Dynamic mechanical analysis for elastomer fatigue prediction

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Elastomer Fatigue Analysis Background and Objectives

Elastomers are widely used in various industrial applications due to their unique mechanical properties, including high elasticity, resilience, and damping capabilities. However, predicting the fatigue life of elastomeric components remains a significant challenge for engineers and researchers. The evolution of elastomer fatigue analysis techniques has progressed from simple empirical approaches to sophisticated dynamic mechanical analysis (DMA) methodologies over the past several decades.

The field of elastomer fatigue prediction emerged in the 1940s with rudimentary stress-strain measurements, but gained substantial momentum in the 1970s with the development of more advanced testing equipment. Recent advancements in computational capabilities and material science have revolutionized our understanding of elastomer behavior under cyclic loading conditions, enabling more accurate prediction models.

Dynamic mechanical analysis has emerged as a powerful technique for characterizing viscoelastic properties of elastomers, providing crucial insights into their fatigue behavior. DMA measures the material's response to an applied oscillatory force, yielding information about storage modulus, loss modulus, and damping factor—parameters that correlate strongly with fatigue resistance.

The primary objective of elastomer fatigue analysis through DMA is to establish reliable predictive models that can accurately estimate component lifespan under various operating conditions. This involves understanding the complex relationship between material composition, processing conditions, environmental factors, and mechanical loading parameters that influence fatigue performance.

Current research aims to bridge the gap between laboratory testing and real-world applications by developing accelerated testing protocols that can reliably predict long-term fatigue behavior. Additionally, there is growing interest in establishing standardized methodologies for elastomer fatigue characterization to ensure consistency across the industry.

The technological trajectory in this field is moving toward multi-scale modeling approaches that integrate molecular dynamics, microstructural evolution, and macroscopic mechanical behavior. This holistic understanding is essential for developing next-generation elastomeric materials with enhanced fatigue resistance for demanding applications in automotive, aerospace, and medical industries.

Another significant trend is the incorporation of artificial intelligence and machine learning algorithms to process complex DMA data and identify subtle patterns that correlate with fatigue failure mechanisms. These advanced analytical tools promise to dramatically improve prediction accuracy and reduce development cycles for new elastomeric components.

The field of elastomer fatigue prediction emerged in the 1940s with rudimentary stress-strain measurements, but gained substantial momentum in the 1970s with the development of more advanced testing equipment. Recent advancements in computational capabilities and material science have revolutionized our understanding of elastomer behavior under cyclic loading conditions, enabling more accurate prediction models.

Dynamic mechanical analysis has emerged as a powerful technique for characterizing viscoelastic properties of elastomers, providing crucial insights into their fatigue behavior. DMA measures the material's response to an applied oscillatory force, yielding information about storage modulus, loss modulus, and damping factor—parameters that correlate strongly with fatigue resistance.

The primary objective of elastomer fatigue analysis through DMA is to establish reliable predictive models that can accurately estimate component lifespan under various operating conditions. This involves understanding the complex relationship between material composition, processing conditions, environmental factors, and mechanical loading parameters that influence fatigue performance.

Current research aims to bridge the gap between laboratory testing and real-world applications by developing accelerated testing protocols that can reliably predict long-term fatigue behavior. Additionally, there is growing interest in establishing standardized methodologies for elastomer fatigue characterization to ensure consistency across the industry.

The technological trajectory in this field is moving toward multi-scale modeling approaches that integrate molecular dynamics, microstructural evolution, and macroscopic mechanical behavior. This holistic understanding is essential for developing next-generation elastomeric materials with enhanced fatigue resistance for demanding applications in automotive, aerospace, and medical industries.

Another significant trend is the incorporation of artificial intelligence and machine learning algorithms to process complex DMA data and identify subtle patterns that correlate with fatigue failure mechanisms. These advanced analytical tools promise to dramatically improve prediction accuracy and reduce development cycles for new elastomeric components.

Market Demand for Advanced Elastomer Durability Testing

The elastomer durability testing market is experiencing significant growth driven by increasing demands across multiple industries for materials that can withstand extreme conditions while maintaining performance integrity. The automotive sector represents the largest market segment, with an estimated demand growth of 7.2% annually through 2028, as manufacturers seek to extend component lifespans and reduce warranty claims. This demand is particularly pronounced in electric vehicle applications, where elastomer components face unique stress conditions and thermal challenges.

