Dynamic mechanical analysis of polymer viscoelastic behavior

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polymer Viscoelasticity Background and Research Objectives

Polymer viscoelasticity represents a fundamental property of polymeric materials that combines both elastic and viscous behaviors under mechanical stress. This dual nature has been studied extensively since the early 20th century, beginning with the pioneering work of researchers like Boltzmann and Maxwell who established the theoretical foundations for understanding time-dependent material responses. The field has evolved significantly over the decades, transitioning from empirical observations to sophisticated molecular-level understanding of polymer chain dynamics.

Dynamic mechanical analysis (DMA) emerged as a critical analytical technique in the 1950s and has since become an indispensable tool for characterizing viscoelastic properties. The technique applies oscillatory stress or strain to materials and measures the resulting mechanical response, providing insights into storage modulus, loss modulus, and damping characteristics across different temperatures and frequencies.

Recent technological advancements have expanded the capabilities of DMA instrumentation, enabling measurements across broader frequency ranges, temperature spans, and environmental conditions. These developments have paralleled the growing complexity of polymer applications in industries ranging from automotive to biomedical, where precise control of viscoelastic properties is essential for product performance.

The current research landscape shows a clear trend toward multi-scale characterization approaches that connect macroscopic viscoelastic behavior to molecular architecture and dynamics. This evolution reflects the increasing sophistication of polymer science and the demand for materials with tailored viscoelastic responses for specific applications.

Our technical research objectives focus on several key areas. First, we aim to develop enhanced methodologies for DMA that can provide more comprehensive characterization of complex polymer systems, including multi-phase materials, nanocomposites, and stimuli-responsive polymers. These methodologies should bridge the gap between laboratory measurements and real-world performance predictions.

Second, we seek to establish robust structure-property relationships that connect molecular architecture to viscoelastic response, enabling more rational design of polymeric materials with predetermined mechanical behaviors. This includes investigating the effects of molecular weight distribution, chain branching, crosslinking density, and supramolecular interactions.

Third, we intend to explore the integration of artificial intelligence and machine learning approaches with DMA data analysis to extract deeper insights from complex viscoelastic data sets and potentially predict long-term material behavior from short-term tests.

Finally, our research aims to develop standardized protocols for viscoelastic characterization that can be applied across different polymer classes and application domains, facilitating more effective material selection and performance comparison in industrial settings.

Dynamic mechanical analysis (DMA) emerged as a critical analytical technique in the 1950s and has since become an indispensable tool for characterizing viscoelastic properties. The technique applies oscillatory stress or strain to materials and measures the resulting mechanical response, providing insights into storage modulus, loss modulus, and damping characteristics across different temperatures and frequencies.

Recent technological advancements have expanded the capabilities of DMA instrumentation, enabling measurements across broader frequency ranges, temperature spans, and environmental conditions. These developments have paralleled the growing complexity of polymer applications in industries ranging from automotive to biomedical, where precise control of viscoelastic properties is essential for product performance.

The current research landscape shows a clear trend toward multi-scale characterization approaches that connect macroscopic viscoelastic behavior to molecular architecture and dynamics. This evolution reflects the increasing sophistication of polymer science and the demand for materials with tailored viscoelastic responses for specific applications.

Our technical research objectives focus on several key areas. First, we aim to develop enhanced methodologies for DMA that can provide more comprehensive characterization of complex polymer systems, including multi-phase materials, nanocomposites, and stimuli-responsive polymers. These methodologies should bridge the gap between laboratory measurements and real-world performance predictions.

Second, we seek to establish robust structure-property relationships that connect molecular architecture to viscoelastic response, enabling more rational design of polymeric materials with predetermined mechanical behaviors. This includes investigating the effects of molecular weight distribution, chain branching, crosslinking density, and supramolecular interactions.

Third, we intend to explore the integration of artificial intelligence and machine learning approaches with DMA data analysis to extract deeper insights from complex viscoelastic data sets and potentially predict long-term material behavior from short-term tests.

Finally, our research aims to develop standardized protocols for viscoelastic characterization that can be applied across different polymer classes and application domains, facilitating more effective material selection and performance comparison in industrial settings.

