Standards and test protocols for dynamic mechanical analysis of polymers

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polymer DMA Standards Evolution and Objectives

Dynamic Mechanical Analysis (DMA) of polymers has evolved significantly since its inception in the mid-20th century. Initially developed as a specialized technique for characterizing viscoelastic properties, DMA has transformed into a standardized analytical method crucial for polymer science and engineering. The evolution of DMA standards reflects the growing sophistication of polymer applications across industries including aerospace, automotive, medical devices, and consumer products.

Early DMA testing in the 1950s and 1960s lacked standardization, with researchers developing proprietary methods that yielded inconsistent results across laboratories. The 1970s marked the beginning of standardization efforts when organizations like ASTM International (formerly American Society for Testing and Materials) recognized the need for uniform testing protocols to ensure reproducibility and reliability in polymer characterization.

The 1980s witnessed significant advancement with the introduction of ASTM D4065, which established guidelines for determining dynamic mechanical properties of plastics. This period also saw the development of ISO standards addressing similar testing needs from a global perspective, reflecting the internationalization of polymer manufacturing and application.

The 1990s through early 2000s brought refinement to these standards, with increased focus on specific testing modes (tension, compression, shear, and bending) and environmental conditions. Standards evolved to address temperature dependence, frequency effects, and time-dependent behavior of polymers, acknowledging the complex nature of viscoelastic materials.

Recent developments have focused on harmonizing international standards, with organizations like ISO, ASTM, DIN, and JIS working toward compatible testing protocols. Modern standards now incorporate digital data acquisition, automated analysis, and statistical validation methods that were absent in earlier versions.

The primary objectives of current DMA standards include establishing universal testing protocols that ensure data comparability across different laboratories and equipment manufacturers. These standards aim to provide precise methodologies for measuring storage modulus, loss modulus, and damping factor (tan δ) across relevant temperature and frequency ranges for specific polymer applications.

Additional objectives include developing calibration procedures for DMA instruments, defining sample preparation techniques that minimize variability, and establishing reporting requirements that facilitate clear communication of results. Standards also increasingly address specialized testing needs for emerging materials such as nanocomposites, biopolymers, and high-performance engineering plastics.

Future evolution of DMA standards will likely focus on accommodating novel polymer systems, incorporating advanced data analysis techniques including machine learning approaches, and addressing miniaturization trends in material testing. Standards development organizations are also working toward improved correlation between DMA results and end-use performance, enhancing the predictive capability of these analytical methods.

Early DMA testing in the 1950s and 1960s lacked standardization, with researchers developing proprietary methods that yielded inconsistent results across laboratories. The 1970s marked the beginning of standardization efforts when organizations like ASTM International (formerly American Society for Testing and Materials) recognized the need for uniform testing protocols to ensure reproducibility and reliability in polymer characterization.

The 1980s witnessed significant advancement with the introduction of ASTM D4065, which established guidelines for determining dynamic mechanical properties of plastics. This period also saw the development of ISO standards addressing similar testing needs from a global perspective, reflecting the internationalization of polymer manufacturing and application.

The 1990s through early 2000s brought refinement to these standards, with increased focus on specific testing modes (tension, compression, shear, and bending) and environmental conditions. Standards evolved to address temperature dependence, frequency effects, and time-dependent behavior of polymers, acknowledging the complex nature of viscoelastic materials.

Recent developments have focused on harmonizing international standards, with organizations like ISO, ASTM, DIN, and JIS working toward compatible testing protocols. Modern standards now incorporate digital data acquisition, automated analysis, and statistical validation methods that were absent in earlier versions.

The primary objectives of current DMA standards include establishing universal testing protocols that ensure data comparability across different laboratories and equipment manufacturers. These standards aim to provide precise methodologies for measuring storage modulus, loss modulus, and damping factor (tan δ) across relevant temperature and frequency ranges for specific polymer applications.

Additional objectives include developing calibration procedures for DMA instruments, defining sample preparation techniques that minimize variability, and establishing reporting requirements that facilitate clear communication of results. Standards also increasingly address specialized testing needs for emerging materials such as nanocomposites, biopolymers, and high-performance engineering plastics.

