Dynamic mechanical analysis of biopolymers and biodegradable composites

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biopolymer DMA Background and Objectives

Dynamic mechanical analysis (DMA) has emerged as a pivotal analytical technique in the field of biopolymers and biodegradable composites over the past three decades. This technique measures the mechanical response of materials as they are deformed under periodic stress, providing critical insights into viscoelastic properties that conventional mechanical testing cannot reveal. The evolution of DMA technology has paralleled the growing interest in sustainable materials, transitioning from simple thermal-mechanical analyzers to sophisticated instruments capable of multi-frequency analysis under various environmental conditions.

The historical development of biopolymer DMA began in the 1980s with rudimentary investigations of natural polymers like cellulose and starch. By the 1990s, researchers had expanded their focus to include a wider range of biopolymers including proteins, chitosan, and alginate. The 2000s marked a significant advancement with the integration of biodegradable synthetic polymers such as polylactic acid (PLA) and polyhydroxyalkanoates (PHAs) into DMA studies, while the 2010s witnessed the rise of complex biocomposites analysis.

Current technological trends in this field include the development of high-resolution DMA equipment capable of detecting subtle transitions in biopolymer structures, multi-modal analysis combining DMA with spectroscopic techniques, and in-situ environmental chambers that simulate real-world conditions. These advancements have enabled researchers to better understand structure-property relationships in increasingly complex biomaterial systems.

The primary objective of biopolymer DMA research is to establish comprehensive viscoelastic profiles of sustainable materials across various temperature ranges, frequencies, and environmental conditions. This knowledge is essential for predicting material performance in applications ranging from packaging to biomedical devices. Additionally, researchers aim to correlate molecular structure with macroscopic mechanical behavior, enabling the rational design of next-generation biodegradable materials with tailored properties.

Another critical goal is standardizing DMA methodologies specifically for biopolymers, which often present unique challenges due to their hygroscopic nature and complex hierarchical structures. This standardization would facilitate more reliable comparisons between different biomaterials and accelerate their commercial adoption. Furthermore, researchers seek to develop predictive models that can accurately forecast the long-term performance of biodegradable materials, addressing concerns about their stability and durability in various applications.

The ultimate technological objective remains the creation of a comprehensive database of DMA parameters for biopolymers and their composites, which would serve as a valuable resource for materials scientists and engineers working to replace petroleum-based plastics with sustainable alternatives. This database would accelerate material selection processes and support the ongoing transition toward a more circular bioeconomy.

The historical development of biopolymer DMA began in the 1980s with rudimentary investigations of natural polymers like cellulose and starch. By the 1990s, researchers had expanded their focus to include a wider range of biopolymers including proteins, chitosan, and alginate. The 2000s marked a significant advancement with the integration of biodegradable synthetic polymers such as polylactic acid (PLA) and polyhydroxyalkanoates (PHAs) into DMA studies, while the 2010s witnessed the rise of complex biocomposites analysis.

Current technological trends in this field include the development of high-resolution DMA equipment capable of detecting subtle transitions in biopolymer structures, multi-modal analysis combining DMA with spectroscopic techniques, and in-situ environmental chambers that simulate real-world conditions. These advancements have enabled researchers to better understand structure-property relationships in increasingly complex biomaterial systems.

The primary objective of biopolymer DMA research is to establish comprehensive viscoelastic profiles of sustainable materials across various temperature ranges, frequencies, and environmental conditions. This knowledge is essential for predicting material performance in applications ranging from packaging to biomedical devices. Additionally, researchers aim to correlate molecular structure with macroscopic mechanical behavior, enabling the rational design of next-generation biodegradable materials with tailored properties.

Another critical goal is standardizing DMA methodologies specifically for biopolymers, which often present unique challenges due to their hygroscopic nature and complex hierarchical structures. This standardization would facilitate more reliable comparisons between different biomaterials and accelerate their commercial adoption. Furthermore, researchers seek to develop predictive models that can accurately forecast the long-term performance of biodegradable materials, addressing concerns about their stability and durability in various applications.

The ultimate technological objective remains the creation of a comprehensive database of DMA parameters for biopolymers and their composites, which would serve as a valuable resource for materials scientists and engineers working to replace petroleum-based plastics with sustainable alternatives. This database would accelerate material selection processes and support the ongoing transition toward a more circular bioeconomy.

