Photocatalytic Disinfection Technologies in the Context of Airborne Disease Control

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocatalytic Disinfection Background and Objectives

Photocatalytic disinfection has emerged as a promising technology for controlling airborne diseases, particularly in the wake of global health crises like the COVID-19 pandemic. The concept dates back to the 1970s when Fujishima and Honda discovered the photocatalytic properties of titanium dioxide (TiO2), which could decompose water into hydrogen and oxygen under ultraviolet light. This discovery laid the foundation for subsequent research into photocatalytic materials and their applications in environmental remediation and disinfection.

Over the past five decades, photocatalytic technology has evolved significantly, transitioning from simple water purification applications to sophisticated air disinfection systems. The fundamental principle involves the activation of a semiconductor photocatalyst by light of appropriate wavelength, generating reactive oxygen species (ROS) that can effectively inactivate microorganisms including bacteria, viruses, and fungi by damaging their cellular components.

The development trajectory has been marked by several key advancements, including the discovery of new photocatalytic materials beyond TiO2, such as zinc oxide (ZnO), tungsten oxide (WO3), and various composite materials. These innovations have expanded the light absorption range from primarily UV to visible light spectrum, significantly enhancing the practical applicability of photocatalytic disinfection technologies in indoor environments where UV light is limited.

Recent technological trends have focused on enhancing photocatalytic efficiency through nanostructuring, doping, and creating heterojunctions between different semiconductors. These approaches aim to address the primary limitations of traditional photocatalysts, including narrow light absorption range, rapid recombination of electron-hole pairs, and limited quantum efficiency.

In the context of airborne disease control, photocatalytic disinfection offers several advantages over conventional methods such as HEPA filtration, UV irradiation, and chemical disinfection. These include continuous operation capability, minimal maintenance requirements, absence of harmful byproducts, and effectiveness against a broad spectrum of pathogens including antibiotic-resistant strains.

The primary objectives of current research and development in photocatalytic disinfection for airborne disease control include: developing visible-light-responsive photocatalysts with enhanced efficiency; designing scalable and cost-effective air purification systems for various indoor environments; establishing standardized testing protocols to evaluate performance; and understanding the long-term efficacy and safety profiles of these technologies in real-world settings.

Additionally, there is growing interest in integrating photocatalytic materials into building materials, HVAC systems, and personal protective equipment, creating multifunctional surfaces that can continuously disinfect air and prevent the spread of airborne pathogens. This integration represents a paradigm shift from reactive to proactive approaches in infection control and public health management.

Over the past five decades, photocatalytic technology has evolved significantly, transitioning from simple water purification applications to sophisticated air disinfection systems. The fundamental principle involves the activation of a semiconductor photocatalyst by light of appropriate wavelength, generating reactive oxygen species (ROS) that can effectively inactivate microorganisms including bacteria, viruses, and fungi by damaging their cellular components.

The development trajectory has been marked by several key advancements, including the discovery of new photocatalytic materials beyond TiO2, such as zinc oxide (ZnO), tungsten oxide (WO3), and various composite materials. These innovations have expanded the light absorption range from primarily UV to visible light spectrum, significantly enhancing the practical applicability of photocatalytic disinfection technologies in indoor environments where UV light is limited.

Recent technological trends have focused on enhancing photocatalytic efficiency through nanostructuring, doping, and creating heterojunctions between different semiconductors. These approaches aim to address the primary limitations of traditional photocatalysts, including narrow light absorption range, rapid recombination of electron-hole pairs, and limited quantum efficiency.

In the context of airborne disease control, photocatalytic disinfection offers several advantages over conventional methods such as HEPA filtration, UV irradiation, and chemical disinfection. These include continuous operation capability, minimal maintenance requirements, absence of harmful byproducts, and effectiveness against a broad spectrum of pathogens including antibiotic-resistant strains.

The primary objectives of current research and development in photocatalytic disinfection for airborne disease control include: developing visible-light-responsive photocatalysts with enhanced efficiency; designing scalable and cost-effective air purification systems for various indoor environments; establishing standardized testing protocols to evaluate performance; and understanding the long-term efficacy and safety profiles of these technologies in real-world settings.

Additionally, there is growing interest in integrating photocatalytic materials into building materials, HVAC systems, and personal protective equipment, creating multifunctional surfaces that can continuously disinfect air and prevent the spread of airborne pathogens. This integration represents a paradigm shift from reactive to proactive approaches in infection control and public health management.

