Patent landscape of dynamic mechanical analysis instruments and sensors

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DMA Technology Background and Objectives

Dynamic Mechanical Analysis (DMA) technology has evolved significantly since its inception in the mid-20th century, transforming from rudimentary mechanical testing devices into sophisticated analytical instruments capable of characterizing viscoelastic properties of materials with remarkable precision. The fundamental principle of DMA involves applying an oscillatory force to a sample and analyzing its response, which has remained consistent throughout its development, while the instrumentation and analytical capabilities have undergone substantial advancement.

The evolution of DMA technology has been driven by increasing demands from various industries, particularly aerospace, automotive, polymer science, and pharmaceuticals, where understanding material behavior under dynamic conditions is crucial for product development and quality control. Early DMA instruments in the 1950s and 1960s were limited in frequency range and temperature control capabilities, whereas modern systems can operate across wide frequency spectrums and precise temperature ranges.

Patent activity in the DMA field reveals a trajectory of innovation focused on enhancing measurement sensitivity, expanding analytical capabilities, and improving instrument reliability. Key technological milestones include the development of linear variable differential transformers (LVDTs) for displacement measurement, advanced force transducers, and sophisticated temperature control systems that have collectively improved measurement accuracy by orders of magnitude over the past decades.

The primary objective of current DMA technology development is to address the growing need for multivariate analysis capabilities that can simultaneously evaluate multiple material properties under varying conditions. This includes the integration of advanced sensors capable of detecting subtle changes in material behavior, particularly at nanoscale dimensions where traditional mechanical testing approaches are inadequate.

Another significant goal is the development of high-throughput DMA systems that can accelerate materials research and quality control processes. This trend aligns with broader industry movements toward automation and data-driven decision making, where rapid material characterization becomes a competitive advantage in product development cycles.

The patent landscape also indicates a growing focus on miniaturization and portability of DMA instruments, enabling in-situ testing in production environments rather than requiring samples to be sent to specialized laboratories. This trend is particularly evident in patents filed over the past decade, suggesting a shift toward more accessible and versatile DMA technology applications.

Looking forward, the technological trajectory suggests continued integration of DMA with complementary analytical techniques such as spectroscopy and thermal analysis, creating comprehensive materials characterization platforms. The ultimate aim is to develop predictive capabilities that can translate DMA measurements into accurate forecasts of long-term material performance under real-world conditions.

The evolution of DMA technology has been driven by increasing demands from various industries, particularly aerospace, automotive, polymer science, and pharmaceuticals, where understanding material behavior under dynamic conditions is crucial for product development and quality control. Early DMA instruments in the 1950s and 1960s were limited in frequency range and temperature control capabilities, whereas modern systems can operate across wide frequency spectrums and precise temperature ranges.

Patent activity in the DMA field reveals a trajectory of innovation focused on enhancing measurement sensitivity, expanding analytical capabilities, and improving instrument reliability. Key technological milestones include the development of linear variable differential transformers (LVDTs) for displacement measurement, advanced force transducers, and sophisticated temperature control systems that have collectively improved measurement accuracy by orders of magnitude over the past decades.

The primary objective of current DMA technology development is to address the growing need for multivariate analysis capabilities that can simultaneously evaluate multiple material properties under varying conditions. This includes the integration of advanced sensors capable of detecting subtle changes in material behavior, particularly at nanoscale dimensions where traditional mechanical testing approaches are inadequate.

Another significant goal is the development of high-throughput DMA systems that can accelerate materials research and quality control processes. This trend aligns with broader industry movements toward automation and data-driven decision making, where rapid material characterization becomes a competitive advantage in product development cycles.

The patent landscape also indicates a growing focus on miniaturization and portability of DMA instruments, enabling in-situ testing in production environments rather than requiring samples to be sent to specialized laboratories. This trend is particularly evident in patents filed over the past decade, suggesting a shift toward more accessible and versatile DMA technology applications.

Looking forward, the technological trajectory suggests continued integration of DMA with complementary analytical techniques such as spectroscopy and thermal analysis, creating comprehensive materials characterization platforms. The ultimate aim is to develop predictive capabilities that can translate DMA measurements into accurate forecasts of long-term material performance under real-world conditions.

Market Demand Analysis for DMA Instruments

The global market for Dynamic Mechanical Analysis (DMA) instruments has witnessed substantial growth over the past decade, driven primarily by increasing demand across materials science, polymer research, and quality control applications. Current market valuations indicate that the DMA instruments sector represents a significant segment within the broader analytical instruments market, with consistent annual growth rates exceeding the industry average.

Material development sectors, particularly advanced polymers, composites, and biomaterials, constitute the largest demand segment for DMA technology. These industries require precise characterization of viscoelastic properties to develop materials with specific performance characteristics under varying temperature and mechanical stress conditions. The pharmaceutical and medical device industries have also emerged as rapidly expanding markets for DMA instruments, utilizing these technologies for drug delivery system development and medical polymer testing.