Market Applications and Industry Demand for DMA Testing

The Dynamic Mechanical Analysis (DMA) testing market has witnessed substantial growth in recent years, driven by increasing demand across multiple industries requiring precise characterization of polymer viscoelastic properties. The global DMA testing equipment market is currently valued at approximately 382 million USD, with projections indicating a compound annual growth rate of 4.7% through 2028.

Aerospace and automotive industries represent the largest application segments, collectively accounting for over 40% of the total market demand. In aerospace, DMA testing is critical for evaluating composite materials used in aircraft structures, where understanding viscoelastic behavior under varying temperature and frequency conditions directly impacts safety and performance. The automotive sector similarly relies on DMA for developing lightweight, high-performance polymers and composites that meet stringent regulatory requirements for fuel efficiency and crash safety.

The medical device industry has emerged as the fastest-growing application segment, with demand increasing at nearly 6% annually. This growth is primarily driven by the need to characterize biomaterials and polymers used in implantable devices, where viscoelastic properties directly influence biocompatibility and long-term performance in physiological environments.

Electronics manufacturers increasingly utilize DMA testing for evaluating polymeric materials in flexible displays, circuit boards, and encapsulants. The miniaturization trend in electronics has heightened the importance of understanding how polymers behave under thermal and mechanical stress at micro and nano scales, creating specialized demand for high-precision DMA instruments.

Construction and infrastructure sectors show growing interest in DMA testing for developing advanced polymer-modified concrete, asphalt, and structural adhesives with enhanced durability and performance characteristics. This segment is expected to grow significantly as green building initiatives drive innovation in sustainable construction materials.

Academic and research institutions constitute approximately 18% of the market, serving as both end-users and innovation drivers. Their research activities often translate into commercial applications, creating a symbiotic relationship with industrial demand.

Geographically, North America and Europe currently dominate the market with a combined share of 62%, though Asia-Pacific is experiencing the highest growth rate, particularly in China, Japan, and South Korea. This regional shift reflects the expanding manufacturing base and increasing R&D investments in polymer science across Asian economies.

The market is further stimulated by evolving regulatory standards in various industries that mandate more comprehensive material characterization, particularly regarding aging, fatigue, and environmental stability of polymeric components in critical applications.

Aerospace and automotive industries represent the largest application segments, collectively accounting for over 40% of the total market demand. In aerospace, DMA testing is critical for evaluating composite materials used in aircraft structures, where understanding viscoelastic behavior under varying temperature and frequency conditions directly impacts safety and performance. The automotive sector similarly relies on DMA for developing lightweight, high-performance polymers and composites that meet stringent regulatory requirements for fuel efficiency and crash safety.

The medical device industry has emerged as the fastest-growing application segment, with demand increasing at nearly 6% annually. This growth is primarily driven by the need to characterize biomaterials and polymers used in implantable devices, where viscoelastic properties directly influence biocompatibility and long-term performance in physiological environments.

Electronics manufacturers increasingly utilize DMA testing for evaluating polymeric materials in flexible displays, circuit boards, and encapsulants. The miniaturization trend in electronics has heightened the importance of understanding how polymers behave under thermal and mechanical stress at micro and nano scales, creating specialized demand for high-precision DMA instruments.

Construction and infrastructure sectors show growing interest in DMA testing for developing advanced polymer-modified concrete, asphalt, and structural adhesives with enhanced durability and performance characteristics. This segment is expected to grow significantly as green building initiatives drive innovation in sustainable construction materials.

Academic and research institutions constitute approximately 18% of the market, serving as both end-users and innovation drivers. Their research activities often translate into commercial applications, creating a symbiotic relationship with industrial demand.

Geographically, North America and Europe currently dominate the market with a combined share of 62%, though Asia-Pacific is experiencing the highest growth rate, particularly in China, Japan, and South Korea. This regional shift reflects the expanding manufacturing base and increasing R&D investments in polymer science across Asian economies.

The market is further stimulated by evolving regulatory standards in various industries that mandate more comprehensive material characterization, particularly regarding aging, fatigue, and environmental stability of polymeric components in critical applications.

