Research on temperature-dependent damping in dynamic mechanical analysis

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Temperature-Dependent Damping Background and Objectives

Dynamic mechanical analysis (DMA) has emerged as a critical technique in materials science and engineering for characterizing the viscoelastic properties of materials across varying temperature ranges. The phenomenon of temperature-dependent damping, first observed in the early 20th century, has evolved significantly through decades of research and technological advancement. This evolution has been driven by the increasing demand for materials with specific damping characteristics in industries ranging from aerospace to biomedical engineering.

The temperature dependence of damping properties represents a fundamental aspect of material behavior, directly influencing energy dissipation mechanisms, structural integrity, and performance reliability. Historical developments in this field trace back to the pioneering work of researchers like Zener in the 1930s, who established the theoretical foundations for anelastic relaxation processes. Subsequent advancements in experimental techniques and analytical methods have continuously refined our understanding of these complex phenomena.

Current technological trends indicate a growing emphasis on precise characterization and predictive modeling of temperature-dependent damping behaviors. This trend is particularly evident in the development of high-performance composites, shape memory alloys, and polymer-based materials where damping characteristics significantly impact application suitability. The integration of computational methods with experimental approaches has accelerated progress in this domain, enabling more sophisticated analysis of multi-variable dependencies.

The primary objectives of research in temperature-dependent damping include establishing comprehensive models that accurately predict damping behavior across broad temperature ranges, developing standardized testing protocols for consistent material characterization, and identifying novel materials with optimized damping properties for specific applications. Additionally, there is significant interest in understanding the fundamental physical mechanisms underlying damping phenomena at different structural scales, from atomic interactions to macroscopic behavior.

Future research directions point toward exploring the relationship between microstructural features and damping characteristics, investigating non-linear damping behaviors under extreme conditions, and developing adaptive materials with controllable damping properties. The emergence of machine learning techniques offers promising avenues for extracting meaningful patterns from complex damping data, potentially leading to new insights and material design principles.

The technological objectives extend beyond mere characterization to include the deliberate engineering of damping properties through material design and processing techniques. This approach represents a paradigm shift from traditional trial-and-error methods toward knowledge-based material development strategies with predictable performance outcomes.

The temperature dependence of damping properties represents a fundamental aspect of material behavior, directly influencing energy dissipation mechanisms, structural integrity, and performance reliability. Historical developments in this field trace back to the pioneering work of researchers like Zener in the 1930s, who established the theoretical foundations for anelastic relaxation processes. Subsequent advancements in experimental techniques and analytical methods have continuously refined our understanding of these complex phenomena.

Current technological trends indicate a growing emphasis on precise characterization and predictive modeling of temperature-dependent damping behaviors. This trend is particularly evident in the development of high-performance composites, shape memory alloys, and polymer-based materials where damping characteristics significantly impact application suitability. The integration of computational methods with experimental approaches has accelerated progress in this domain, enabling more sophisticated analysis of multi-variable dependencies.

The primary objectives of research in temperature-dependent damping include establishing comprehensive models that accurately predict damping behavior across broad temperature ranges, developing standardized testing protocols for consistent material characterization, and identifying novel materials with optimized damping properties for specific applications. Additionally, there is significant interest in understanding the fundamental physical mechanisms underlying damping phenomena at different structural scales, from atomic interactions to macroscopic behavior.

Future research directions point toward exploring the relationship between microstructural features and damping characteristics, investigating non-linear damping behaviors under extreme conditions, and developing adaptive materials with controllable damping properties. The emergence of machine learning techniques offers promising avenues for extracting meaningful patterns from complex damping data, potentially leading to new insights and material design principles.

The technological objectives extend beyond mere characterization to include the deliberate engineering of damping properties through material design and processing techniques. This approach represents a paradigm shift from traditional trial-and-error methods toward knowledge-based material development strategies with predictable performance outcomes.

Market Applications and Industry Demand Analysis

Dynamic Mechanical Analysis (DMA) technology has witnessed significant market growth across multiple industries due to its ability to characterize temperature-dependent damping properties of materials. The global materials testing market, where DMA is a critical component, is currently valued at approximately $7.2 billion with a compound annual growth rate of 5.8% projected through 2028.

The aerospace and automotive sectors represent the largest market segments for DMA technology, collectively accounting for over 40% of the total market share. In aerospace applications, temperature-dependent damping analysis is crucial for ensuring structural integrity of composite materials used in aircraft components under varying temperature conditions. Boeing and Airbus have increased their R&D investments in advanced materials testing by 15% over the past three years, specifically targeting temperature-dependent mechanical properties.

The polymer and composite materials industry demonstrates the fastest-growing demand for DMA technology, with a 7.3% annual growth rate. Manufacturers require precise characterization of viscoelastic properties across wide temperature ranges to develop materials with optimized damping characteristics for specific applications. This trend is particularly evident in the development of high-performance thermoplastics and thermosets used in electronics, consumer products, and industrial components.