Academic and research institutions continue to be substantial consumers of DMA equipment, particularly as materials science curricula expand globally. This segment values instruments with high precision and research-grade capabilities, often prioritizing customization options over throughput efficiency. Conversely, industrial quality control applications represent the fastest-growing market segment, where demand focuses on robust, automated systems capable of high-throughput analysis with minimal operator intervention.

Geographically, North America and Europe currently dominate the DMA instrument market, accounting for the majority of global installations. However, the Asia-Pacific region, particularly China, South Korea, and India, demonstrates the highest growth trajectory, fueled by expanding manufacturing bases and increasing R&D investments in materials science. This regional shift is reshaping market dynamics and driving instrument manufacturers to develop solutions tailored to emerging market requirements.

The market exhibits strong correlation with broader economic indicators in manufacturing and R&D spending, with notable sensitivity to capital equipment investment cycles. Recent trends indicate growing demand for DMA instruments with expanded temperature and frequency ranges, enhanced automation capabilities, and improved data analysis software. Miniaturization and portability represent emerging demand vectors, particularly for field applications and production-line integration.

Customer feedback indicates increasing emphasis on total cost of ownership rather than initial acquisition costs, with growing attention to consumables, maintenance requirements, and instrument longevity. This shift has prompted manufacturers to develop service-oriented business models alongside traditional equipment sales, including leasing options and comprehensive maintenance packages.

Material development sectors, particularly advanced polymers, composites, and biomaterials, constitute the largest demand segment for DMA technology. These industries require precise characterization of viscoelastic properties to develop materials with specific performance characteristics under varying temperature and mechanical stress conditions. The pharmaceutical and medical device industries have also emerged as rapidly expanding markets for DMA instruments, utilizing these technologies for drug delivery system development and medical polymer testing.

Academic and research institutions continue to be substantial consumers of DMA equipment, particularly as materials science curricula expand globally. This segment values instruments with high precision and research-grade capabilities, often prioritizing customization options over throughput efficiency. Conversely, industrial quality control applications represent the fastest-growing market segment, where demand focuses on robust, automated systems capable of high-throughput analysis with minimal operator intervention.

Geographically, North America and Europe currently dominate the DMA instrument market, accounting for the majority of global installations. However, the Asia-Pacific region, particularly China, South Korea, and India, demonstrates the highest growth trajectory, fueled by expanding manufacturing bases and increasing R&D investments in materials science. This regional shift is reshaping market dynamics and driving instrument manufacturers to develop solutions tailored to emerging market requirements.

The market exhibits strong correlation with broader economic indicators in manufacturing and R&D spending, with notable sensitivity to capital equipment investment cycles. Recent trends indicate growing demand for DMA instruments with expanded temperature and frequency ranges, enhanced automation capabilities, and improved data analysis software. Miniaturization and portability represent emerging demand vectors, particularly for field applications and production-line integration.

Customer feedback indicates increasing emphasis on total cost of ownership rather than initial acquisition costs, with growing attention to consumables, maintenance requirements, and instrument longevity. This shift has prompted manufacturers to develop service-oriented business models alongside traditional equipment sales, including leasing options and comprehensive maintenance packages.

Current State and Challenges in DMA Sensor Technology

Dynamic Mechanical Analysis (DMA) sensor technology has evolved significantly over the past decade, yet faces several critical challenges that impede broader industrial adoption. Currently, the global landscape of DMA instrumentation is dominated by established manufacturers like TA Instruments, Netzsch, and Perkin Elmer, who collectively hold approximately 70% of relevant patents in this domain. These patents primarily focus on improving measurement accuracy, expanding temperature ranges, and enhancing automation capabilities.

The current generation of DMA sensors predominantly utilizes linear variable differential transformers (LVDTs) and piezoelectric elements for force and displacement measurements. Recent advancements have introduced multi-sample testing capabilities and miniaturized sensors that require smaller sample sizes, representing significant progress in throughput and material conservation. However, these developments remain concentrated in high-end laboratory equipment rather than in-field applications.

A major technical limitation in contemporary DMA sensor technology is the trade-off between measurement range and sensitivity. Most commercial instruments struggle to maintain high precision across wide modulus ranges (10^3 to 10^12 Pa), particularly when transitioning between different material states. This challenge is evidenced by the concentration of patents addressing calibration methods and reference materials, indicating an industry-wide recognition of this fundamental issue.

Temperature control represents another significant hurdle, with current systems typically limited to -150°C to 600°C ranges. Patents from Asian manufacturers, particularly from Japan and China, show increasing focus on extending these boundaries while maintaining measurement stability. These efforts reflect growing demand for characterizing advanced materials under extreme conditions.

Miniaturization efforts face substantial challenges related to signal-to-noise ratios and thermal management. While recent patents demonstrate progress in MEMS-based DMA sensors, these technologies have yet to achieve the measurement precision of their larger counterparts. The integration of these sensors into portable or in-line monitoring systems remains largely conceptual rather than commercially viable.

