Dynamic mechanical analysis for thermoset curing characterization

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoset Curing Analysis Background and Objectives

Dynamic mechanical analysis (DMA) has emerged as a critical analytical technique in the field of polymer science, particularly for characterizing the curing process of thermoset materials. The evolution of this technology spans several decades, beginning with rudimentary thermal analysis methods in the 1950s and advancing to sophisticated computer-controlled instrumentation capable of multi-frequency, multi-mode testing in contemporary applications.

The fundamental principle of DMA involves applying an oscillating force to a sample and analyzing its response, which provides valuable insights into viscoelastic properties during the curing process. This technique has become increasingly important as industries demand more precise control over material properties and processing parameters for advanced applications in aerospace, automotive, electronics, and medical devices.

Current technological trends in thermoset curing analysis show a clear movement toward in-situ monitoring capabilities, integration with other analytical techniques, and development of predictive models that can accelerate material development cycles. The convergence of DMA with artificial intelligence and machine learning algorithms represents a particularly promising frontier, enabling more accurate prediction of final material properties based on early-stage curing data.

The primary technical objectives of DMA for thermoset curing characterization include precise determination of gelation and vitrification points, comprehensive mapping of the time-temperature-transformation (TTT) diagrams, quantification of cure kinetics, and establishment of structure-property relationships throughout the curing process. These objectives serve the broader goal of optimizing processing conditions while minimizing production costs and environmental impact.

Recent advancements have expanded the application scope to include multi-component systems, nanocomposites, and bio-based thermosets, reflecting the growing complexity of modern materials. The push toward sustainable chemistry has also influenced research directions, with increasing focus on developing analytical methodologies suitable for environmentally friendly curing systems that operate at lower temperatures or use less toxic hardeners.

The technical evolution of DMA instrumentation itself has been marked by improvements in sensitivity, temperature control precision, and data acquisition rates. Modern systems now routinely incorporate multiple sensing technologies and can operate under various environmental conditions, including controlled humidity, gas atmosphere, and pressure, providing a more comprehensive understanding of curing behavior under realistic processing conditions.

The fundamental principle of DMA involves applying an oscillating force to a sample and analyzing its response, which provides valuable insights into viscoelastic properties during the curing process. This technique has become increasingly important as industries demand more precise control over material properties and processing parameters for advanced applications in aerospace, automotive, electronics, and medical devices.

Current technological trends in thermoset curing analysis show a clear movement toward in-situ monitoring capabilities, integration with other analytical techniques, and development of predictive models that can accelerate material development cycles. The convergence of DMA with artificial intelligence and machine learning algorithms represents a particularly promising frontier, enabling more accurate prediction of final material properties based on early-stage curing data.

The primary technical objectives of DMA for thermoset curing characterization include precise determination of gelation and vitrification points, comprehensive mapping of the time-temperature-transformation (TTT) diagrams, quantification of cure kinetics, and establishment of structure-property relationships throughout the curing process. These objectives serve the broader goal of optimizing processing conditions while minimizing production costs and environmental impact.

Recent advancements have expanded the application scope to include multi-component systems, nanocomposites, and bio-based thermosets, reflecting the growing complexity of modern materials. The push toward sustainable chemistry has also influenced research directions, with increasing focus on developing analytical methodologies suitable for environmentally friendly curing systems that operate at lower temperatures or use less toxic hardeners.

The technical evolution of DMA instrumentation itself has been marked by improvements in sensitivity, temperature control precision, and data acquisition rates. Modern systems now routinely incorporate multiple sensing technologies and can operate under various environmental conditions, including controlled humidity, gas atmosphere, and pressure, providing a more comprehensive understanding of curing behavior under realistic processing conditions.

Market Applications and Industry Demand for DMA Technology

Dynamic Mechanical Analysis (DMA) technology has witnessed significant market growth across various industries due to its unparalleled capabilities in characterizing thermoset curing processes. The global DMA equipment market currently exceeds $300 million, with a compound annual growth rate of approximately 5-6%, driven primarily by increasing demand in advanced materials development sectors.