Market Analysis for Airborne Disease Control Solutions

The global market for airborne disease control solutions has experienced significant growth in recent years, particularly accelerated by the COVID-19 pandemic. The market was valued at approximately $8.5 billion in 2021 and is projected to reach $15.3 billion by 2027, representing a compound annual growth rate (CAGR) of 10.2%. This growth is driven by increasing awareness of airborne pathogens, stricter indoor air quality regulations, and heightened public health concerns.

Healthcare facilities represent the largest market segment, accounting for 34% of the total market share. These institutions prioritize advanced disinfection technologies to prevent hospital-acquired infections and protect vulnerable patients. Commercial buildings, including offices, shopping centers, and educational institutions, constitute the second-largest segment at 28%, with growing implementation of air purification systems as part of return-to-work strategies.

Regionally, North America leads the market with 38% share, followed by Europe (27%) and Asia-Pacific (22%). The Asia-Pacific region is expected to witness the fastest growth rate of 12.8% annually through 2027, driven by rapid urbanization, increasing healthcare expenditure, and growing awareness of air quality issues in densely populated countries like China and India.

Traditional air disinfection technologies currently dominate the market, with HEPA filtration systems holding 42% market share, followed by UV-C disinfection at 25%. Photocatalytic disinfection technologies, while still emerging, have shown the most promising growth trajectory, expanding at 15.7% annually—significantly outpacing the overall market growth rate.

Consumer behavior analysis indicates a willingness to pay premium prices for effective air disinfection solutions, with 67% of institutional buyers citing efficacy against pathogens as their primary purchase consideration, followed by operational costs (58%) and ease of implementation (52%). The pandemic has fundamentally altered market dynamics, with 73% of facility managers reporting increased budgets for air quality improvement measures.

Key market restraints include high initial implementation costs, technical complexity of advanced solutions, and lack of standardized performance metrics for comparing different technologies. Additionally, there remains significant untapped potential in residential markets, public transportation systems, and developing economies, where awareness of advanced air disinfection technologies remains relatively low.

Healthcare facilities represent the largest market segment, accounting for 34% of the total market share. These institutions prioritize advanced disinfection technologies to prevent hospital-acquired infections and protect vulnerable patients. Commercial buildings, including offices, shopping centers, and educational institutions, constitute the second-largest segment at 28%, with growing implementation of air purification systems as part of return-to-work strategies.

Regionally, North America leads the market with 38% share, followed by Europe (27%) and Asia-Pacific (22%). The Asia-Pacific region is expected to witness the fastest growth rate of 12.8% annually through 2027, driven by rapid urbanization, increasing healthcare expenditure, and growing awareness of air quality issues in densely populated countries like China and India.

Traditional air disinfection technologies currently dominate the market, with HEPA filtration systems holding 42% market share, followed by UV-C disinfection at 25%. Photocatalytic disinfection technologies, while still emerging, have shown the most promising growth trajectory, expanding at 15.7% annually—significantly outpacing the overall market growth rate.

Consumer behavior analysis indicates a willingness to pay premium prices for effective air disinfection solutions, with 67% of institutional buyers citing efficacy against pathogens as their primary purchase consideration, followed by operational costs (58%) and ease of implementation (52%). The pandemic has fundamentally altered market dynamics, with 73% of facility managers reporting increased budgets for air quality improvement measures.

Key market restraints include high initial implementation costs, technical complexity of advanced solutions, and lack of standardized performance metrics for comparing different technologies. Additionally, there remains significant untapped potential in residential markets, public transportation systems, and developing economies, where awareness of advanced air disinfection technologies remains relatively low.

Current Photocatalytic Technology Landscape and Barriers

The global landscape of photocatalytic disinfection technologies has evolved significantly in recent years, particularly in response to the COVID-19 pandemic which highlighted the critical importance of airborne pathogen control. Currently, titanium dioxide (TiO₂) remains the most widely utilized photocatalyst due to its stability, low cost, and relatively high efficiency. Commercial applications predominantly employ TiO₂ in various forms including nanoparticles, thin films, and composite materials integrated into air purification systems, HVAC components, and surface coatings.

Visible light-responsive photocatalysts represent a significant advancement in the field, with materials such as carbon-doped TiO₂, graphitic carbon nitride (g-C₃N₄), and bismuth-based compounds gaining traction. These materials address one of the fundamental limitations of traditional TiO₂ systems—the requirement for UV light activation—enabling operation under standard indoor lighting conditions without specialized UV sources.