Market Demand for Biodegradable Materials

The global market for biodegradable materials has experienced significant growth in recent years, driven by increasing environmental concerns and regulatory pressures. The biodegradable plastics market alone was valued at approximately 4.2 billion USD in 2021 and is projected to reach 7.8 billion USD by 2026, growing at a CAGR of 13.3% during this period. This growth trajectory reflects the expanding applications of biopolymers and biodegradable composites across various industries.

Consumer awareness regarding environmental sustainability has become a major market driver. Surveys indicate that over 70% of consumers across North America and Europe express willingness to pay premium prices for environmentally friendly packaging and products. This shift in consumer preference has prompted major brands to incorporate biodegradable materials into their product lines, creating substantial market pull for innovations in this sector.

The packaging industry represents the largest application segment for biodegradable materials, accounting for approximately 45% of the total market share. Food packaging, in particular, has seen rapid adoption of biodegradable solutions due to stringent regulations on single-use plastics in many countries. The European Union's Single-Use Plastics Directive and similar legislation in over 60 countries worldwide have accelerated the transition toward biodegradable alternatives.

Agriculture and horticulture constitute another significant market segment, with biodegradable mulch films, plant pots, and controlled-release systems gaining traction. The agricultural applications market for biodegradable materials is growing at approximately 15% annually, outpacing the overall market growth rate. This trend is particularly strong in regions with intensive agricultural practices such as Europe, North America, and parts of Asia.

The medical and pharmaceutical sectors present high-value application opportunities for biopolymers. Biodegradable sutures, implants, drug delivery systems, and tissue engineering scaffolds represent premium market segments where mechanical properties determined through dynamic mechanical analysis are critical performance parameters. This sector is expected to grow at 18% annually through 2027, driven by innovations in biocompatible materials with tailored degradation profiles.

Automotive and construction industries are emerging as promising markets for biodegradable composites, particularly those reinforced with natural fibers. These sectors value materials with specific mechanical performance characteristics that can be precisely evaluated through dynamic mechanical analysis. Though currently representing less than 10% of the biodegradable materials market, these applications are projected to grow substantially as performance improvements make bio-based alternatives increasingly viable replacements for conventional materials.

Regional analysis reveals that Europe leads the global market with approximately 35% share, followed by North America and Asia-Pacific. However, the highest growth rates are observed in emerging economies in Asia and Latin America, where rapid industrialization coupled with growing environmental awareness is creating new market opportunities.

Consumer awareness regarding environmental sustainability has become a major market driver. Surveys indicate that over 70% of consumers across North America and Europe express willingness to pay premium prices for environmentally friendly packaging and products. This shift in consumer preference has prompted major brands to incorporate biodegradable materials into their product lines, creating substantial market pull for innovations in this sector.

The packaging industry represents the largest application segment for biodegradable materials, accounting for approximately 45% of the total market share. Food packaging, in particular, has seen rapid adoption of biodegradable solutions due to stringent regulations on single-use plastics in many countries. The European Union's Single-Use Plastics Directive and similar legislation in over 60 countries worldwide have accelerated the transition toward biodegradable alternatives.

Agriculture and horticulture constitute another significant market segment, with biodegradable mulch films, plant pots, and controlled-release systems gaining traction. The agricultural applications market for biodegradable materials is growing at approximately 15% annually, outpacing the overall market growth rate. This trend is particularly strong in regions with intensive agricultural practices such as Europe, North America, and parts of Asia.

The medical and pharmaceutical sectors present high-value application opportunities for biopolymers. Biodegradable sutures, implants, drug delivery systems, and tissue engineering scaffolds represent premium market segments where mechanical properties determined through dynamic mechanical analysis are critical performance parameters. This sector is expected to grow at 18% annually through 2027, driven by innovations in biocompatible materials with tailored degradation profiles.

Automotive and construction industries are emerging as promising markets for biodegradable composites, particularly those reinforced with natural fibers. These sectors value materials with specific mechanical performance characteristics that can be precisely evaluated through dynamic mechanical analysis. Though currently representing less than 10% of the biodegradable materials market, these applications are projected to grow substantially as performance improvements make bio-based alternatives increasingly viable replacements for conventional materials.