The aerospace and automotive industries represent the largest application segments for DMA technology, collectively accounting for nearly 40% of the total market share. In aerospace manufacturing, DMA has become an essential tool for qualifying composite materials used in critical structural components, where precise understanding of curing behavior directly impacts safety and performance characteristics. Boeing, Airbus, and their tier-one suppliers have integrated DMA testing as a standard quality control procedure in their manufacturing protocols.

Similarly, the automotive sector has embraced DMA technology to optimize the production of lightweight composite components, addressing the industry's push toward fuel efficiency and emissions reduction. Major manufacturers utilize DMA data to fine-tune curing cycles, reducing production time while maintaining or improving mechanical properties of components.

The electronics industry represents another rapidly growing application area, particularly in semiconductor packaging and printed circuit board manufacturing. As electronic devices continue to miniaturize while increasing in complexity, the thermal and mechanical properties of encapsulation materials become increasingly critical. DMA provides essential data for optimizing curing parameters to prevent issues such as warpage, delamination, and residual stress.

Medical device manufacturing has emerged as a high-value niche market for DMA technology, especially in the development of biocompatible thermoset materials for implantable devices. The stringent regulatory requirements in this sector necessitate comprehensive material characterization, driving adoption of advanced analytical techniques like DMA.

Research institutions and academic laboratories constitute approximately 15% of the market, utilizing DMA equipment for fundamental materials research and educational purposes. This segment plays a crucial role in developing new methodologies and applications that eventually transfer to industrial settings.

Geographically, North America and Europe currently dominate the market with approximately 60% combined share, though Asia-Pacific represents the fastest-growing region with increasing investments in advanced manufacturing capabilities, particularly in China, Japan, and South Korea. The region's growth is further accelerated by the expansion of electronics manufacturing and automotive production facilities requiring sophisticated material characterization capabilities.

The aerospace and automotive industries represent the largest application segments for DMA technology, collectively accounting for nearly 40% of the total market share. In aerospace manufacturing, DMA has become an essential tool for qualifying composite materials used in critical structural components, where precise understanding of curing behavior directly impacts safety and performance characteristics. Boeing, Airbus, and their tier-one suppliers have integrated DMA testing as a standard quality control procedure in their manufacturing protocols.

Similarly, the automotive sector has embraced DMA technology to optimize the production of lightweight composite components, addressing the industry's push toward fuel efficiency and emissions reduction. Major manufacturers utilize DMA data to fine-tune curing cycles, reducing production time while maintaining or improving mechanical properties of components.

The electronics industry represents another rapidly growing application area, particularly in semiconductor packaging and printed circuit board manufacturing. As electronic devices continue to miniaturize while increasing in complexity, the thermal and mechanical properties of encapsulation materials become increasingly critical. DMA provides essential data for optimizing curing parameters to prevent issues such as warpage, delamination, and residual stress.

Medical device manufacturing has emerged as a high-value niche market for DMA technology, especially in the development of biocompatible thermoset materials for implantable devices. The stringent regulatory requirements in this sector necessitate comprehensive material characterization, driving adoption of advanced analytical techniques like DMA.

Research institutions and academic laboratories constitute approximately 15% of the market, utilizing DMA equipment for fundamental materials research and educational purposes. This segment plays a crucial role in developing new methodologies and applications that eventually transfer to industrial settings.

Geographically, North America and Europe currently dominate the market with approximately 60% combined share, though Asia-Pacific represents the fastest-growing region with increasing investments in advanced manufacturing capabilities, particularly in China, Japan, and South Korea. The region's growth is further accelerated by the expansion of electronics manufacturing and automotive production facilities requiring sophisticated material characterization capabilities.

Current DMA Technology Status and Challenges

Dynamic Mechanical Analysis (DMA) has evolved significantly over the past decades as a critical technique for characterizing thermoset curing processes. Currently, the global landscape of DMA technology demonstrates considerable advancement, yet faces several persistent challenges that limit its full potential in industrial and research applications.

Modern commercial DMA instruments typically operate across temperature ranges from -150°C to 600°C with frequency capabilities between 0.01 Hz and 200 Hz. These systems can measure modulus values spanning from 103 to 1012 Pa with strain resolution as precise as 1 nanometer. Despite these impressive specifications, the technology encounters significant limitations when applied to in-situ curing characterization of thermoset materials.