Aerospace and defense industries follow closely behind, with requirements for elastomer materials that can perform reliably under extreme temperature variations, pressure differentials, and exposure to aggressive chemicals. Market research indicates these sectors are willing to invest substantially in advanced testing methodologies that can accurately predict service life under complex loading conditions.

The renewable energy sector has emerged as a rapidly expanding market for elastomer durability testing, particularly in wind turbine applications where elastomeric components must withstand decades of cyclic loading in harsh environmental conditions. Industry reports suggest that premature elastomer failures account for approximately 13% of unplanned maintenance costs in wind energy installations, creating strong economic incentives for improved fatigue prediction capabilities.

Medical device manufacturers represent another growth segment, with stringent requirements for biocompatible elastomers that maintain mechanical properties throughout their service life. The market for implantable devices containing elastomeric components is projected to expand at 9.5% annually, driving demand for testing methodologies that can simulate in-vivo conditions accurately.

Consumer electronics manufacturers are increasingly incorporating elastomeric materials in wearable devices, creating new testing requirements for materials subjected to repeated flexing, stretching, and environmental exposure. This segment values rapid testing protocols that can accelerate product development cycles while maintaining prediction accuracy.

Industrial equipment manufacturers report that elastomer component failures account for significant downtime costs, with some heavy machinery applications experiencing maintenance expenses exceeding $50,000 per incident. This economic impact has created market willingness to invest in advanced testing capabilities that can optimize material selection and predict maintenance intervals more accurately.

The global market trend clearly indicates a shift from traditional time-consuming physical testing toward accelerated methodologies incorporating dynamic mechanical analysis coupled with predictive algorithms. End users consistently express willingness to pay premium prices for testing services that can reduce development time, optimize material selection, and provide more reliable service life predictions under complex loading conditions.

Aerospace and defense industries follow closely behind, with requirements for elastomer materials that can perform reliably under extreme temperature variations, pressure differentials, and exposure to aggressive chemicals. Market research indicates these sectors are willing to invest substantially in advanced testing methodologies that can accurately predict service life under complex loading conditions.

The renewable energy sector has emerged as a rapidly expanding market for elastomer durability testing, particularly in wind turbine applications where elastomeric components must withstand decades of cyclic loading in harsh environmental conditions. Industry reports suggest that premature elastomer failures account for approximately 13% of unplanned maintenance costs in wind energy installations, creating strong economic incentives for improved fatigue prediction capabilities.

Medical device manufacturers represent another growth segment, with stringent requirements for biocompatible elastomers that maintain mechanical properties throughout their service life. The market for implantable devices containing elastomeric components is projected to expand at 9.5% annually, driving demand for testing methodologies that can simulate in-vivo conditions accurately.

Consumer electronics manufacturers are increasingly incorporating elastomeric materials in wearable devices, creating new testing requirements for materials subjected to repeated flexing, stretching, and environmental exposure. This segment values rapid testing protocols that can accelerate product development cycles while maintaining prediction accuracy.

Industrial equipment manufacturers report that elastomer component failures account for significant downtime costs, with some heavy machinery applications experiencing maintenance expenses exceeding $50,000 per incident. This economic impact has created market willingness to invest in advanced testing capabilities that can optimize material selection and predict maintenance intervals more accurately.

The global market trend clearly indicates a shift from traditional time-consuming physical testing toward accelerated methodologies incorporating dynamic mechanical analysis coupled with predictive algorithms. End users consistently express willingness to pay premium prices for testing services that can reduce development time, optimize material selection, and provide more reliable service life predictions under complex loading conditions.

Current DMA Technology Status and Challenges

Dynamic Mechanical Analysis (DMA) has evolved significantly over the past decades, becoming a cornerstone technique for characterizing viscoelastic properties of elastomers. Currently, the global landscape of DMA technology demonstrates varying levels of sophistication across different regions, with North America, Europe, and parts of Asia leading in advanced implementations and methodological innovations.