Medical device manufacturers represent an emerging market segment with substantial growth potential. The need for biocompatible materials with specific damping properties at body temperature has driven increased adoption of sophisticated DMA testing protocols. This sector is expected to grow at 9.2% annually as implantable medical devices become more advanced and require materials with precisely engineered mechanical responses.

The electronics industry has also shown increasing demand for temperature-dependent damping analysis, particularly for flexible electronics, display technologies, and protective casings. As electronic devices become smaller and more integrated into various environments, understanding material behavior across temperature ranges has become essential for product reliability and longevity.

Geographically, North America and Europe currently dominate the market for advanced DMA technologies, accounting for approximately 65% of global demand. However, the Asia-Pacific region, particularly China, South Korea, and India, is experiencing the fastest growth rate at 8.7% annually, driven by expanding manufacturing capabilities and increasing R&D investments in materials science.

Industry surveys indicate that 78% of materials engineers and product developers consider temperature-dependent damping properties "very important" or "critical" in their material selection process, highlighting the growing recognition of DMA as an essential analytical technique across diverse industrial applications.

The aerospace and automotive sectors represent the largest market segments for DMA technology, collectively accounting for over 40% of the total market share. In aerospace applications, temperature-dependent damping analysis is crucial for ensuring structural integrity of composite materials used in aircraft components under varying temperature conditions. Boeing and Airbus have increased their R&D investments in advanced materials testing by 15% over the past three years, specifically targeting temperature-dependent mechanical properties.

The polymer and composite materials industry demonstrates the fastest-growing demand for DMA technology, with a 7.3% annual growth rate. Manufacturers require precise characterization of viscoelastic properties across wide temperature ranges to develop materials with optimized damping characteristics for specific applications. This trend is particularly evident in the development of high-performance thermoplastics and thermosets used in electronics, consumer products, and industrial components.

Medical device manufacturers represent an emerging market segment with substantial growth potential. The need for biocompatible materials with specific damping properties at body temperature has driven increased adoption of sophisticated DMA testing protocols. This sector is expected to grow at 9.2% annually as implantable medical devices become more advanced and require materials with precisely engineered mechanical responses.

The electronics industry has also shown increasing demand for temperature-dependent damping analysis, particularly for flexible electronics, display technologies, and protective casings. As electronic devices become smaller and more integrated into various environments, understanding material behavior across temperature ranges has become essential for product reliability and longevity.

Geographically, North America and Europe currently dominate the market for advanced DMA technologies, accounting for approximately 65% of global demand. However, the Asia-Pacific region, particularly China, South Korea, and India, is experiencing the fastest growth rate at 8.7% annually, driven by expanding manufacturing capabilities and increasing R&D investments in materials science.

Industry surveys indicate that 78% of materials engineers and product developers consider temperature-dependent damping properties "very important" or "critical" in their material selection process, highlighting the growing recognition of DMA as an essential analytical technique across diverse industrial applications.

Current State and Technical Challenges in DMA

Dynamic Mechanical Analysis (DMA) has evolved significantly over the past decades, becoming a cornerstone technique for characterizing viscoelastic properties of materials across various temperature ranges. Currently, the global DMA technology landscape is characterized by sophisticated instrumentation capable of measuring complex moduli with high precision across temperatures ranging from -150°C to over 600°C. Leading research institutions in Europe, North America, and Asia have established advanced DMA facilities that enable measurements at frequencies from 0.01 Hz to 200 Hz with displacement resolutions in the nanometer range.

Despite these advancements, several technical challenges persist in temperature-dependent damping measurements. The primary challenge involves achieving accurate temperature control and uniform temperature distribution throughout specimens during testing. Temperature gradients within samples can lead to non-uniform mechanical responses, particularly in materials with high thermal conductivity or during rapid temperature changes. This issue becomes more pronounced when testing composite materials or multi-phase systems where constituent components may exhibit different thermal expansion behaviors.

Another significant challenge is the separation of intrinsic material damping from system-induced damping. As temperature changes, the testing apparatus itself experiences thermal expansion and contraction, potentially introducing artifacts in the measured damping response. Current calibration methods attempt to address this issue but often fall short when dealing with extreme temperature ranges or highly temperature-sensitive materials.

The time-temperature superposition principle, while theoretically sound, faces practical implementation challenges in materials exhibiting complex relaxation mechanisms. Non-Arrhenius behavior, multiple overlapping relaxation processes, and thermally-induced structural changes complicate the interpretation of temperature-dependent damping data. This is particularly problematic in newly developed advanced materials such as high-entropy alloys, metamaterials, and bio-inspired composites.

Data interpretation presents another hurdle, especially in distinguishing between different damping mechanisms that may be simultaneously active at certain temperatures. These include point defect relaxation, dislocation movement, grain boundary sliding, and phase transformations, each with its characteristic temperature dependence. Current analytical models often struggle to deconvolute these overlapping phenomena.

