensors to measure properties such as storage modulus, loss modulus, and tan delta. Advanced DMA equipment may incorporate multiple testing modes (tension, compression, shear) and automated sample handling for high-throughput analysis.

- Polymer and composite material characterization: DMA is particularly valuable for characterizing polymers and composite materials, providing insights into viscoelastic behavior, glass transition temperatures, and phase transitions. The technique allows for the measurement of stiffness and damping properties as functions of temperature, frequency, and time. This information is crucial for understanding material behavior under various environmental conditions and for predicting long-term performance in applications ranging from automotive components to aerospace structures.

- Computational modeling and simulation of mechanical properties: Advanced computational methods are employed to model and simulate the mechanical behavior of materials based on DMA data. These approaches include finite element analysis, molecular dynamics simulations, and machine learning algorithms that can predict material responses under various loading conditions. Such computational tools enable researchers to optimize material formulations and processing parameters without extensive physical testing, accelerating product development cycles.

- Quality control and material testing standards: DMA serves as a critical quality control tool in manufacturing processes, ensuring consistency in mechanical properties across production batches. Standardized testing protocols have been developed to enable reliable comparison of results between different laboratories and testing equipment. These standards specify sample preparation methods, testing parameters, and data analysis procedures to minimize variability and enhance reproducibility in mechanical property measurements.

- Novel applications and specialized DMA techniques: Innovative applications of DMA include the characterization of biological tissues, pharmaceutical formulations, and nanomaterials. Specialized techniques such as multi-frequency DMA, time-temperature superposition, and creep-recovery testing provide deeper insights into material behavior under complex loading conditions. These advanced methodologies enable researchers to investigate structure-property relationships and develop materials with tailored mechanical responses for specific applications.

02 Polymer and composite material characterization

DMA is particularly valuable for characterizing polymers and composite materials, providing insights into their viscoelastic properties, glass transition temperatures, and phase transitions. The analysis helps in understanding how these materials respond to mechanical stress under different environmental conditions. This information is crucial for predicting long-term performance, durability, and failure mechanisms in applications ranging from automotive components to aerospace structures.Expand Specific Solutions03 Computer modeling and simulation of mechanical properties

Advanced computational methods are employed to model and simulate the mechanical behavior of materials based on DMA data. These models help predict material performance under various conditions without extensive physical testing. Machine learning algorithms and finite element analysis are increasingly used to process DMA results and create predictive models that can accelerate material development and optimization processes.Expand Specific Solutions04 Quality control and material testing standards

DMA serves as a critical quality control tool in manufacturing processes, ensuring materials meet specified mechanical property requirements. Standardized testing protocols have been developed to ensure consistency and reliability in DMA measurements across different laboratories and testing conditions. These standards define sample preparation methods, testing parameters, and data analysis procedures to obtain reproducible results that can be used for material certification and quality assurance.Expand Specific Solutions05 Novel applications and specialized DMA techniques

Emerging applications of DMA include characterization of biological materials, pharmaceuticals, and nanomaterials. Specialized DMA techniques have been developed for specific material classes or property measurements, such as submersion testing for hydrogels or high-frequency testing for impact-resistant materials. These novel approaches extend the utility of DMA beyond traditional materials science into fields like biomedical engineering, food science, and electronics, providing valuable insights into mechanical behavior at different scales and under unique conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Dynamic mechanical analysis under cyclic thermal conditions represents a maturing field with significant growth potential. The market is transitioning from early adoption to mainstream implementation, with an estimated global market size of $300-400 million and projected annual growth of 8-12%. Leading players demonstrate varying levels of technical sophistication: established industrial giants like Siemens AG, ABB Group, and Honeywell International Technologies have developed comprehensive solutions, while specialized equipment manufacturers such as Bruker Nano and Mettler-Toledo GmbH offer advanced analytical instruments. Academic institutions including Zhejiang University, Ohio State University, and Northwestern University are driving fundamental research, while Baker Hughes and Tokyo Electron are applying these technologies in specific industrial contexts. The ecosystem shows a healthy balance between commercial applications and ongoing research, indicating continued innovation potential.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed comprehensive dynamic mechanical analysis capabilities for cyclic thermal conditions through their Advanced Materials division. Their technology integrates high-precision force transducers (with resolution down to 0.001N) with environmental chambers capable of rapid temperature cycling rates (up to 50°C/min) while maintaining exceptional temperature uniformity across samples. Honeywell's systems feature multi-sample testing capabilities that enable simultaneous characterization of multiple materials under identical thermal cycling conditions, critical for comparative studies and quality control applications. Their technology incorporates non-contact optical strain measurement systems that maintain accuracy during thermal cycling without interference from thermal expansion of measurement components. Honeywell has developed specialized software algorithms that can isolate reversible and irreversible components of material response during thermal cycling, providing insights into material degradation mechanisms. Their systems include automated calibration routines that compensate for instrument response changes during thermal cycling, ensuring measurement consistency across extended test campaigns.