One primary challenge involves the difficulty in maintaining sample integrity during the measurement of curing processes. As thermosets transition from liquid to solid states, the dramatic changes in mechanical properties often exceed the measurement range of a single fixture configuration, necessitating multiple experimental setups that introduce discontinuities in data collection.

Temperature control represents another critical challenge, particularly for exothermic curing reactions. Current DMA systems struggle to maintain precise isothermal conditions during highly exothermic curing events, leading to temperature gradients within samples that compromise measurement accuracy. This limitation becomes especially problematic when characterizing fast-curing systems or those with complex cure kinetics.

The rheological complexity of thermosets during cure presents additional difficulties. The viscoelastic behavior changes dramatically throughout the curing process, transitioning from predominantly viscous to predominantly elastic responses. Existing DMA technologies often fail to capture this full transition accurately, particularly in the early stages of cure when the material exhibits very low modulus values.

Geographically, advanced DMA technology development remains concentrated in North America, Western Europe, and Japan, with companies like TA Instruments, Netzsch, and Mettler Toledo leading innovation. However, emerging research centers in China and India are increasingly contributing to technological advancements in this field.

Recent developments have attempted to address these challenges through multimodal approaches that combine DMA with complementary techniques such as Fourier-transform infrared spectroscopy (FTIR) or differential scanning calorimetry (DSC). These hybrid systems aim to correlate mechanical property evolution with chemical conversion, though integration challenges and data synchronization issues persist.

The miniaturization of DMA technology represents another frontier, with microelectromechanical systems (MEMS) approaches showing promise for high-throughput screening of curing behaviors. However, these micro-scale techniques currently struggle with reproducibility and correlation to bulk material properties.

Modern commercial DMA instruments typically operate across temperature ranges from -150°C to 600°C with frequency capabilities between 0.01 Hz and 200 Hz. These systems can measure modulus values spanning from 103 to 1012 Pa with strain resolution as precise as 1 nanometer. Despite these impressive specifications, the technology encounters significant limitations when applied to in-situ curing characterization of thermoset materials.

One primary challenge involves the difficulty in maintaining sample integrity during the measurement of curing processes. As thermosets transition from liquid to solid states, the dramatic changes in mechanical properties often exceed the measurement range of a single fixture configuration, necessitating multiple experimental setups that introduce discontinuities in data collection.

Temperature control represents another critical challenge, particularly for exothermic curing reactions. Current DMA systems struggle to maintain precise isothermal conditions during highly exothermic curing events, leading to temperature gradients within samples that compromise measurement accuracy. This limitation becomes especially problematic when characterizing fast-curing systems or those with complex cure kinetics.

The rheological complexity of thermosets during cure presents additional difficulties. The viscoelastic behavior changes dramatically throughout the curing process, transitioning from predominantly viscous to predominantly elastic responses. Existing DMA technologies often fail to capture this full transition accurately, particularly in the early stages of cure when the material exhibits very low modulus values.

Geographically, advanced DMA technology development remains concentrated in North America, Western Europe, and Japan, with companies like TA Instruments, Netzsch, and Mettler Toledo leading innovation. However, emerging research centers in China and India are increasingly contributing to technological advancements in this field.

Recent developments have attempted to address these challenges through multimodal approaches that combine DMA with complementary techniques such as Fourier-transform infrared spectroscopy (FTIR) or differential scanning calorimetry (DSC). These hybrid systems aim to correlate mechanical property evolution with chemical conversion, though integration challenges and data synchronization issues persist.

The miniaturization of DMA technology represents another frontier, with microelectromechanical systems (MEMS) approaches showing promise for high-throughput screening of curing behaviors. However, these micro-scale techniques currently struggle with reproducibility and correlation to bulk material properties.

