How strain amplitude affects phase transition detection in DMA

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DMA Phase Transition Detection Background & Objectives

Dynamic Mechanical Analysis (DMA) has emerged as a powerful analytical technique for characterizing the viscoelastic properties of materials since its development in the mid-20th century. The technique has evolved significantly from simple mechanical testing to sophisticated computer-controlled systems capable of detecting subtle phase transitions in various materials. The fundamental principle of DMA involves applying an oscillatory force to a sample and analyzing its response, which provides valuable insights into material behavior under different conditions.

The evolution of DMA technology has been marked by continuous improvements in sensitivity, accuracy, and versatility. Early systems were limited in their ability to detect phase transitions, particularly when using different strain amplitudes. However, modern DMA instruments can detect glass transitions, melting points, and other phase changes with remarkable precision, making them indispensable tools in materials science, polymer research, and pharmaceutical development.

The relationship between strain amplitude and phase transition detection represents a critical area of investigation in DMA methodology. Historically, researchers have observed that the strain amplitude applied during testing can significantly influence the measured transition temperatures and the clarity of transition signals. This phenomenon has important implications for standardization of testing protocols and interpretation of results across different experimental conditions.

The primary objective of this technical research is to comprehensively understand how varying strain amplitudes affect the detection and characterization of phase transitions in different material systems using DMA. Specifically, we aim to establish quantitative relationships between strain amplitude parameters and the accuracy, sensitivity, and reproducibility of phase transition measurements.

Additionally, this research seeks to develop optimized testing protocols that account for strain amplitude effects, potentially leading to more reliable and consistent DMA results across different laboratories and testing conditions. Understanding these relationships will enable more precise material characterization and potentially reveal previously undetected phase behaviors in complex materials.

The technological significance of this research extends beyond academic interest, as improved phase transition detection directly impacts quality control in manufacturing, formulation optimization in pharmaceuticals, and performance prediction in advanced materials. By elucidating the fundamental mechanisms by which strain amplitude influences phase transition signals, we anticipate contributing to both theoretical understanding and practical applications of DMA technology.

Current industry trends indicate growing demand for higher precision in material characterization, particularly for emerging materials with complex phase behaviors. This research aligns with these trends by addressing a fundamental methodological question that affects measurement accuracy across multiple industries.

The evolution of DMA technology has been marked by continuous improvements in sensitivity, accuracy, and versatility. Early systems were limited in their ability to detect phase transitions, particularly when using different strain amplitudes. However, modern DMA instruments can detect glass transitions, melting points, and other phase changes with remarkable precision, making them indispensable tools in materials science, polymer research, and pharmaceutical development.

The relationship between strain amplitude and phase transition detection represents a critical area of investigation in DMA methodology. Historically, researchers have observed that the strain amplitude applied during testing can significantly influence the measured transition temperatures and the clarity of transition signals. This phenomenon has important implications for standardization of testing protocols and interpretation of results across different experimental conditions.

The primary objective of this technical research is to comprehensively understand how varying strain amplitudes affect the detection and characterization of phase transitions in different material systems using DMA. Specifically, we aim to establish quantitative relationships between strain amplitude parameters and the accuracy, sensitivity, and reproducibility of phase transition measurements.

Additionally, this research seeks to develop optimized testing protocols that account for strain amplitude effects, potentially leading to more reliable and consistent DMA results across different laboratories and testing conditions. Understanding these relationships will enable more precise material characterization and potentially reveal previously undetected phase behaviors in complex materials.

The technological significance of this research extends beyond academic interest, as improved phase transition detection directly impacts quality control in manufacturing, formulation optimization in pharmaceuticals, and performance prediction in advanced materials. By elucidating the fundamental mechanisms by which strain amplitude influences phase transition signals, we anticipate contributing to both theoretical understanding and practical applications of DMA technology.

Current industry trends indicate growing demand for higher precision in material characterization, particularly for emerging materials with complex phase behaviors. This research aligns with these trends by addressing a fundamental methodological question that affects measurement accuracy across multiple industries.

