Comparative study of dynamic mechanical analysis and differential scanning calorimetry

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Analysis Background and Objectives

Thermal analysis techniques have evolved significantly over the past century, becoming essential tools for materials characterization across various industries. Dynamic Mechanical Analysis (DMA) and Differential Scanning Calorimetry (DSC) represent two cornerstone methodologies in this field, each offering unique insights into material properties and behavior under thermal conditions. The historical development of these techniques traces back to the early 20th century, with significant advancements occurring post-1960s when instrumentation technology enabled more precise measurements and broader applications.

The evolution of DMA has been driven by the need to understand viscoelastic properties of materials under dynamic loading conditions. Initially limited to simple stress-strain measurements, modern DMA systems can now characterize complex moduli across wide temperature and frequency ranges. Similarly, DSC has progressed from basic calorimetric measurements to sophisticated systems capable of detecting minute thermal transitions with exceptional sensitivity and reproducibility.

Current technological trends indicate a convergence toward multi-modal analysis systems that combine the strengths of both techniques, allowing for simultaneous measurement of mechanical and thermal properties. This integration represents a significant advancement in comprehensive material characterization methodologies, particularly valuable for complex polymeric systems and composite materials.

The primary objective of comparing DMA and DSC is to establish a comprehensive understanding of their complementary nature in material characterization. While DMA excels in evaluating mechanical responses to thermal changes, DSC provides detailed insights into thermodynamic transitions and reactions. Together, they offer a more complete picture of material behavior than either technique alone.

This comparative study aims to systematically evaluate the fundamental principles, experimental methodologies, data interpretation approaches, and application domains of both techniques. By identifying their respective strengths, limitations, and synergistic potential, we seek to optimize their combined utilization in research and industrial settings.

Additionally, this investigation intends to explore emerging applications where the complementary use of DMA and DSC can address complex material challenges in advanced manufacturing, aerospace, biomedical, and electronic industries. The findings will contribute to establishing best practices for selecting appropriate thermal analysis techniques based on specific material systems and research questions.

The technological goal extends beyond mere comparison to developing integrated analytical frameworks that maximize the informational yield from both techniques, potentially leading to new standards in material characterization protocols and more efficient material development processes.

The evolution of DMA has been driven by the need to understand viscoelastic properties of materials under dynamic loading conditions. Initially limited to simple stress-strain measurements, modern DMA systems can now characterize complex moduli across wide temperature and frequency ranges. Similarly, DSC has progressed from basic calorimetric measurements to sophisticated systems capable of detecting minute thermal transitions with exceptional sensitivity and reproducibility.

Current technological trends indicate a convergence toward multi-modal analysis systems that combine the strengths of both techniques, allowing for simultaneous measurement of mechanical and thermal properties. This integration represents a significant advancement in comprehensive material characterization methodologies, particularly valuable for complex polymeric systems and composite materials.

The primary objective of comparing DMA and DSC is to establish a comprehensive understanding of their complementary nature in material characterization. While DMA excels in evaluating mechanical responses to thermal changes, DSC provides detailed insights into thermodynamic transitions and reactions. Together, they offer a more complete picture of material behavior than either technique alone.

This comparative study aims to systematically evaluate the fundamental principles, experimental methodologies, data interpretation approaches, and application domains of both techniques. By identifying their respective strengths, limitations, and synergistic potential, we seek to optimize their combined utilization in research and industrial settings.

Additionally, this investigation intends to explore emerging applications where the complementary use of DMA and DSC can address complex material challenges in advanced manufacturing, aerospace, biomedical, and electronic industries. The findings will contribute to establishing best practices for selecting appropriate thermal analysis techniques based on specific material systems and research questions.

The technological goal extends beyond mere comparison to developing integrated analytical frameworks that maximize the informational yield from both techniques, potentially leading to new standards in material characterization protocols and more efficient material development processes.