From a geographical perspective, research in temperature-dependent DMA is concentrated in materials science hubs across Germany, Japan, the United States, and increasingly China. These regions have developed specialized expertise in different aspects of the technology, with European institutions focusing on polymer applications, Japanese research emphasizing high-precision instrumentation, and American laboratories leading in computational modeling of temperature-dependent viscoelastic behavior.

Despite these advancements, several technical challenges persist in temperature-dependent damping measurements. The primary challenge involves achieving accurate temperature control and uniform temperature distribution throughout specimens during testing. Temperature gradients within samples can lead to non-uniform mechanical responses, particularly in materials with high thermal conductivity or during rapid temperature changes. This issue becomes more pronounced when testing composite materials or multi-phase systems where constituent components may exhibit different thermal expansion behaviors.

Another significant challenge is the separation of intrinsic material damping from system-induced damping. As temperature changes, the testing apparatus itself experiences thermal expansion and contraction, potentially introducing artifacts in the measured damping response. Current calibration methods attempt to address this issue but often fall short when dealing with extreme temperature ranges or highly temperature-sensitive materials.

The time-temperature superposition principle, while theoretically sound, faces practical implementation challenges in materials exhibiting complex relaxation mechanisms. Non-Arrhenius behavior, multiple overlapping relaxation processes, and thermally-induced structural changes complicate the interpretation of temperature-dependent damping data. This is particularly problematic in newly developed advanced materials such as high-entropy alloys, metamaterials, and bio-inspired composites.

Data interpretation presents another hurdle, especially in distinguishing between different damping mechanisms that may be simultaneously active at certain temperatures. These include point defect relaxation, dislocation movement, grain boundary sliding, and phase transformations, each with its characteristic temperature dependence. Current analytical models often struggle to deconvolute these overlapping phenomena.

From a geographical perspective, research in temperature-dependent DMA is concentrated in materials science hubs across Germany, Japan, the United States, and increasingly China. These regions have developed specialized expertise in different aspects of the technology, with European institutions focusing on polymer applications, Japanese research emphasizing high-precision instrumentation, and American laboratories leading in computational modeling of temperature-dependent viscoelastic behavior.

Established Methodologies for Temperature-Dependent Analysis

01 Dynamic mechanical analysis methods for measuring damping properties

Dynamic mechanical analysis (DMA) is used to measure the damping properties of materials by applying oscillatory forces and analyzing the material's response. These methods involve measuring the phase lag between stress and strain, which indicates the damping capacity. The analysis provides information about viscoelastic properties, including storage modulus, loss modulus, and tan delta (damping factor). These techniques are valuable for characterizing materials' energy dissipation capabilities under dynamic loading conditions.- DMA testing methods and apparatus: Dynamic mechanical analysis (DMA) testing methods and apparatus are used to measure the damping properties of materials. These systems typically include fixtures for holding samples, mechanisms for applying oscillatory forces, and sensors for measuring the material's response. Advanced systems may incorporate temperature control chambers, frequency sweep capabilities, and automated data collection to characterize viscoelastic properties including damping factor (tan δ).

- Damping characterization in composite materials: Dynamic mechanical analysis is used to characterize damping properties in composite materials, which is crucial for applications requiring vibration control. The analysis measures how these materials dissipate energy through internal friction when subjected to cyclic loading. Parameters such as storage modulus, loss modulus, and damping factor provide insights into the viscoelastic behavior of composites, helping engineers design materials with optimal damping characteristics for specific applications.

- Temperature-dependent damping analysis: Temperature plays a significant role in the damping behavior of materials, which can be analyzed through dynamic mechanical analysis. As temperature changes, materials may undergo transitions that significantly affect their damping properties. DMA techniques that incorporate temperature control allow for the identification of glass transition temperatures, relaxation processes, and other thermal events that influence damping characteristics, providing valuable data for material selection in various environmental conditions.

- Computational modeling of damping properties: Computational methods are employed to model and predict the damping properties of materials based on dynamic mechanical analysis data. These models use finite element analysis, machine learning algorithms, or other computational techniques to simulate material behavior under various loading conditions. By creating digital representations of material damping characteristics, engineers can optimize designs without extensive physical testing, accelerating product development and improving performance prediction.

- Novel materials with enhanced damping properties: Research focuses on developing new materials with superior damping properties that can be characterized through dynamic mechanical analysis. These innovations include specially formulated polymers, nanocomposites, and hybrid materials designed to provide enhanced vibration absorption and noise reduction. The materials often incorporate specific additives or structural modifications that increase internal friction and energy dissipation, resulting in higher damping capacity while maintaining other desirable mechanical properties.

