Analysis of Photocatalytic Disinfection Efficiency under UV-LED Irradiation

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UV-LED Photocatalysis Background and Objectives

Photocatalytic disinfection using UV-LED technology represents a significant advancement in water and surface treatment methodologies. This technology has evolved considerably over the past three decades, transitioning from traditional mercury-based UV lamps to more efficient, environmentally friendly LED-based systems. The evolution began in the early 1990s with the discovery of titanium dioxide's photocatalytic properties under UV irradiation, followed by significant breakthroughs in UV-LED manufacturing in the early 2000s that enabled practical applications.

The integration of UV-LED technology with photocatalytic materials has created a synergistic effect, enhancing disinfection efficiency while reducing energy consumption. Recent advancements have focused on optimizing wavelength specificity, with research indicating that certain UV wavelengths (particularly in the UVC range of 250-280 nm) demonstrate superior germicidal properties when combined with appropriate photocatalysts.

Current technological trends point toward the development of more efficient photocatalytic materials that can operate under lower-intensity UV-LED irradiation, extending operational lifespans and reducing energy requirements. Additionally, there is growing interest in visible-light-responsive photocatalysts that can utilize broader spectrum LEDs, potentially reducing costs and expanding application scenarios.

The primary objective of this technical research is to comprehensively analyze the efficiency parameters of photocatalytic disinfection systems under UV-LED irradiation across various operational conditions. Specifically, we aim to quantify the relationship between UV-LED wavelength, intensity, exposure time, and the resulting disinfection efficacy against common pathogens when combined with different photocatalytic materials.

Secondary objectives include identifying optimal operational parameters for maximum disinfection efficiency while minimizing energy consumption, evaluating the long-term stability and durability of various photocatalyst-UV-LED combinations, and assessing the potential for scaling these technologies for industrial and municipal applications.

The research also seeks to address current limitations in UV-LED photocatalysis, particularly regarding the quantum efficiency of photocatalytic reactions, the narrow effective bandwidth of many photocatalysts, and challenges related to uniform irradiation in complex geometries. By systematically analyzing these factors, we aim to establish a comprehensive framework for evaluating and optimizing photocatalytic disinfection systems powered by UV-LED technology.

This investigation is particularly timely given the increasing global demand for sustainable, chemical-free disinfection technologies in water treatment, healthcare settings, and food processing industries, where traditional disinfection methods face challenges related to chemical residues, pathogen resistance, and environmental impact.

The integration of UV-LED technology with photocatalytic materials has created a synergistic effect, enhancing disinfection efficiency while reducing energy consumption. Recent advancements have focused on optimizing wavelength specificity, with research indicating that certain UV wavelengths (particularly in the UVC range of 250-280 nm) demonstrate superior germicidal properties when combined with appropriate photocatalysts.

Current technological trends point toward the development of more efficient photocatalytic materials that can operate under lower-intensity UV-LED irradiation, extending operational lifespans and reducing energy requirements. Additionally, there is growing interest in visible-light-responsive photocatalysts that can utilize broader spectrum LEDs, potentially reducing costs and expanding application scenarios.

The primary objective of this technical research is to comprehensively analyze the efficiency parameters of photocatalytic disinfection systems under UV-LED irradiation across various operational conditions. Specifically, we aim to quantify the relationship between UV-LED wavelength, intensity, exposure time, and the resulting disinfection efficacy against common pathogens when combined with different photocatalytic materials.

Secondary objectives include identifying optimal operational parameters for maximum disinfection efficiency while minimizing energy consumption, evaluating the long-term stability and durability of various photocatalyst-UV-LED combinations, and assessing the potential for scaling these technologies for industrial and municipal applications.

The research also seeks to address current limitations in UV-LED photocatalysis, particularly regarding the quantum efficiency of photocatalytic reactions, the narrow effective bandwidth of many photocatalysts, and challenges related to uniform irradiation in complex geometries. By systematically analyzing these factors, we aim to establish a comprehensive framework for evaluating and optimizing photocatalytic disinfection systems powered by UV-LED technology.