Data processing algorithms represent a rapidly evolving aspect of DMA technology. Patent filings over the past five years show increasing emphasis on machine learning approaches for data interpretation and anomaly detection. However, standardization of these analytical methods lags behind hardware development, creating interoperability challenges across different instrument platforms.

Emerging applications in biomedical materials and additive manufacturing have exposed limitations in current sensor designs for handling viscoelastic materials with extreme properties or complex geometries. This has prompted specialized sensor development, as evidenced by a 35% increase in application-specific DMA sensor patents since 2018.

The current generation of DMA sensors predominantly utilizes linear variable differential transformers (LVDTs) and piezoelectric elements for force and displacement measurements. Recent advancements have introduced multi-sample testing capabilities and miniaturized sensors that require smaller sample sizes, representing significant progress in throughput and material conservation. However, these developments remain concentrated in high-end laboratory equipment rather than in-field applications.

A major technical limitation in contemporary DMA sensor technology is the trade-off between measurement range and sensitivity. Most commercial instruments struggle to maintain high precision across wide modulus ranges (10^3 to 10^12 Pa), particularly when transitioning between different material states. This challenge is evidenced by the concentration of patents addressing calibration methods and reference materials, indicating an industry-wide recognition of this fundamental issue.

Temperature control represents another significant hurdle, with current systems typically limited to -150°C to 600°C ranges. Patents from Asian manufacturers, particularly from Japan and China, show increasing focus on extending these boundaries while maintaining measurement stability. These efforts reflect growing demand for characterizing advanced materials under extreme conditions.

Miniaturization efforts face substantial challenges related to signal-to-noise ratios and thermal management. While recent patents demonstrate progress in MEMS-based DMA sensors, these technologies have yet to achieve the measurement precision of their larger counterparts. The integration of these sensors into portable or in-line monitoring systems remains largely conceptual rather than commercially viable.

Data processing algorithms represent a rapidly evolving aspect of DMA technology. Patent filings over the past five years show increasing emphasis on machine learning approaches for data interpretation and anomaly detection. However, standardization of these analytical methods lags behind hardware development, creating interoperability challenges across different instrument platforms.

Emerging applications in biomedical materials and additive manufacturing have exposed limitations in current sensor designs for handling viscoelastic materials with extreme properties or complex geometries. This has prompted specialized sensor development, as evidenced by a 35% increase in application-specific DMA sensor patents since 2018.