Market Applications of Strain-Sensitive DMA Testing

The strain amplitude sensitivity in Dynamic Mechanical Analysis (DMA) testing has found significant applications across multiple industries, transforming quality control processes and material development workflows. In the aerospace sector, strain-sensitive DMA testing enables manufacturers to evaluate composite materials under varying strain conditions that simulate real-world flight stresses. This capability has proven crucial for detecting phase transitions in polymer matrix composites used in aircraft structures, where material behavior under different strain amplitudes directly impacts safety and performance.

The automotive industry has embraced strain-sensitive DMA testing for evaluating elastomers and thermoplastics used in vibration damping components. By analyzing how different strain amplitudes affect phase transition detection, manufacturers can optimize materials for specific operating conditions, resulting in components with enhanced durability and noise reduction properties. Several major automotive suppliers report up to 15% improvement in component lifespan through strain-optimized material selection.

In the biomedical field, strain-sensitive DMA testing has revolutionized the development of biomaterials for implants and prosthetics. The ability to detect subtle phase transitions at physiologically relevant strain amplitudes allows researchers to develop materials that more closely mimic natural tissue behavior. This application has been particularly valuable for orthopedic implants where material response to cyclic loading determines long-term performance and patient comfort.

The consumer electronics industry utilizes strain-sensitive DMA for developing flexible displays and wearable technology. By understanding how strain amplitude affects phase transitions in polymer films and adhesives, manufacturers can design devices with improved flexibility and durability. This market application has grown substantially with the increasing demand for foldable smartphones and wearable health monitors.

In the construction sector, strain-sensitive DMA testing helps evaluate building materials under various environmental and loading conditions. Manufacturers of structural adhesives and sealants use this technique to ensure their products maintain performance across temperature ranges and mechanical stresses. The ability to detect phase transitions at different strain amplitudes provides critical data for predicting material behavior during seismic events or extreme weather conditions.

The packaging industry has adopted strain-sensitive DMA testing for developing sustainable materials with controlled degradation properties. By analyzing how biodegradable polymers respond to different strain amplitudes, manufacturers can engineer packaging that maintains structural integrity during use but undergoes predictable degradation after disposal. This application supports the growing market demand for environmentally responsible packaging solutions while ensuring product protection during transportation and storage.

The automotive industry has embraced strain-sensitive DMA testing for evaluating elastomers and thermoplastics used in vibration damping components. By analyzing how different strain amplitudes affect phase transition detection, manufacturers can optimize materials for specific operating conditions, resulting in components with enhanced durability and noise reduction properties. Several major automotive suppliers report up to 15% improvement in component lifespan through strain-optimized material selection.

In the biomedical field, strain-sensitive DMA testing has revolutionized the development of biomaterials for implants and prosthetics. The ability to detect subtle phase transitions at physiologically relevant strain amplitudes allows researchers to develop materials that more closely mimic natural tissue behavior. This application has been particularly valuable for orthopedic implants where material response to cyclic loading determines long-term performance and patient comfort.

The consumer electronics industry utilizes strain-sensitive DMA for developing flexible displays and wearable technology. By understanding how strain amplitude affects phase transitions in polymer films and adhesives, manufacturers can design devices with improved flexibility and durability. This market application has grown substantially with the increasing demand for foldable smartphones and wearable health monitors.

In the construction sector, strain-sensitive DMA testing helps evaluate building materials under various environmental and loading conditions. Manufacturers of structural adhesives and sealants use this technique to ensure their products maintain performance across temperature ranges and mechanical stresses. The ability to detect phase transitions at different strain amplitudes provides critical data for predicting material behavior during seismic events or extreme weather conditions.

The packaging industry has adopted strain-sensitive DMA testing for developing sustainable materials with controlled degradation properties. By analyzing how biodegradable polymers respond to different strain amplitudes, manufacturers can engineer packaging that maintains structural integrity during use but undergoes predictable degradation after disposal. This application supports the growing market demand for environmentally responsible packaging solutions while ensuring product protection during transportation and storage.