02 Damping measurement in composite and polymer materials

Dynamic mechanical analysis is particularly useful for evaluating damping characteristics in composite and polymer materials. The technique allows for the assessment of damping as a function of temperature, frequency, and strain amplitude. This is crucial for understanding how these materials dissipate energy under various conditions. The damping properties are influenced by the material's composition, structure, and processing conditions, making DMA an essential tool for material development and quality control in industries requiring vibration control.Expand Specific Solutions03 Computer modeling and simulation of damping behavior

Advanced computational methods are employed to model and simulate the damping behavior of materials and structures. These approaches include finite element analysis, machine learning algorithms, and digital twins that can predict dynamic mechanical responses. The simulations help in understanding complex damping mechanisms and optimizing material designs before physical testing. This reduces development time and costs while enabling the exploration of a wider range of design parameters for achieving desired damping characteristics.Expand Specific Solutions04 Damping measurement devices and apparatus

Specialized equipment and apparatus have been developed for conducting dynamic mechanical analysis to measure damping properties. These devices typically include precision force actuators, displacement sensors, environmental chambers for temperature control, and sophisticated data acquisition systems. The equipment allows for testing under various conditions including different frequencies, temperatures, and loading modes. Recent innovations focus on improving measurement accuracy, expanding testing capabilities, and enhancing automation for more efficient characterization of damping properties.Expand Specific Solutions05 Applications of damping analysis in structural health monitoring

Dynamic mechanical analysis of damping properties is increasingly used in structural health monitoring applications. Changes in damping characteristics can indicate material degradation, damage, or structural failures before they become visually apparent. This approach enables predictive maintenance strategies and enhances safety in critical infrastructure, aerospace components, and automotive systems. The analysis involves continuous or periodic monitoring of damping parameters and comparing them against baseline values to detect anomalies that may require intervention.Expand Specific Solutions

Leading Research Institutions and Equipment Manufacturers

The dynamic mechanical analysis (DMA) market for temperature-dependent damping research is currently in a growth phase, with increasing applications across automotive, aerospace, and materials science sectors. The market size is expanding as industries seek more precise characterization of viscoelastic properties under varying temperature conditions. Technologically, the field shows moderate maturity with established methodologies, but continues to evolve with advanced instrumentation. Leading players include specialized instrumentation companies like Mettler-Toledo GmbH and Bruker Nano, alongside materials science innovators such as Sumitomo Riko and NOK Corp. Major industrial conglomerates including Honeywell, IBM, and Robert Bosch are investing in this technology for applications in vibration control and materials development. Academic institutions like New York University are contributing fundamental research, while companies like GERB Schwingungsisolierungen focus on specialized vibration isolation applications leveraging temperature-dependent damping principles.

GERB Schwingungsisolierungen GmbH & Co.KG

Technical Solution: GERB has developed specialized methodologies for analyzing temperature-dependent damping in large-scale vibration isolation systems. Their approach combines experimental dynamic mechanical analysis with finite element modeling to characterize how temperature fluctuations affect damping performance in structural applications. The company's proprietary viscoelastic materials undergo extensive temperature-sweep testing to map damping coefficient variations across operational temperature ranges (-30°C to +70°C). Their research incorporates long-term aging studies that quantify how temperature cycling affects damping properties over time, with some test programs extending beyond 10 years to capture slow degradation mechanisms. GERB's analytical framework includes temperature-dependent spring-dashpot models that can predict frequency-dependent damping behavior under variable temperature conditions. For critical infrastructure applications, they've developed specialized testing chambers that can simulate extreme temperature events while measuring dynamic response characteristics at full scale, allowing direct correlation between laboratory DMA results and field performance.

Strengths: Unparalleled expertise in large-scale structural damping applications; comprehensive long-term aging data on temperature effects; direct correlation between laboratory testing and field implementation. Weaknesses: Research primarily focused on civil engineering applications rather than materials science fundamentals; proprietary nature of some testing methodologies limits academic collaboration.

Sumitomo Riko Co. Ltd.

Technical Solution: Sumitomo Riko has pioneered innovative approaches to temperature-dependent damping research, particularly for automotive and industrial applications. Their proprietary technology combines traditional DMA with specialized sample preparation techniques that preserve the native structure of elastomers and polymer composites. Their research methodology incorporates multi-axial loading conditions to simulate real-world mechanical environments while precisely controlling temperature variables. Sumitomo's advanced characterization system can measure damping properties across temperature ranges from -40°C to 200°C with specialized environmental chambers that can introduce controlled humidity and chemical exposure factors. The company has developed proprietary viscoelastic materials with tailored temperature-dependent damping characteristics, achieved through precise control of polymer chain architecture, cross-linking density, and nano-scale filler distribution. Their analytical models incorporate non-linear viscoelastic behavior predictions that account for temperature-history effects on damping performance.

Strengths: Extensive practical application experience in automotive vibration control systems; proprietary materials designed specifically for temperature-stable damping; comprehensive testing capabilities that simulate real-world conditions. Weaknesses: Research primarily focused on elastomeric materials rather than broader material classes; some proprietary testing methodologies limit comparability with academic research standards.