Current DMA Technology Status and Technical Barriers

Dynamic Mechanical Analysis (DMA) technology has evolved significantly over the past decades, becoming an essential tool for characterizing polymer viscoelastic behavior. Current state-of-the-art DMA instruments typically operate across temperature ranges from -150°C to 600°C and frequency ranges from 0.01 Hz to 200 Hz, with force sensitivity in the millinewton range. These capabilities allow for comprehensive characterization of polymer transitions, including glass transitions, secondary transitions, and crystalline melting.

Modern commercial DMA systems predominantly employ one of three deformation modes: tension, compression, or shear. Each mode offers distinct advantages for specific material types and property investigations. Tension mode is particularly effective for thin films and fibers, while compression is suited for rigid materials and shear excels at measuring interfacial properties in composites.

Despite these advancements, significant technical barriers persist in DMA technology. A primary challenge involves measurement accuracy at extreme conditions, particularly at very high temperatures where instrument compliance becomes problematic, or at very low temperatures where material brittleness introduces measurement artifacts. These limitations often necessitate complex calibration procedures that can introduce additional uncertainties.

Frequency limitations represent another substantial barrier. While time-temperature superposition principles can extend the effective frequency range mathematically, direct measurements at very high frequencies (>200 Hz) remain challenging due to inertial effects and resonance phenomena in the measurement systems. This gap is particularly problematic for understanding polymer behavior under rapid loading conditions relevant to impact scenarios.

Sample geometry constraints also present significant challenges. Current DMA technologies require careful sample preparation with precise dimensions, limiting applicability for heterogeneous or irregularly shaped materials. This becomes particularly problematic when analyzing composite materials with complex microstructures or when sample quantities are limited, as in the case of novel material development.

Data interpretation remains another substantial barrier, particularly for complex polymer systems exhibiting multiple overlapping transitions or for multi-phase materials. Current analytical models often struggle to deconvolute these complex responses into meaningful structural information, limiting the depth of insights obtainable from DMA measurements.

Miniaturization represents an emerging challenge, with increasing demand for characterizing microscale and nanoscale polymer structures. While some progress has been made in developing micro-DMA techniques, significant barriers remain in achieving the necessary force sensitivity while maintaining temperature control at these reduced scales.

Modern commercial DMA systems predominantly employ one of three deformation modes: tension, compression, or shear. Each mode offers distinct advantages for specific material types and property investigations. Tension mode is particularly effective for thin films and fibers, while compression is suited for rigid materials and shear excels at measuring interfacial properties in composites.

Despite these advancements, significant technical barriers persist in DMA technology. A primary challenge involves measurement accuracy at extreme conditions, particularly at very high temperatures where instrument compliance becomes problematic, or at very low temperatures where material brittleness introduces measurement artifacts. These limitations often necessitate complex calibration procedures that can introduce additional uncertainties.

Frequency limitations represent another substantial barrier. While time-temperature superposition principles can extend the effective frequency range mathematically, direct measurements at very high frequencies (>200 Hz) remain challenging due to inertial effects and resonance phenomena in the measurement systems. This gap is particularly problematic for understanding polymer behavior under rapid loading conditions relevant to impact scenarios.

Sample geometry constraints also present significant challenges. Current DMA technologies require careful sample preparation with precise dimensions, limiting applicability for heterogeneous or irregularly shaped materials. This becomes particularly problematic when analyzing composite materials with complex microstructures or when sample quantities are limited, as in the case of novel material development.

Data interpretation remains another substantial barrier, particularly for complex polymer systems exhibiting multiple overlapping transitions or for multi-phase materials. Current analytical models often struggle to deconvolute these complex responses into meaningful structural information, limiting the depth of insights obtainable from DMA measurements.

Miniaturization represents an emerging challenge, with increasing demand for characterizing microscale and nanoscale polymer structures. While some progress has been made in developing micro-DMA techniques, significant barriers remain in achieving the necessary force sensitivity while maintaining temperature control at these reduced scales.