Current Limitations in Strain Amplitude Methodologies

Despite significant advancements in Dynamic Mechanical Analysis (DMA) techniques, current strain amplitude methodologies face several critical limitations that impact the accuracy and reliability of phase transition detection. The conventional approach of using fixed strain amplitudes across varying temperature ranges fails to account for the dramatic changes in material properties that occur during phase transitions, particularly in polymers and complex composites.

One fundamental limitation is the strain amplitude dependency phenomenon, where different strain amplitudes can yield significantly different transition temperatures for the same material. This creates inconsistency in reported glass transition temperatures (Tg) and other phase transitions across laboratories and testing conditions, making standardization difficult. Research has shown variations of up to 15°C in measured Tg values solely due to differences in applied strain amplitude.

The nonlinear viscoelastic response at higher strain amplitudes presents another significant challenge. While higher amplitudes can improve signal-to-noise ratios, they often push materials beyond their linear viscoelastic region, introducing artifacts and distortions in the measured mechanical response. This nonlinearity becomes particularly problematic near transition regions where material properties are already undergoing rapid changes.

Current methodologies also struggle with the strain amplitude selection paradox. Low strain amplitudes maintain linearity but suffer from poor signal resolution, while high amplitudes provide better signal clarity but introduce nonlinear effects. This trade-off lacks systematic guidelines for optimal amplitude selection based on material type and transition characteristics.

Temperature-dependent strain sensitivity represents another unresolved issue. The optimal strain amplitude for detecting transitions varies with temperature, yet most protocols employ a single amplitude throughout the entire temperature sweep. This one-size-fits-all approach compromises detection sensitivity across different temperature regions.

Instrumentation limitations further compound these challenges. Many commercial DMA systems have limited capabilities for real-time strain amplitude adjustment during temperature sweeps. The hardware and software constraints prevent implementation of adaptive strain amplitude protocols that could potentially overcome many of the aforementioned limitations.

Finally, there exists a significant knowledge gap in correlating molecular dynamics with macroscopic strain responses. The fundamental mechanisms by which strain amplitude influences phase transition detection at the molecular level remain poorly understood, hindering the development of more sophisticated analytical models. This gap is particularly evident in multi-phase materials and nanocomposites, where interfacial effects and phase separation dynamics add layers of complexity to strain amplitude effects.

One fundamental limitation is the strain amplitude dependency phenomenon, where different strain amplitudes can yield significantly different transition temperatures for the same material. This creates inconsistency in reported glass transition temperatures (Tg) and other phase transitions across laboratories and testing conditions, making standardization difficult. Research has shown variations of up to 15°C in measured Tg values solely due to differences in applied strain amplitude.

The nonlinear viscoelastic response at higher strain amplitudes presents another significant challenge. While higher amplitudes can improve signal-to-noise ratios, they often push materials beyond their linear viscoelastic region, introducing artifacts and distortions in the measured mechanical response. This nonlinearity becomes particularly problematic near transition regions where material properties are already undergoing rapid changes.

Current methodologies also struggle with the strain amplitude selection paradox. Low strain amplitudes maintain linearity but suffer from poor signal resolution, while high amplitudes provide better signal clarity but introduce nonlinear effects. This trade-off lacks systematic guidelines for optimal amplitude selection based on material type and transition characteristics.

Temperature-dependent strain sensitivity represents another unresolved issue. The optimal strain amplitude for detecting transitions varies with temperature, yet most protocols employ a single amplitude throughout the entire temperature sweep. This one-size-fits-all approach compromises detection sensitivity across different temperature regions.

Instrumentation limitations further compound these challenges. Many commercial DMA systems have limited capabilities for real-time strain amplitude adjustment during temperature sweeps. The hardware and software constraints prevent implementation of adaptive strain amplitude protocols that could potentially overcome many of the aforementioned limitations.