This investigation is particularly timely given the increasing global demand for sustainable, chemical-free disinfection technologies in water treatment, healthcare settings, and food processing industries, where traditional disinfection methods face challenges related to chemical residues, pathogen resistance, and environmental impact.

Market Analysis for UV-LED Disinfection Technologies

The global UV-LED disinfection technology market has experienced remarkable growth in recent years, driven by increasing awareness of hygiene and sanitation across various sectors. The market size was valued at approximately $380 million in 2021 and is projected to reach $1.3 billion by 2028, representing a compound annual growth rate (CAGR) of 19.3% during the forecast period. This substantial growth trajectory reflects the expanding applications of UV-LED disinfection technologies across healthcare, water treatment, food processing, and consumer electronics industries.

The healthcare sector currently dominates the market share, accounting for nearly 35% of the total market value. Hospitals and medical facilities increasingly adopt UV-LED disinfection systems to combat healthcare-associated infections (HAIs) and reduce the spread of pathogens in clinical environments. The COVID-19 pandemic has significantly accelerated this trend, with healthcare institutions worldwide investing in advanced disinfection technologies to ensure patient and staff safety.

Water treatment applications represent the fastest-growing segment, with a projected CAGR of 22.7% through 2028. Municipal water treatment facilities, particularly in developing regions facing water scarcity and contamination challenges, are rapidly integrating UV-LED systems as environmentally friendly alternatives to chemical disinfection methods. The compact size, energy efficiency, and mercury-free operation of UV-LED systems align perfectly with sustainable development goals.

Consumer markets have also shown substantial growth potential, with portable UV-LED disinfection devices gaining popularity. The market for household UV-LED disinfection products has expanded by 215% since 2020, driven by heightened consumer awareness of surface and air disinfection needs. This segment is characterized by innovative product designs focusing on user-friendly interfaces and integration with smart home systems.

Regionally, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization, urbanization, and increasing healthcare expenditure in countries like China, Japan, and South Korea. These nations are also emerging as manufacturing hubs for UV-LED components, potentially reshaping the global supply chain dynamics.

The market is characterized by increasing competition among established players and new entrants, with over 75 companies actively participating in the UV-LED disinfection space. Key market differentiators include wavelength precision, energy efficiency, device longevity, and system integration capabilities. Price sensitivity varies significantly across different application segments, with healthcare showing less elasticity compared to consumer markets.

The healthcare sector currently dominates the market share, accounting for nearly 35% of the total market value. Hospitals and medical facilities increasingly adopt UV-LED disinfection systems to combat healthcare-associated infections (HAIs) and reduce the spread of pathogens in clinical environments. The COVID-19 pandemic has significantly accelerated this trend, with healthcare institutions worldwide investing in advanced disinfection technologies to ensure patient and staff safety.

Water treatment applications represent the fastest-growing segment, with a projected CAGR of 22.7% through 2028. Municipal water treatment facilities, particularly in developing regions facing water scarcity and contamination challenges, are rapidly integrating UV-LED systems as environmentally friendly alternatives to chemical disinfection methods. The compact size, energy efficiency, and mercury-free operation of UV-LED systems align perfectly with sustainable development goals.

Consumer markets have also shown substantial growth potential, with portable UV-LED disinfection devices gaining popularity. The market for household UV-LED disinfection products has expanded by 215% since 2020, driven by heightened consumer awareness of surface and air disinfection needs. This segment is characterized by innovative product designs focusing on user-friendly interfaces and integration with smart home systems.

Regionally, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization, urbanization, and increasing healthcare expenditure in countries like China, Japan, and South Korea. These nations are also emerging as manufacturing hubs for UV-LED components, potentially reshaping the global supply chain dynamics.