Established DMA Methodologies and Testing Protocols

01 Viscoelastic polymer compositions for enhanced oil recovery

Viscoelastic polymer compositions are used in enhanced oil recovery operations to improve the efficiency of oil extraction from reservoirs. These polymers exhibit both viscous and elastic properties that help control fluid mobility and increase sweep efficiency in reservoir formations. The viscoelastic behavior allows for better displacement of oil from porous media and reduces fingering effects during flooding operations, ultimately leading to higher recovery rates.- Viscoelastic polymer compositions for enhanced oil recovery: Viscoelastic polymer compositions are used in enhanced oil recovery operations to improve oil displacement efficiency. These polymers exhibit both viscous and elastic properties that help control fluid mobility in reservoirs. When injected into oil-bearing formations, they can modify the flow behavior of water, reducing fingering effects and improving sweep efficiency. The viscoelastic properties allow for better conformance control and increased oil recovery from heterogeneous reservoirs.

- Measurement and characterization of polymer viscoelastic properties: Various methods and devices are used to measure and characterize the viscoelastic behavior of polymers. These include rheological testing equipment, dynamic mechanical analysis, and specialized sensors that can determine properties such as storage modulus, loss modulus, and complex viscosity. Advanced techniques allow for the measurement of viscoelastic properties under different conditions of temperature, pressure, and deformation rates, providing valuable data for polymer design and application development.

- Viscoelastic polymers in medical and pharmaceutical applications: Viscoelastic polymers are utilized in various medical and pharmaceutical applications due to their unique mechanical properties. These materials can be formulated to mimic biological tissues, making them suitable for implants, drug delivery systems, and tissue engineering scaffolds. Their ability to absorb and dissipate energy makes them valuable in applications requiring shock absorption or controlled deformation. Additionally, their viscoelastic response can be tuned to provide specific release profiles for pharmaceutical compounds.

- Polymer viscoelasticity in adhesive and coating technologies: The viscoelastic behavior of polymers plays a crucial role in adhesive and coating technologies. Polymers with optimized viscoelastic properties provide the right balance of tack, peel strength, and shear resistance in adhesives. In coatings, viscoelasticity affects film formation, durability, and resistance to environmental stresses. By controlling the viscoelastic response through polymer design and formulation, materials can be developed with specific performance characteristics for various industrial and consumer applications.

- Modification of polymer viscoelastic properties through additives and processing: The viscoelastic properties of polymers can be modified through the incorporation of additives and specific processing techniques. Plasticizers, fillers, crosslinking agents, and other additives can significantly alter the viscoelastic response of polymer systems. Processing conditions such as temperature, pressure, and shear rate during extrusion, molding, or other forming operations also influence the final viscoelastic behavior. These modifications allow for the tailoring of polymer materials to meet specific performance requirements in various applications.

02 Measurement and characterization of polymer viscoelastic properties

Various methods and devices are employed to measure and characterize the viscoelastic behavior of polymers. These include rheological testing instruments, dynamic mechanical analysis, and specialized testing protocols that can determine properties such as storage modulus, loss modulus, and complex viscosity. Advanced measurement techniques allow for the evaluation of polymer response under different conditions of temperature, pressure, and deformation rates, providing crucial data for material selection and process optimization.Expand Specific Solutions03 Viscoelastic polymers in medical and healthcare applications

Viscoelastic polymers are utilized in various medical and healthcare applications due to their unique mechanical properties that can mimic biological tissues. These materials are employed in the development of implants, drug delivery systems, wound dressings, and tissue engineering scaffolds. The viscoelastic behavior allows these polymers to provide appropriate mechanical support while maintaining biocompatibility and facilitating integration with surrounding tissues.Expand Specific Solutions04 Polymer viscoelasticity in construction and structural applications

Viscoelastic polymers are incorporated into construction materials and structural components to provide damping, energy absorption, and vibration control. These polymers can dissipate mechanical energy through their time-dependent deformation characteristics, making them valuable in applications such as seismic isolation systems, vibration dampers, and impact-resistant structures. The viscoelastic response helps to improve structural performance under dynamic loading conditions.Expand Specific Solutions05 Modification and control of polymer viscoelastic behavior