Established DMA Methodologies for Curing Process Analysis

01 DMA techniques for monitoring curing processes

Dynamic mechanical analysis (DMA) is used to monitor and characterize the curing process of various materials by measuring changes in viscoelastic properties during curing. This technique allows for real-time tracking of the transition from liquid to solid state, providing information about cure kinetics, gelation points, and the development of mechanical properties. DMA measurements can detect changes in storage modulus, loss modulus, and tan delta that correspond to different stages of the curing reaction.- DMA techniques for polymer curing characterization: Dynamic mechanical analysis (DMA) is used to characterize the curing process of polymers by measuring changes in viscoelastic properties during crosslinking. This technique monitors the storage modulus, loss modulus, and tan delta as functions of time and temperature, providing insights into the gelation point, vitrification, and degree of cure. DMA allows for the determination of optimal curing conditions and can detect subtle changes in material properties throughout the curing process.

- Real-time monitoring of curing processes: Real-time monitoring systems employ dynamic mechanical analysis to track curing progression in manufacturing environments. These systems provide immediate feedback on the curing state, allowing for process adjustments and quality control. By continuously measuring mechanical properties during curing, manufacturers can optimize cycle times, reduce defects, and ensure consistent product quality. This approach is particularly valuable for complex composite materials where cure kinetics significantly impact final properties.

- Temperature-dependent curing characterization: Temperature plays a critical role in curing processes, and dynamic mechanical analysis provides valuable insights into temperature-dependent curing behavior. By conducting temperature ramps or isothermal holds while measuring mechanical responses, researchers can determine activation energies, reaction kinetics, and optimal curing temperatures. This approach helps identify temperature windows for effective curing and reveals how temperature fluctuations affect the final material properties and performance.

- Multi-parameter analysis for comprehensive curing characterization: Advanced curing characterization combines dynamic mechanical analysis with complementary techniques such as differential scanning calorimetry, rheology, and spectroscopic methods. This multi-parameter approach provides a comprehensive understanding of both chemical and physical changes during curing. By correlating mechanical property evolution with chemical conversion, heat flow, and molecular structure changes, researchers can develop more accurate curing models and optimize formulations for specific applications.

- DMA for specialty material curing applications: Dynamic mechanical analysis has been adapted for characterizing the curing behavior of specialty materials including dental composites, aerospace adhesives, and electronic encapsulants. These applications often require customized testing protocols to account for unique curing mechanisms, filler effects, and performance requirements. DMA provides insights into how formulation variables affect curing behavior and final properties, enabling the development of materials with tailored performance characteristics for demanding applications.

02 Temperature-dependent curing characterization

Temperature plays a critical role in curing processes and can be systematically analyzed using dynamic mechanical analysis. By conducting temperature ramps or isothermal holds while measuring mechanical properties, researchers can determine optimal curing temperatures, activation energies, and temperature-dependent cure rates. This approach helps in developing efficient curing protocols and understanding how temperature affects the final properties of cured materials, including crosslinking density and glass transition temperature.Expand Specific Solutions03 Rheological characterization of curing systems

Rheological measurements during curing provide insights into flow behavior, viscosity changes, and structural development of materials as they cure. Dynamic mechanical analysis can track the evolution of rheological properties throughout the curing process, identifying critical transitions such as gelation and vitrification. These measurements are particularly valuable for optimizing processing parameters in manufacturing, ensuring proper flow before gelation, and predicting the final mechanical performance of cured products.Expand Specific Solutions04 Advanced data analysis methods for curing characterization

Sophisticated data analysis techniques enhance the interpretation of dynamic mechanical analysis results for curing characterization. These methods include machine learning algorithms, mathematical modeling of cure kinetics, time-temperature superposition, and multivariate analysis. By applying these analytical approaches to DMA data, researchers can extract more detailed information about reaction mechanisms, predict curing behavior under various conditions, and develop structure-property relationships for cured materials.Expand Specific Solutions05 In-situ monitoring and quality control applications

Dynamic mechanical analysis can be implemented as an in-situ monitoring tool for real-time quality control during manufacturing processes. By continuously tracking the curing progress through mechanical property measurements, manufacturers can detect anomalies, ensure consistent product quality, and optimize process parameters. This approach enables adaptive control of curing processes, reduces waste, and improves the reliability of production methods for composite materials, adhesives, coatings, and other curable systems.Expand Specific Solutions