The market is characterized by increasing competition among established players and new entrants, with over 75 companies actively participating in the UV-LED disinfection space. Key market differentiators include wavelength precision, energy efficiency, device longevity, and system integration capabilities. Price sensitivity varies significantly across different application segments, with healthcare showing less elasticity compared to consumer markets.

Current Status and Challenges in Photocatalytic Disinfection

Photocatalytic disinfection technology utilizing UV-LED irradiation has gained significant attention globally as a sustainable approach to water and air purification. Currently, the field demonstrates promising advancements but faces several critical challenges that require innovative solutions. The global research landscape shows concentrated efforts in North America, Europe, and East Asia, with China, the United States, and Japan leading in patent applications and scientific publications.

The current state of photocatalytic disinfection under UV-LED irradiation reveals varying efficiency levels depending on catalyst composition, light wavelength, and target microorganisms. TiO2-based photocatalysts remain dominant in commercial applications, demonstrating 90-99% inactivation rates for common pathogens under optimal conditions. However, efficiency significantly decreases in real-world applications due to water turbidity, organic matter interference, and biofilm formation on catalyst surfaces.

A major technical challenge involves the quantum efficiency of photocatalytic processes, which typically remains below 10% in practical applications. This inefficiency stems from rapid electron-hole recombination and limited light absorption range of conventional photocatalysts. Additionally, most commercial systems operate effectively only under UV-A and UV-C wavelengths, limiting their energy efficiency and increasing operational costs.

Material stability presents another significant hurdle, as many advanced photocatalysts exhibit degradation under prolonged UV exposure or in complex water matrices. Doped and composite materials show promising initial performance but often suffer from leaching of active components or structural breakdown during extended operation cycles.

Scaling challenges persist in transitioning from laboratory demonstrations to industrial implementations. Current reactor designs struggle with uniform light distribution, catalyst immobilization, and flow dynamics optimization. Large-scale systems frequently experience reduced disinfection efficiency compared to bench-scale experiments, with performance drops of 30-50% commonly reported.

Regulatory frameworks and standardization remain underdeveloped, with inconsistent testing protocols across regions hampering comparative analysis and technology validation. The absence of universally accepted performance metrics complicates market adoption and technology assessment.

Emerging research indicates potential health and environmental concerns regarding nanoparticle release from photocatalytic surfaces and the formation of disinfection byproducts during treatment. These aspects require thorough investigation before widespread implementation can be recommended.

Despite these challenges, recent breakthroughs in visible-light active photocatalysts, quantum dot sensitization, and advanced reactor designs suggest promising pathways forward. The integration of artificial intelligence for process optimization and the development of self-cleaning photocatalytic surfaces represent frontier research directions with significant potential to overcome current limitations.

The current state of photocatalytic disinfection under UV-LED irradiation reveals varying efficiency levels depending on catalyst composition, light wavelength, and target microorganisms. TiO2-based photocatalysts remain dominant in commercial applications, demonstrating 90-99% inactivation rates for common pathogens under optimal conditions. However, efficiency significantly decreases in real-world applications due to water turbidity, organic matter interference, and biofilm formation on catalyst surfaces.

A major technical challenge involves the quantum efficiency of photocatalytic processes, which typically remains below 10% in practical applications. This inefficiency stems from rapid electron-hole recombination and limited light absorption range of conventional photocatalysts. Additionally, most commercial systems operate effectively only under UV-A and UV-C wavelengths, limiting their energy efficiency and increasing operational costs.

Material stability presents another significant hurdle, as many advanced photocatalysts exhibit degradation under prolonged UV exposure or in complex water matrices. Doped and composite materials show promising initial performance but often suffer from leaching of active components or structural breakdown during extended operation cycles.

Scaling challenges persist in transitioning from laboratory demonstrations to industrial implementations. Current reactor designs struggle with uniform light distribution, catalyst immobilization, and flow dynamics optimization. Large-scale systems frequently experience reduced disinfection efficiency compared to bench-scale experiments, with performance drops of 30-50% commonly reported.