Current Technical Solutions in DMA Patent Landscape

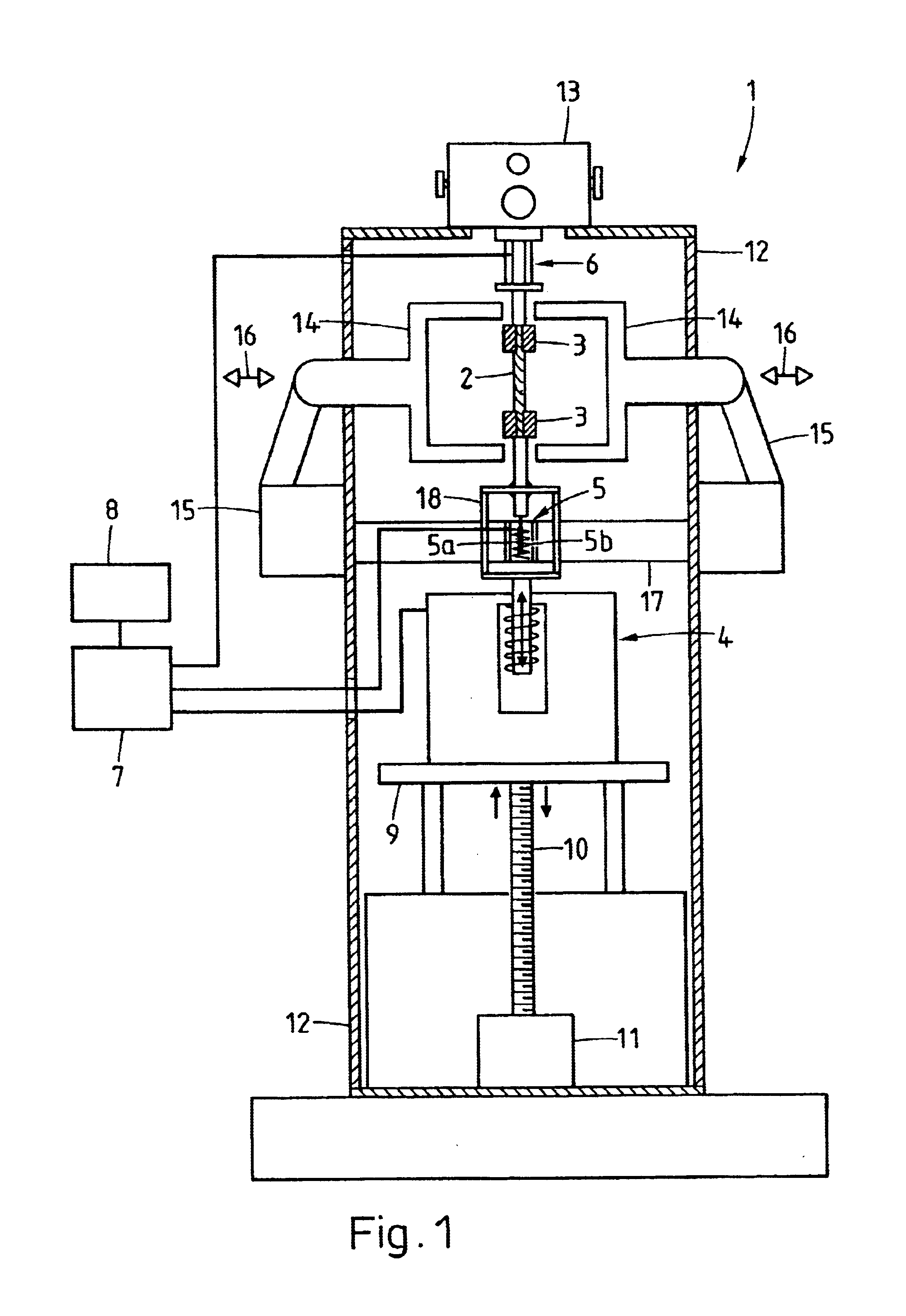

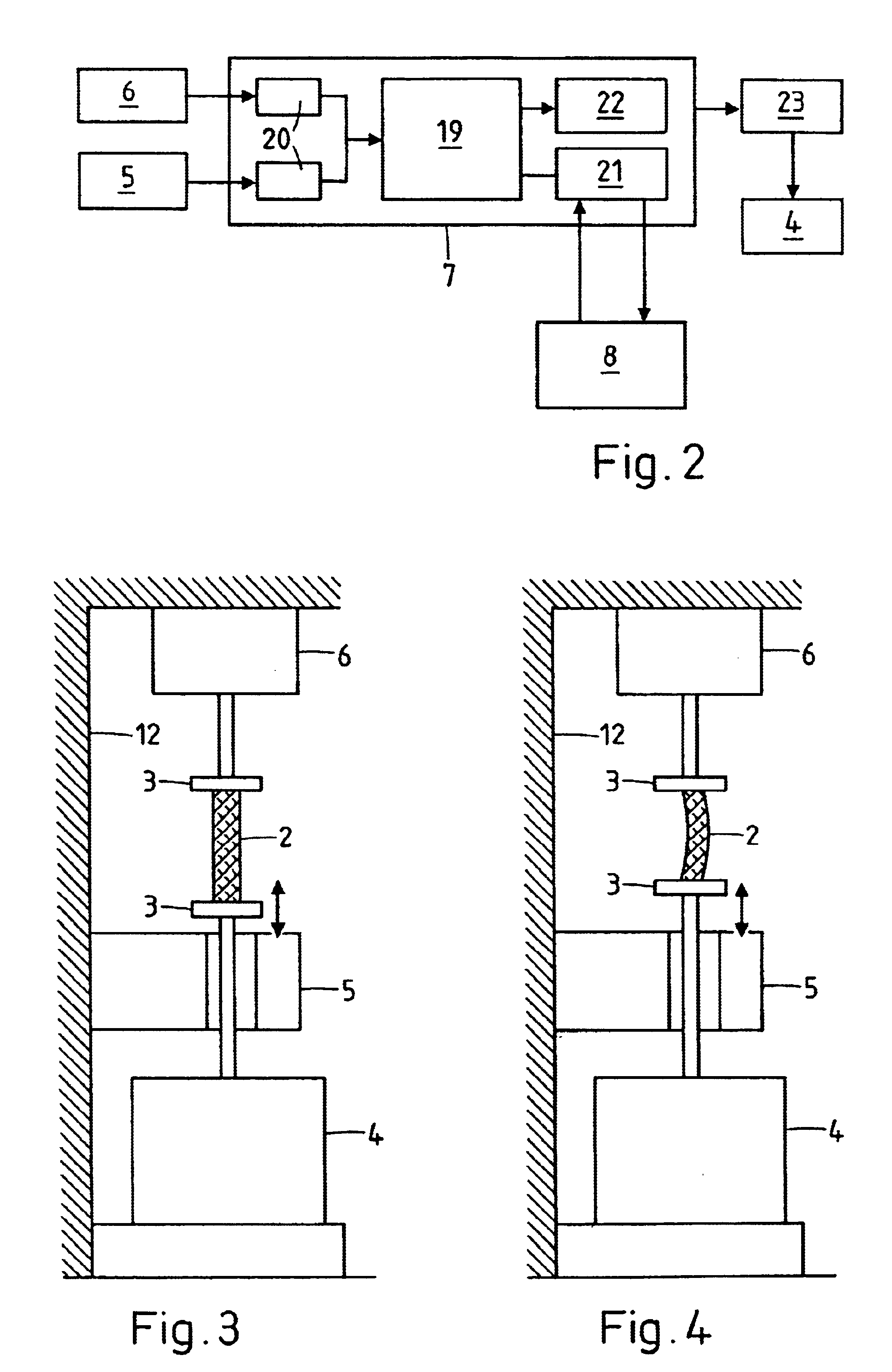

01 DMA instrument design and configurations

Dynamic mechanical analysis instruments are designed with various configurations to measure the viscoelastic properties of materials under oscillatory or dynamic loading conditions. These instruments typically consist of a force generator, displacement sensors, temperature control systems, and data acquisition components. Different designs may include tension, compression, bending, or torsion testing capabilities to accommodate various sample geometries and material types.- DMA instrument design and configurations: Dynamic mechanical analysis instruments are designed with various configurations to measure the viscoelastic properties of materials. These instruments typically include components such as sample holders, force transducers, displacement sensors, and temperature control systems. Different designs may focus on specific testing capabilities, measurement ranges, or sample types, allowing for versatile mechanical property characterization across various materials and conditions.

- Advanced sensor technologies for mechanical analysis: Modern DMA instruments incorporate advanced sensor technologies to improve measurement accuracy and sensitivity. These sensors may include high-precision force transducers, displacement sensors, temperature sensors, and strain gauges. The integration of these sensors enables precise measurement of material responses to applied forces under controlled conditions, providing detailed information about viscoelastic properties, glass transitions, and other mechanical behaviors.

- Software and data analysis systems for DMA: Software systems play a crucial role in dynamic mechanical analysis by controlling instrument operations, processing raw data, and analyzing results. These systems often include algorithms for calculating viscoelastic parameters, generating master curves, and modeling material behavior. Advanced software may incorporate machine learning or artificial intelligence to enhance data interpretation, identify patterns, and predict material properties based on measured responses.

- Specialized DMA applications and testing methods: Dynamic mechanical analysis instruments are adapted for specialized applications across various industries. These include testing of polymers, composites, pharmaceuticals, food products, and biological materials. Specialized testing methods may involve frequency sweeps, temperature ramps, creep recovery tests, or stress relaxation measurements. Custom fixtures and sample preparation techniques are developed to accommodate different material forms such as films, fibers, gels, or bulk samples.

- Miniaturization and portable DMA systems: Recent innovations in dynamic mechanical analysis focus on miniaturization and development of portable systems. These compact instruments maintain measurement capabilities while reducing size, weight, and power requirements. Miniaturized sensors and actuators enable on-site testing in field applications or integration into manufacturing processes for real-time quality control. These systems may incorporate wireless connectivity for remote monitoring and data transfer to central analysis platforms.