Regional analysis reveals that Europe leads the global market with approximately 35% share, followed by North America and Asia-Pacific. However, the highest growth rates are observed in emerging economies in Asia and Latin America, where rapid industrialization coupled with growing environmental awareness is creating new market opportunities.

Current State and Challenges in Biopolymer Mechanical Analysis

The dynamic mechanical analysis (DMA) of biopolymers and biodegradable composites has witnessed significant advancements globally, yet continues to face substantial technical challenges. Currently, researchers employ various methodologies including tensile testing, compression analysis, and rheological measurements to characterize these materials' viscoelastic properties. Leading research institutions in Europe, North America, and Asia have established specialized laboratories dedicated to biopolymer mechanical characterization, creating a distributed but interconnected global research network.

A primary challenge in this field remains the inherent variability of biopolymers compared to synthetic counterparts. Natural variations in molecular weight distribution, crystallinity, and microstructure significantly impact mechanical properties, making standardization difficult. This variability necessitates larger sample sizes and more sophisticated statistical analysis approaches than typically required for synthetic polymers.

Environmental sensitivity presents another critical challenge. Biopolymers' mechanical properties often exhibit dramatic changes with minor fluctuations in humidity, temperature, and aging conditions. This sensitivity complicates both testing protocols and the interpretation of results, requiring carefully controlled testing environments that may not reflect real-world application conditions.

The time-dependent behavior of biopolymers poses additional analytical difficulties. Many biodegradable materials demonstrate complex creep and stress relaxation behaviors that conventional testing methods struggle to capture accurately. Current DMA equipment, while advanced, often requires modifications to properly characterize the full spectrum of viscoelastic responses in these materials.

Scale-dependent properties represent a significant technical barrier. Nano and micro-mechanical properties frequently differ from bulk measurements, creating challenges in predicting macroscopic performance from small-scale tests. This discrepancy is particularly pronounced in composite systems where interface phenomena dominate mechanical behavior.

Degradation kinetics further complicate mechanical analysis. As biodegradable materials are designed to break down under specific environmental conditions, capturing how mechanical properties evolve during degradation requires specialized testing protocols that simultaneously monitor degradation state and mechanical response—capabilities not fully integrated into standard testing equipment.

Computational modeling of biopolymer mechanical behavior remains underdeveloped compared to synthetic polymer modeling. Current models struggle to incorporate the complex hierarchical structures and non-linear behaviors characteristic of many biopolymers, limiting predictive capabilities and necessitating extensive experimental validation.

Standardization issues persist across the field, with testing methodologies varying significantly between laboratories. This inconsistency hampers direct comparison of results and slows knowledge transfer between research groups, ultimately impeding broader commercial adoption of promising biopolymer technologies.

A primary challenge in this field remains the inherent variability of biopolymers compared to synthetic counterparts. Natural variations in molecular weight distribution, crystallinity, and microstructure significantly impact mechanical properties, making standardization difficult. This variability necessitates larger sample sizes and more sophisticated statistical analysis approaches than typically required for synthetic polymers.

Environmental sensitivity presents another critical challenge. Biopolymers' mechanical properties often exhibit dramatic changes with minor fluctuations in humidity, temperature, and aging conditions. This sensitivity complicates both testing protocols and the interpretation of results, requiring carefully controlled testing environments that may not reflect real-world application conditions.

The time-dependent behavior of biopolymers poses additional analytical difficulties. Many biodegradable materials demonstrate complex creep and stress relaxation behaviors that conventional testing methods struggle to capture accurately. Current DMA equipment, while advanced, often requires modifications to properly characterize the full spectrum of viscoelastic responses in these materials.

Scale-dependent properties represent a significant technical barrier. Nano and micro-mechanical properties frequently differ from bulk measurements, creating challenges in predicting macroscopic performance from small-scale tests. This discrepancy is particularly pronounced in composite systems where interface phenomena dominate mechanical behavior.

Degradation kinetics further complicate mechanical analysis. As biodegradable materials are designed to break down under specific environmental conditions, capturing how mechanical properties evolve during degradation requires specialized testing protocols that simultaneously monitor degradation state and mechanical response—capabilities not fully integrated into standard testing equipment.