Market Applications and Industry Demand

The market for thermal analysis technologies, particularly Dynamic Mechanical Analysis (DMA) and Differential Scanning Calorimetry (DSC), has experienced substantial growth driven by increasing demand across multiple industries. The global thermal analysis market, which encompasses these technologies, was valued at approximately $1.23 billion in 2021 and is projected to reach $1.8 billion by 2027, growing at a CAGR of 6.5%.

Polymer manufacturing represents the largest application segment for both DMA and DSC technologies. These analytical methods are critical for quality control, material development, and process optimization in industries producing plastics, elastomers, composites, and specialty polymers. The ability to characterize viscoelastic properties through DMA and thermal transitions via DSC provides manufacturers with essential data for product development and performance prediction.

The pharmaceutical and biotechnology sectors have emerged as rapidly growing markets for thermal analysis. DSC is particularly valuable for drug formulation studies, stability testing, and polymorph characterization, while DMA offers insights into the mechanical properties of drug delivery systems and medical devices. Regulatory requirements for thorough material characterization have further accelerated adoption in these industries.

Aerospace and automotive industries rely heavily on both technologies for advanced material development and quality assurance. The trend toward lightweight, high-performance materials has intensified the need for comprehensive thermal and mechanical characterization. DMA's ability to simulate real-world mechanical stresses while monitoring temperature-dependent behavior makes it especially valuable for these applications.

Academic and research institutions constitute a significant market segment, particularly as materials science education and research continue to expand globally. The complementary nature of DMA and DSC makes them essential tools in research laboratories studying structure-property relationships in novel materials.

Regional market analysis reveals North America and Europe as the largest markets for these technologies, with Asia-Pacific showing the fastest growth rate. China, India, and South Korea are experiencing rapid industrialization and increasing investment in R&D infrastructure, driving demand for sophisticated analytical instruments.

Market trends indicate growing interest in combined or hyphenated techniques that offer simultaneous measurement capabilities. Manufacturers are responding with integrated systems that perform both DMA and DSC analyses, providing more comprehensive material characterization in a single experiment. This trend aligns with industry demands for increased efficiency, reduced sample requirements, and more complete data sets.

Polymer manufacturing represents the largest application segment for both DMA and DSC technologies. These analytical methods are critical for quality control, material development, and process optimization in industries producing plastics, elastomers, composites, and specialty polymers. The ability to characterize viscoelastic properties through DMA and thermal transitions via DSC provides manufacturers with essential data for product development and performance prediction.

The pharmaceutical and biotechnology sectors have emerged as rapidly growing markets for thermal analysis. DSC is particularly valuable for drug formulation studies, stability testing, and polymorph characterization, while DMA offers insights into the mechanical properties of drug delivery systems and medical devices. Regulatory requirements for thorough material characterization have further accelerated adoption in these industries.

Aerospace and automotive industries rely heavily on both technologies for advanced material development and quality assurance. The trend toward lightweight, high-performance materials has intensified the need for comprehensive thermal and mechanical characterization. DMA's ability to simulate real-world mechanical stresses while monitoring temperature-dependent behavior makes it especially valuable for these applications.

Academic and research institutions constitute a significant market segment, particularly as materials science education and research continue to expand globally. The complementary nature of DMA and DSC makes them essential tools in research laboratories studying structure-property relationships in novel materials.

Regional market analysis reveals North America and Europe as the largest markets for these technologies, with Asia-Pacific showing the fastest growth rate. China, India, and South Korea are experiencing rapid industrialization and increasing investment in R&D infrastructure, driving demand for sophisticated analytical instruments.

Market trends indicate growing interest in combined or hyphenated techniques that offer simultaneous measurement capabilities. Manufacturers are responding with integrated systems that perform both DMA and DSC analyses, providing more comprehensive material characterization in a single experiment. This trend aligns with industry demands for increased efficiency, reduced sample requirements, and more complete data sets.