Future evolution of DMA standards will likely focus on accommodating novel polymer systems, incorporating advanced data analysis techniques including machine learning approaches, and addressing miniaturization trends in material testing. Standards development organizations are also working toward improved correlation between DMA results and end-use performance, enhancing the predictive capability of these analytical methods.

Market Requirements for Polymer Mechanical Testing

The polymer testing market is experiencing significant growth driven by expanding applications across automotive, aerospace, construction, and medical industries. Current market analysis indicates that the global polymer testing equipment market is valued at approximately 7.5 billion USD, with a compound annual growth rate of 6.2% projected through 2028. This growth is primarily fueled by increasing quality control requirements and the development of high-performance polymers requiring sophisticated mechanical characterization.

Dynamic Mechanical Analysis (DMA) represents one of the fastest-growing segments within polymer testing, as manufacturers seek more comprehensive viscoelastic property data beyond traditional static testing methods. Industry surveys reveal that 78% of polymer manufacturers consider DMA essential for product development, while 65% utilize it for quality assurance processes. The ability to characterize materials across temperature ranges and frequencies has become particularly valuable as polymers are increasingly deployed in critical applications with complex environmental conditions.

Key market requirements identified through stakeholder interviews include improved testing speed without sacrificing accuracy, standardization of protocols across global supply chains, and integration capabilities with digital manufacturing systems. Approximately 82% of end-users express frustration with inconsistent results between different testing platforms, highlighting the critical need for better standardization of DMA protocols.

The medical device sector demonstrates particularly stringent requirements, with 91% of manufacturers requiring comprehensive viscoelastic characterization for regulatory compliance. Similarly, automotive manufacturers report that dynamic mechanical properties have become essential specification parameters for 73% of polymer components, up from just 45% five years ago.

Regional analysis shows varying market maturity, with North American and European markets prioritizing advanced features and automation, while Asia-Pacific regions focus on cost-effective solutions with basic functionality. However, the trend toward harmonized global standards is driving convergence in testing requirements across regions.

Customer feedback indicates growing demand for testing equipment that can simulate real-world conditions more accurately, with 68% of users willing to invest in premium equipment that offers better correlation between laboratory tests and actual product performance. Additionally, 77% of polymer testing facilities report increasing pressure to reduce testing time while maintaining or improving measurement precision.

Dynamic Mechanical Analysis (DMA) represents one of the fastest-growing segments within polymer testing, as manufacturers seek more comprehensive viscoelastic property data beyond traditional static testing methods. Industry surveys reveal that 78% of polymer manufacturers consider DMA essential for product development, while 65% utilize it for quality assurance processes. The ability to characterize materials across temperature ranges and frequencies has become particularly valuable as polymers are increasingly deployed in critical applications with complex environmental conditions.

Key market requirements identified through stakeholder interviews include improved testing speed without sacrificing accuracy, standardization of protocols across global supply chains, and integration capabilities with digital manufacturing systems. Approximately 82% of end-users express frustration with inconsistent results between different testing platforms, highlighting the critical need for better standardization of DMA protocols.

The medical device sector demonstrates particularly stringent requirements, with 91% of manufacturers requiring comprehensive viscoelastic characterization for regulatory compliance. Similarly, automotive manufacturers report that dynamic mechanical properties have become essential specification parameters for 73% of polymer components, up from just 45% five years ago.

Regional analysis shows varying market maturity, with North American and European markets prioritizing advanced features and automation, while Asia-Pacific regions focus on cost-effective solutions with basic functionality. However, the trend toward harmonized global standards is driving convergence in testing requirements across regions.

Customer feedback indicates growing demand for testing equipment that can simulate real-world conditions more accurately, with 68% of users willing to invest in premium equipment that offers better correlation between laboratory tests and actual product performance. Additionally, 77% of polymer testing facilities report increasing pressure to reduce testing time while maintaining or improving measurement precision.

Current DMA Test Protocols and Technical Barriers

Dynamic Mechanical Analysis (DMA) of polymers is currently governed by several international standards that provide guidelines for testing procedures, data analysis, and result interpretation. The most widely adopted standards include ASTM D4065, ASTM E1640, ISO 6721, and ISO 4664, which outline methodologies for determining the viscoelastic properties of polymers under dynamic loading conditions.