Despite promising laboratory results, several substantial barriers impede widespread adoption of photocatalytic disinfection technologies for airborne disease control. The efficiency gap between controlled laboratory environments and real-world applications remains considerable, with disinfection rates often decreasing dramatically under typical indoor conditions characterized by variable humidity, temperature fluctuations, and diverse airborne contaminants.

Scalability presents another significant challenge, as most current photocatalytic systems demonstrate optimal performance only at relatively low air flow rates and limited treatment volumes. This creates a fundamental engineering dilemma when designing systems for large indoor spaces that require high air exchange rates for effective ventilation.

Catalyst durability and longevity constitute persistent concerns, with performance degradation occurring through mechanisms including photocorrosion, surface fouling by organic compounds, and physical deterioration. Many systems require frequent maintenance or replacement, significantly increasing operational costs and limiting practical implementation.

Safety considerations also present barriers to adoption, particularly regarding the potential generation of harmful byproducts. Incomplete mineralization of organic compounds can produce aldehydes, ketones, and other potentially harmful intermediates. Additionally, the potential release of nanoparticles from photocatalytic surfaces raises concerns about respiratory exposure risks that remain inadequately characterized.

Standardization represents another critical gap in the current landscape, with inconsistent testing protocols and performance metrics making direct comparisons between different technologies challenging. This lack of standardization complicates regulatory approval processes and creates market confusion regarding efficacy claims.

Visible light-responsive photocatalysts represent a significant advancement in the field, with materials such as carbon-doped TiO₂, graphitic carbon nitride (g-C₃N₄), and bismuth-based compounds gaining traction. These materials address one of the fundamental limitations of traditional TiO₂ systems—the requirement for UV light activation—enabling operation under standard indoor lighting conditions without specialized UV sources.

Despite promising laboratory results, several substantial barriers impede widespread adoption of photocatalytic disinfection technologies for airborne disease control. The efficiency gap between controlled laboratory environments and real-world applications remains considerable, with disinfection rates often decreasing dramatically under typical indoor conditions characterized by variable humidity, temperature fluctuations, and diverse airborne contaminants.

Scalability presents another significant challenge, as most current photocatalytic systems demonstrate optimal performance only at relatively low air flow rates and limited treatment volumes. This creates a fundamental engineering dilemma when designing systems for large indoor spaces that require high air exchange rates for effective ventilation.

Catalyst durability and longevity constitute persistent concerns, with performance degradation occurring through mechanisms including photocorrosion, surface fouling by organic compounds, and physical deterioration. Many systems require frequent maintenance or replacement, significantly increasing operational costs and limiting practical implementation.

Safety considerations also present barriers to adoption, particularly regarding the potential generation of harmful byproducts. Incomplete mineralization of organic compounds can produce aldehydes, ketones, and other potentially harmful intermediates. Additionally, the potential release of nanoparticles from photocatalytic surfaces raises concerns about respiratory exposure risks that remain inadequately characterized.

Standardization represents another critical gap in the current landscape, with inconsistent testing protocols and performance metrics making direct comparisons between different technologies challenging. This lack of standardization complicates regulatory approval processes and creates market confusion regarding efficacy claims.

Existing Photocatalytic Solutions for Airborne Pathogen Elimination

01 TiO2-based photocatalytic disinfection systems

Titanium dioxide (TiO2) is widely used as a photocatalyst in disinfection technologies due to its strong oxidizing capabilities when activated by UV light. These systems generate reactive oxygen species that can effectively destroy bacteria, viruses, and other pathogens. TiO2-based photocatalytic disinfection can be applied in various forms including coatings, films, and nanoparticles, making it versatile for water treatment, air purification, and surface disinfection applications.- TiO2-based photocatalytic disinfection systems: Titanium dioxide (TiO2) is widely used as a photocatalyst in disinfection technologies due to its strong oxidizing capabilities when activated by UV light. These systems generate reactive oxygen species that can effectively destroy bacteria, viruses, and other pathogens. TiO2-based photocatalytic disinfection can be applied in various forms including coatings, films, and nanoparticles, making it versatile for different applications such as water treatment, air purification, and surface sterilization.

- Advanced photocatalytic reactor designs: Innovative reactor designs enhance the efficiency of photocatalytic disinfection processes. These designs focus on maximizing light distribution, optimizing contact between the photocatalyst and target contaminants, and improving flow dynamics. Features may include specialized light sources, reflective surfaces, and structured catalyst supports. Advanced reactors can be configured for continuous operation, batch processing, or modular deployment depending on the specific disinfection requirements.