Finally, there exists a significant knowledge gap in correlating molecular dynamics with macroscopic strain responses. The fundamental mechanisms by which strain amplitude influences phase transition detection at the molecular level remain poorly understood, hindering the development of more sophisticated analytical models. This gap is particularly evident in multi-phase materials and nanocomposites, where interfacial effects and phase separation dynamics add layers of complexity to strain amplitude effects.

Established Protocols for Strain Amplitude Optimization

01 DMA techniques for polymer phase transition detection

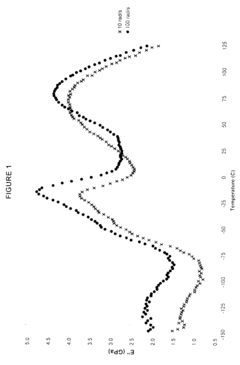

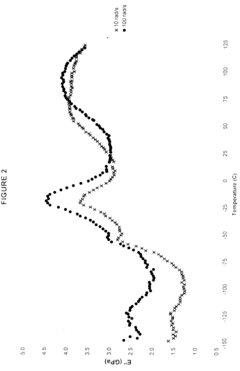

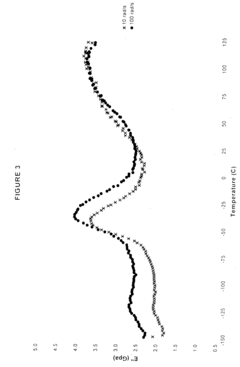

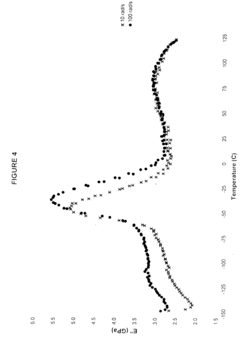

Dynamic Mechanical Analysis (DMA) can be used to detect phase transitions in polymeric materials by measuring changes in mechanical properties as a function of temperature. This technique is particularly effective for identifying glass transitions, melting points, and crystallization behaviors in polymers. The analysis typically involves monitoring storage modulus, loss modulus, and tan delta values, which show significant changes at transition points. These measurements provide valuable information about material structure and performance under various conditions.- DMA techniques for polymer phase transition detection: Dynamic Mechanical Analysis (DMA) can be used to detect phase transitions in polymeric materials by measuring changes in mechanical properties as a function of temperature. This technique is particularly effective for identifying glass transitions, melting points, and other thermal transitions in polymers. The analysis typically involves monitoring storage modulus, loss modulus, and tan delta values, which show significant changes at transition points. These measurements provide valuable information about material behavior under different thermal conditions.

- Temperature control systems for precise DMA measurements: Advanced temperature control systems are essential for accurate phase transition detection using DMA. These systems enable precise heating and cooling rates, temperature stability, and uniform temperature distribution across the sample. Some innovations include multi-zone temperature controllers, rapid thermal response mechanisms, and calibration techniques that minimize thermal gradients. Improved temperature control allows for more reliable detection of subtle phase transitions and enhances the reproducibility of DMA measurements.

- Data analysis methods for phase transition identification: Sophisticated data analysis methods enhance the detection and characterization of phase transitions in DMA results. These include peak detection algorithms, derivative analysis of modulus curves, and statistical methods to identify transition points with high precision. Some approaches incorporate machine learning techniques to automatically recognize patterns associated with different types of transitions. Advanced software solutions can process complex DMA data to extract meaningful information about material phase behavior and transition kinetics.

- Sample preparation and mounting techniques for DMA: Proper sample preparation and mounting are critical for accurate phase transition detection using DMA. Innovations in this area include specialized sample holders, improved clamping mechanisms, and techniques to ensure optimal sample geometry. These advancements help minimize measurement artifacts and ensure that the detected transitions are representative of the material's true behavior. Some methods focus on preparing thin films, fibers, or composite materials in ways that maximize the sensitivity of the DMA measurement to phase transitions.