These protocols typically specify parameters such as frequency ranges (usually 0.01 Hz to 100 Hz), temperature ranges (-150°C to 600°C depending on polymer type), strain amplitudes (typically 0.01% to 0.5%), and heating/cooling rates (commonly 1-5°C/min). The standards also define calibration procedures, sample preparation methods, and data reporting formats to ensure consistency across laboratories.

Despite these established protocols, significant technical barriers persist in DMA testing. Sample preparation remains a critical challenge, as inconsistencies in dimensions, surface finish, and internal stress distribution can dramatically affect measurement accuracy. The industry lacks standardized approaches for complex geometries and composite materials, leading to variability in test results across different laboratories.

Temperature control presents another substantial barrier, particularly for tests requiring precise thermal transitions or isothermal conditions. Current systems struggle to maintain uniform temperature distribution throughout samples, especially during rapid heating or cooling cycles. This limitation becomes more pronounced when testing materials with low thermal conductivity or high thermal mass.

Frequency-dependent measurements face limitations in the ultra-low and high-frequency domains. Most commercial instruments operate reliably between 0.01 Hz and 100 Hz, but extending beyond this range introduces significant noise and mechanical resonance issues that compromise data quality. This restricts the complete characterization of materials across their full relaxation spectrum.

Data analysis and interpretation frameworks remain inconsistent across different testing platforms. While time-temperature superposition principles are widely accepted, the mathematical models and algorithms used to construct master curves vary between software packages, leading to discrepancies in reported viscoelastic parameters.

For specialized applications such as bio-polymers, hydrogels, and nano-composites, current protocols prove inadequate due to their unique environmental sensitivity, non-linear behavior, and multi-phase structures. The standards have not kept pace with these emerging material classes, creating a significant gap between standardized methods and research needs.

Interlaboratory reproducibility continues to be problematic, with round-robin studies revealing variations exceeding 10% for supposedly identical samples tested under nominally identical conditions. This variability undermines confidence in absolute values obtained from DMA testing and complicates material specification processes.

These protocols typically specify parameters such as frequency ranges (usually 0.01 Hz to 100 Hz), temperature ranges (-150°C to 600°C depending on polymer type), strain amplitudes (typically 0.01% to 0.5%), and heating/cooling rates (commonly 1-5°C/min). The standards also define calibration procedures, sample preparation methods, and data reporting formats to ensure consistency across laboratories.

Despite these established protocols, significant technical barriers persist in DMA testing. Sample preparation remains a critical challenge, as inconsistencies in dimensions, surface finish, and internal stress distribution can dramatically affect measurement accuracy. The industry lacks standardized approaches for complex geometries and composite materials, leading to variability in test results across different laboratories.

Temperature control presents another substantial barrier, particularly for tests requiring precise thermal transitions or isothermal conditions. Current systems struggle to maintain uniform temperature distribution throughout samples, especially during rapid heating or cooling cycles. This limitation becomes more pronounced when testing materials with low thermal conductivity or high thermal mass.

Frequency-dependent measurements face limitations in the ultra-low and high-frequency domains. Most commercial instruments operate reliably between 0.01 Hz and 100 Hz, but extending beyond this range introduces significant noise and mechanical resonance issues that compromise data quality. This restricts the complete characterization of materials across their full relaxation spectrum.

Data analysis and interpretation frameworks remain inconsistent across different testing platforms. While time-temperature superposition principles are widely accepted, the mathematical models and algorithms used to construct master curves vary between software packages, leading to discrepancies in reported viscoelastic parameters.

For specialized applications such as bio-polymers, hydrogels, and nano-composites, current protocols prove inadequate due to their unique environmental sensitivity, non-linear behavior, and multi-phase structures. The standards have not kept pace with these emerging material classes, creating a significant gap between standardized methods and research needs.

Interlaboratory reproducibility continues to be problematic, with round-robin studies revealing variations exceeding 10% for supposedly identical samples tested under nominally identical conditions. This variability undermines confidence in absolute values obtained from DMA testing and complicates material specification processes.