Computational modeling of biopolymer mechanical behavior remains underdeveloped compared to synthetic polymer modeling. Current models struggle to incorporate the complex hierarchical structures and non-linear behaviors characteristic of many biopolymers, limiting predictive capabilities and necessitating extensive experimental validation.

Standardization issues persist across the field, with testing methodologies varying significantly between laboratories. This inconsistency hampers direct comparison of results and slows knowledge transfer between research groups, ultimately impeding broader commercial adoption of promising biopolymer technologies.

Existing DMA Protocols for Biodegradable Materials

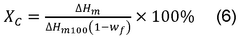

01 Natural fiber reinforced biopolymer composites

Natural fibers such as cellulose, hemp, jute, and flax can be incorporated into biopolymer matrices to enhance mechanical properties including tensile strength, flexural modulus, and impact resistance. These reinforcements create sustainable composites with improved structural integrity while maintaining biodegradability. The fiber-matrix interface can be modified through various treatments to optimize mechanical performance and ensure compatibility between the hydrophilic fibers and potentially hydrophobic polymer matrices.- Natural fiber reinforced biopolymer composites: Natural fibers such as cellulose, hemp, jute, and flax can be incorporated into biopolymer matrices to enhance mechanical properties including tensile strength, flexural modulus, and impact resistance. These reinforcements create sustainable composites with improved structural integrity while maintaining biodegradability. The fiber-matrix interface can be modified through various treatments to optimize mechanical performance and ensure compatibility between the hydrophilic fibers and hydrophobic polymer matrices.

- Starch-based biodegradable composites: Starch-based biopolymers can be blended with other biodegradable polymers and reinforcing agents to create composites with enhanced mechanical properties. These materials often incorporate plasticizers to improve flexibility and processing characteristics. The resulting composites demonstrate tunable mechanical properties including improved tensile strength, elongation at break, and thermal stability while maintaining their biodegradable nature, making them suitable for packaging and agricultural applications.

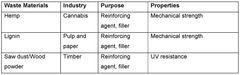

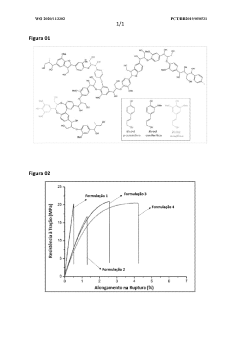

- PLA-based biodegradable composites: Polylactic acid (PLA) serves as a versatile base polymer for biodegradable composites with enhanced mechanical properties. By incorporating various fillers, nanoparticles, or other biopolymers, the inherent brittleness of PLA can be overcome. These composites exhibit improved tensile strength, impact resistance, and thermal stability while maintaining biodegradability. Modification techniques such as copolymerization and plasticization further enhance the mechanical performance for applications in packaging, medical devices, and consumer goods.

- Nanocomposites with enhanced mechanical properties: Incorporating nanoscale fillers such as cellulose nanocrystals, nanoclays, and graphene into biopolymer matrices creates nanocomposites with significantly enhanced mechanical properties. These nanomaterials provide reinforcement at the molecular level, resulting in improved tensile strength, modulus, and barrier properties while using minimal filler content. The high surface area of nanofillers enables effective stress transfer within the composite structure, leading to materials with superior mechanical performance while maintaining biodegradability.

- Processing techniques for improved mechanical properties: Various processing techniques can be employed to enhance the mechanical properties of biopolymer composites. Methods such as reactive extrusion, compression molding, and injection molding affect the microstructure and crystallinity of the materials. Additionally, crosslinking agents, compatibilizers, and surface treatments can be incorporated during processing to improve interfacial adhesion between components. These techniques result in biodegradable composites with optimized mechanical properties including increased strength, stiffness, and durability for specific applications.