- Multi-modal characterization combining DMA with other analytical techniques: Combining DMA with complementary analytical techniques provides comprehensive characterization of phase transitions. These integrated approaches may include simultaneous thermal analysis (such as DSC-DMA), spectroscopic methods, or dielectric analysis performed in parallel with mechanical measurements. Such multi-modal characterization allows for correlation between mechanical property changes and other physical or chemical transitions, providing deeper insights into material behavior during phase transitions and enhancing the detection sensitivity for complex materials.

02 Temperature control systems for precise DMA measurements

Advanced temperature control systems are essential for accurate phase transition detection in DMA. These systems enable precise heating and cooling rates, temperature stability, and uniform temperature distribution across samples. Modern DMA instruments incorporate sophisticated temperature chambers, sensors, and feedback control mechanisms to maintain programmed temperature profiles. This precision is critical when detecting subtle phase transitions that occur within narrow temperature ranges or when analyzing materials with complex thermal behaviors.Expand Specific Solutions03 Data analysis methods for phase transition identification

Specialized data analysis methods enhance the detection and characterization of phase transitions in DMA results. These include peak analysis of tan delta curves, inflection point detection in storage modulus data, and derivative analysis techniques. Advanced algorithms can automatically identify transition temperatures and calculate associated parameters such as activation energy. Some systems employ machine learning approaches to recognize patterns indicative of specific types of transitions, improving detection reliability especially for complex materials with multiple or overlapping transitions.Expand Specific Solutions04 Multi-frequency DMA for comprehensive phase analysis

Multi-frequency DMA testing provides more comprehensive characterization of phase transitions than single-frequency methods. By applying oscillatory deformation at multiple frequencies simultaneously or sequentially, researchers can construct frequency-temperature maps that reveal frequency-dependent transitions. This approach helps distinguish between different relaxation processes and phase changes, providing insights into molecular mobility and structural reorganization. The technique is particularly valuable for materials with time-dependent properties or multiple relaxation mechanisms operating at different timescales.Expand Specific Solutions05 Sample preparation and mounting techniques for DMA phase transition studies

Proper sample preparation and mounting are crucial for accurate phase transition detection using DMA. Techniques include precise sample dimensioning, surface preparation, and selection of appropriate clamping geometries (tension, compression, shear, etc.) based on material properties. Special fixtures and sample holders are designed to minimize measurement artifacts and ensure uniform stress distribution. For certain materials, pre-conditioning steps such as drying, annealing, or controlled aging may be necessary to obtain reproducible results and clearly identifiable transition signatures.Expand Specific Solutions

Leading Manufacturers and Research Groups in DMA Technology

The dynamic mechanical analysis (DMA) market is currently in a growth phase, with increasing applications across materials science and engineering. The market size is expanding due to rising demand for advanced material characterization techniques in industries like aerospace, automotive, and pharmaceuticals. Regarding strain amplitude effects on phase transition detection, the technology has reached moderate maturity, with leading players developing increasingly sensitive instruments. Companies like Bruker Nano, PerkinElmer, and Mettler-Toledo lead commercial instrumentation development, while Hitachi High-Tech Science and TA Instruments offer advanced solutions with varying strain amplitude capabilities. Academic institutions including Dartmouth College and New York University contribute significant research, particularly in polymer phase transitions. The competitive landscape shows a balance between established analytical instrument manufacturers and specialized research institutions advancing fundamental understanding of strain-dependent phase behavior.

Bruker Nano, Inc.

Technical Solution: Bruker Nano has developed advanced DMA systems that specifically address strain amplitude effects on phase transition detection. Their technology employs multi-frequency DMA capabilities that allow simultaneous measurement across different strain amplitudes, enabling researchers to identify the critical strain thresholds where phase transitions occur. Their proprietary algorithms can differentiate between linear and non-linear viscoelastic responses, which is crucial for accurate phase transition detection at varying strain amplitudes. Bruker's systems incorporate temperature-modulated DMA techniques that can separate reversible and non-reversible phase transitions while controlling strain amplitude, providing unprecedented insight into material behavior. Their latest instruments feature high-resolution strain control (down to nanometer displacements) with real-time feedback mechanisms that maintain precise strain amplitude throughout temperature ramps, ensuring consistent measurement conditions during phase transitions.