Various methods are employed to modify and control the viscoelastic properties of polymers, including chemical modification, blending with other materials, and incorporation of additives. These approaches allow for the tailoring of viscoelastic response to meet specific application requirements. Techniques such as crosslinking, plasticization, and the addition of fillers can significantly alter the time-dependent mechanical behavior of polymers, enabling the development of materials with customized viscoelastic characteristics.Expand Specific Solutions

Leading Manufacturers and Research Institutions in DMA Field

The dynamic mechanical analysis of polymer viscoelastic behavior market is currently in a growth phase, with increasing applications across automotive, aerospace, and medical industries. The global market size for polymer testing equipment is estimated at $1.2-1.5 billion, with viscoelastic analysis instruments representing a significant segment. Leading players include established materials science companies like BASF, ExxonMobil Chemical, and 3M Innovative Properties, alongside specialized testing equipment manufacturers such as Bruker Nano. The technology has reached moderate maturity, with companies like Bridgestone, Michelin, and Toyo Tire leveraging it for advanced material development. Academic institutions including University of Akron and Clarkson University collaborate with industry leaders to advance fundamental understanding of polymer viscoelasticity, while research organizations like Naval Research Laboratory contribute to specialized applications.

Borealis GmbH

Technical Solution: Borealis has developed advanced multi-frequency DMA methodologies for polyolefin characterization, focusing on time-temperature superposition principles to predict long-term mechanical behavior. Their approach combines traditional isothermal frequency sweeps with temperature ramps to generate master curves that span beyond the experimentally accessible time scale. The company employs proprietary algorithms to analyze the complex modulus data (storage and loss modulus) across different crystallinity levels and molecular weight distributions. Their technology enables precise mapping of viscoelastic transitions in semi-crystalline polymers, particularly for pipe and automotive applications where long-term performance prediction is critical. Borealis has integrated rheological models with DMA data to establish structure-property relationships that inform their material development process.

Strengths: Superior prediction of long-term creep behavior in polyolefins; excellent correlation between molecular architecture and mechanical performance. Weaknesses: Methodology may be less effective for highly filled systems; requires specialized equipment and expertise for proper implementation.

Bruker Nano, Inc.

Technical Solution: Bruker Nano has pioneered high-precision DMA instrumentation with nanoscale resolution capabilities for polymer viscoelastic characterization. Their technology combines traditional DMA with atomic force microscopy (AFM) to enable nanomechanical analysis at unprecedented spatial resolution. The company's NanoDMA III system allows for quantitative mapping of viscoelastic properties with nanometer precision, measuring storage modulus, loss modulus, and tan delta at the nanoscale. This approach enables researchers to correlate bulk viscoelastic behavior with local structural features in heterogeneous polymer systems, including phase-separated blends, nanocomposites, and multilayer films. Bruker's technology employs frequency-specific excitation combined with temperature control to generate comprehensive viscoelastic property maps across multiple length scales, providing insights into structure-property relationships that conventional DMA cannot achieve.

Strengths: Unparalleled spatial resolution for heterogeneous systems; ability to correlate nanoscale and bulk properties; excellent for interface and interphase analysis. Weaknesses: Higher cost compared to conventional DMA; requires specialized training; sample preparation can be challenging for certain polymer systems.

Critical Patents and Literature in Polymer Viscoelastic Analysis

Tire Tread

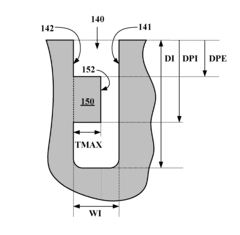

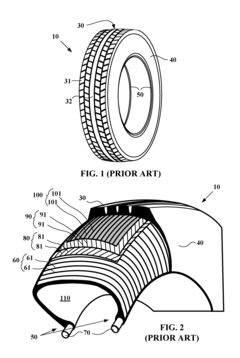

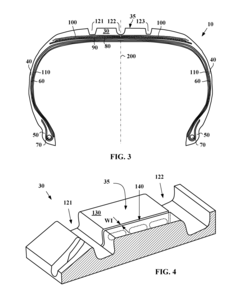

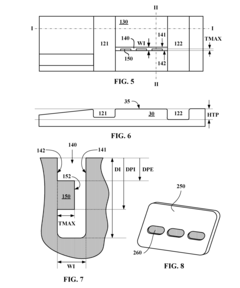

PatentInactiveUS20130306209A1

Innovation

- A tire tread with a rubber composition of Shore A hardness between 58 and 65, featuring incisions delimited by two rubber walls with protuberances that reduce the incision width, and a radial tread pattern height between 5 and 8 mm, which enhances cornering stiffness and wear resistance.