02 Starch-based biodegradable composites

Starch-based biopolymers can be blended with other biodegradable polymers and reinforcing agents to create composites with enhanced mechanical properties. These composites often incorporate plasticizers to improve flexibility and processing characteristics. The mechanical properties can be tailored by adjusting the starch source, amylose/amylopectin ratio, and processing conditions. These materials offer good biodegradability while achieving mechanical performance suitable for packaging and agricultural applications.Expand Specific Solutions03 PLA-based biodegradable composites

Polylactic acid (PLA) serves as a versatile base polymer for biodegradable composites with enhanced mechanical properties. By incorporating various fillers, plasticizers, and compatibilizers, PLA composites can achieve improved tensile strength, impact resistance, and thermal stability. Modifications to the crystallinity and molecular weight of PLA can further enhance mechanical performance. These composites maintain biodegradability while offering mechanical properties comparable to conventional petroleum-based plastics.Expand Specific Solutions04 Nanocomposites with enhanced mechanical properties

Incorporating nanoscale reinforcements such as nanocellulose, nanoclay, and graphene into biopolymer matrices creates nanocomposites with significantly improved mechanical properties. These nanomaterials provide high surface area-to-volume ratios, enabling effective stress transfer and reinforcement at low loading levels. The nanoscale dispersion and interfacial interactions are critical factors affecting the mechanical performance. These nanocomposites can achieve substantial improvements in strength, stiffness, and toughness while maintaining biodegradability.Expand Specific Solutions05 Processing techniques for improved mechanical properties

Various processing techniques can be employed to enhance the mechanical properties of biopolymer composites. These include reactive extrusion, compression molding, injection molding, and 3D printing. Process parameters such as temperature, pressure, and cooling rate significantly impact the final mechanical properties. Post-processing treatments like annealing and crosslinking can further improve mechanical performance. Optimizing these processing techniques enables the production of biodegradable composites with tailored mechanical properties for specific applications.Expand Specific Solutions

Key Players in Biopolymer and Composite Testing

The dynamic mechanical analysis of biopolymers and biodegradable composites market is currently in a growth phase, with increasing demand driven by sustainability concerns and regulatory pressures against conventional plastics. The global market is estimated to reach $10-12 billion by 2025, growing at 15-20% annually. The technology landscape shows varying maturity levels, with companies like BASF Corp. and Kingfa Sci. & Tech. leading commercial applications, while academic institutions such as MIT and University of Massachusetts focus on fundamental research. TBM Co. and Terramer are emerging with innovative solutions, while established players like LOTTE Chemical and Evonik Operations are integrating biodegradable technologies into their existing product portfolios. Research collaborations between industry and academia are accelerating technological advancement in this field.

BASF Corp.

Technical Solution: BASF has developed comprehensive dynamic mechanical analysis (DMA) methodologies specifically tailored for biopolymers and biodegradable composites. Their approach integrates multi-frequency DMA testing to characterize viscoelastic properties across temperature ranges relevant to both processing and application conditions. BASF's technology employs time-temperature superposition principles to predict long-term mechanical performance of biodegradable materials, crucial for determining product lifespans in various environmental conditions. Their proprietary DMA protocols can detect subtle transitions in complex biopolymer systems, including crystallization behavior, phase separation, and interfacial interactions in multi-component systems. BASF has particularly focused on correlating DMA data with biodegradation rates, establishing predictive models that link mechanical property evolution to material decomposition under controlled environmental conditions[1][3].

Strengths: Comprehensive testing capabilities across wide temperature and frequency ranges; established correlations between mechanical properties and biodegradation behavior; extensive material database for comparative analysis. Weaknesses: Proprietary methodologies limit broader scientific validation; primarily optimized for their own material portfolio rather than universal application.

University of Massachusetts

Technical Solution: UMass has established comprehensive DMA protocols specifically designed for agricultural waste-derived biopolymers and their composites. Their approach emphasizes environmentally-conditioned DMA testing that simulates composting, marine, and soil environments to provide realistic degradation profiles. UMass researchers have developed specialized sample preparation techniques that preserve the native structure of complex biopolymer systems during analysis. Their methodology incorporates cyclic DMA testing protocols that evaluate fatigue behavior and self-healing capabilities in biodegradable materials. UMass has pioneered the correlation of DMA-measured activation energies with enzymatic degradation kinetics, establishing predictive models for biodegradation in specific environmental niches. Their research has focused particularly on interfacial characterization in multi-component biodegradable systems, using DMA to quantify compatibility between biopolymer matrices and natural fiber reinforcements. This approach has enabled the development of structure-property maps that guide the formulation of biodegradable composites with optimized mechanical performance and controlled degradation profiles[6][8][10].