Strengths: Superior resolution in strain control allowing detection of subtle phase transitions; advanced multi-frequency capabilities enabling comprehensive material characterization. Weakness: Higher cost compared to competitors; complex systems require significant expertise to fully utilize all capabilities.

Hitachi High-Tech Science Corp.

Technical Solution: Hitachi High-Tech Science has pioneered strain-controlled DMA technology that specifically addresses the relationship between strain amplitude and phase transition detection. Their systems utilize proprietary "Strain Sweep Intelligence" technology that automatically varies strain amplitude during measurement to identify optimal detection parameters for different material phases. The company's DMA instruments incorporate high-precision force transducers capable of detecting nanoscale changes in material response across a wide range of strain amplitudes (10^-6 to 10^-1). This enables researchers to observe how increasing strain can either enhance visibility of certain transitions or potentially mask others through induced molecular mobility. Hitachi's analysis software includes advanced algorithms that can deconvolute complex responses at different strain amplitudes, helping to distinguish between true phase transitions and strain-induced artifacts. Their technology also features temperature-strain mapping capabilities that generate 3D viscoelastic landscapes showing how phase transitions shift with both temperature and strain amplitude.

Strengths: Exceptional strain amplitude control precision; sophisticated software for distinguishing between true phase transitions and strain-induced phenomena. Weakness: Systems require frequent calibration to maintain accuracy at very low strain amplitudes; limited integration with other analytical techniques.

Critical Patents in Strain-Dependent Phase Transition Detection

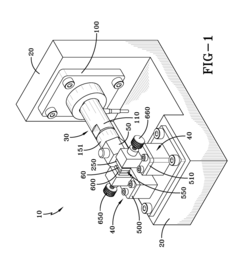

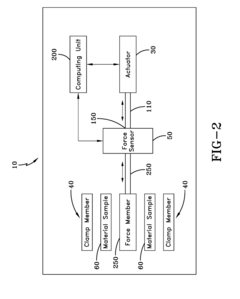

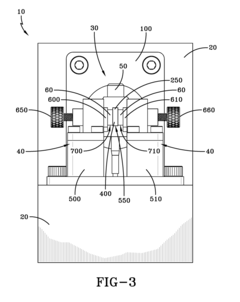

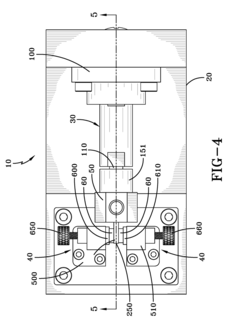

Dynamic mechanical analysis system

PatentActiveUS20190017912A1

Innovation

- A dynamic mechanical analysis system comprising a fixture, an actuator, a force sensor, and an adjustable clamp assembly, where the actuator applies periodic forces between 100 Hz to 10 kHz, allowing for direct measurement of viscoelastic properties with independent strain control, eliminating the need for the Williams, Landel, and Ferry equation.

Drawn gel-spun polyethylene yarns

PatentInactiveUS20070122618A1

Innovation

- Developed polyethylene multi-filament yarns with specific processing conditions, including gel-spinning and drawing techniques, to achieve unique DMA signatures characterized by a low or absent γ-dispersion peak and high integral strength of the β-dispersion, resulting in enhanced ballistic resistance.

Material-Specific Considerations for DMA Testing Parameters

Different materials exhibit unique viscoelastic behaviors that significantly influence DMA testing parameters, particularly when examining phase transitions through strain amplitude variations. Polymers, for instance, demonstrate pronounced sensitivity to strain amplitude due to their complex chain structures and molecular mobility characteristics. Semi-crystalline polymers require careful strain amplitude calibration as excessive strain may disrupt crystalline regions, potentially masking or artificially shifting detected transition temperatures.