Critical Patents and Literature in Damping Characterization

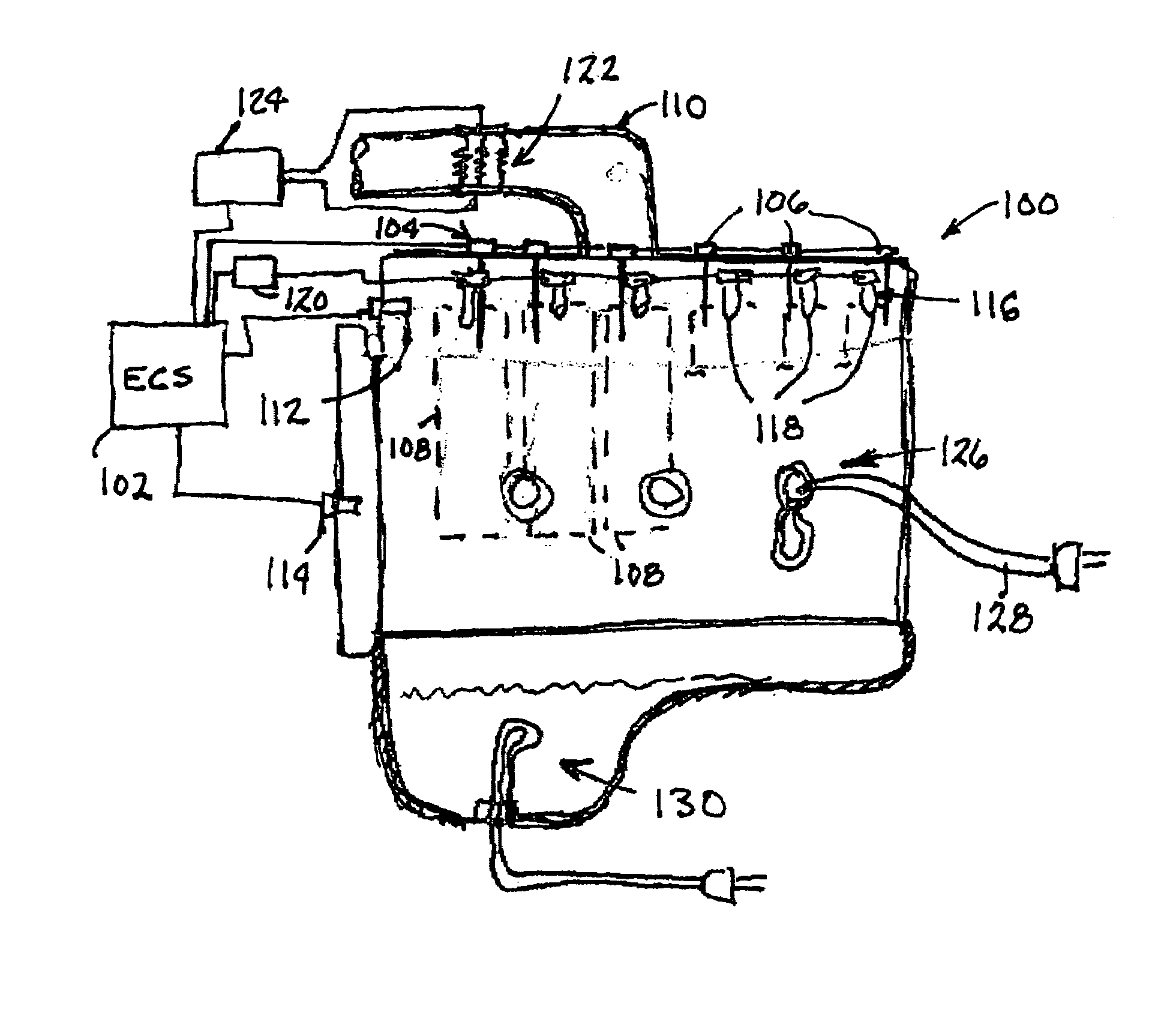

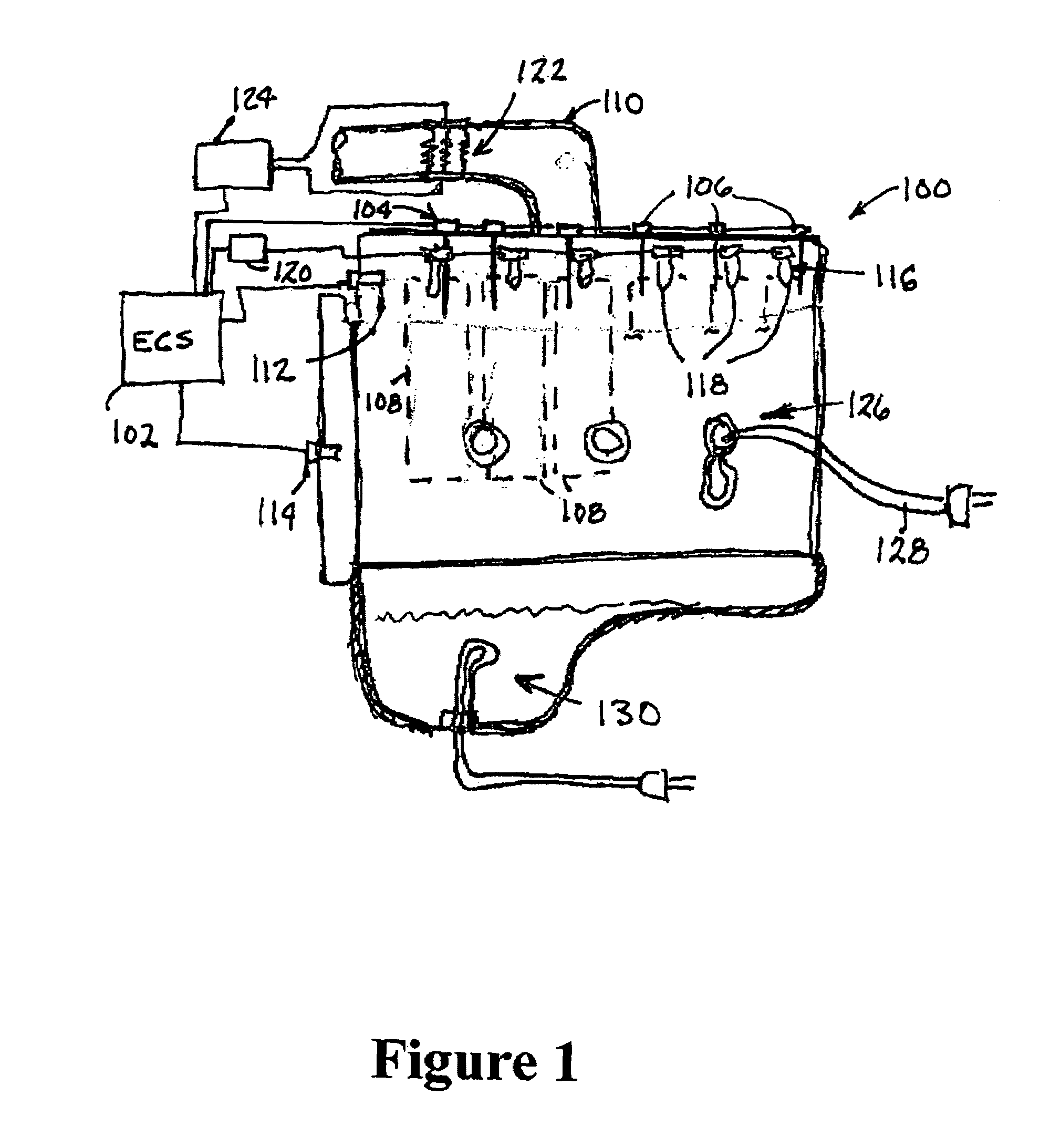

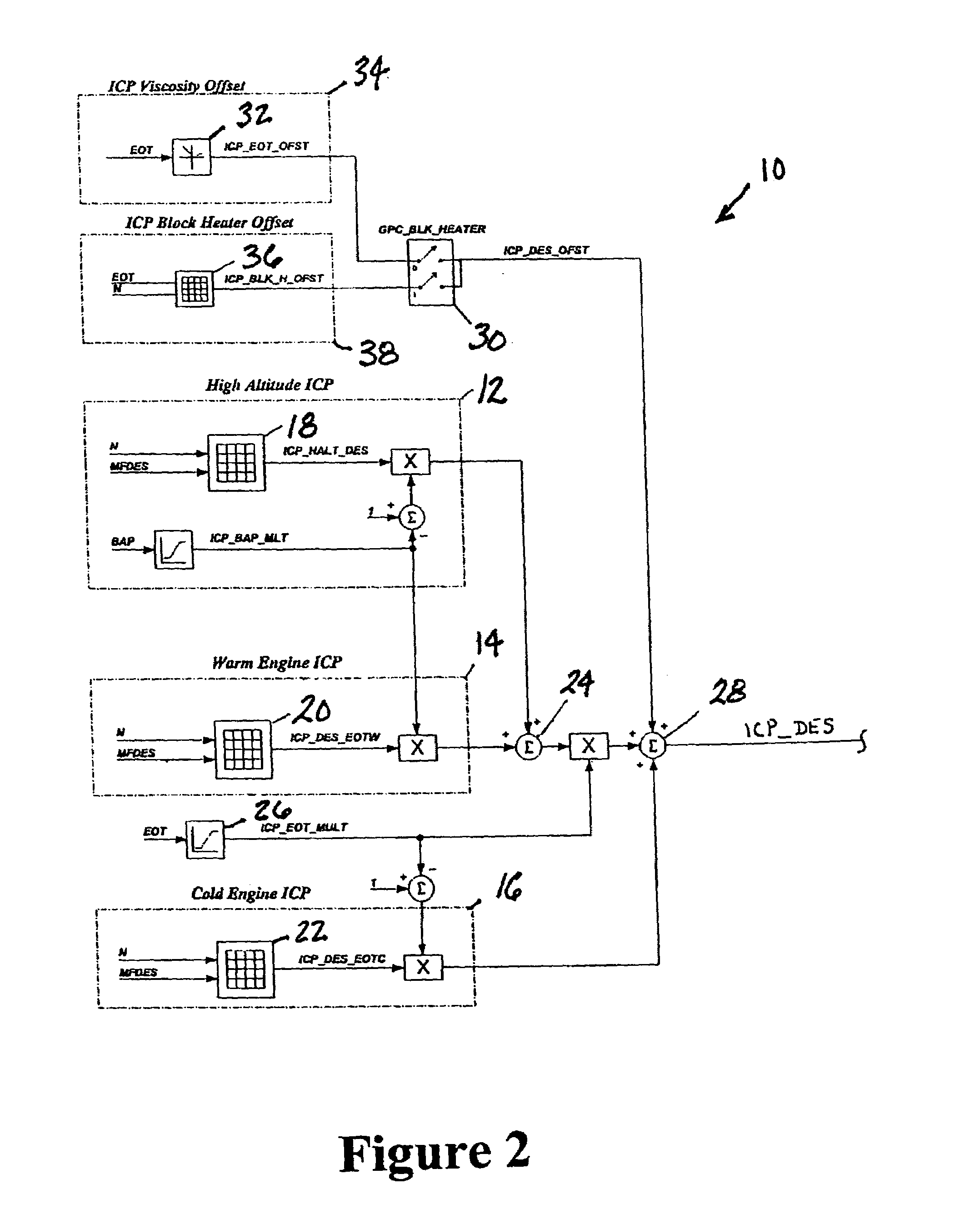

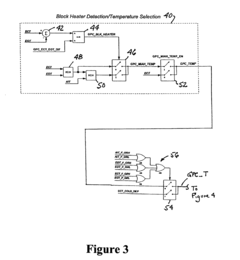

Strategy for detecting use of a block heater and for modifying temperature-dependent variables to account for its use

PatentActiveUS7277791B2

Innovation

- A control system that processes data from multiple temperature sources to detect temperature differentials between engine oil and coolant, adjusting temperature-dependent variables such as ICP and intake air heater settings based on the detected heating by a block heater, ensuring optimal starting parameters regardless of block heating usage.

Materials Science Implications and Cross-Industry Applications

Temperature-dependent damping in dynamic mechanical analysis has profound implications across materials science disciplines, serving as a critical bridge between fundamental research and practical applications. The viscoelastic behavior revealed through temperature-dependent damping provides essential insights into material structure-property relationships, enabling scientists to predict performance under various environmental conditions. This understanding has revolutionized polymer science, where glass transition temperatures and relaxation mechanisms directly influence product development for applications ranging from automotive components to medical devices.