Temperature and Frequency Effects on Polymer Performance

Temperature and frequency are two critical parameters that significantly influence the viscoelastic behavior of polymers during dynamic mechanical analysis (DMA). The temperature dependence of polymer performance is characterized by distinct transitions, most notably the glass transition temperature (Tg), where the material transforms from a rigid, glassy state to a more flexible, rubbery state. This transition is accompanied by dramatic changes in mechanical properties, including storage modulus, loss modulus, and damping factor (tan δ).

At temperatures below Tg, polymers exhibit high stiffness and limited molecular mobility, resulting in predominantly elastic behavior with minimal viscous response. As temperature increases through the glass transition region, there is a substantial decrease in storage modulus, often by several orders of magnitude, while the loss modulus and tan δ typically show pronounced peaks. This behavior reflects the onset of coordinated segmental motion within the polymer chains.

Beyond Tg, in the rubbery plateau region, polymers display temperature-dependent behavior governed by entropic elasticity until reaching the flow region at higher temperatures, where permanent deformation occurs. The breadth and position of these transitions provide valuable insights into polymer structure, including crosslinking density, crystallinity, and molecular weight distribution.

Frequency effects are equally important in characterizing polymer viscoelasticity. At low frequencies, polymers have sufficient time to respond to applied stresses, exhibiting more viscous-like behavior. Conversely, at high frequencies, the material response becomes increasingly elastic as molecular rearrangements cannot keep pace with the rapid deformation cycles. This frequency dependence is often described using the time-temperature superposition principle, which establishes an equivalence between the effects of changing temperature and frequency.

The combined analysis of temperature and frequency effects enables the construction of master curves that predict polymer performance across a broader range of conditions than experimentally accessible. This approach is particularly valuable for applications involving varying service temperatures or loading rates, such as automotive components, aerospace materials, and biomedical devices.

Modern DMA techniques allow for precise control of both temperature and frequency parameters, facilitating comprehensive characterization of complex polymer systems, including blends, composites, and nanostructured materials. The resulting data provides essential inputs for constitutive models used in finite element analysis and product design, enabling more accurate prediction of long-term performance and failure mechanisms in polymer-based products.

At temperatures below Tg, polymers exhibit high stiffness and limited molecular mobility, resulting in predominantly elastic behavior with minimal viscous response. As temperature increases through the glass transition region, there is a substantial decrease in storage modulus, often by several orders of magnitude, while the loss modulus and tan δ typically show pronounced peaks. This behavior reflects the onset of coordinated segmental motion within the polymer chains.

Beyond Tg, in the rubbery plateau region, polymers display temperature-dependent behavior governed by entropic elasticity until reaching the flow region at higher temperatures, where permanent deformation occurs. The breadth and position of these transitions provide valuable insights into polymer structure, including crosslinking density, crystallinity, and molecular weight distribution.

Frequency effects are equally important in characterizing polymer viscoelasticity. At low frequencies, polymers have sufficient time to respond to applied stresses, exhibiting more viscous-like behavior. Conversely, at high frequencies, the material response becomes increasingly elastic as molecular rearrangements cannot keep pace with the rapid deformation cycles. This frequency dependence is often described using the time-temperature superposition principle, which establishes an equivalence between the effects of changing temperature and frequency.

The combined analysis of temperature and frequency effects enables the construction of master curves that predict polymer performance across a broader range of conditions than experimentally accessible. This approach is particularly valuable for applications involving varying service temperatures or loading rates, such as automotive components, aerospace materials, and biomedical devices.