Strengths: Multi-sample testing capabilities enabling high throughput characterization; non-contact measurement systems eliminating measurement artifacts during thermal cycling; advanced data analysis for separating reversible/irreversible responses. Weaknesses: Systems typically optimized for specific material classes limiting versatility; complex calibration requirements for highest precision measurements; significant expertise required for test protocol development.

Bruker Nano, Inc.

Technical Solution: Bruker Nano has developed advanced dynamic mechanical analysis (DMA) systems specifically designed for cyclic thermal conditions testing. Their technology incorporates high-precision temperature control chambers that can achieve rapid heating and cooling rates (up to 60°C/min) while maintaining exceptional temperature stability (±0.1°C). Their DMA instruments feature multi-frequency capabilities (0.001 to 200 Hz) allowing simultaneous measurement of viscoelastic properties across different frequencies during thermal cycling. Bruker's proprietary algorithms compensate for thermal expansion effects during cycling, ensuring accurate measurement of true material response rather than thermal artifacts. Their systems can characterize materials under complex thermal profiles including step changes, ramps, and sinusoidal temperature variations while simultaneously applying mechanical deformation, enabling comprehensive characterization of thermomechanical behavior in polymers, composites, and metals.

Strengths: Superior temperature control precision and stability during cycling; advanced multi-frequency capabilities allowing comprehensive viscoelastic characterization; proprietary thermal expansion compensation algorithms. Weaknesses: Higher cost compared to simpler DMA systems; requires specialized training for optimal operation; limited portability due to sophisticated temperature control systems.

Key Innovations in Cyclic Thermal DMA Technology

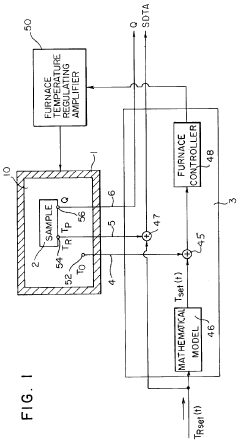

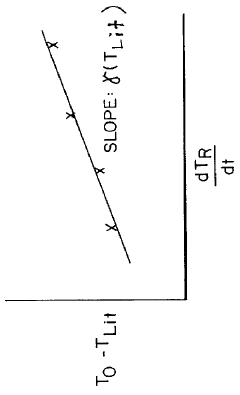

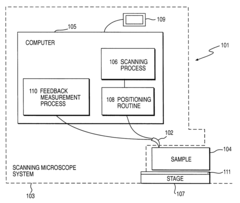

Differential thermal analysis system including dynamic mechanical analysis

PatentInactiveUS6146013A

Innovation

- The implementation of Single Differential Thermal Analysis (SDTA) where the temperature behavior of the reference and sample are determined at the same spot, using identical heating and temperature measurement probes, and a mathematical model to account for the thermal analysis apparatus behavior, allowing for simultaneous measurement of temperature and physical properties without the need for adjacent pans.