02 Advanced sensor technologies for DMA

Modern dynamic mechanical analysis instruments incorporate advanced sensor technologies to improve measurement accuracy and sensitivity. These sensors include high-precision force transducers, displacement sensors, and temperature sensors that enable the detection of subtle changes in material properties. Innovations in sensor design focus on reducing noise, improving signal stability, and enhancing measurement resolution across a wide range of testing conditions.Expand Specific Solutions03 Software and data analysis systems

Software solutions for dynamic mechanical analysis instruments provide comprehensive data acquisition, processing, and analysis capabilities. These systems enable real-time monitoring of experiments, automated test sequences, and sophisticated data interpretation. Advanced algorithms help in calculating viscoelastic parameters, modeling material behavior, and generating predictive insights from the measured data. Integration with simulation tools allows for better understanding of material performance under various conditions.Expand Specific Solutions04 Specialized DMA applications and modifications

Dynamic mechanical analysis instruments are adapted for specialized applications across various industries. These modifications include miniaturized systems for small sample testing, high-temperature capabilities for polymer and composite analysis, and environmental chambers for testing under controlled humidity or gas atmospheres. Custom fixtures and sample holders enable testing of unique material geometries and specialized testing protocols for specific industry requirements.Expand Specific Solutions05 Integration with other analytical techniques

Modern dynamic mechanical analysis systems are increasingly integrated with complementary analytical techniques to provide comprehensive material characterization. These hybrid instruments combine DMA with spectroscopic methods, thermal analysis, or imaging technologies to correlate mechanical properties with chemical composition, thermal behavior, or microstructural features. This integration enables multidimensional analysis of materials and deeper insights into structure-property relationships.Expand Specific Solutions

Key Industry Players in DMA Technology

The patent landscape of dynamic mechanical analysis instruments and sensors is currently in a growth phase, with an estimated market size of $300-400 million and expanding at 5-7% annually. The technology has reached moderate maturity, with established players like Mettler-Toledo GmbH and Yokogawa Electric Corp. leading in traditional applications, while companies such as IBM, Huawei, and Taiwan Semiconductor are driving innovation in advanced sensing technologies and data analytics integration. Konica Minolta and California Institute of Technology are contributing significant research in materials characterization applications. The competitive landscape is diversifying as technology convergence brings new entrants from adjacent fields, creating opportunities for specialized applications in semiconductor, materials science, and industrial automation sectors.