Elastomers present another distinct category requiring specialized consideration. These materials typically exhibit significant non-linear behavior even at relatively low strain amplitudes, necessitating preliminary strain sweeps to identify the linear viscoelastic region (LVR) before conducting temperature-dependent measurements. The strain amplitude selection becomes particularly critical near the glass transition temperature where material properties undergo dramatic changes.

Composite materials introduce additional complexity due to their heterogeneous nature. The interface between matrix and reinforcement elements often represents a critical region where strain localization can occur. Testing parameters must account for these structural peculiarities to ensure accurate phase transition detection. Generally, lower strain amplitudes (0.01-0.1%) are recommended for rigid composites to maintain measurement within the LVR.

For amorphous polymers, strain amplitude selection must consider the dramatic stiffness changes occurring through the glass transition. A strain amplitude appropriate for the glassy state may prove insufficient for accurate measurement in the rubbery state. Adaptive testing protocols that modify strain parameters throughout temperature sweeps may provide more consistent results across transition regions.

Crystalline materials and semi-crystalline polymers require particular attention to strain amplitude effects on melting and crystallization transitions. Higher strain amplitudes may induce premature melting through mechanical energy input or disrupt crystallization kinetics during cooling cycles. Conversely, insufficient strain may fail to detect subtle transitions, particularly in materials with complex morphologies or multiple crystalline phases.

Material aging and thermal history also influence optimal testing parameters. Previously processed or thermally cycled materials may exhibit different strain sensitivity compared to virgin materials. This consideration becomes especially important when using DMA for quality control applications where consistent testing parameters are essential for comparative analysis across material batches or processing conditions.

Elastomers present another distinct category requiring specialized consideration. These materials typically exhibit significant non-linear behavior even at relatively low strain amplitudes, necessitating preliminary strain sweeps to identify the linear viscoelastic region (LVR) before conducting temperature-dependent measurements. The strain amplitude selection becomes particularly critical near the glass transition temperature where material properties undergo dramatic changes.

Composite materials introduce additional complexity due to their heterogeneous nature. The interface between matrix and reinforcement elements often represents a critical region where strain localization can occur. Testing parameters must account for these structural peculiarities to ensure accurate phase transition detection. Generally, lower strain amplitudes (0.01-0.1%) are recommended for rigid composites to maintain measurement within the LVR.

For amorphous polymers, strain amplitude selection must consider the dramatic stiffness changes occurring through the glass transition. A strain amplitude appropriate for the glassy state may prove insufficient for accurate measurement in the rubbery state. Adaptive testing protocols that modify strain parameters throughout temperature sweeps may provide more consistent results across transition regions.

Crystalline materials and semi-crystalline polymers require particular attention to strain amplitude effects on melting and crystallization transitions. Higher strain amplitudes may induce premature melting through mechanical energy input or disrupt crystallization kinetics during cooling cycles. Conversely, insufficient strain may fail to detect subtle transitions, particularly in materials with complex morphologies or multiple crystalline phases.

Material aging and thermal history also influence optimal testing parameters. Previously processed or thermally cycled materials may exhibit different strain sensitivity compared to virgin materials. This consideration becomes especially important when using DMA for quality control applications where consistent testing parameters are essential for comparative analysis across material batches or processing conditions.

Data Analysis Algorithms for Enhanced Phase Transition Identification

Data analysis algorithms play a crucial role in enhancing phase transition identification in Dynamic Mechanical Analysis (DMA), particularly when examining how strain amplitude affects these transitions. Traditional signal processing techniques often struggle with the complex data patterns generated during phase transitions under varying strain conditions.

Advanced machine learning algorithms have emerged as powerful tools for identifying subtle phase transition signatures in DMA data. Supervised learning approaches, including support vector machines and random forests, demonstrate remarkable accuracy in classifying transition regions when trained on properly labeled datasets. These algorithms can effectively distinguish between noise and genuine phase transition signals even at challenging strain amplitudes.