The cross-disciplinary nature of this research extends beyond traditional materials science boundaries. In aerospace engineering, temperature-dependent damping data informs the selection of materials for components subjected to extreme thermal cycling and vibration. The ability to predict how damping characteristics evolve with temperature allows engineers to design structures with optimal vibration isolation properties throughout their operational temperature range, significantly enhancing safety and reliability.

Electronics manufacturing has similarly benefited from these advances, particularly in the development of vibration-resistant packaging for sensitive components. As electronic devices continue to miniaturize while operating at higher temperatures, understanding damping behavior becomes increasingly critical for ensuring product longevity and performance stability. The semiconductor industry specifically relies on temperature-dependent damping research to develop encapsulation materials that maintain consistent mechanical properties across wide temperature ranges.

In biomedical applications, temperature-dependent damping research has enabled the development of implantable materials with mechanical properties that closely mimic human tissues. This biomimetic approach has led to breakthroughs in prosthetics and tissue engineering, where materials must respond appropriately to the body's thermal environment while maintaining specific damping characteristics to ensure comfort and functionality.

The construction industry has incorporated these research findings into the development of advanced building materials with enhanced seismic resistance properties. Temperature-dependent damping characteristics are particularly relevant for structures in regions experiencing extreme temperature variations, where maintaining consistent vibration damping performance is essential for structural integrity during seismic events.

Energy sector applications include the development of more efficient vibration damping systems for wind turbines and other renewable energy infrastructure. By understanding how materials respond to temperature fluctuations, engineers can design components that maintain optimal damping properties throughout seasonal temperature changes, extending equipment lifespan and reducing maintenance requirements.

The cross-disciplinary nature of this research extends beyond traditional materials science boundaries. In aerospace engineering, temperature-dependent damping data informs the selection of materials for components subjected to extreme thermal cycling and vibration. The ability to predict how damping characteristics evolve with temperature allows engineers to design structures with optimal vibration isolation properties throughout their operational temperature range, significantly enhancing safety and reliability.

Electronics manufacturing has similarly benefited from these advances, particularly in the development of vibration-resistant packaging for sensitive components. As electronic devices continue to miniaturize while operating at higher temperatures, understanding damping behavior becomes increasingly critical for ensuring product longevity and performance stability. The semiconductor industry specifically relies on temperature-dependent damping research to develop encapsulation materials that maintain consistent mechanical properties across wide temperature ranges.