The state-of-the-art DMA equipment now offers unprecedented precision in measuring storage modulus, loss modulus, and tan delta across wide temperature and frequency ranges. Modern systems can operate at frequencies from 0.001 Hz to 200 Hz and temperatures from -150°C to 600°C, providing comprehensive viscoelastic fingerprints of elastomeric materials. Recent advancements have also introduced multi-axial testing capabilities, allowing for more realistic simulation of complex loading conditions experienced in real-world applications.

Despite these advancements, several significant technical challenges persist in applying DMA for elastomer fatigue prediction. The primary limitation lies in the correlation between short-term DMA measurements and long-term fatigue behavior. The time-temperature superposition principles, while valuable, often fail to accurately capture the complex damage accumulation mechanisms in elastomers under cyclic loading conditions.

Another critical challenge is the inability of conventional DMA to account for strain history effects and the Mullins effect in elastomers, which significantly influence fatigue performance. Current methodologies struggle to incorporate these non-linear behaviors into predictive models, resulting in substantial discrepancies between laboratory predictions and field performance.

Data interpretation presents another formidable obstacle. The vast amount of data generated by modern DMA requires sophisticated analytical frameworks to extract meaningful fatigue indicators. Current analytical approaches often rely on simplified models that fail to capture the complex interplay between different viscoelastic parameters and their collective impact on fatigue resistance.

Material-specific calibration remains a persistent challenge, as elastomers exhibit highly individualized responses to mechanical loading based on their formulation, processing history, and environmental exposure. This necessitates extensive calibration procedures that are time-consuming and resource-intensive, limiting the widespread industrial adoption of DMA-based fatigue prediction methodologies.

Environmental factors pose additional complications, as temperature fluctuations, humidity, and chemical exposure significantly alter elastomer behavior. Current DMA systems have limited capabilities to simulate these multi-factor environmental conditions simultaneously with mechanical loading, creating a disconnect between laboratory testing and real-world performance prediction.

The integration of DMA data with computational models represents perhaps the most promising yet challenging frontier. While finite element analysis and machine learning approaches show potential, the development of robust algorithms that can translate DMA parameters into accurate fatigue life predictions remains an active area of research with considerable technical hurdles.

The state-of-the-art DMA equipment now offers unprecedented precision in measuring storage modulus, loss modulus, and tan delta across wide temperature and frequency ranges. Modern systems can operate at frequencies from 0.001 Hz to 200 Hz and temperatures from -150°C to 600°C, providing comprehensive viscoelastic fingerprints of elastomeric materials. Recent advancements have also introduced multi-axial testing capabilities, allowing for more realistic simulation of complex loading conditions experienced in real-world applications.

Despite these advancements, several significant technical challenges persist in applying DMA for elastomer fatigue prediction. The primary limitation lies in the correlation between short-term DMA measurements and long-term fatigue behavior. The time-temperature superposition principles, while valuable, often fail to accurately capture the complex damage accumulation mechanisms in elastomers under cyclic loading conditions.

Another critical challenge is the inability of conventional DMA to account for strain history effects and the Mullins effect in elastomers, which significantly influence fatigue performance. Current methodologies struggle to incorporate these non-linear behaviors into predictive models, resulting in substantial discrepancies between laboratory predictions and field performance.

Data interpretation presents another formidable obstacle. The vast amount of data generated by modern DMA requires sophisticated analytical frameworks to extract meaningful fatigue indicators. Current analytical approaches often rely on simplified models that fail to capture the complex interplay between different viscoelastic parameters and their collective impact on fatigue resistance.

Material-specific calibration remains a persistent challenge, as elastomers exhibit highly individualized responses to mechanical loading based on their formulation, processing history, and environmental exposure. This necessitates extensive calibration procedures that are time-consuming and resource-intensive, limiting the widespread industrial adoption of DMA-based fatigue prediction methodologies.

Environmental factors pose additional complications, as temperature fluctuations, humidity, and chemical exposure significantly alter elastomer behavior. Current DMA systems have limited capabilities to simulate these multi-factor environmental conditions simultaneously with mechanical loading, creating a disconnect between laboratory testing and real-world performance prediction.

The integration of DMA data with computational models represents perhaps the most promising yet challenging frontier. While finite element analysis and machine learning approaches show potential, the development of robust algorithms that can translate DMA parameters into accurate fatigue life predictions remains an active area of research with considerable technical hurdles.