Deep learning neural networks represent the cutting edge in phase transition detection algorithms. Convolutional neural networks (CNNs) excel at identifying spatial patterns in DMA response curves, while recurrent neural networks (RNNs) capture the temporal dependencies critical for analyzing dynamic mechanical behavior. Recent research shows that hybrid CNN-RNN architectures achieve superior performance by simultaneously processing both spatial and temporal features of DMA data across different strain amplitudes.

Frequency domain transformation algorithms provide complementary analytical power. Fast Fourier Transform (FFT) and wavelet analysis techniques reveal frequency components that change characteristically during phase transitions. Strain amplitude variations produce distinct frequency signatures that, when properly analyzed, serve as reliable transition markers. Multi-resolution wavelet analysis has proven particularly effective for detecting transitions across multiple strain scales simultaneously.

Statistical pattern recognition algorithms enhance detection reliability through probabilistic approaches. Bayesian inference models can incorporate prior knowledge about material behavior under different strain conditions, improving detection accuracy. Gaussian mixture models effectively separate overlapping transition regions in complex DMA data, while principal component analysis reduces dimensionality to highlight key transition features.

Real-time processing algorithms are increasingly important for industrial applications. Adaptive filtering techniques can dynamically adjust to changing signal characteristics as strain amplitude varies, maintaining detection sensitivity. Edge computing implementations of these algorithms enable immediate phase transition identification during material testing, significantly reducing analysis time and enabling rapid material characterization.

Ensemble methods that combine multiple algorithmic approaches show the most promise for robust phase transition detection across diverse strain conditions. By integrating the strengths of different analytical techniques, these hybrid systems achieve higher accuracy and reliability than any single algorithm, particularly when analyzing materials with complex phase behavior under varying strain amplitudes.

Advanced machine learning algorithms have emerged as powerful tools for identifying subtle phase transition signatures in DMA data. Supervised learning approaches, including support vector machines and random forests, demonstrate remarkable accuracy in classifying transition regions when trained on properly labeled datasets. These algorithms can effectively distinguish between noise and genuine phase transition signals even at challenging strain amplitudes.

Deep learning neural networks represent the cutting edge in phase transition detection algorithms. Convolutional neural networks (CNNs) excel at identifying spatial patterns in DMA response curves, while recurrent neural networks (RNNs) capture the temporal dependencies critical for analyzing dynamic mechanical behavior. Recent research shows that hybrid CNN-RNN architectures achieve superior performance by simultaneously processing both spatial and temporal features of DMA data across different strain amplitudes.

Frequency domain transformation algorithms provide complementary analytical power. Fast Fourier Transform (FFT) and wavelet analysis techniques reveal frequency components that change characteristically during phase transitions. Strain amplitude variations produce distinct frequency signatures that, when properly analyzed, serve as reliable transition markers. Multi-resolution wavelet analysis has proven particularly effective for detecting transitions across multiple strain scales simultaneously.

Statistical pattern recognition algorithms enhance detection reliability through probabilistic approaches. Bayesian inference models can incorporate prior knowledge about material behavior under different strain conditions, improving detection accuracy. Gaussian mixture models effectively separate overlapping transition regions in complex DMA data, while principal component analysis reduces dimensionality to highlight key transition features.

Real-time processing algorithms are increasingly important for industrial applications. Adaptive filtering techniques can dynamically adjust to changing signal characteristics as strain amplitude varies, maintaining detection sensitivity. Edge computing implementations of these algorithms enable immediate phase transition identification during material testing, significantly reducing analysis time and enabling rapid material characterization.

Ensemble methods that combine multiple algorithmic approaches show the most promise for robust phase transition detection across diverse strain conditions. By integrating the strengths of different analytical techniques, these hybrid systems achieve higher accuracy and reliability than any single algorithm, particularly when analyzing materials with complex phase behavior under varying strain amplitudes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!