Regulatory frameworks and standardization remain underdeveloped, with inconsistent testing protocols across regions hampering comparative analysis and technology validation. The absence of universally accepted performance metrics complicates market adoption and technology assessment.

Emerging research indicates potential health and environmental concerns regarding nanoparticle release from photocatalytic surfaces and the formation of disinfection byproducts during treatment. These aspects require thorough investigation before widespread implementation can be recommended.

Despite these challenges, recent breakthroughs in visible-light active photocatalysts, quantum dot sensitization, and advanced reactor designs suggest promising pathways forward. The integration of artificial intelligence for process optimization and the development of self-cleaning photocatalytic surfaces represent frontier research directions with significant potential to overcome current limitations.

Current Photocatalytic Disinfection Methodologies

01 Photocatalytic materials for disinfection

Various photocatalytic materials can be used for disinfection purposes. These materials, when activated by light, generate reactive oxygen species that can effectively kill or inactivate microorganisms. Common photocatalytic materials include titanium dioxide (TiO2), zinc oxide (ZnO), and other metal oxides. The efficiency of disinfection depends on the properties of these materials, such as particle size, crystallinity, and surface area.- Photocatalytic materials for disinfection: Various photocatalytic materials can be used for disinfection purposes. These materials, when activated by light, generate reactive oxygen species that can effectively kill or inactivate microorganisms. Common photocatalytic materials include titanium dioxide (TiO2), zinc oxide (ZnO), and other metal oxides. The efficiency of disinfection depends on the properties of the photocatalyst, such as particle size, crystallinity, and surface area.

- Light sources and activation methods: The efficiency of photocatalytic disinfection is significantly influenced by the light source used for activation. UV light, visible light, and solar radiation can be employed depending on the photocatalyst. Enhanced disinfection efficiency can be achieved by optimizing light intensity, wavelength, and exposure time. Some systems incorporate specialized light sources or optical components to maximize the activation of photocatalytic materials.

- Reactor design and system configuration: The design of photocatalytic reactors plays a crucial role in disinfection efficiency. Factors such as reactor geometry, flow patterns, contact time, and distribution of photocatalyst affect the overall performance. Various configurations include fixed-bed reactors, slurry reactors, and membrane reactors. Innovative designs focus on maximizing light penetration, ensuring uniform catalyst distribution, and optimizing fluid dynamics to enhance disinfection efficiency.

- Enhancement techniques for disinfection efficiency: Various techniques can be employed to enhance photocatalytic disinfection efficiency. These include doping of photocatalysts with metals or non-metals, creating composite materials, surface modification, and coupling with other disinfection methods. Advanced approaches involve the use of nanotechnology to improve catalyst performance, incorporation of plasmonic materials, and development of hierarchical structures to increase active surface area and light absorption.

- Application-specific disinfection systems: Photocatalytic disinfection systems are designed for specific applications such as water treatment, air purification, surface sterilization, and medical device disinfection. Each application requires tailored approaches to maximize disinfection efficiency. Factors considered include the type of contaminants, environmental conditions, operational requirements, and integration with existing systems. These specialized systems often incorporate monitoring and control mechanisms to ensure consistent disinfection performance.

02 Light sources and activation methods

The efficiency of photocatalytic disinfection is significantly influenced by the light source used for activation. UV light, visible light, and solar radiation can be employed depending on the photocatalyst. Advanced systems may use LED technology or specialized lamps to provide the optimal wavelength for catalyst activation. The intensity, wavelength, and exposure time of the light source directly impact the disinfection efficiency and energy consumption of the system.Expand Specific Solutions03 System design and operational parameters

The design of photocatalytic disinfection systems plays a crucial role in determining their efficiency. Factors such as reactor configuration, contact time, flow rate, and mixing conditions affect the interaction between the photocatalyst, light, and target microorganisms. Optimized system designs ensure uniform light distribution, adequate catalyst exposure, and sufficient contact between the catalyst and contaminants, thereby enhancing disinfection efficiency.Expand Specific Solutions04 Enhanced photocatalytic materials and composites