In biomedical applications, temperature-dependent damping research has enabled the development of implantable materials with mechanical properties that closely mimic human tissues. This biomimetic approach has led to breakthroughs in prosthetics and tissue engineering, where materials must respond appropriately to the body's thermal environment while maintaining specific damping characteristics to ensure comfort and functionality.

The construction industry has incorporated these research findings into the development of advanced building materials with enhanced seismic resistance properties. Temperature-dependent damping characteristics are particularly relevant for structures in regions experiencing extreme temperature variations, where maintaining consistent vibration damping performance is essential for structural integrity during seismic events.

Energy sector applications include the development of more efficient vibration damping systems for wind turbines and other renewable energy infrastructure. By understanding how materials respond to temperature fluctuations, engineers can design components that maintain optimal damping properties throughout seasonal temperature changes, extending equipment lifespan and reducing maintenance requirements.

Standardization and Testing Protocols Development

The development of standardized testing protocols for temperature-dependent damping in dynamic mechanical analysis (DMA) represents a critical advancement in materials characterization. Current methodologies exhibit significant variations across laboratories, equipment manufacturers, and research institutions, leading to inconsistent results and challenges in data comparison. A comprehensive standardization framework must address multiple parameters including specimen preparation, temperature control accuracy, heating/cooling rates, frequency ranges, and data processing algorithms.

International standards organizations such as ASTM, ISO, and DIN have initiated collaborative efforts to establish unified testing protocols. The ASTM E756 standard provides foundational guidelines for measuring damping properties, but requires specific extensions to address temperature-dependent behaviors across wider material classes. Recent developments have focused on calibration procedures using reference materials with well-characterized temperature-dependent damping properties to ensure measurement accuracy across different DMA instruments.

Temperature control represents a particularly challenging aspect requiring standardization. Protocols must specify acceptable temperature gradients within test specimens, stabilization periods before measurement, and verification methods to confirm actual specimen temperature versus reported system temperature. Research indicates that temperature ramp rates significantly impact measured damping properties, necessitating standardized heating/cooling profiles based on material thermal conductivity and specimen geometry.

Data processing standardization presents another critical component, particularly regarding the application of time-temperature superposition principles and relaxation spectra calculations. Protocols must define acceptable mathematical models for extracting damping parameters from raw data and specify reporting requirements including phase angle precision, storage and loss moduli units, and temperature reference points for comparative studies.

Round-robin testing programs involving multiple laboratories have demonstrated that implementing standardized protocols can reduce inter-laboratory variation from typical ranges of 15-30% down to 5-8% for temperature-dependent damping measurements. These programs have identified critical control variables including specimen mounting techniques, clamping force consistency, and environmental chamber airflow patterns that significantly impact measurement reproducibility.

Future standardization efforts must address emerging materials with complex temperature-dependent behaviors, including polymer nanocomposites, biomaterials, and high-performance aerospace alloys. Additionally, protocols must evolve to incorporate non-linear viscoelastic behaviors observed at temperature transition regions and establish clear guidelines for reporting uncertainty in temperature-dependent damping measurements across the full operational temperature range of materials.

International standards organizations such as ASTM, ISO, and DIN have initiated collaborative efforts to establish unified testing protocols. The ASTM E756 standard provides foundational guidelines for measuring damping properties, but requires specific extensions to address temperature-dependent behaviors across wider material classes. Recent developments have focused on calibration procedures using reference materials with well-characterized temperature-dependent damping properties to ensure measurement accuracy across different DMA instruments.

Temperature control represents a particularly challenging aspect requiring standardization. Protocols must specify acceptable temperature gradients within test specimens, stabilization periods before measurement, and verification methods to confirm actual specimen temperature versus reported system temperature. Research indicates that temperature ramp rates significantly impact measured damping properties, necessitating standardized heating/cooling profiles based on material thermal conductivity and specimen geometry.

Data processing standardization presents another critical component, particularly regarding the application of time-temperature superposition principles and relaxation spectra calculations. Protocols must define acceptable mathematical models for extracting damping parameters from raw data and specify reporting requirements including phase angle precision, storage and loss moduli units, and temperature reference points for comparative studies.

Round-robin testing programs involving multiple laboratories have demonstrated that implementing standardized protocols can reduce inter-laboratory variation from typical ranges of 15-30% down to 5-8% for temperature-dependent damping measurements. These programs have identified critical control variables including specimen mounting techniques, clamping force consistency, and environmental chamber airflow patterns that significantly impact measurement reproducibility.

Future standardization efforts must address emerging materials with complex temperature-dependent behaviors, including polymer nanocomposites, biomaterials, and high-performance aerospace alloys. Additionally, protocols must evolve to incorporate non-linear viscoelastic behaviors observed at temperature transition regions and establish clear guidelines for reporting uncertainty in temperature-dependent damping measurements across the full operational temperature range of materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!