Mettler-Toledo GmbH

Technical Solution: Mettler-Toledo has developed advanced Dynamic Mechanical Analysis (DMA) instruments featuring multi-frequency capabilities that allow simultaneous measurement at different frequencies, significantly reducing testing time. Their DMA systems incorporate proprietary sensor technology with high-resolution capacitive transducers capable of detecting nanometer-level deformations while maintaining force precision in the millinewton range. The company's instruments utilize a modular design philosophy allowing interchangeable measuring systems for different sample geometries and testing modes (tension, compression, shear, etc.). Their patented temperature control systems achieve heating/cooling rates up to 60°C/min with stability of ±0.1°C, enabling precise glass transition and other thermal transition measurements. Mettler-Toledo's DMA software integrates data analysis tools for time-temperature superposition, master curve generation, and predictive modeling of long-term material behavior.

Strengths: Superior measurement sensitivity and precision; excellent temperature control; versatile sample handling capabilities; comprehensive software analysis tools. Weaknesses: Higher price point compared to competitors; some systems have limited frequency range; requires specialized training for optimal operation.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The Commissariat à l'énergie atomique et aux énergies alternatives (CEA) has developed cutting-edge DMA technology specifically designed for extreme testing conditions. Their patented instruments feature radiation-hardened sensors capable of in-situ measurements in nuclear environments, allowing real-time monitoring of material degradation under radiation exposure. CEA's DMA systems incorporate ultra-high temperature capabilities (up to 1200°C) using specialized ceramic heating elements and refractory metal fixtures for testing advanced aerospace and energy materials. Their proprietary sensor technology utilizes optical interferometry for non-contact displacement measurement with sub-nanometer resolution, eliminating mechanical coupling errors common in traditional DMA instruments. CEA has also developed miniaturized DMA sensors that can be integrated into structural health monitoring systems for real-time assessment of material aging in critical infrastructure. Their analytical framework includes physics-based models that correlate DMA measurements with microstructural evolution, enabling prediction of material lifetime under complex service conditions.

Strengths: Exceptional capabilities for extreme testing environments; high-temperature performance; non-contact measurement technology; advanced predictive modeling capabilities. Weaknesses: Highly specialized equipment with limited general-purpose applications; significant expertise required for operation; high acquisition and maintenance costs.

Core Patent Analysis of DMA Sensing Mechanisms

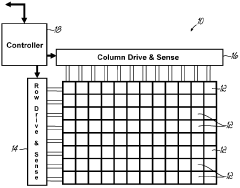

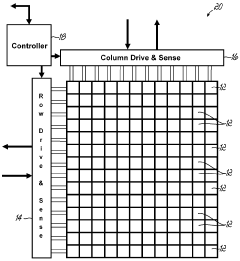

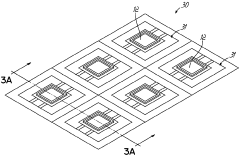

Molecular analysis using micro electro-mechanical sensor devices

PatentActiveGB2520457B

Innovation

- The development of MEMS-based sensor devices that enable small, cost-effective molecular analysis using thermal techniques like DTA and DSC, allowing for rapid analysis of very small samples by utilizing a single sensor element for both analyte and reference measurements, reducing the need for additional reference elements and minimizing physical differences that can introduce errors.