Research has focused on developing enhanced photocatalytic materials to improve disinfection efficiency. These include doped photocatalysts, noble metal-loaded catalysts, and composite materials that exhibit improved light absorption, reduced electron-hole recombination, and enhanced antimicrobial activity. Some innovations incorporate graphene, carbon nanotubes, or other nanomaterials to create synergistic effects that boost the overall disinfection performance.Expand Specific Solutions05 Applications and specialized disinfection systems

Photocatalytic disinfection technology has been applied in various fields including water treatment, air purification, surface sterilization, and medical device disinfection. Specialized systems have been developed for specific applications, such as point-of-use water disinfection units, air purifiers, self-cleaning surfaces, and healthcare facility disinfection systems. These applications demonstrate the versatility of photocatalytic disinfection and its potential to address diverse sanitation challenges.Expand Specific Solutions

Key Industry Players in UV-LED Photocatalysis

The photocatalytic disinfection market under UV-LED irradiation is currently in a growth phase, with increasing adoption across water treatment, healthcare, and industrial applications. The global market size is expanding rapidly, projected to reach significant value as UV-LED technology becomes more cost-effective. Technologically, the field shows varying maturity levels among key players. Industry leaders like Signify Holding and Crystal IS have established advanced UV-LED solutions, while specialized companies such as Atlantium Technologies, Xenex Disinfection Services, and Bolb Inc. are driving innovation with high-performance UVC LEDs reaching 200mW per emitter. Research institutions including Fraunhofer-Gesellschaft and University of South Florida are advancing fundamental technologies, while companies like Sensor Electronic Technology and Airbus Operations are developing application-specific implementations for disinfection systems across multiple sectors.

Atlantium Technologies Ltd.

Technical Solution: Atlantium Technologies has developed an advanced UV-LED based photocatalytic disinfection system called Hydro-Optic™ that combines medium-pressure UV-LED technology with innovative optical engineering. Their approach utilizes a unique total internal reflection design that recycles UV photons within a quartz reactor, significantly increasing UV dose delivery efficiency. For photocatalytic applications, Atlantium has engineered specialized reactor surfaces coated with nano-structured TiO2 that maximize surface area exposure to UV irradiation. Their system achieves disinfection rates exceeding 99.999% for challenging microorganisms including Cryptosporidium and Giardia. The company's proprietary UV intensity distribution algorithm ensures uniform photocatalyst activation throughout the treatment chamber, eliminating dead zones and ensuring consistent performance. Atlantium's technology incorporates real-time UV transmission sensors and automated dose control systems that adjust LED output based on water quality fluctuations, maintaining disinfection efficacy while optimizing energy consumption. Recent advancements include the integration of machine learning algorithms that predict maintenance needs based on operational parameters and water quality data.

Strengths: Exceptional UV dose delivery efficiency through photon recycling; sophisticated monitoring and control systems ensure consistent performance; modular design allows for easy scaling; significantly reduced energy consumption compared to conventional UV systems. Weaknesses: Complex optical design increases manufacturing costs; specialized maintenance requirements; higher initial capital investment compared to basic UV systems; requires careful water quality management to prevent fouling of optical surfaces.

Sensor Electronic Technology, Inc.

Technical Solution: Sensor Electronic Technology (SET) has developed advanced UV-LED technology specifically for photocatalytic disinfection applications. Their approach utilizes deep UV LEDs in the 260-280nm wavelength range, which has proven optimal for both direct germicidal action and photocatalyst activation. SET's proprietary AlGaN-based LED technology enables precise wavelength targeting to match specific photocatalyst activation energies, maximizing quantum efficiency. Their system incorporates advanced thermal management solutions to extend LED lifetime and maintain consistent output intensity. SET has demonstrated disinfection rates exceeding 99.9% for common pathogens including E. coli and MRSA when their UV-LEDs are used with TiO2-based photocatalysts. The company has also pioneered modular designs that allow for scalable implementation across various water and air treatment applications, with power efficiencies approximately 30% higher than first-generation UV-LED systems.