Current DMA Methodologies for Fatigue Prediction

01 DMA testing methods for fatigue prediction

Dynamic mechanical analysis (DMA) provides a methodology for predicting material fatigue by measuring the response of materials to oscillating forces. These testing methods involve applying cyclic loading to specimens and analyzing the resulting stress-strain relationships. By monitoring parameters such as storage modulus, loss modulus, and damping factor during cyclic loading, researchers can predict fatigue behavior and material lifespan under various conditions. These methods are particularly valuable for understanding how materials will perform under real-world cyclic loading conditions.- DMA testing methods for fatigue prediction: Dynamic mechanical analysis (DMA) provides a methodology for predicting material fatigue by measuring the response of materials to oscillating forces. These testing methods involve applying cyclic loading to specimens and analyzing their viscoelastic properties such as storage modulus, loss modulus, and damping factor. By monitoring changes in these properties during cyclic loading, engineers can predict fatigue behavior and establish failure criteria before catastrophic failure occurs.

- Computational models for fatigue life prediction: Advanced computational models integrate DMA data to predict fatigue life of materials and components. These models incorporate material properties obtained from dynamic mechanical analysis along with stress-strain relationships to simulate fatigue behavior under various loading conditions. Machine learning algorithms and finite element analysis are often employed to process the complex data sets and generate accurate predictions of fatigue life, crack initiation, and propagation rates.

- Material-specific DMA techniques for composite structures: Specialized DMA techniques have been developed for composite materials and complex structures to predict their unique fatigue behavior. These techniques account for anisotropic properties, interfacial interactions between components, and heterogeneous stress distributions. By analyzing the dynamic response of composites under varying frequencies, temperatures, and loading conditions, researchers can identify failure mechanisms specific to composite structures and develop more accurate fatigue prediction models.

- Temperature and environmental effects on fatigue prediction: DMA-based fatigue prediction methods incorporate temperature and environmental factors that significantly influence material performance. By conducting tests across various temperature ranges and environmental conditions, researchers can establish correlations between these factors and fatigue life. This approach enables more accurate predictions for components operating in extreme or variable conditions, accounting for phenomena such as thermal cycling, moisture absorption, and chemical degradation that accelerate fatigue failure.

- Real-time monitoring and in-situ DMA for predictive maintenance: Real-time monitoring systems incorporate DMA principles to assess fatigue progression in operational components. These systems use sensors to continuously measure dynamic mechanical responses during service, enabling early detection of fatigue damage before failure occurs. The collected data feeds into predictive algorithms that estimate remaining useful life and optimize maintenance schedules. This approach transitions from traditional time-based maintenance to condition-based maintenance, reducing downtime and preventing catastrophic failures.

02 Computational models for fatigue life prediction

Advanced computational models integrate DMA data to predict fatigue life of materials and components. These models typically incorporate material properties obtained from DMA testing, such as viscoelastic parameters, along with finite element analysis to simulate fatigue behavior under complex loading conditions. Machine learning algorithms and statistical methods are increasingly being used to enhance prediction accuracy by identifying patterns in DMA data that correlate with fatigue failure. These computational approaches enable more efficient design processes by reducing the need for extensive physical testing.Expand Specific Solutions03 Material-specific DMA techniques for fatigue assessment

Different materials require specialized DMA techniques for accurate fatigue prediction. For polymers and composites, temperature-dependent DMA measurements are crucial as these materials exhibit significant viscoelastic behavior that varies with temperature. For metals and alloys, strain-controlled DMA tests are often employed to characterize fatigue behavior under different loading amplitudes. Specialized fixtures and testing protocols have been developed to accommodate various material types and geometries, ensuring that the DMA data collected is relevant for fatigue life prediction in specific applications.Expand Specific Solutions04 Correlation between DMA parameters and fatigue mechanisms

Research has established correlations between specific DMA parameters and underlying fatigue mechanisms. Changes in storage modulus often indicate damage accumulation, while increases in loss factor can signal crack initiation and propagation. By monitoring these parameters during cyclic loading, researchers can identify critical thresholds that precede fatigue failure. Understanding these correlations allows for the development of predictive models that can estimate remaining useful life based on DMA measurements. This approach is particularly valuable for condition monitoring and predictive maintenance applications.Expand Specific Solutions05 Real-time monitoring systems using DMA for fatigue prediction