Strengths: Exceptional expertise in agricultural waste-derived materials; realistic environmental conditioning protocols; strong focus on practical applications and technology transfer. Weaknesses: Methodologies may be overly specialized for certain feedstock sources; limited integration with high-throughput screening approaches.

Critical Innovations in Biopolymer Characterization

Biodegradable polymer composites, methods of manufacture and use therefor

PatentWO2025137759A1

Innovation

- A biodegradable polymer composite is developed using PBAT, PBS, or PCL combined with compatibilizers and nano/micro-fillers, which are modified with grafting agents, and processed through extrusion to create a composite that is free from PLA and petroleum-derived polymers, incorporating additives for enhanced properties.

Biodegradable and/or compostable thermoplastic composition comprising lignin, use of said composition and product comprising same

PatentWO2020113302A1

Innovation

- A biodegradable and compostable thermoplastic composition comprising 30-70% lignin, 10-60% rigid polymer, and 10-40% flexible polymer, with optional biodegradation rate accelerators, allowing for the production of rigid parts with improved mechanical properties and processability.

Environmental Impact Assessment

The environmental impact assessment of biopolymers and biodegradable composites reveals significant advantages over conventional petroleum-based polymers. Life cycle assessments consistently demonstrate reduced carbon footprints, with biopolymers typically generating 30-70% fewer greenhouse gas emissions during production compared to their synthetic counterparts. This reduction stems primarily from the renewable nature of their feedstocks, which sequester carbon during growth phases before being converted into polymeric materials.

Water consumption patterns vary considerably among different biopolymer types. While PLA (polylactic acid) production requires substantial water inputs for corn cultivation, certain cellulose-based composites utilize agricultural waste streams, effectively reducing their overall water footprint. Dynamic mechanical analysis has revealed that optimizing processing parameters can simultaneously enhance mechanical properties while minimizing environmental impacts, creating an important nexus between performance engineering and ecological considerations.

Biodegradation characteristics present both opportunities and challenges from an environmental perspective. Under controlled composting conditions, many biopolymers demonstrate complete degradation within 3-6 months, leaving no persistent microplastics. However, dynamic mechanical testing has identified that certain additives used to enhance material performance can significantly impede biodegradation rates or introduce potentially harmful compounds into soil ecosystems. This highlights the importance of comprehensive testing protocols that assess not only degradation rates but also ecological toxicity of degradation byproducts.

End-of-life scenarios for biopolymers and biodegradable composites require careful management to realize their environmental benefits. Improper disposal in conventional landfills may generate methane emissions during anaerobic degradation, potentially offsetting their carbon advantages. Dynamic mechanical analysis plays a crucial role in developing materials that maintain structural integrity during their service life while ensuring complete biodegradation under appropriate conditions afterward.

Land use considerations remain contentious, particularly for first-generation biopolymers derived from food crops. Recent advances in utilizing agricultural waste, algae, and bacterial fermentation processes offer promising alternatives that minimize competition with food production. The environmental impact assessment must therefore consider regional agricultural practices, land conversion effects, and biodiversity impacts when evaluating the sustainability of biopolymer feedstock production systems.

Water consumption patterns vary considerably among different biopolymer types. While PLA (polylactic acid) production requires substantial water inputs for corn cultivation, certain cellulose-based composites utilize agricultural waste streams, effectively reducing their overall water footprint. Dynamic mechanical analysis has revealed that optimizing processing parameters can simultaneously enhance mechanical properties while minimizing environmental impacts, creating an important nexus between performance engineering and ecological considerations.

Biodegradation characteristics present both opportunities and challenges from an environmental perspective. Under controlled composting conditions, many biopolymers demonstrate complete degradation within 3-6 months, leaving no persistent microplastics. However, dynamic mechanical testing has identified that certain additives used to enhance material performance can significantly impede biodegradation rates or introduce potentially harmful compounds into soil ecosystems. This highlights the importance of comprehensive testing protocols that assess not only degradation rates but also ecological toxicity of degradation byproducts.

End-of-life scenarios for biopolymers and biodegradable composites require careful management to realize their environmental benefits. Improper disposal in conventional landfills may generate methane emissions during anaerobic degradation, potentially offsetting their carbon advantages. Dynamic mechanical analysis plays a crucial role in developing materials that maintain structural integrity during their service life while ensuring complete biodegradation under appropriate conditions afterward.