- Visible light-activated photocatalytic disinfection: Recent advancements have focused on developing photocatalysts that can be activated by visible light rather than just UV radiation. This innovation significantly expands the practical applications of photocatalytic disinfection by enabling the use of natural sunlight or common indoor lighting. Techniques include doping conventional photocatalysts with metals or non-metals, creating composite materials, or developing entirely new photocatalytic compounds that respond to the visible light spectrum.

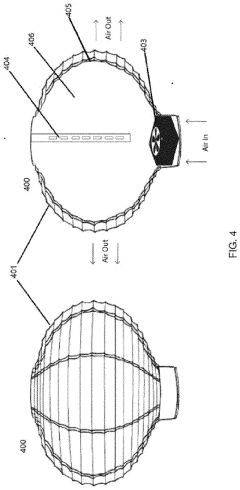

- Portable and modular photocatalytic disinfection devices: Compact, portable photocatalytic disinfection systems have been developed for applications where centralized treatment is not feasible. These devices integrate light sources, photocatalysts, and control systems in self-contained units that can be deployed in remote locations, emergency situations, or point-of-use applications. Modular designs allow for scalability and adaptability to different disinfection needs, from personal water purifiers to room-scale air disinfection systems.

- Combined photocatalytic disinfection with other technologies: Hybrid systems that combine photocatalytic disinfection with other treatment technologies offer enhanced performance and broader application scope. These integrated approaches may pair photocatalysis with membrane filtration, adsorption, electrochemical processes, or conventional disinfection methods. The synergistic effects can overcome limitations of individual technologies, providing more complete disinfection, addressing a wider range of contaminants, or reducing energy consumption and operating costs.

02 Advanced photocatalytic reactor designs

Innovative reactor designs enhance the efficiency of photocatalytic disinfection processes. These designs focus on maximizing light distribution, optimizing contact between the photocatalyst and target contaminants, and improving flow dynamics. Features may include specialized light sources, reflective surfaces, and structured catalyst supports. Advanced reactors can be configured for continuous operation, batch processing, or point-of-use applications, providing flexibility for different disinfection needs.Expand Specific Solutions03 Solar-activated photocatalytic disinfection technologies

Solar-activated photocatalytic systems harness natural sunlight to power disinfection processes, making them energy-efficient and suitable for remote or off-grid applications. These technologies often employ modified photocatalysts that can operate under visible light rather than requiring UV radiation. Solar photocatalytic disinfection is particularly valuable for water treatment in developing regions, emergency situations, and sustainable infrastructure applications where conventional power sources may be limited.Expand Specific Solutions04 Composite and doped photocatalysts for enhanced disinfection

Composite and doped photocatalytic materials offer improved disinfection performance through enhanced light absorption, reduced electron-hole recombination, and increased reactive species generation. These advanced materials may combine traditional photocatalysts with metals, non-metals, or other semiconductors to create synergistic effects. Modifications can extend activity into the visible light spectrum, increase quantum efficiency, and improve durability, resulting in more effective and practical disinfection solutions.Expand Specific Solutions05 Integrated photocatalytic disinfection systems for specific applications

Integrated photocatalytic disinfection systems combine photocatalysis with other technologies or are specifically designed for particular applications such as air purification, water treatment, or surface sterilization. These systems may incorporate filtration, adsorption, or other treatment methods to create comprehensive disinfection solutions. Purpose-built designs address the unique requirements of healthcare facilities, public spaces, industrial settings, or household applications, optimizing disinfection performance for the intended use case.Expand Specific Solutions

Leading Companies and Research Institutions in Photocatalysis

Photocatalytic disinfection technologies for airborne disease control are currently in an early growth phase, with the market expected to expand significantly due to increasing health concerns and regulatory pressures. The global market size is projected to reach substantial growth as these technologies prove effective against airborne pathogens. In terms of technical maturity, the field shows varying development stages across key players. Academic institutions like University of Florida, Hunan University, and University of Maryland are driving fundamental research, while commercial entities such as DAIKIN INDUSTRIES, Aleddra, and Shenzhen Airgle are focusing on practical applications. Companies like Exposome Pvt Ltd and Ondine International Holdings are developing specialized solutions integrating photocatalytic technologies with existing air purification systems, indicating a transition from research to commercialization phase with significant potential for innovation and market disruption.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin has developed advanced photocatalytic air purification systems utilizing titanium dioxide (TiO2) coatings activated by UV light. Their patented Streamer Technology combines photocatalysis with plasma discharge to generate high-speed electrons that decompose harmful substances. This technology creates hydroxyl radicals that effectively break down viruses, bacteria, allergens, and VOCs. Daikin's systems incorporate multi-layer filtration with photocatalytic elements strategically positioned to maximize air contact time. Their latest innovations include visible light-responsive photocatalysts doped with nitrogen or metal ions that can operate under indoor lighting conditions, eliminating the need for dedicated UV sources and reducing energy consumption. Field tests have demonstrated 99.9% inactivation of airborne pathogens within 2-3 hours in room-sized environments.