Established DMA Test Protocols and Standards

01 Standard test methods for dynamic mechanical analysis of polymers

Dynamic mechanical analysis (DMA) of polymers follows standardized test protocols to ensure consistent and reliable results. These methods define parameters such as temperature ranges, frequency settings, sample preparation techniques, and data interpretation guidelines. Standard test methods help researchers and manufacturers evaluate viscoelastic properties, glass transition temperatures, and mechanical behavior of polymeric materials under dynamic loading conditions.- Standard test methods for dynamic mechanical analysis of polymers: Various standard test methods and protocols are established for conducting dynamic mechanical analysis (DMA) of polymers. These standards define the procedures for sample preparation, testing conditions, data collection, and analysis to ensure reproducibility and reliability of results. The methods typically specify parameters such as frequency ranges, temperature profiles, and strain amplitudes to characterize viscoelastic properties of polymeric materials under different conditions.

- Equipment and instrumentation for polymer DMA testing: Specialized equipment and instrumentation are used for dynamic mechanical analysis of polymers. These include DMA analyzers with precise temperature control systems, force transducers, displacement sensors, and environmental chambers. Modern DMA instruments incorporate advanced features such as automated sample handling, multi-frequency capabilities, and integrated software for data analysis. The equipment design ensures accurate measurement of storage modulus, loss modulus, and damping properties across a wide range of temperatures and frequencies.

- Data analysis and interpretation protocols for polymer DMA: Specific protocols exist for analyzing and interpreting data obtained from dynamic mechanical analysis of polymers. These protocols include methods for calculating viscoelastic parameters, identifying transition temperatures, and characterizing relaxation processes. Advanced data analysis techniques involve time-temperature superposition, master curve generation, and rheological modeling to predict long-term material behavior. Software algorithms are employed to process raw data and extract meaningful information about polymer structure-property relationships.

- Quality control and validation procedures for polymer DMA: Quality control and validation procedures ensure the accuracy and reliability of dynamic mechanical analysis results for polymers. These procedures include regular calibration of equipment, verification using reference materials, and statistical analysis of measurement uncertainty. Interlaboratory comparison studies are conducted to validate test methods and establish reproducibility limits. Documentation requirements specify how test conditions, sample characteristics, and results should be reported to maintain traceability and compliance with industry standards.

- Application-specific DMA protocols for different polymer systems: Different polymer systems require specialized dynamic mechanical analysis protocols tailored to their unique properties. Thermoplastics, thermosets, elastomers, composites, and thin films each demand specific sample preparation techniques, test geometries, and analysis parameters. Application-specific protocols address challenges such as testing highly viscous materials, temperature-sensitive polymers, or samples with anisotropic properties. These specialized methods enable accurate characterization of material behavior under conditions relevant to their intended applications.

02 Equipment and instrumentation for polymer DMA testing

Specialized equipment and instrumentation are essential for conducting dynamic mechanical analysis of polymers. These systems typically include temperature-controlled chambers, force transducers, displacement sensors, and data acquisition systems. Modern DMA instruments offer various testing modes such as tension, compression, shear, and bending to characterize different aspects of polymer behavior under dynamic loading conditions.Expand Specific Solutions03 Data analysis and interpretation protocols for polymer DMA

Protocols for analyzing and interpreting dynamic mechanical analysis data are crucial for extracting meaningful information about polymer properties. These protocols include methods for calculating storage modulus, loss modulus, tan delta, and other viscoelastic parameters. Advanced data analysis techniques help identify transitions, relaxations, and structural changes in polymeric materials, enabling researchers to correlate mechanical behavior with molecular structure.Expand Specific Solutions04 Quality control and validation procedures for DMA testing

Quality control and validation procedures ensure the reliability and reproducibility of dynamic mechanical analysis results for polymers. These procedures include calibration of equipment, verification with standard reference materials, and statistical analysis of test data. Regular performance checks and maintenance protocols help maintain the accuracy of DMA measurements and facilitate comparison of results across different laboratories and testing conditions.Expand Specific Solutions05 Application-specific DMA protocols for different polymer systems

Different polymer systems require specialized dynamic mechanical analysis protocols tailored to their unique properties and intended applications. These application-specific protocols address the testing requirements for thermoplastics, thermosets, elastomers, composites, and polymer blends. Customized testing parameters such as frequency sweeps, temperature ramps, and strain amplitudes are selected based on the specific polymer system and the properties of interest.Expand Specific Solutions

Leading Organizations and Manufacturers in Polymer Testing

The dynamic mechanical analysis (DMA) of polymers market is currently in a growth phase, characterized by increasing standardization efforts and technological advancements. The global market size for polymer testing equipment is expanding steadily, driven by quality control requirements across automotive, aerospace, and medical industries. From a technical maturity perspective, the field shows varying levels of development among key players. Industry leaders like 3M, Dow Global Technologies, and ExxonMobil Chemical Patents have established robust testing protocols, while research institutions such as Korea Advanced Institute of Science & Technology and Japan Advanced Institute of Science & Technology are advancing fundamental methodologies. Companies including Borealis GmbH, LG Chem, and UL LLC are actively contributing to standards development, with testing certification bodies like China Testing & Certification International Group playing crucial roles in protocol validation and standardization efforts.