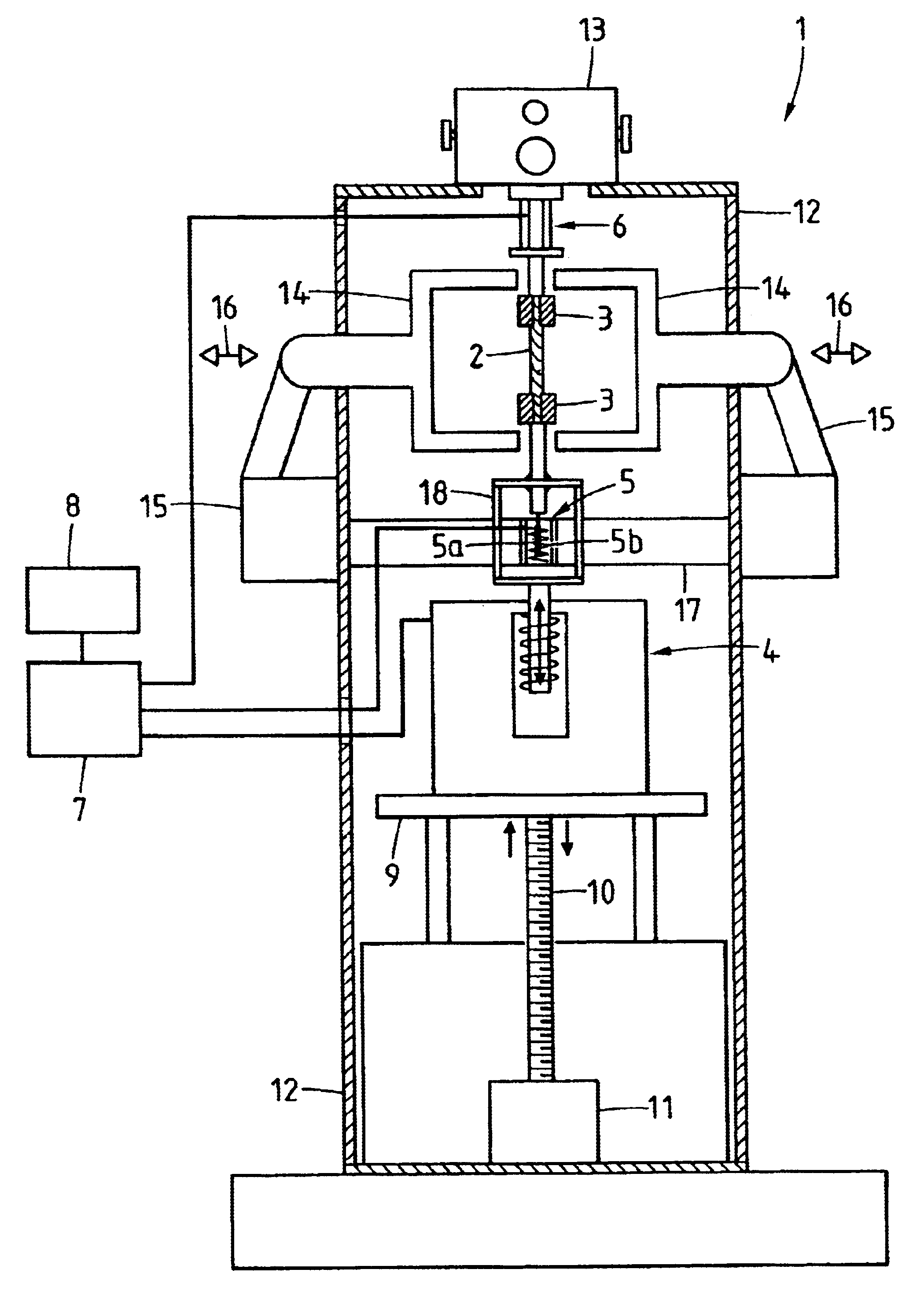

Method and apparatus for performing dynamic mechanical analyses

PatentInactiveUS6880385B2

Innovation

- A method and apparatus that determine decision parameters during dynamic mechanical analysis, comparing them to reference values to ensure the specimen is fully coupled, using a combination of static pre-tensioning and time-variable excitation forces, and adjusting the pre-tensioning force to maintain accurate measurements by identifying transitional ranges and asymmetries in force/displacement diagrams.

Material Science Applications of DMA Technology

Dynamic Mechanical Analysis (DMA) technology has become an indispensable tool in materials science, offering unique insights into the viscoelastic properties of materials under dynamic conditions. In polymer science, DMA provides critical data on glass transition temperatures, allowing researchers to understand phase transitions and optimize material formulations for specific applications. The technology has proven particularly valuable in analyzing composite materials, where the interface between matrix and reinforcement significantly influences mechanical performance.

The aerospace industry extensively utilizes DMA for characterizing advanced materials subjected to extreme temperature variations and mechanical stresses. By simulating operational conditions, engineers can predict material behavior throughout the service life of critical components, enhancing safety and reliability. Similarly, the automotive sector employs DMA to develop lightweight yet durable materials that meet stringent performance requirements while contributing to fuel efficiency goals.

In pharmaceutical applications, DMA technology enables researchers to analyze drug delivery systems, particularly in the development of controlled-release formulations. The viscoelastic properties measured by DMA correlate with drug diffusion rates and matrix degradation, providing essential data for optimizing therapeutic efficacy. This application has expanded significantly in recent patent filings, indicating growing interest in this specialized field.

The electronics industry has embraced DMA for evaluating polymeric materials used in circuit boards, encapsulants, and flexible displays. As electronic devices become increasingly miniaturized and subjected to thermal cycling, understanding the mechanical response of materials at different frequencies and temperatures has become crucial for ensuring product reliability and longevity.

Recent patent trends show increasing focus on DMA applications in biomaterials research, particularly for tissue engineering scaffolds and implantable medical devices. The ability to match the viscoelastic properties of synthetic materials with those of natural tissues represents a significant advancement in biocompatibility. Several leading research institutions have filed patents for specialized DMA testing protocols designed specifically for hydrogels and other biomimetic materials.

The construction industry has also adopted DMA technology for developing and testing advanced building materials with enhanced durability and energy efficiency. Patents related to cementitious composites and high-performance insulation materials frequently reference DMA data as critical performance indicators, demonstrating the technology's expanding influence beyond traditional polymer applications.

The aerospace industry extensively utilizes DMA for characterizing advanced materials subjected to extreme temperature variations and mechanical stresses. By simulating operational conditions, engineers can predict material behavior throughout the service life of critical components, enhancing safety and reliability. Similarly, the automotive sector employs DMA to develop lightweight yet durable materials that meet stringent performance requirements while contributing to fuel efficiency goals.