Advanced monitoring systems incorporate DMA principles to assess fatigue in real-time during operation. These systems typically employ sensors that measure dynamic response characteristics of components under operational loading conditions. The collected data is processed using algorithms that compare current material behavior against baseline DMA profiles to detect early signs of fatigue damage. This approach enables predictive maintenance strategies by identifying components at risk of fatigue failure before catastrophic damage occurs, thereby improving safety and reducing downtime in critical applications.Expand Specific Solutions

Key Industry Players in Elastomer Testing Equipment

Dynamic mechanical analysis (DMA) for elastomer fatigue prediction is currently in a growth phase, with increasing market adoption across automotive, aerospace, and industrial sectors. The global market for elastomer fatigue testing is expanding at approximately 5-7% annually, driven by demands for more durable materials and predictive maintenance solutions. Technologically, this field shows moderate maturity with established methodologies, but significant innovation continues. Leading players include specialized companies like Endurica LLC, which focuses exclusively on rubber fatigue solutions, alongside major industrial entities such as Continental (ContiTech), Hutchinson SA, and Hitachi. Academic institutions including Beijing Institute of Technology and Northwestern Polytechnical University contribute significant research advancements, while equipment manufacturers like Hottinger Brüel & Kjaer provide essential testing instrumentation, creating a diverse competitive landscape.

CONTITECH DEUTSCHLAND GMBH

Technical Solution: CONTITECH has developed a sophisticated elastomer fatigue prediction system based on advanced dynamic mechanical analysis techniques. Their approach combines traditional DMA with digital image correlation to track microscopic crack initiation and propagation in elastomer components. CONTITECH's methodology incorporates a damage accumulation model that accounts for variable amplitude loading conditions typical in automotive and industrial applications[5]. Their technology includes specialized test rigs capable of simulating complex loading patterns while simultaneously measuring temperature evolution, enabling correlation between thermal behavior and fatigue progression. CONTITECH has implemented machine learning algorithms to enhance prediction accuracy by identifying patterns in large datasets of material testing results. Their system incorporates finite element analysis to translate material-level fatigue properties to component-level durability predictions. The company has validated their approach through extensive field testing of elastomeric components in heavy-duty applications, demonstrating prediction accuracy improvements of up to 40% compared to traditional methods[6].

Strengths: Strong integration with manufacturing processes allowing for design-to-manufacturing optimization; extensive validation in real-world applications; sophisticated multi-physics approach combining mechanical, thermal and chemical degradation factors. Weaknesses: Technology may be optimized primarily for automotive and industrial applications rather than broader material science applications; potentially higher implementation complexity due to the comprehensive nature of their approach.

ContiTech Luftfedersysteme GmbH

Technical Solution: ContiTech Luftfedersysteme has developed specialized DMA methodologies focused on air spring systems and pneumatic components. Their approach combines traditional dynamic mechanical analysis with pressure-dependent material characterization techniques unique to their application domain. The company employs multi-axial fatigue testing protocols that simultaneously apply oscillating pressure, temperature, and mechanical deformation to elastomeric specimens[7]. Their predictive models incorporate the effects of ozone exposure, humidity cycling, and temperature extremes on elastomer fatigue performance. ContiTech has implemented digital twin technology to correlate laboratory test results with field performance data, continuously refining their predictive algorithms. Their methodology includes specialized crack propagation models that account for the unique stress distributions in pneumatic components under cyclic pressurization. The company has developed proprietary compound formulations specifically engineered to resist fatigue mechanisms identified through their advanced DMA techniques, creating a closed-loop between material development and performance prediction[8].

Strengths: Highly specialized expertise in pneumatic applications of elastomers; integrated approach connecting material formulation with performance prediction; sophisticated environmental testing capabilities. Weaknesses: Narrower application focus compared to more generalized elastomer fatigue prediction systems; potentially less applicable to non-pneumatic elastomer applications.