Land use considerations remain contentious, particularly for first-generation biopolymers derived from food crops. Recent advances in utilizing agricultural waste, algae, and bacterial fermentation processes offer promising alternatives that minimize competition with food production. The environmental impact assessment must therefore consider regional agricultural practices, land conversion effects, and biodiversity impacts when evaluating the sustainability of biopolymer feedstock production systems.

Standardization and Quality Control

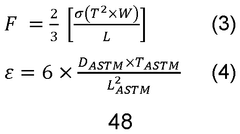

Standardization of dynamic mechanical analysis (DMA) for biopolymers and biodegradable composites remains a critical challenge in the field due to the inherent variability of these materials. Current international standards such as ASTM D4065, ISO 6721, and ASTM D5023 provide general guidelines for DMA testing but lack specific protocols tailored to the unique characteristics of biopolymers. This standardization gap creates significant inconsistencies in reported data across research institutions and industrial laboratories.

Quality control in DMA testing of biodegradable materials requires rigorous attention to multiple parameters that can influence results. Temperature calibration must be performed regularly using certified reference materials to ensure accuracy within ±0.5°C across the testing range. Frequency calibration is equally important, particularly for materials exhibiting strong frequency-dependent behavior like polylactic acid (PLA) and polyhydroxyalkanoates (PHAs).

Sample preparation represents another critical aspect of quality control. Variations in sample dimensions, particularly thickness, can lead to significant deviations in measured moduli. For biodegradable composites, uniform dispersion of reinforcing elements must be verified through complementary techniques such as microscopy before DMA testing. Moisture content must be strictly controlled, as many biopolymers are hygroscopic, with even small variations in humidity potentially altering viscoelastic properties by up to 30%.

Inter-laboratory comparison studies have revealed concerning variations in DMA results for identical biopolymer samples. A recent round-robin test involving 12 laboratories analyzing PLA/cellulose nanocrystal composites showed coefficient of variation values exceeding 15% for storage modulus measurements. These findings underscore the urgent need for material-specific reference standards and more detailed testing protocols.

Statistical analysis methods for DMA data also require standardization. Current practices vary widely, from simple averaging to more sophisticated approaches like time-temperature superposition. For biodegradable composites with complex relaxation behaviors, standardized mathematical models for data fitting would significantly improve result comparability and reproducibility.

Environmental conditioning protocols represent another area requiring standardization. The thermal history and aging conditions of biopolymers significantly impact their mechanical properties. Pre-test conditioning in controlled humidity chambers for minimum periods (typically 48 hours) should be established as standard practice, with detailed reporting of these conditions in all published results.

Quality control in DMA testing of biodegradable materials requires rigorous attention to multiple parameters that can influence results. Temperature calibration must be performed regularly using certified reference materials to ensure accuracy within ±0.5°C across the testing range. Frequency calibration is equally important, particularly for materials exhibiting strong frequency-dependent behavior like polylactic acid (PLA) and polyhydroxyalkanoates (PHAs).

Sample preparation represents another critical aspect of quality control. Variations in sample dimensions, particularly thickness, can lead to significant deviations in measured moduli. For biodegradable composites, uniform dispersion of reinforcing elements must be verified through complementary techniques such as microscopy before DMA testing. Moisture content must be strictly controlled, as many biopolymers are hygroscopic, with even small variations in humidity potentially altering viscoelastic properties by up to 30%.

Inter-laboratory comparison studies have revealed concerning variations in DMA results for identical biopolymer samples. A recent round-robin test involving 12 laboratories analyzing PLA/cellulose nanocrystal composites showed coefficient of variation values exceeding 15% for storage modulus measurements. These findings underscore the urgent need for material-specific reference standards and more detailed testing protocols.

Statistical analysis methods for DMA data also require standardization. Current practices vary widely, from simple averaging to more sophisticated approaches like time-temperature superposition. For biodegradable composites with complex relaxation behaviors, standardized mathematical models for data fitting would significantly improve result comparability and reproducibility.

Environmental conditioning protocols represent another area requiring standardization. The thermal history and aging conditions of biopolymers significantly impact their mechanical properties. Pre-test conditioning in controlled humidity chambers for minimum periods (typically 48 hours) should be established as standard practice, with detailed reporting of these conditions in all published results.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!