Strengths: Daikin's combined Streamer-photocatalytic approach provides superior disinfection efficiency compared to standard photocatalysis alone. Their systems operate effectively at room temperature and normal humidity levels without producing harmful byproducts. Weaknesses: The technology requires periodic replacement of photocatalytic elements to maintain optimal performance, and initial costs are higher than conventional air purification systems.

Aleddra, inc.

Technical Solution: Aleddra has developed a specialized photocatalytic air disinfection technology called Air-Sanitizing Purifiers (ASP) that utilizes a proprietary titanium dioxide formulation enhanced with noble metal nanoparticles. Their system employs UV-A LEDs (365-395nm) to activate the photocatalyst, which is coated on a high-surface-area substrate within their air purification units. The photocatalytic reaction generates reactive oxygen species that effectively destroy airborne pathogens by oxidizing their cellular components. Aleddra's innovation includes a patented air circulation design that ensures optimal contact time between contaminated air and the photocatalytic surface while minimizing pressure drop. Their latest generation products incorporate visible light-responsive photocatalysts that can be partially activated by ambient lighting, providing continuous low-level disinfection even when the UV system is not operating at full power. Laboratory testing has demonstrated >99% reduction in airborne bacterial and viral loads within 60 minutes in standard room environments, with particularly strong performance against enveloped viruses similar to influenza and coronaviruses.

Strengths: Aleddra's technology operates with lower energy consumption than traditional UV disinfection systems due to the use of efficient LED light sources and photocatalyst formulations that require less activation energy. Their systems produce minimal ozone and can operate continuously in occupied spaces. Weaknesses: The photocatalytic elements require periodic replacement (typically annually) to maintain optimal performance, and the initial cost is higher than conventional filtration systems without disinfection capabilities.

Key Patents and Scientific Breakthroughs in Photocatalytic Materials

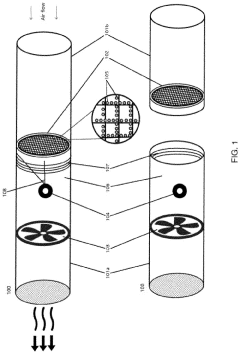

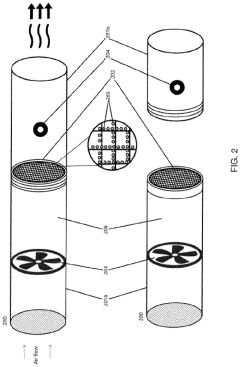

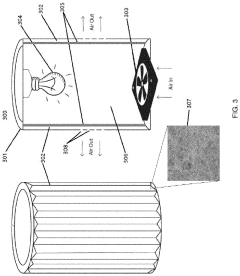

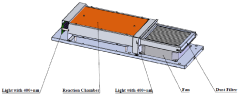

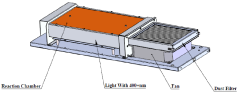

Air-Disinfecting Photocatalytic Device

PatentInactiveUS20220047753A1

Innovation

- An air-disinfecting photocatalytic device with a built-in air circulation mechanism and an air-permeable porous carrier containing a photocatalyst material, activated by a light source, which creates an air pressure difference to pass air through the carrier, trapping and killing pathogens without the need for air movement, and features a replaceable and potentially cleanable photocatalyst carrier to maintain effectiveness.

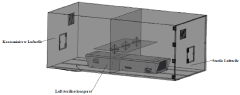

An intrinsically safe air sterilization and deodorization equipment that use a non-toxic photocatalyst activated using visible light as an energy source

PatentPendingIN202114001465A

Innovation

- A photocatalyst reaction chamber utilizing non-toxic photocatalysts coated on baffle plates activated by visible light, specifically Low Energy Cascade Oxidation (LECO) technology, which enhances microbial and VOC deactivation through cascade oxidation, using visible light with a wavelength of 400+nm and optimized light distribution.