Leading Manufacturers and Research Institutions in DMA Field

Dynamic mechanical analysis (DMA) for thermoset curing characterization is currently in a growth phase, with the global market expanding due to increasing demand in aerospace, automotive, and electronics industries. The market is projected to reach significant value as manufacturers seek advanced materials with superior thermal and mechanical properties. Technologically, the field shows varying maturity levels across players. Industry leaders like Boeing, Airbus, and Hexcel Composites demonstrate advanced capabilities in aerospace applications, while chemical giants including BASF, Dow Global Technologies, and LG Chem offer sophisticated thermoset formulations. Japanese corporations such as Sekisui Chemical, Sumitomo Bakelite, and Sony Group are making notable advancements in electronics applications. Research institutions like Fraunhofer-Gesellschaft and CNRS provide crucial innovation support, creating a competitive landscape balanced between established industrial players and emerging research-driven entities.

Airbus Operations Ltd.

Technical Solution: Airbus has developed a comprehensive DMA-based thermoset characterization platform specifically optimized for aerospace-grade prepreg systems. Their approach focuses on correlating DMA measurements with actual manufacturing outcomes in large composite structures. Airbus's technology incorporates multi-temperature, multi-frequency DMA protocols that can accurately predict cure behavior across the complex thermal gradients encountered in large aircraft components. Their system includes specialized fixtures designed to simulate the constraints imposed by tooling during actual manufacturing, providing more realistic assessment of residual stress development during cure. Airbus has pioneered the use of DMA for detecting subtle formulation variations in incoming prepreg materials, implementing it as a quality control tool in their supply chain management. Their methodology includes proprietary algorithms that translate DMA data into finite element models for predicting part distortion during cure, allowing for tool design optimization. Airbus has documented significant cost savings through reduced trial-and-error in tool design and cure cycle development for new composite components. Their research has also established correlations between specific DMA parameters and critical mechanical properties like interlaminar shear strength and damage tolerance, creating a more direct link between process monitoring and final part qualification.

Strengths: Directly applicable to large-scale aerospace manufacturing with proven industrial implementation; strong correlation between analytical measurements and actual part performance. Weaknesses: System is highly specialized for aerospace-grade prepreg systems; may have limited applicability to other thermoset applications like casting resins or adhesives.

The Boeing Co.

Technical Solution: Boeing has developed a sophisticated DMA-based thermoset characterization system specifically designed for aerospace composite materials. Their approach integrates traditional DMA with dielectric analysis (DEA) to provide complementary data on both mechanical and electrical property evolution during cure. Boeing's system employs custom-designed fixtures that can accommodate carbon fiber reinforced samples, allowing for more realistic assessment of cure behavior in actual composite parts rather than neat resin samples. Their methodology includes specialized algorithms that account for the anisotropic nature of fiber-reinforced composites during cure, providing more accurate predictions of residual stresses and dimensional stability. Boeing has implemented in-situ DMA monitoring systems directly in autoclave environments, enabling real-time process adjustments based on actual cure progression rather than predetermined cure cycles. This adaptive curing approach has been demonstrated to reduce energy consumption by up to 15% while improving part consistency. Boeing's research has also focused on correlating DMA data with mechanical performance testing, establishing quantitative relationships between cure parameters and final part properties.

Strengths: Highly specialized for aerospace applications with direct implementation in production environments; integration with other analytical techniques provides comprehensive cure monitoring. Weaknesses: Systems are extremely capital-intensive and primarily designed for high-value aerospace components; may be economically impractical for lower-value applications.

Critical Patents and Research in Thermoset Curing Characterization

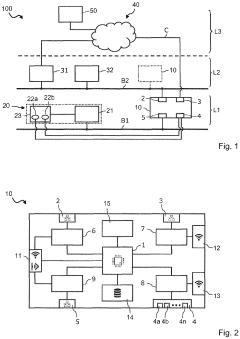

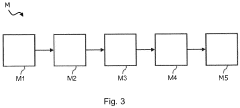

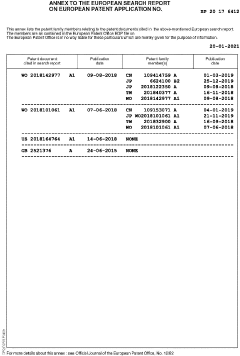

Data acquisition system, system and method for real-time in-line monitoring of industrial production processes

PatentActiveEP3786731A1

Innovation

- A data acquisition system integrating sensors within the machining zone of industrial manufacturing machines, connected to cloud-based resources for real-time data analysis and feedback, enabling the transmission of measurement values and control signals to optimize manufacturing processes and improve quality control.