Dow Global Technologies LLC

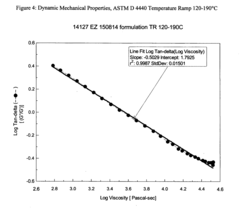

Technical Solution: Dow Global Technologies has developed comprehensive dynamic mechanical analysis (DMA) protocols specifically tailored for polymer characterization. Their approach includes multi-frequency DMA testing that allows for time-temperature superposition analysis to predict long-term polymer performance. The company has standardized procedures for measuring storage modulus, loss modulus, and tan delta across temperature ranges from -150°C to 400°C, providing crucial viscoelastic property data. Dow's protocols incorporate precise sample preparation techniques with controlled geometry and dimensions to ensure reproducibility. Their methodology includes specialized fixtures for different deformation modes (tension, compression, shear) and has established correction factors for instrument compliance and thermal expansion effects. Dow's test protocols are particularly notable for their ability to characterize polymer transitions (glass transition, secondary transitions) with high precision and repeatability across multiple polymer families[1][3].

Strengths: Comprehensive multi-frequency capabilities allowing time-temperature superposition for long-term performance prediction; highly standardized procedures ensuring excellent reproducibility across global testing facilities. Weaknesses: Proprietary nature of some testing protocols limits broader industry adoption; requires specialized high-cost equipment that may not be accessible to smaller laboratories.

Victrex Manufacturing Ltd.

Technical Solution: Victrex has established rigorous DMA test protocols specifically tailored for high-performance polymers like PEEK (polyetheretherketone) and other high-temperature thermoplastics. Their methodology incorporates extended temperature range testing (up to 400°C) with controlled cooling rates to accurately characterize crystallization behavior and thermal transitions in semi-crystalline polymers. Victrex's protocols feature specialized sample preparation techniques that account for processing-induced anisotropy and molecular orientation effects on mechanical properties. Their approach includes frequency-dependent measurements across 0.01-100 Hz to evaluate viscoelastic response under conditions ranging from quasi-static to impact loading. The company has developed standardized procedures for evaluating environmental effects (moisture, chemical exposure) on the dynamic mechanical properties of high-performance polymers used in demanding applications. Victrex's test standards incorporate precise dimensional measurements before, during, and after testing to account for thermal expansion and provide true stress-strain relationships[6][8].

Strengths: Specialized expertise in high-temperature polymers with testing capabilities extending to 400°C; excellent correlation between DMA results and performance in extreme environments. Weaknesses: Protocols primarily optimized for high-performance engineering thermoplastics rather than commodity polymers; requires specialized high-temperature testing equipment.

Critical Technical Innovations in Dynamic Mechanical Analysis

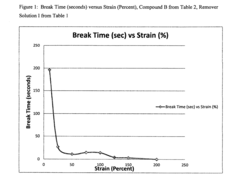

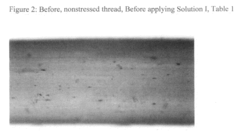

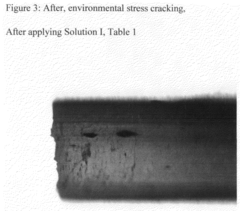

Hair Weave Thread that is Conveniently Removable via Solvent-Catalyzed Stress Cracking

PatentInactiveUS20160060447A1

Innovation

- The use of stress-cracking polymeric threads, specifically thermoplastic elastomers like plasticized PVC, which can be extended significantly and rupture quickly when exposed to specific solvents like acetone or butylene carbonate, allowing for easy removal without damaging the hair.