Current State and Technical Challenges

Dynamic Mechanical Analysis (DMA) and Differential Scanning Calorimetry (DSC) represent two cornerstone analytical techniques in materials characterization, each with distinct developmental trajectories and current implementation challenges. Globally, these technologies have reached considerable maturity, with widespread adoption across research institutions and industrial settings, yet significant technical hurdles remain.

The current state of DMA technology features advanced instrumentation capable of measuring viscoelastic properties across wide temperature and frequency ranges. Modern DMA systems offer multi-frequency capabilities, enhanced sensitivity, and automated sample handling. However, standardization issues persist across different manufacturer platforms, creating challenges in cross-laboratory result comparison and validation.

DSC technology has similarly evolved with high-sensitivity instruments capable of detecting minute thermal transitions. Contemporary DSC systems incorporate modulated temperature capabilities, ultra-fast scanning rates, and improved baseline stability. The integration of automation and sophisticated software has enhanced data processing capabilities, though interpretation complexity remains a significant challenge.

A critical technical limitation for both technologies involves sample preparation consistency. Minor variations in sample geometry, thermal history, or mounting techniques can significantly impact measurement outcomes, particularly for heterogeneous or anisotropic materials. This challenge is especially pronounced when attempting comparative studies between the two techniques.

Data interpretation represents another substantial hurdle. The correlation between mechanical transitions detected by DMA and thermal events identified by DSC requires sophisticated analytical frameworks that are not yet fully standardized. Researchers often encounter difficulties in establishing direct relationships between viscoelastic responses and calorimetric signatures, particularly for complex polymer systems or composite materials.

Geographical distribution of technical expertise shows concentration in North America, Western Europe, and East Asia, with emerging capabilities in other regions. This uneven distribution creates knowledge gaps and implementation barriers in developing markets.

Recent technological advances have focused on miniaturization, enhanced sensitivity, and integration with complementary techniques. Hyphenated systems combining DMA or DSC with spectroscopic methods represent a promising frontier, though such systems face challenges in data synchronization and interpretation complexity.

The push toward high-throughput screening applications has driven development of multi-sample capabilities, but these advances often come with trade-offs in measurement precision or environmental control. Additionally, extending the operational range of both techniques to extreme conditions (ultra-low temperatures, high pressures, aggressive chemical environments) remains technically challenging despite significant research investment.

The current state of DMA technology features advanced instrumentation capable of measuring viscoelastic properties across wide temperature and frequency ranges. Modern DMA systems offer multi-frequency capabilities, enhanced sensitivity, and automated sample handling. However, standardization issues persist across different manufacturer platforms, creating challenges in cross-laboratory result comparison and validation.

DSC technology has similarly evolved with high-sensitivity instruments capable of detecting minute thermal transitions. Contemporary DSC systems incorporate modulated temperature capabilities, ultra-fast scanning rates, and improved baseline stability. The integration of automation and sophisticated software has enhanced data processing capabilities, though interpretation complexity remains a significant challenge.

A critical technical limitation for both technologies involves sample preparation consistency. Minor variations in sample geometry, thermal history, or mounting techniques can significantly impact measurement outcomes, particularly for heterogeneous or anisotropic materials. This challenge is especially pronounced when attempting comparative studies between the two techniques.

Data interpretation represents another substantial hurdle. The correlation between mechanical transitions detected by DMA and thermal events identified by DSC requires sophisticated analytical frameworks that are not yet fully standardized. Researchers often encounter difficulties in establishing direct relationships between viscoelastic responses and calorimetric signatures, particularly for complex polymer systems or composite materials.

Geographical distribution of technical expertise shows concentration in North America, Western Europe, and East Asia, with emerging capabilities in other regions. This uneven distribution creates knowledge gaps and implementation barriers in developing markets.

Recent technological advances have focused on miniaturization, enhanced sensitivity, and integration with complementary techniques. Hyphenated systems combining DMA or DSC with spectroscopic methods represent a promising frontier, though such systems face challenges in data synchronization and interpretation complexity.