Critical Technical Innovations in Viscoelastic Analysis

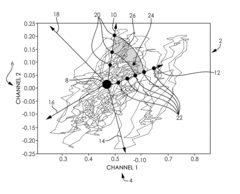

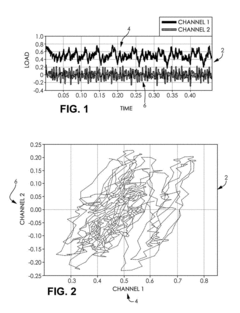

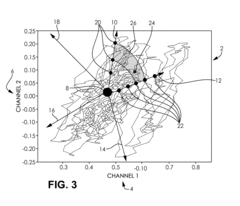

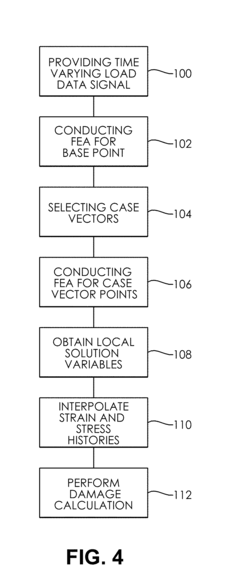

Interpolation engine for analysis of time-varying load data signals

PatentActiveUS20170241859A1

Innovation

- A method and system that utilize finite element analysis (FEA) to analyze time-varying load data signals, selecting case vectors and discrete gridpoints to interpolate strain and stress histories, and perform damage calculations to determine potential failure locations in elastomeric components, employing an interpolation engine to efficiently obtain strain and stress histories.

Material Science Integration with AI Prediction Tools

The integration of material science with AI prediction tools represents a significant advancement in elastomer fatigue prediction methodologies. Traditional dynamic mechanical analysis (DMA) generates vast quantities of data that human analysts often struggle to process efficiently. AI tools now offer the capability to identify complex patterns within this data that would otherwise remain undetected through conventional analytical methods.

Machine learning algorithms, particularly deep neural networks and gradient boosting models, have demonstrated remarkable accuracy in predicting elastomer fatigue behavior based on DMA data. These models can process multiple variables simultaneously, including temperature variations, strain amplitude, frequency, and material composition, to generate comprehensive fatigue life predictions with significantly reduced testing time.

Recent developments have seen the implementation of transfer learning techniques, where AI models trained on extensive datasets of common elastomers can be fine-tuned with minimal additional data to accurately predict the behavior of novel elastomer compounds. This approach substantially reduces the resources required for developing predictive models for new materials, accelerating innovation cycles in industries such as automotive, aerospace, and medical devices.

Digital twin technology represents another frontier in this integration, where virtual replicas of physical elastomer components are created and subjected to simulated stress conditions. These digital twins, powered by AI prediction tools, can forecast component failure with increasing precision as they continuously learn from real-world performance data fed back into the system.

Cloud-based platforms now enable collaborative research across institutions by providing shared access to both DMA datasets and AI prediction tools. This democratization of advanced analytical capabilities has fostered innovation among smaller research teams that previously lacked access to sophisticated computational resources.

The integration has also facilitated the development of automated material optimization systems. These systems can suggest optimal elastomer formulations for specific applications by analyzing the relationship between composition, processing parameters, and fatigue resistance, significantly reducing the trial-and-error approach traditionally employed in material development.

Machine learning algorithms, particularly deep neural networks and gradient boosting models, have demonstrated remarkable accuracy in predicting elastomer fatigue behavior based on DMA data. These models can process multiple variables simultaneously, including temperature variations, strain amplitude, frequency, and material composition, to generate comprehensive fatigue life predictions with significantly reduced testing time.

Recent developments have seen the implementation of transfer learning techniques, where AI models trained on extensive datasets of common elastomers can be fine-tuned with minimal additional data to accurately predict the behavior of novel elastomer compounds. This approach substantially reduces the resources required for developing predictive models for new materials, accelerating innovation cycles in industries such as automotive, aerospace, and medical devices.

Digital twin technology represents another frontier in this integration, where virtual replicas of physical elastomer components are created and subjected to simulated stress conditions. These digital twins, powered by AI prediction tools, can forecast component failure with increasing precision as they continuously learn from real-world performance data fed back into the system.