Strengths: Precise wavelength control allows optimal photocatalyst activation; modular design enables application flexibility; significantly longer operational lifetime (20,000+ hours) compared to traditional UV sources; lower power consumption and mercury-free operation. Weaknesses: Higher initial cost compared to conventional UV lamps; requires specialized driving electronics; heat management remains challenging in compact installations.

Critical Photocatalytic Materials and Mechanisms

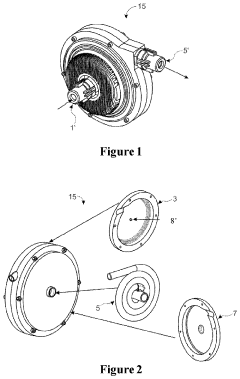

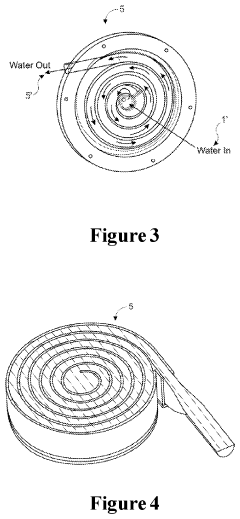

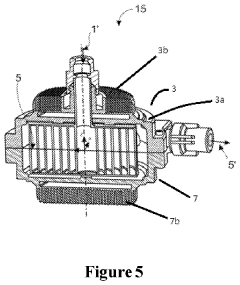

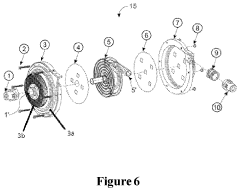

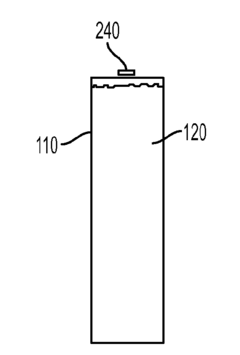

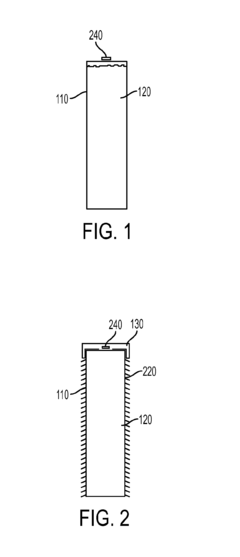

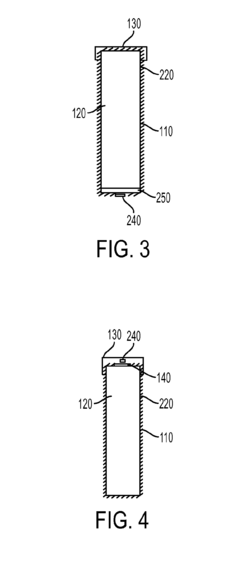

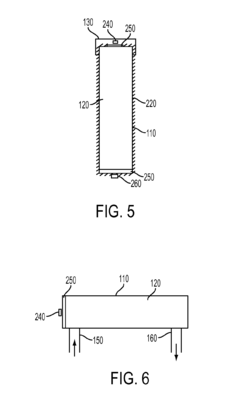

Compact ultraviolet fluid disinfection device and method

PatentPendingUS20230373822A1

Innovation

- A compact UV disinfection device featuring a spiral fluid passage with UV-LEDs emitting radiation from opposite directions, utilizing reflection plates and heat sinks, and a reflective finish to ensure uniform UV exposure and efficient disinfection.

UVA germicidal device

PatentInactiveUS20150144575A1

Innovation

- The use of UVA LEDs with peak wavelengths between 350-400 nm, which offer higher efficiency and output power, combined with reflective designs that allow for increased irradiation intensity and dwell time within a treatment vessel, utilizing materials that effectively reflect or transmit UVA light, and incorporating reflective surfaces to recirculate UV radiation, thereby enhancing germicidal efficacy.