The push toward high-throughput screening applications has driven development of multi-sample capabilities, but these advances often come with trade-offs in measurement precision or environmental control. Additionally, extending the operational range of both techniques to extreme conditions (ultra-low temperatures, high pressures, aggressive chemical environments) remains technically challenging despite significant research investment.

Methodological Approaches in DMA and DSC

01 Thermal characterization techniques for material analysis

Dynamic mechanical analysis (DMA) and differential scanning calorimetry (DSC) are complementary thermal characterization techniques used to analyze material properties. DMA measures the mechanical response of materials under oscillating stress as a function of temperature, while DSC measures heat flow into or out of a sample compared to a reference. Together, these techniques provide comprehensive data on glass transition temperatures, crystallization behavior, melting points, and other thermal events in materials.- Combined DMA and DSC analysis systems: Integrated systems that combine dynamic mechanical analysis (DMA) and differential scanning calorimetry (DSC) capabilities allow for simultaneous measurement of both mechanical properties and thermal transitions of materials. These combined systems provide comprehensive characterization of materials by correlating mechanical behavior with thermal events, offering more complete analysis than either technique alone. Such systems are particularly valuable for polymer research, composite materials development, and quality control applications.

- Material characterization for polymers and composites: DMA and DSC techniques are extensively used for characterizing polymers and composite materials. DMA measures viscoelastic properties including storage modulus, loss modulus, and tan delta as functions of temperature, frequency, or time, while DSC measures heat flow, glass transition temperatures, melting points, and crystallization behavior. Together, these techniques provide critical information about material structure-property relationships, helping to optimize formulations and processing conditions for specific applications.

- Thermal analysis instrumentation advancements: Recent advancements in thermal analysis instrumentation have improved the sensitivity, accuracy, and automation of DMA and DSC measurements. These innovations include enhanced temperature control systems, more sensitive sensors, automated sample handling, and improved data analysis software. Modern instruments offer higher resolution, better reproducibility, and the ability to analyze smaller samples, enabling researchers to detect subtle thermal transitions and mechanical property changes that were previously difficult to measure.

- Quality control and failure analysis applications: DMA and DSC are valuable tools for quality control and failure analysis in manufacturing environments. These techniques can identify material inconsistencies, detect contamination, verify curing processes, and investigate product failures. By establishing baseline thermal and mechanical profiles for materials, manufacturers can quickly identify deviations that might affect product performance. This application is particularly important in industries with strict quality requirements, such as aerospace, automotive, and medical device manufacturing.

- Novel materials development and characterization: DMA and DSC play crucial roles in the development and characterization of novel materials, including smart polymers, nanomaterials, and biomaterials. These analytical techniques help researchers understand structure-property relationships, optimize material formulations, and predict performance under various conditions. By providing insights into thermal transitions, crystallinity, crosslinking density, and mechanical behavior, DMA and DSC facilitate the design of materials with tailored properties for specific applications in fields ranging from electronics to medicine.

02 Polymer and composite material characterization

DMA and DSC are widely used for characterizing polymers and composite materials. DMA provides information about viscoelastic properties, including storage modulus, loss modulus, and tan delta, while DSC reveals phase transitions and thermal stability. These techniques help in understanding structure-property relationships, curing behavior, and thermal degradation mechanisms in polymers and composites, which is crucial for product development and quality control.Expand Specific Solutions03 Integrated DMA-DSC systems and equipment

Advanced analytical systems that integrate DMA and DSC capabilities allow for simultaneous measurement of mechanical and thermal properties. These integrated systems provide correlated data from a single sample under identical conditions, improving efficiency and data reliability. The equipment typically includes temperature-controlled chambers, sensitive force transducers, and precise heat flow sensors, enabling accurate characterization across a wide temperature range.Expand Specific Solutions04 Applications in pharmaceutical and biomedical research