Quality Control Standards for Thermoset Materials

Quality control standards for thermoset materials have evolved significantly to accommodate the complex curing processes these materials undergo. The implementation of dynamic mechanical analysis (DMA) has revolutionized how manufacturers establish and maintain quality benchmarks throughout the production cycle. These standards typically encompass several critical parameters including glass transition temperature (Tg), crosslinking density, cure degree, and viscoelastic properties that directly influence the final product performance.

Industry standards such as ASTM D4065, ASTM E1640, and ISO 6721 provide comprehensive frameworks for conducting DMA tests on thermoset materials. These standards define specific testing protocols, sample preparation methods, and data interpretation guidelines to ensure consistency across different manufacturing facilities and laboratories. The temperature ranges, heating rates, and frequency parameters are precisely defined to capture the complete curing profile of various thermoset formulations.

Manufacturing quality control systems increasingly incorporate real-time DMA monitoring to detect deviations from established curing profiles. This approach allows for immediate corrective actions rather than post-production quality assessment. Statistical process control (SPC) methodologies applied to DMA data enable manufacturers to establish upper and lower control limits for critical parameters such as storage modulus, loss modulus, and tan delta values at different stages of the curing process.

Material certification protocols now routinely include DMA-derived metrics as acceptance criteria. These specifications typically define acceptable ranges for cure onset temperature, peak cure rate, final conversion percentage, and residual cure potential. The integration of these parameters into formal quality management systems ensures traceability and consistency in thermoset material performance across different production batches.

Advanced quality standards also address the correlation between DMA results and end-use performance characteristics. This includes establishing relationships between viscoelastic properties measured during curing and final mechanical properties such as tensile strength, impact resistance, and environmental stability. These correlations serve as predictive tools for product performance without requiring extensive destructive testing of finished components.

International harmonization efforts have focused on standardizing DMA methodologies for thermoset characterization across different industries including aerospace, automotive, and electronics manufacturing. These initiatives aim to establish universal quality benchmarks that facilitate global supply chain integration while maintaining rigorous performance requirements for critical applications where thermoset materials are deployed.

Industry standards such as ASTM D4065, ASTM E1640, and ISO 6721 provide comprehensive frameworks for conducting DMA tests on thermoset materials. These standards define specific testing protocols, sample preparation methods, and data interpretation guidelines to ensure consistency across different manufacturing facilities and laboratories. The temperature ranges, heating rates, and frequency parameters are precisely defined to capture the complete curing profile of various thermoset formulations.

Manufacturing quality control systems increasingly incorporate real-time DMA monitoring to detect deviations from established curing profiles. This approach allows for immediate corrective actions rather than post-production quality assessment. Statistical process control (SPC) methodologies applied to DMA data enable manufacturers to establish upper and lower control limits for critical parameters such as storage modulus, loss modulus, and tan delta values at different stages of the curing process.

Material certification protocols now routinely include DMA-derived metrics as acceptance criteria. These specifications typically define acceptable ranges for cure onset temperature, peak cure rate, final conversion percentage, and residual cure potential. The integration of these parameters into formal quality management systems ensures traceability and consistency in thermoset material performance across different production batches.

Advanced quality standards also address the correlation between DMA results and end-use performance characteristics. This includes establishing relationships between viscoelastic properties measured during curing and final mechanical properties such as tensile strength, impact resistance, and environmental stability. These correlations serve as predictive tools for product performance without requiring extensive destructive testing of finished components.

International harmonization efforts have focused on standardizing DMA methodologies for thermoset characterization across different industries including aerospace, automotive, and electronics manufacturing. These initiatives aim to establish universal quality benchmarks that facilitate global supply chain integration while maintaining rigorous performance requirements for critical applications where thermoset materials are deployed.