Modern DMA techniques allow for precise control of both temperature and frequency parameters, facilitating comprehensive characterization of complex polymer systems, including blends, composites, and nanostructured materials. The resulting data provides essential inputs for constitutive models used in finite element analysis and product design, enabling more accurate prediction of long-term performance and failure mechanisms in polymer-based products.

Computational Modeling Advances for Viscoelastic Properties

Computational modeling has revolutionized the study of polymer viscoelastic behavior by providing powerful tools to predict material responses under various conditions without extensive physical testing. Recent advances in finite element analysis (FEA) have enabled more accurate simulations of complex viscoelastic phenomena, incorporating multi-scale modeling approaches that bridge molecular dynamics with macroscopic material behavior.

Machine learning algorithms have emerged as game-changers in viscoelastic property prediction, with neural networks demonstrating remarkable accuracy in forecasting time-dependent mechanical responses. These models can process vast experimental datasets to identify patterns and relationships that traditional constitutive equations might miss, leading to more precise predictions of creep, stress relaxation, and dynamic mechanical properties.

Molecular dynamics (MD) simulations have advanced significantly, now capable of modeling polymer chain interactions at the atomic level while accounting for temperature effects, crosslinking density, and molecular weight distribution. These simulations provide unprecedented insights into the molecular mechanisms underlying viscoelastic behavior, particularly in understanding the glass transition and relaxation processes.

Cloud computing and parallel processing technologies have dramatically reduced computation times for complex viscoelastic models. Simulations that once required weeks on specialized hardware can now be completed in hours, enabling iterative design processes and parameter optimization studies that were previously impractical.

Digital twin technology represents the frontier of computational modeling for viscoelastic materials, creating virtual replicas of physical polymer systems that update in real-time based on operational data. These digital twins enable predictive maintenance, performance optimization, and accelerated material development by continuously refining their predictive capabilities through feedback loops with physical testing.

Open-source modeling frameworks have democratized access to advanced computational tools, fostering collaboration across academic and industrial research communities. Platforms like LAMMPS for molecular dynamics and FEniCS for finite element analysis provide researchers with sophisticated capabilities for modeling viscoelastic behavior without prohibitive licensing costs.

The integration of multi-physics modeling approaches has enabled more holistic simulations that account for coupled thermal, mechanical, and chemical processes in viscoelastic materials. These integrated models are particularly valuable for predicting behavior under complex loading conditions and environmental factors that influence polymer performance in real-world applications.

Machine learning algorithms have emerged as game-changers in viscoelastic property prediction, with neural networks demonstrating remarkable accuracy in forecasting time-dependent mechanical responses. These models can process vast experimental datasets to identify patterns and relationships that traditional constitutive equations might miss, leading to more precise predictions of creep, stress relaxation, and dynamic mechanical properties.

Molecular dynamics (MD) simulations have advanced significantly, now capable of modeling polymer chain interactions at the atomic level while accounting for temperature effects, crosslinking density, and molecular weight distribution. These simulations provide unprecedented insights into the molecular mechanisms underlying viscoelastic behavior, particularly in understanding the glass transition and relaxation processes.

Cloud computing and parallel processing technologies have dramatically reduced computation times for complex viscoelastic models. Simulations that once required weeks on specialized hardware can now be completed in hours, enabling iterative design processes and parameter optimization studies that were previously impractical.

Digital twin technology represents the frontier of computational modeling for viscoelastic materials, creating virtual replicas of physical polymer systems that update in real-time based on operational data. These digital twins enable predictive maintenance, performance optimization, and accelerated material development by continuously refining their predictive capabilities through feedback loops with physical testing.

Open-source modeling frameworks have democratized access to advanced computational tools, fostering collaboration across academic and industrial research communities. Platforms like LAMMPS for molecular dynamics and FEniCS for finite element analysis provide researchers with sophisticated capabilities for modeling viscoelastic behavior without prohibitive licensing costs.

The integration of multi-physics modeling approaches has enabled more holistic simulations that account for coupled thermal, mechanical, and chemical processes in viscoelastic materials. These integrated models are particularly valuable for predicting behavior under complex loading conditions and environmental factors that influence polymer performance in real-world applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!