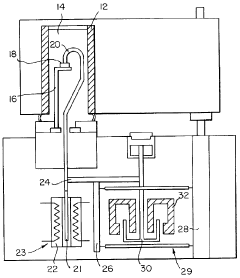

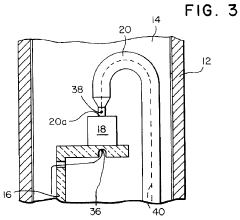

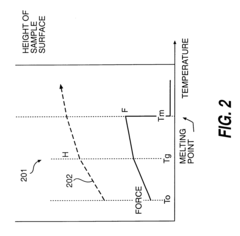

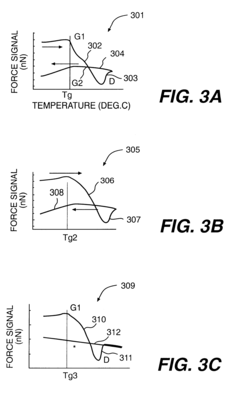

Method and apparatus for localized dynamic mechano-thermal analysis with scanning probe microscopy

PatentInactiveUS6200022B1

Innovation

- The development of Mechanothermal Analysis with Scanning Microscopy (MASM) that uses a scanning probe microscope to perform localized thermomechanical and calorimetric analysis, allowing for the selection of regions at high spatial resolution and simultaneous measurement of quasi-static and dynamic mechanical compliance, heat flow, and thermal events.

Material Performance Standards and Certification

The standardization of material performance evaluation under dynamic mechanical analysis (DMA) with cyclic thermal conditions has become increasingly critical for industries requiring high reliability materials. International standards organizations such as ASTM, ISO, and JIS have developed comprehensive testing protocols specifically addressing the behavior of materials under combined mechanical and thermal cycling stresses. ASTM D7028, for instance, provides standardized procedures for determining the dynamic mechanical properties of plastics under varying temperature conditions, while ISO 6721-11 focuses on glass transition temperature determination through DMA.

These standards establish precise requirements for sample preparation, equipment calibration, test parameters, and data analysis methodologies. For cyclic thermal conditions specifically, standards typically mandate temperature range specifications, heating/cooling rates, dwell times, and cycle counts to ensure reproducibility across different testing facilities. The certification process for materials undergoing cyclic thermal DMA typically involves third-party verification against these established standards, with materials receiving performance classifications based on their viscoelastic response characteristics.

Material certification systems have evolved to incorporate specific ratings for thermal-mechanical fatigue resistance, with classifications often denoting the number of thermal cycles a material can withstand before significant property degradation occurs. For instance, aerospace-grade polymers might require certification demonstrating stability through 1,000+ thermal cycles between -55°C and 175°C while under mechanical loading. The automotive industry similarly employs certification standards requiring materials to maintain specific damping characteristics after exposure to defined thermal cycling profiles.

Recent advancements in standardization have introduced digital certification frameworks where DMA data under cyclic thermal conditions is stored in standardized formats, allowing for improved traceability and comparative analysis across material batches. These digital certificates often include complete viscoelastic property maps showing storage modulus, loss modulus, and tan delta values across the entire testing temperature range and frequency spectrum.

Compliance with these standards provides manufacturers with legal protection and quality assurance, while offering end-users confidence in material performance under real-world operating conditions. As applications for advanced materials in extreme environments continue to expand, certification standards for cyclic thermal DMA are becoming increasingly stringent, with particular emphasis on long-term reliability prediction methodologies and accelerated testing protocols that can accurately simulate years of service conditions within reasonable testing timeframes.

These standards establish precise requirements for sample preparation, equipment calibration, test parameters, and data analysis methodologies. For cyclic thermal conditions specifically, standards typically mandate temperature range specifications, heating/cooling rates, dwell times, and cycle counts to ensure reproducibility across different testing facilities. The certification process for materials undergoing cyclic thermal DMA typically involves third-party verification against these established standards, with materials receiving performance classifications based on their viscoelastic response characteristics.

Material certification systems have evolved to incorporate specific ratings for thermal-mechanical fatigue resistance, with classifications often denoting the number of thermal cycles a material can withstand before significant property degradation occurs. For instance, aerospace-grade polymers might require certification demonstrating stability through 1,000+ thermal cycles between -55°C and 175°C while under mechanical loading. The automotive industry similarly employs certification standards requiring materials to maintain specific damping characteristics after exposure to defined thermal cycling profiles.

Recent advancements in standardization have introduced digital certification frameworks where DMA data under cyclic thermal conditions is stored in standardized formats, allowing for improved traceability and comparative analysis across material batches. These digital certificates often include complete viscoelastic property maps showing storage modulus, loss modulus, and tan delta values across the entire testing temperature range and frequency spectrum.