DMA and DSC techniques are valuable tools in pharmaceutical and biomedical research for characterizing drug formulations, biomaterials, and medical devices. These methods help in determining drug-polymer compatibility, stability of formulations, protein denaturation, and phase behavior of biological materials. The thermal and mechanical property data obtained assist in developing stable drug delivery systems and biocompatible materials with desired performance characteristics.Expand Specific Solutions05 Quality control and failure analysis applications

DMA and DSC are essential techniques for quality control and failure analysis in manufacturing processes. These methods can detect subtle changes in material properties that might indicate processing issues, contamination, or degradation. By establishing thermal and mechanical property profiles of materials, manufacturers can ensure consistency in raw materials and finished products, identify root causes of failures, and optimize processing parameters to enhance product performance and reliability.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The dynamic mechanical analysis (DMA) and differential scanning calorimetry (DSC) market is currently in a mature growth phase, with an estimated global market size of $500-600 million annually. The competitive landscape features established analytical instrument manufacturers like Netzsch Gerätebau GmbH, Hitachi High-Tech Science Corp., and Mettler-Toledo GmbH dominating the high-end segment, while companies such as Malvern Panalytical and Waters Technology Corp. offer specialized solutions. The technology has reached high maturity in pharmaceutical and materials science applications, evidenced by adoption from AbbVie, Abbott Laboratories, and Sunshine Lake Pharma. Recent innovations focus on integration with other analytical techniques and automation capabilities, with Revvity (formerly PerkinElmer) and Seiko Instruments developing next-generation systems featuring enhanced sensitivity and data analysis capabilities for advanced material characterization.

Hitachi High-Tech Science Corp.

Technical Solution: Hitachi High-Tech Science has developed the EXSTAR series that integrates both DMA and DSC capabilities with advanced comparative analysis features. Their DMA7100 system offers multi-frequency capabilities (0.01-100Hz) with temperature ranges from -150°C to 600°C, while their DSC7000X provides sensitivity of 0.1μW and temperature precision of ±0.1K[5]. Their proprietary MUSE software platform enables direct overlay and correlation of DMA modulus data with DSC thermal transitions, particularly useful for analyzing complex polymer systems. Hitachi has pioneered techniques for separating reversing and non-reversing components in both DMA and DSC measurements, allowing more detailed comparison of thermodynamic versus kinetic aspects of material transitions[6]. Their research has focused on correlating mechanical relaxations detected by DMA with enthalpic relaxations measured by DSC to provide comprehensive characterization of amorphous materials, particularly for pharmaceutical stability studies and polymer aging investigations.

Strengths: Excellent integration between different thermal analysis techniques; strong software capabilities for direct data comparison; high sensitivity in both DMA and DSC measurements; strong presence in Asian markets. Weaknesses: Less market penetration in Western countries compared to European competitors; some advanced comparative features require additional software modules.

Netzsch Gerätebau GmbH

Technical Solution: Netzsch has developed comprehensive thermal analysis solutions integrating both DMA and DSC technologies. Their NETZSCH Kinetics Neo software enables advanced comparative analysis between DMA and DSC data for material characterization. Their DMA instruments feature a wide temperature range (-170°C to 600°C) with multiple deformation modes (tension, compression, bending) and frequency ranges from 0.01 Hz to 100 Hz[1]. Their DSC instruments offer high resolution (0.1 μW) and temperature precision (±0.1K). Netzsch's approach emphasizes correlative analysis between DMA's viscoelastic properties measurement and DSC's thermal transition detection, particularly for polymer characterization where they've developed protocols for comparing glass transition temperatures obtained by both methods[2]. Their Proteus software platform enables direct comparison of modulus changes from DMA with heat flow changes from DSC to establish comprehensive structure-property relationships.

Strengths: Industry-leading temperature range and resolution in both DMA and DSC instruments; sophisticated software for direct comparative analysis; extensive experience in polymer characterization. Weaknesses: Higher price point compared to competitors; complex software may require specialized training; some instruments require separate modules for full comparative capabilities.