Environmental Impact of Thermoset Processing Technologies

The environmental impact of thermoset processing technologies has become increasingly significant as industries face mounting pressure to adopt sustainable practices. Traditional thermoset curing processes often involve substantial energy consumption, with curing ovens and autoclaves operating at elevated temperatures for extended periods. Dynamic Mechanical Analysis (DMA) has emerged as a valuable tool for optimizing these processes by providing precise characterization of curing kinetics, potentially reducing energy requirements and associated carbon emissions.

Thermoset manufacturing typically generates considerable waste through material trimming, rejected parts, and expired raw materials. The inability to recycle conventional thermosets compounds this environmental burden. Advanced DMA techniques enable manufacturers to fine-tune formulations and processing parameters, resulting in higher first-time-right rates and reduced material waste. By accurately predicting gel points and optimum cure cycles, DMA helps minimize the ecological footprint of thermoset production.

Volatile organic compound (VOC) emissions represent another environmental concern in thermoset processing. Many traditional thermoset systems release harmful compounds during curing, contributing to air pollution and potential health hazards. DMA characterization facilitates the development of low-VOC and solvent-free formulations by providing detailed insights into how these environmentally friendly alternatives cure compared to conventional systems.

Water consumption in thermoset processing, particularly for cooling systems and cleaning operations, presents additional environmental challenges. DMA-optimized cure cycles can reduce processing times and cooling requirements, subsequently decreasing water usage. Furthermore, the data obtained through DMA supports the transition toward waterborne thermoset systems that inherently reduce environmental impact.

Recent life cycle assessment (LCA) studies have demonstrated that thermoset products optimized through advanced characterization techniques like DMA can achieve 15-30% reductions in overall environmental impact. This improvement stems from more efficient resource utilization, reduced energy consumption, and extended product lifespans due to enhanced material performance. As regulatory frameworks increasingly emphasize environmental sustainability, DMA-driven process optimization represents a critical pathway for thermoset manufacturers to achieve compliance while maintaining economic viability.

The integration of DMA with digital manufacturing platforms and Industry 4.0 technologies offers further environmental benefits through real-time process monitoring and adaptive control systems. These integrated approaches enable continuous optimization of curing parameters based on actual material behavior, minimizing resource consumption while maximizing product quality and consistency.

Thermoset manufacturing typically generates considerable waste through material trimming, rejected parts, and expired raw materials. The inability to recycle conventional thermosets compounds this environmental burden. Advanced DMA techniques enable manufacturers to fine-tune formulations and processing parameters, resulting in higher first-time-right rates and reduced material waste. By accurately predicting gel points and optimum cure cycles, DMA helps minimize the ecological footprint of thermoset production.

Volatile organic compound (VOC) emissions represent another environmental concern in thermoset processing. Many traditional thermoset systems release harmful compounds during curing, contributing to air pollution and potential health hazards. DMA characterization facilitates the development of low-VOC and solvent-free formulations by providing detailed insights into how these environmentally friendly alternatives cure compared to conventional systems.

Water consumption in thermoset processing, particularly for cooling systems and cleaning operations, presents additional environmental challenges. DMA-optimized cure cycles can reduce processing times and cooling requirements, subsequently decreasing water usage. Furthermore, the data obtained through DMA supports the transition toward waterborne thermoset systems that inherently reduce environmental impact.

Recent life cycle assessment (LCA) studies have demonstrated that thermoset products optimized through advanced characterization techniques like DMA can achieve 15-30% reductions in overall environmental impact. This improvement stems from more efficient resource utilization, reduced energy consumption, and extended product lifespans due to enhanced material performance. As regulatory frameworks increasingly emphasize environmental sustainability, DMA-driven process optimization represents a critical pathway for thermoset manufacturers to achieve compliance while maintaining economic viability.

The integration of DMA with digital manufacturing platforms and Industry 4.0 technologies offers further environmental benefits through real-time process monitoring and adaptive control systems. These integrated approaches enable continuous optimization of curing parameters based on actual material behavior, minimizing resource consumption while maximizing product quality and consistency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!