Compliance with these standards provides manufacturers with legal protection and quality assurance, while offering end-users confidence in material performance under real-world operating conditions. As applications for advanced materials in extreme environments continue to expand, certification standards for cyclic thermal DMA are becoming increasingly stringent, with particular emphasis on long-term reliability prediction methodologies and accelerated testing protocols that can accurately simulate years of service conditions within reasonable testing timeframes.

Environmental Impact and Sustainability Considerations

Dynamic mechanical analysis (DMA) under cyclic thermal conditions presents significant environmental considerations that must be addressed in both research and industrial applications. The energy consumption associated with thermal cycling processes is substantial, particularly when tests require extreme temperature ranges or rapid cycling rates. This energy footprint contributes to greenhouse gas emissions when fossil fuel-based electricity is used to power testing equipment. Modern DMA systems are increasingly incorporating energy-efficient technologies, including improved insulation, regenerative heating systems, and smart power management, which can reduce energy consumption by 15-30% compared to older generation equipment.

Material waste generated during DMA testing represents another environmental concern. Test specimens are often single-use and may contain polymers, composites, or other materials with significant environmental footprints. The development of standardized micro-scale testing methodologies has emerged as a sustainable alternative, reducing sample size requirements by up to 90% while maintaining measurement accuracy. Additionally, some research facilities have implemented sample recycling programs for certain materials, though this practice remains limited by potential material contamination concerns.

The environmental impact of cooling systems used in DMA equipment deserves particular attention. Traditional cooling methods often rely on refrigerants with high global warming potential (GWP). The transition to natural refrigerants and closed-loop cooling systems represents a positive trend in reducing the environmental impact of thermal cycling equipment. Several manufacturers now offer systems using refrigerants with GWP values reduced by 99% compared to older hydrofluorocarbon-based systems.

Life cycle assessment (LCA) studies of DMA equipment reveal that the use phase typically accounts for 70-85% of lifetime environmental impact, highlighting the importance of operational efficiency improvements. Extended equipment lifespan through modular design and upgradeable components has become an industry focus, with newer systems designed for 15+ years of service compared to the previous 8-10 year standard. This approach significantly reduces electronic waste and embodied carbon associated with manufacturing replacement equipment.

The integration of DMA into sustainable materials development represents a positive environmental contribution. By enabling precise characterization of bio-based polymers, recycled composites, and other environmentally friendly materials, DMA facilitates the transition to more sustainable material solutions across industries. Research indicates that advanced material characterization techniques like cyclic thermal DMA can accelerate sustainable material development timelines by 30-40% through more efficient property optimization.

Material waste generated during DMA testing represents another environmental concern. Test specimens are often single-use and may contain polymers, composites, or other materials with significant environmental footprints. The development of standardized micro-scale testing methodologies has emerged as a sustainable alternative, reducing sample size requirements by up to 90% while maintaining measurement accuracy. Additionally, some research facilities have implemented sample recycling programs for certain materials, though this practice remains limited by potential material contamination concerns.

The environmental impact of cooling systems used in DMA equipment deserves particular attention. Traditional cooling methods often rely on refrigerants with high global warming potential (GWP). The transition to natural refrigerants and closed-loop cooling systems represents a positive trend in reducing the environmental impact of thermal cycling equipment. Several manufacturers now offer systems using refrigerants with GWP values reduced by 99% compared to older hydrofluorocarbon-based systems.

Life cycle assessment (LCA) studies of DMA equipment reveal that the use phase typically accounts for 70-85% of lifetime environmental impact, highlighting the importance of operational efficiency improvements. Extended equipment lifespan through modular design and upgradeable components has become an industry focus, with newer systems designed for 15+ years of service compared to the previous 8-10 year standard. This approach significantly reduces electronic waste and embodied carbon associated with manufacturing replacement equipment.

The integration of DMA into sustainable materials development represents a positive environmental contribution. By enabling precise characterization of bio-based polymers, recycled composites, and other environmentally friendly materials, DMA facilitates the transition to more sustainable material solutions across industries. Research indicates that advanced material characterization techniques like cyclic thermal DMA can accelerate sustainable material development timelines by 30-40% through more efficient property optimization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!