Key Technical Principles and Innovations

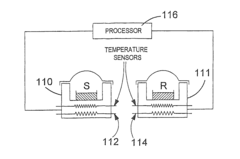

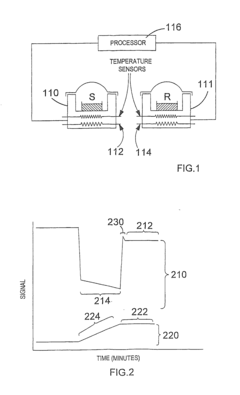

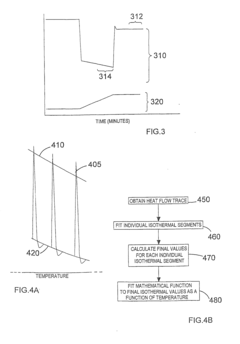

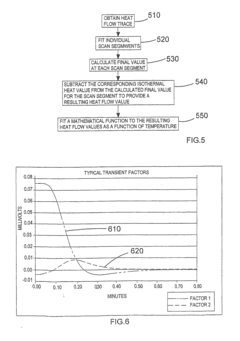

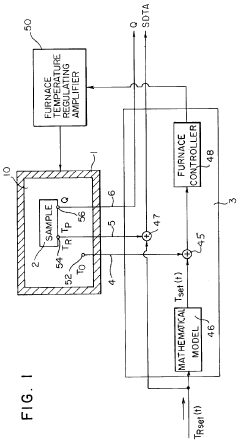

Differential scanning calorimetry and calibration methods for use therewith

PatentInactiveUS20110313713A1

Innovation

- A method involving a processor that calculates and subtracts a baseline from heat flow traces, using mathematical functions to represent isothermal, scanned, and transient components, allowing for a more flexible and accurate baseline correction that adapts to changes in scan conditions, including the use of fifth-order polynomials and principal components analysis to analyze transient components.

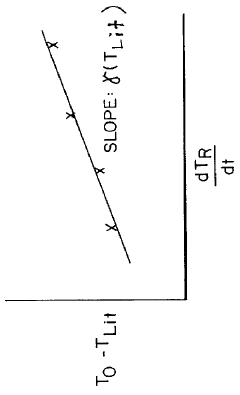

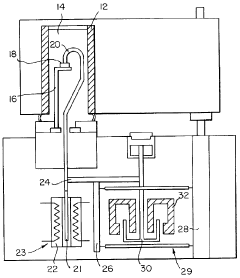

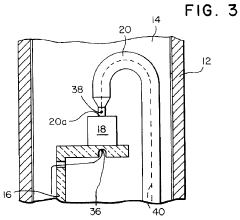

Differential thermal analysis system including dynamic mechanical analysis

PatentInactiveUS6146013A

Innovation

- The implementation of Single Differential Thermal Analysis (SDTA) where the temperature behavior of the reference and sample are determined at the same spot, using identical heating and temperature measurement probes, and a mathematical model to account for the thermal analysis apparatus behavior, allowing for simultaneous measurement of temperature and physical properties without the need for adjacent pans.

Instrumentation and Hardware Considerations

The instrumentation for Dynamic Mechanical Analysis (DMA) and Differential Scanning Calorimetry (DSC) represents a critical aspect of their comparative performance and application suitability. DMA instruments typically consist of a force generator, displacement sensor, temperature control system, and sample holder. Modern DMA systems employ linear variable differential transformers (LVDTs) for precise displacement measurement with resolutions down to nanometers, enabling accurate determination of viscoelastic properties across a wide frequency range (0.01-200 Hz).

The force generation mechanisms in DMA vary between manufacturers, with electromagnetic motors providing superior control for sinusoidal deformation patterns compared to older mechanical systems. Temperature control systems in advanced DMA instruments can achieve stability within ±0.1°C across operating ranges from -150°C to 600°C, utilizing liquid nitrogen cooling systems for sub-ambient testing and resistive heating elements for elevated temperatures.