Environmental Impact and Sustainability Considerations

The adoption of UV-LED photocatalytic disinfection systems represents a significant advancement in sustainable water treatment technologies. Unlike traditional mercury-based UV lamps, UV-LED systems consume substantially less energy, with studies indicating energy efficiency improvements of 40-60% depending on system design and operational parameters. This reduced energy consumption directly translates to lower greenhouse gas emissions associated with power generation, particularly in regions where fossil fuels remain the primary energy source.

Material sustainability constitutes another critical environmental advantage of UV-LED photocatalytic systems. The elimination of mercury and other hazardous substances found in conventional UV lamps significantly reduces the risk of environmental contamination during manufacturing, operation, and disposal phases. Additionally, LED components typically contain recoverable materials such as gallium, indium, and precious metals that can be reclaimed through proper recycling processes, supporting circular economy principles.

The extended operational lifespan of UV-LED systems—often 3-5 times longer than traditional UV lamps—further enhances their environmental profile by reducing replacement frequency and associated manufacturing impacts. This longevity, combined with their compact size, results in reduced material throughput and waste generation across the technology lifecycle.

From a water conservation perspective, photocatalytic disinfection under UV-LED irradiation offers notable benefits. The process requires minimal chemical inputs compared to conventional disinfection methods, thereby reducing the chemical burden in treated effluent. Studies demonstrate that properly designed systems can achieve complete disinfection without producing harmful disinfection byproducts commonly associated with chlorination and other chemical treatment approaches.

The scalability of UV-LED photocatalytic systems presents opportunities for decentralized water treatment applications, potentially reducing infrastructure requirements and associated environmental impacts. Small-scale, point-of-use systems can be deployed in remote or resource-limited settings, providing safe drinking water without extensive distribution networks.

However, environmental considerations must include the end-of-life management of photocatalytic materials, particularly nanomaterials like TiO2, which may pose ecological risks if improperly disposed of. Research indicates the importance of immobilization techniques to prevent catalyst leaching and subsequent environmental contamination. Additionally, comprehensive life cycle assessments reveal that manufacturing impacts of specialized semiconductor materials used in advanced LEDs can partially offset operational environmental benefits, necessitating continued innovation in production processes.

Material sustainability constitutes another critical environmental advantage of UV-LED photocatalytic systems. The elimination of mercury and other hazardous substances found in conventional UV lamps significantly reduces the risk of environmental contamination during manufacturing, operation, and disposal phases. Additionally, LED components typically contain recoverable materials such as gallium, indium, and precious metals that can be reclaimed through proper recycling processes, supporting circular economy principles.

The extended operational lifespan of UV-LED systems—often 3-5 times longer than traditional UV lamps—further enhances their environmental profile by reducing replacement frequency and associated manufacturing impacts. This longevity, combined with their compact size, results in reduced material throughput and waste generation across the technology lifecycle.

From a water conservation perspective, photocatalytic disinfection under UV-LED irradiation offers notable benefits. The process requires minimal chemical inputs compared to conventional disinfection methods, thereby reducing the chemical burden in treated effluent. Studies demonstrate that properly designed systems can achieve complete disinfection without producing harmful disinfection byproducts commonly associated with chlorination and other chemical treatment approaches.

The scalability of UV-LED photocatalytic systems presents opportunities for decentralized water treatment applications, potentially reducing infrastructure requirements and associated environmental impacts. Small-scale, point-of-use systems can be deployed in remote or resource-limited settings, providing safe drinking water without extensive distribution networks.

However, environmental considerations must include the end-of-life management of photocatalytic materials, particularly nanomaterials like TiO2, which may pose ecological risks if improperly disposed of. Research indicates the importance of immobilization techniques to prevent catalyst leaching and subsequent environmental contamination. Additionally, comprehensive life cycle assessments reveal that manufacturing impacts of specialized semiconductor materials used in advanced LEDs can partially offset operational environmental benefits, necessitating continued innovation in production processes.