Polyethylene composition with high flexibility and high temperature resistance suitable for pipe applications

PatentWO2015090596A1

Innovation

- A polyethylene composition comprising a copolymer of ethylene and alpha-olefins with a specific molecular weight distribution and density range, produced through a multistage process using a Ziegler-Natta catalyst, which includes a low molecular weight component and a high molecular weight component, and optional additives to achieve optimal mechanical and processability properties.

International Harmonization of DMA Test Methods

The global nature of polymer research and applications necessitates standardized testing methodologies across different regions and regulatory frameworks. Currently, Dynamic Mechanical Analysis (DMA) test methods vary significantly between major standards organizations such as ASTM International, ISO, JIS (Japanese Industrial Standards), and various national standards bodies. This fragmentation creates challenges for multinational corporations, research institutions, and regulatory agencies when comparing test results across different jurisdictions.

Efforts toward international harmonization of DMA test methods have gained momentum in the past decade. The International Organization for Standardization (ISO) Technical Committee 61 on Plastics has been working collaboratively with ASTM Committee D20 on Plastics to develop unified standards that bridge the methodological gaps between different regional approaches. These initiatives aim to establish globally recognized protocols for sample preparation, test conditions, data analysis, and reporting formats.

Key areas of focus in harmonization efforts include temperature calibration procedures, frequency ranges, heating/cooling rates, and specimen geometry specifications. The ISO/ASTM 6721 series represents a significant step toward this harmonization, providing internationally accepted methods for determining the dynamic mechanical properties of polymers. However, challenges remain in reconciling differences in preferred methodologies between European, American, and Asian testing traditions.

Interlaboratory studies conducted between 2018 and 2022 have demonstrated that variations in test results can be significantly reduced when harmonized protocols are implemented. These studies, involving laboratories from over 15 countries, have helped identify critical parameters that require standardization to ensure reproducibility across different testing facilities and equipment manufacturers.

Equipment manufacturers have responded to harmonization initiatives by developing DMA instruments with flexible operating parameters that can accommodate multiple standard protocols. This adaptability allows researchers and quality control professionals to perform tests according to various regional standards while maintaining consistency in their internal procedures.

The economic benefits of harmonization are substantial, including reduced compliance costs for manufacturers operating in multiple markets, simplified validation procedures, and enhanced comparability of research data across international collaborations. Regulatory bodies increasingly recognize harmonized test methods in their approval processes, facilitating faster market access for polymer-based products.

Future harmonization efforts will likely focus on emerging areas such as high-frequency DMA testing, non-linear viscoelastic behavior characterization, and specialized protocols for novel materials like nanocomposites and biopolymers. The development of digital standards that incorporate machine-readable test protocols may further enhance international consistency in DMA testing methodologies.

Efforts toward international harmonization of DMA test methods have gained momentum in the past decade. The International Organization for Standardization (ISO) Technical Committee 61 on Plastics has been working collaboratively with ASTM Committee D20 on Plastics to develop unified standards that bridge the methodological gaps between different regional approaches. These initiatives aim to establish globally recognized protocols for sample preparation, test conditions, data analysis, and reporting formats.

Key areas of focus in harmonization efforts include temperature calibration procedures, frequency ranges, heating/cooling rates, and specimen geometry specifications. The ISO/ASTM 6721 series represents a significant step toward this harmonization, providing internationally accepted methods for determining the dynamic mechanical properties of polymers. However, challenges remain in reconciling differences in preferred methodologies between European, American, and Asian testing traditions.

Interlaboratory studies conducted between 2018 and 2022 have demonstrated that variations in test results can be significantly reduced when harmonized protocols are implemented. These studies, involving laboratories from over 15 countries, have helped identify critical parameters that require standardization to ensure reproducibility across different testing facilities and equipment manufacturers.

Equipment manufacturers have responded to harmonization initiatives by developing DMA instruments with flexible operating parameters that can accommodate multiple standard protocols. This adaptability allows researchers and quality control professionals to perform tests according to various regional standards while maintaining consistency in their internal procedures.

The economic benefits of harmonization are substantial, including reduced compliance costs for manufacturers operating in multiple markets, simplified validation procedures, and enhanced comparability of research data across international collaborations. Regulatory bodies increasingly recognize harmonized test methods in their approval processes, facilitating faster market access for polymer-based products.

Future harmonization efforts will likely focus on emerging areas such as high-frequency DMA testing, non-linear viscoelastic behavior characterization, and specialized protocols for novel materials like nanocomposites and biopolymers. The development of digital standards that incorporate machine-readable test protocols may further enhance international consistency in DMA testing methodologies.