DSC instrumentation, by contrast, employs either heat flux or power compensation designs. Heat flux DSC systems measure temperature differences between sample and reference materials under identical heat flow conditions, while power compensation designs maintain identical temperatures by varying the power input. Modern DSC instruments feature platinum resistance thermometers capable of temperature resolution to 0.01°C and calorimetric sensitivity approaching 0.2 μW.

Sample holders represent another significant hardware distinction. DMA typically employs various geometries (tension, compression, cantilever, shear) requiring specific fixtures, while DSC utilizes standardized aluminum or ceramic pans with volumes ranging from 10-100 μL. This difference impacts sample preparation requirements and experimental versatility.

Data acquisition systems also differ substantially between techniques. DMA requires simultaneous high-speed sampling of force, displacement, and phase angle measurements, necessitating sophisticated signal processing to extract complex modulus values. DSC systems prioritize thermal stability and baseline correction algorithms to isolate true thermal events from instrumental artifacts.

Calibration procedures represent another critical hardware consideration. DMA requires mechanical calibration using standard materials with known moduli, while DSC demands temperature and enthalpy calibration using high-purity reference materials. The frequency of calibration and calibration drift characteristics significantly impact measurement reliability and cross-laboratory reproducibility for both techniques.

Recent hardware innovations include combined DMA-DSC instruments that simultaneously measure mechanical and thermal properties, though these hybrid systems typically sacrifice some measurement sensitivity compared to dedicated instruments. The selection between standalone or combined instrumentation depends on specific research objectives and required measurement precision.

The force generation mechanisms in DMA vary between manufacturers, with electromagnetic motors providing superior control for sinusoidal deformation patterns compared to older mechanical systems. Temperature control systems in advanced DMA instruments can achieve stability within ±0.1°C across operating ranges from -150°C to 600°C, utilizing liquid nitrogen cooling systems for sub-ambient testing and resistive heating elements for elevated temperatures.

DSC instrumentation, by contrast, employs either heat flux or power compensation designs. Heat flux DSC systems measure temperature differences between sample and reference materials under identical heat flow conditions, while power compensation designs maintain identical temperatures by varying the power input. Modern DSC instruments feature platinum resistance thermometers capable of temperature resolution to 0.01°C and calorimetric sensitivity approaching 0.2 μW.

Sample holders represent another significant hardware distinction. DMA typically employs various geometries (tension, compression, cantilever, shear) requiring specific fixtures, while DSC utilizes standardized aluminum or ceramic pans with volumes ranging from 10-100 μL. This difference impacts sample preparation requirements and experimental versatility.

Data acquisition systems also differ substantially between techniques. DMA requires simultaneous high-speed sampling of force, displacement, and phase angle measurements, necessitating sophisticated signal processing to extract complex modulus values. DSC systems prioritize thermal stability and baseline correction algorithms to isolate true thermal events from instrumental artifacts.

Calibration procedures represent another critical hardware consideration. DMA requires mechanical calibration using standard materials with known moduli, while DSC demands temperature and enthalpy calibration using high-purity reference materials. The frequency of calibration and calibration drift characteristics significantly impact measurement reliability and cross-laboratory reproducibility for both techniques.

Recent hardware innovations include combined DMA-DSC instruments that simultaneously measure mechanical and thermal properties, though these hybrid systems typically sacrifice some measurement sensitivity compared to dedicated instruments. The selection between standalone or combined instrumentation depends on specific research objectives and required measurement precision.

Data Analysis and Interpretation Methodologies

The analysis of data from Dynamic Mechanical Analysis (DMA) and Differential Scanning Calorimetry (DSC) requires sophisticated methodologies to extract meaningful insights. These complementary techniques generate distinct data types that necessitate different processing approaches while offering opportunities for integrated interpretation.

Raw data from DMA typically includes storage modulus (E'), loss modulus (E"), and tan delta values across temperature or frequency ranges. The primary challenge lies in noise reduction and baseline correction, particularly at transition regions. Modern software packages employ Savitzky-Golay filtering algorithms to smooth data while preserving peak characteristics. For multi-frequency DMA data, time-temperature superposition principles allow construction of master curves that extend the observable mechanical response range.