Regulatory Framework for UV Disinfection Technologies

The regulatory landscape for UV disinfection technologies, particularly those utilizing UV-LED systems for photocatalytic disinfection, is complex and evolving across different regions globally. These frameworks are essential for ensuring safety, efficacy, and standardization in the implementation of such technologies.

In the United States, the Environmental Protection Agency (EPA) regulates UV disinfection systems under the Safe Drinking Water Act and the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). UV systems making antimicrobial claims must be registered as pesticide devices. The FDA also oversees UV technologies used in food processing and medical device sterilization, requiring validation through established protocols.

The European Union implements the Biocidal Products Regulation (BPR) which covers UV disinfection systems. Additionally, the EU's Medical Device Regulation (MDR) applies to UV technologies used in healthcare settings. European standards such as EN 14897 specifically address UV systems for water treatment, outlining performance requirements and testing methodologies.

International standards play a crucial role in harmonizing regulatory approaches. The International Ultraviolet Association (IUVA) has developed guidelines for UV disinfection that are widely referenced. ISO standards, particularly ISO 15858:2016, provide specifications for UV-C devices used for surface disinfection, while NSF/ANSI standards address water treatment applications.

For photocatalytic systems specifically, regulations are still developing. The novel combination of UV-LED technology with photocatalysts presents unique regulatory challenges, as existing frameworks may not fully address the specific mechanisms and safety considerations of these systems. Japan's Photocatalysis Industry Association has pioneered standards for photocatalytic materials, which are increasingly being adopted internationally.

Emerging regulatory considerations include the validation of disinfection efficacy under variable conditions, long-term safety assessments, and environmental impact evaluations. Energy efficiency requirements are becoming more stringent, particularly for LED-based systems. Additionally, regulations increasingly demand lifecycle assessments that consider the environmental footprint of manufacturing, operation, and disposal.

Compliance with these regulatory frameworks requires comprehensive testing protocols that demonstrate consistent performance across various operational parameters. Manufacturers must navigate certification processes that vary by region and application, often necessitating multiple approvals for global market access.

In the United States, the Environmental Protection Agency (EPA) regulates UV disinfection systems under the Safe Drinking Water Act and the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). UV systems making antimicrobial claims must be registered as pesticide devices. The FDA also oversees UV technologies used in food processing and medical device sterilization, requiring validation through established protocols.

The European Union implements the Biocidal Products Regulation (BPR) which covers UV disinfection systems. Additionally, the EU's Medical Device Regulation (MDR) applies to UV technologies used in healthcare settings. European standards such as EN 14897 specifically address UV systems for water treatment, outlining performance requirements and testing methodologies.

International standards play a crucial role in harmonizing regulatory approaches. The International Ultraviolet Association (IUVA) has developed guidelines for UV disinfection that are widely referenced. ISO standards, particularly ISO 15858:2016, provide specifications for UV-C devices used for surface disinfection, while NSF/ANSI standards address water treatment applications.

For photocatalytic systems specifically, regulations are still developing. The novel combination of UV-LED technology with photocatalysts presents unique regulatory challenges, as existing frameworks may not fully address the specific mechanisms and safety considerations of these systems. Japan's Photocatalysis Industry Association has pioneered standards for photocatalytic materials, which are increasingly being adopted internationally.

Emerging regulatory considerations include the validation of disinfection efficacy under variable conditions, long-term safety assessments, and environmental impact evaluations. Energy efficiency requirements are becoming more stringent, particularly for LED-based systems. Additionally, regulations increasingly demand lifecycle assessments that consider the environmental footprint of manufacturing, operation, and disposal.

Compliance with these regulatory frameworks requires comprehensive testing protocols that demonstrate consistent performance across various operational parameters. Manufacturers must navigate certification processes that vary by region and application, often necessitating multiple approvals for global market access.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!