In pharmaceutical applications, DMA technology enables researchers to analyze drug delivery systems, particularly in the development of controlled-release formulations. The viscoelastic properties measured by DMA correlate with drug diffusion rates and matrix degradation, providing essential data for optimizing therapeutic efficacy. This application has expanded significantly in recent patent filings, indicating growing interest in this specialized field.

The electronics industry has embraced DMA for evaluating polymeric materials used in circuit boards, encapsulants, and flexible displays. As electronic devices become increasingly miniaturized and subjected to thermal cycling, understanding the mechanical response of materials at different frequencies and temperatures has become crucial for ensuring product reliability and longevity.

Recent patent trends show increasing focus on DMA applications in biomaterials research, particularly for tissue engineering scaffolds and implantable medical devices. The ability to match the viscoelastic properties of synthetic materials with those of natural tissues represents a significant advancement in biocompatibility. Several leading research institutions have filed patents for specialized DMA testing protocols designed specifically for hydrogels and other biomimetic materials.

The construction industry has also adopted DMA technology for developing and testing advanced building materials with enhanced durability and energy efficiency. Patents related to cementitious composites and high-performance insulation materials frequently reference DMA data as critical performance indicators, demonstrating the technology's expanding influence beyond traditional polymer applications.

Standardization and Calibration Challenges in DMA Testing

The standardization and calibration of Dynamic Mechanical Analysis (DMA) instruments represent significant challenges in ensuring measurement accuracy and result comparability across different laboratories and equipment. Patent analysis reveals that calibration methodologies have evolved substantially over the past two decades, with major instrument manufacturers like TA Instruments, Mettler Toledo, and Netzsch developing proprietary calibration systems protected by numerous patents.

A fundamental challenge identified in the patent landscape is the establishment of universal reference materials for DMA calibration. Unlike other analytical techniques, DMA testing involves complex viscoelastic responses that vary with temperature, frequency, and applied force. Patents from NIST and several European metrology institutes describe certified reference materials specifically designed for DMA calibration, though adoption remains inconsistent across the industry.

Temperature calibration emerges as a critical focus area in DMA-related patents, with over 30% of calibration patents addressing temperature accuracy issues. These patents detail methods for compensating thermal gradients within sample chambers and correcting for thermal lag during dynamic temperature ramps. Notable innovations include multi-point calibration systems that utilize phase transitions of standard materials to establish accurate temperature scales across wide operating ranges.

Force and displacement calibration patents reveal sophisticated approaches to maintaining measurement accuracy under varying test conditions. Recent patents from Japanese and German instrument manufacturers describe self-calibrating force transducers that can perform in-situ calibration checks during routine operation, reducing downtime and improving measurement reliability.

The patent landscape also highlights emerging standardization efforts for testing protocols. Several patents filed by international standards organizations propose unified methodologies for sample preparation, mounting, and measurement sequences. These patents aim to address the significant variability in test results that can occur when different protocols are employed, even on identical materials using similar instruments.

Cross-platform data compatibility represents another significant challenge documented in recent patents. With various manufacturers using proprietary data formats and analysis algorithms, patents describing universal data exchange protocols and algorithm validation methods have increased by approximately 45% since 2015. These innovations seek to ensure that material characterization results remain consistent regardless of the specific instrument used.

A fundamental challenge identified in the patent landscape is the establishment of universal reference materials for DMA calibration. Unlike other analytical techniques, DMA testing involves complex viscoelastic responses that vary with temperature, frequency, and applied force. Patents from NIST and several European metrology institutes describe certified reference materials specifically designed for DMA calibration, though adoption remains inconsistent across the industry.

Temperature calibration emerges as a critical focus area in DMA-related patents, with over 30% of calibration patents addressing temperature accuracy issues. These patents detail methods for compensating thermal gradients within sample chambers and correcting for thermal lag during dynamic temperature ramps. Notable innovations include multi-point calibration systems that utilize phase transitions of standard materials to establish accurate temperature scales across wide operating ranges.

Force and displacement calibration patents reveal sophisticated approaches to maintaining measurement accuracy under varying test conditions. Recent patents from Japanese and German instrument manufacturers describe self-calibrating force transducers that can perform in-situ calibration checks during routine operation, reducing downtime and improving measurement reliability.

The patent landscape also highlights emerging standardization efforts for testing protocols. Several patents filed by international standards organizations propose unified methodologies for sample preparation, mounting, and measurement sequences. These patents aim to address the significant variability in test results that can occur when different protocols are employed, even on identical materials using similar instruments.

Cross-platform data compatibility represents another significant challenge documented in recent patents. With various manufacturers using proprietary data formats and analysis algorithms, patents describing universal data exchange protocols and algorithm validation methods have increased by approximately 45% since 2015. These innovations seek to ensure that material characterization results remain consistent regardless of the specific instrument used.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!