Data Reproducibility and Validation Frameworks

Data reproducibility and validation represent critical challenges in dynamic mechanical analysis (DMA) of polymers. The scientific community has established several frameworks to address these issues, with ASTM D4065 and ISO 6721 serving as foundational standards. These frameworks incorporate statistical validation methods such as repeatability and reproducibility (R&R) studies, which typically require multiple measurements across different laboratories to establish confidence intervals and measurement uncertainties.

Round-robin testing programs have emerged as a particularly effective validation approach, where identical polymer samples are analyzed by multiple laboratories using standardized protocols. The Versailles Project on Advanced Materials and Standards (VAMPS) has coordinated several such initiatives specifically for DMA testing, generating valuable inter-laboratory comparison data that helps establish measurement reliability boundaries.

Digital data validation frameworks have also gained prominence, with automated systems that flag anomalous results based on predefined acceptance criteria. These systems typically evaluate parameters such as storage modulus consistency, loss tangent curve smoothness, and temperature calibration verification. The implementation of machine learning algorithms has further enhanced these frameworks by identifying subtle patterns in data that might indicate measurement errors or sample preparation inconsistencies.

Traceability chains represent another crucial component of validation frameworks, linking DMA measurements to fundamental SI units through calibration standards. Polymer reference materials with certified viscoelastic properties, such as those provided by NIST and other metrology institutes, serve as critical benchmarks for instrument calibration and method validation.

Documentation protocols within these frameworks have become increasingly standardized, requiring detailed reporting of sample preparation methods, thermal histories, instrument configurations, and environmental conditions. The emergence of digital laboratory notebooks and standardized data formats has facilitated more rigorous documentation practices, enhancing reproducibility across research groups.

Uncertainty quantification methodologies have evolved significantly, moving beyond simple standard deviation reporting to comprehensive uncertainty budgets that account for multiple error sources. These approaches typically incorporate both Type A uncertainties (derived from statistical analysis of repeated measurements) and Type B uncertainties (derived from instrument specifications, calibration certificates, and other non-statistical sources).

Cross-validation with complementary techniques, such as rheometry, dielectric analysis, and calorimetry, provides additional confidence in DMA results. Multi-technique validation approaches have become increasingly common in high-stakes applications where material performance verification is critical, such as aerospace and medical device industries.

Round-robin testing programs have emerged as a particularly effective validation approach, where identical polymer samples are analyzed by multiple laboratories using standardized protocols. The Versailles Project on Advanced Materials and Standards (VAMPS) has coordinated several such initiatives specifically for DMA testing, generating valuable inter-laboratory comparison data that helps establish measurement reliability boundaries.

Digital data validation frameworks have also gained prominence, with automated systems that flag anomalous results based on predefined acceptance criteria. These systems typically evaluate parameters such as storage modulus consistency, loss tangent curve smoothness, and temperature calibration verification. The implementation of machine learning algorithms has further enhanced these frameworks by identifying subtle patterns in data that might indicate measurement errors or sample preparation inconsistencies.

Traceability chains represent another crucial component of validation frameworks, linking DMA measurements to fundamental SI units through calibration standards. Polymer reference materials with certified viscoelastic properties, such as those provided by NIST and other metrology institutes, serve as critical benchmarks for instrument calibration and method validation.

Documentation protocols within these frameworks have become increasingly standardized, requiring detailed reporting of sample preparation methods, thermal histories, instrument configurations, and environmental conditions. The emergence of digital laboratory notebooks and standardized data formats has facilitated more rigorous documentation practices, enhancing reproducibility across research groups.

Uncertainty quantification methodologies have evolved significantly, moving beyond simple standard deviation reporting to comprehensive uncertainty budgets that account for multiple error sources. These approaches typically incorporate both Type A uncertainties (derived from statistical analysis of repeated measurements) and Type B uncertainties (derived from instrument specifications, calibration certificates, and other non-statistical sources).

Cross-validation with complementary techniques, such as rheometry, dielectric analysis, and calorimetry, provides additional confidence in DMA results. Multi-technique validation approaches have become increasingly common in high-stakes applications where material performance verification is critical, such as aerospace and medical device industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!