DSC data processing focuses on heat flow measurements, requiring careful baseline subtraction and calibration against standard materials. Integration of endothermic and exothermic peaks provides quantitative information about transition enthalpies, while peak temperatures indicate transition points. Deconvolution techniques have become increasingly important for resolving overlapping thermal events, with advanced algorithms capable of separating complex transitions into constituent components.

Statistical analysis methods play a crucial role in both techniques. Principal Component Analysis (PCA) and cluster analysis help identify patterns across multiple samples, while machine learning algorithms increasingly assist in identifying subtle correlations between mechanical and thermal properties. These approaches are particularly valuable when analyzing complex polymer blends or composites with multiple phase transitions.

Correlation methodologies between DMA and DSC data represent a significant advancement in materials characterization. Cross-correlation functions can identify relationships between mechanical transitions observed in DMA and thermal events detected by DSC. This integrated approach provides more comprehensive material characterization than either technique alone, particularly for identifying secondary transitions that may be prominent in one technique but subtle in another.

Interpretation frameworks have evolved to connect experimental data to theoretical models. For polymeric materials, the Williams-Landel-Ferry (WLF) equation and Arrhenius relationships help translate temperature-dependent data into activation energy parameters. For semi-crystalline materials, two-phase models incorporating both amorphous and crystalline regions provide frameworks for interpreting complex transition behaviors observed across both techniques.

Recent developments include real-time data processing algorithms that enable in-situ analysis during experiments, facilitating adaptive testing protocols that can automatically adjust parameters based on observed transition regions. Cloud-based platforms now support collaborative analysis across research teams, with standardized data formats enabling more consistent interpretation methodologies across different laboratories.

Raw data from DMA typically includes storage modulus (E'), loss modulus (E"), and tan delta values across temperature or frequency ranges. The primary challenge lies in noise reduction and baseline correction, particularly at transition regions. Modern software packages employ Savitzky-Golay filtering algorithms to smooth data while preserving peak characteristics. For multi-frequency DMA data, time-temperature superposition principles allow construction of master curves that extend the observable mechanical response range.

DSC data processing focuses on heat flow measurements, requiring careful baseline subtraction and calibration against standard materials. Integration of endothermic and exothermic peaks provides quantitative information about transition enthalpies, while peak temperatures indicate transition points. Deconvolution techniques have become increasingly important for resolving overlapping thermal events, with advanced algorithms capable of separating complex transitions into constituent components.

Statistical analysis methods play a crucial role in both techniques. Principal Component Analysis (PCA) and cluster analysis help identify patterns across multiple samples, while machine learning algorithms increasingly assist in identifying subtle correlations between mechanical and thermal properties. These approaches are particularly valuable when analyzing complex polymer blends or composites with multiple phase transitions.

Correlation methodologies between DMA and DSC data represent a significant advancement in materials characterization. Cross-correlation functions can identify relationships between mechanical transitions observed in DMA and thermal events detected by DSC. This integrated approach provides more comprehensive material characterization than either technique alone, particularly for identifying secondary transitions that may be prominent in one technique but subtle in another.

Interpretation frameworks have evolved to connect experimental data to theoretical models. For polymeric materials, the Williams-Landel-Ferry (WLF) equation and Arrhenius relationships help translate temperature-dependent data into activation energy parameters. For semi-crystalline materials, two-phase models incorporating both amorphous and crystalline regions provide frameworks for interpreting complex transition behaviors observed across both techniques.

Recent developments include real-time data processing algorithms that enable in-situ analysis during experiments, facilitating adaptive testing protocols that can automatically adjust parameters based on observed transition regions. Cloud-based platforms now support collaborative analysis across research teams, with standardized data formats enabling more consistent interpretation methodologies across different laboratories.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!