Cloud-based platforms now enable collaborative research across institutions by providing shared access to both DMA datasets and AI prediction tools. This democratization of advanced analytical capabilities has fostered innovation among smaller research teams that previously lacked access to sophisticated computational resources.

The integration has also facilitated the development of automated material optimization systems. These systems can suggest optimal elastomer formulations for specific applications by analyzing the relationship between composition, processing parameters, and fatigue resistance, significantly reducing the trial-and-error approach traditionally employed in material development.

Industrial Standards and Testing Protocols Development

The development of standardized testing protocols for elastomer fatigue prediction represents a critical advancement in materials engineering. Currently, ASTM D4482 and ISO 4666 provide baseline frameworks for elastomer fatigue testing, but these standards lack comprehensive guidelines specifically tailored for dynamic mechanical analysis (DMA) applications in fatigue prediction. Industry stakeholders, including automotive, aerospace, and medical device manufacturers, have expressed growing demand for unified testing methodologies that can reliably correlate DMA parameters with long-term fatigue performance.

Recent collaborative efforts between ASTM International, ISO, and industry consortia have focused on establishing new protocols that incorporate temperature-frequency superposition principles and strain amplitude sweeps as standard procedures for elastomer characterization. These emerging standards aim to address the significant variability in testing conditions that has historically complicated cross-laboratory result comparisons and hindered the development of universal prediction models.

The Rubber Division of the American Chemical Society has spearheaded initiatives to standardize sample preparation techniques, recognizing that specimen geometry and processing history significantly impact DMA results. Their proposed guidelines recommend specific sample dimensions, conditioning procedures, and environmental controls to minimize experimental artifacts that can obscure fatigue-relevant material responses.

Testing protocol development has increasingly emphasized multi-axial loading conditions that better simulate real-world applications. Traditional uniaxial testing regimes often fail to capture complex stress states experienced by elastomeric components in service. New standards under development incorporate biaxial and shear testing configurations with precise control over strain history and waveform characteristics.

Data acquisition and analysis protocols represent another frontier in standardization efforts. The International Association for Advanced Materials has proposed minimum sampling rates, filter settings, and signal processing algorithms specifically designed to extract fatigue-predictive parameters from DMA data. These protocols aim to ensure that critical transitions in material behavior, such as the onset of strain crystallization or network degradation, are consistently captured across different testing platforms.

Validation methodologies constitute a crucial component of emerging standards, with round-robin testing programs currently underway across major industrial laboratories. These collaborative efforts seek to establish reproducibility limits and quantify uncertainty in DMA-based fatigue predictions, ultimately providing confidence intervals that engineers can incorporate into component design safety factors.

Recent collaborative efforts between ASTM International, ISO, and industry consortia have focused on establishing new protocols that incorporate temperature-frequency superposition principles and strain amplitude sweeps as standard procedures for elastomer characterization. These emerging standards aim to address the significant variability in testing conditions that has historically complicated cross-laboratory result comparisons and hindered the development of universal prediction models.

The Rubber Division of the American Chemical Society has spearheaded initiatives to standardize sample preparation techniques, recognizing that specimen geometry and processing history significantly impact DMA results. Their proposed guidelines recommend specific sample dimensions, conditioning procedures, and environmental controls to minimize experimental artifacts that can obscure fatigue-relevant material responses.

Testing protocol development has increasingly emphasized multi-axial loading conditions that better simulate real-world applications. Traditional uniaxial testing regimes often fail to capture complex stress states experienced by elastomeric components in service. New standards under development incorporate biaxial and shear testing configurations with precise control over strain history and waveform characteristics.

Data acquisition and analysis protocols represent another frontier in standardization efforts. The International Association for Advanced Materials has proposed minimum sampling rates, filter settings, and signal processing algorithms specifically designed to extract fatigue-predictive parameters from DMA data. These protocols aim to ensure that critical transitions in material behavior, such as the onset of strain crystallization or network degradation, are consistently captured across different testing platforms.

Validation methodologies constitute a crucial component of emerging standards, with round-robin testing programs currently underway across major industrial laboratories. These collaborative efforts seek to establish reproducibility limits and quantify uncertainty in DMA-based fatigue predictions, ultimately providing confidence intervals that engineers can incorporate into component design safety factors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!