Environmental Impact and Sustainability Considerations

Photocatalytic disinfection technologies represent a promising approach to airborne disease control with significant environmental advantages over conventional methods. These technologies utilize light-activated catalysts that generate reactive oxygen species capable of destroying pathogens without producing harmful chemical byproducts. This inherent characteristic positions photocatalytic systems as environmentally friendly alternatives to chemical disinfectants that often release volatile organic compounds (VOCs) and other toxic substances into the atmosphere.

The sustainability profile of photocatalytic disinfection is particularly noteworthy when considering life cycle assessment metrics. Most photocatalytic materials, such as titanium dioxide (TiO₂), are abundant, non-toxic in their base form, and require relatively low energy inputs for production compared to complex chemical disinfectants. Furthermore, these materials demonstrate exceptional durability, with catalytic properties that can remain active for years without significant degradation, reducing replacement frequency and associated waste generation.

Energy efficiency represents another critical environmental consideration. Advanced photocatalytic systems increasingly incorporate visible light-responsive catalysts that can operate using ambient indoor lighting or natural sunlight, dramatically reducing electricity consumption compared to UV-based disinfection methods. Some innovative designs integrate photocatalytic components with existing building materials or ventilation systems, further minimizing additional resource requirements.

Water conservation benefits also emerge when comparing photocatalytic air disinfection to traditional methods like wet scrubbing or steam-based systems. The dry nature of photocatalytic processes eliminates water consumption entirely, an increasingly important consideration in water-stressed regions facing climate change impacts.

Waste reduction constitutes a significant environmental advantage of photocatalytic technologies. Unlike disposable filters or chemical treatments requiring frequent replacement and disposal, properly designed photocatalytic surfaces can be regenerated through simple cleaning procedures or exposure to specific light wavelengths. This characteristic substantially reduces solid waste generation throughout the system's operational lifetime.

However, environmental considerations must also address potential concerns. Nanoparticle forms of photocatalysts require careful handling during manufacturing and disposal phases to prevent environmental release. Additionally, some advanced photocatalytic materials incorporate rare earth elements or precious metals as dopants, raising questions about resource extraction impacts and long-term supply sustainability.

Future development pathways should prioritize biodegradable catalyst supports, closed-loop manufacturing systems, and improved end-of-life recovery processes to further enhance the environmental credentials of photocatalytic disinfection technologies in airborne disease control applications.

The sustainability profile of photocatalytic disinfection is particularly noteworthy when considering life cycle assessment metrics. Most photocatalytic materials, such as titanium dioxide (TiO₂), are abundant, non-toxic in their base form, and require relatively low energy inputs for production compared to complex chemical disinfectants. Furthermore, these materials demonstrate exceptional durability, with catalytic properties that can remain active for years without significant degradation, reducing replacement frequency and associated waste generation.

Energy efficiency represents another critical environmental consideration. Advanced photocatalytic systems increasingly incorporate visible light-responsive catalysts that can operate using ambient indoor lighting or natural sunlight, dramatically reducing electricity consumption compared to UV-based disinfection methods. Some innovative designs integrate photocatalytic components with existing building materials or ventilation systems, further minimizing additional resource requirements.

Water conservation benefits also emerge when comparing photocatalytic air disinfection to traditional methods like wet scrubbing or steam-based systems. The dry nature of photocatalytic processes eliminates water consumption entirely, an increasingly important consideration in water-stressed regions facing climate change impacts.

Waste reduction constitutes a significant environmental advantage of photocatalytic technologies. Unlike disposable filters or chemical treatments requiring frequent replacement and disposal, properly designed photocatalytic surfaces can be regenerated through simple cleaning procedures or exposure to specific light wavelengths. This characteristic substantially reduces solid waste generation throughout the system's operational lifetime.

However, environmental considerations must also address potential concerns. Nanoparticle forms of photocatalysts require careful handling during manufacturing and disposal phases to prevent environmental release. Additionally, some advanced photocatalytic materials incorporate rare earth elements or precious metals as dopants, raising questions about resource extraction impacts and long-term supply sustainability.

Future development pathways should prioritize biodegradable catalyst supports, closed-loop manufacturing systems, and improved end-of-life recovery processes to further enhance the environmental credentials of photocatalytic disinfection technologies in airborne disease control applications.

Public Health Implementation Strategies and Challenges

The implementation of photocatalytic disinfection technologies for airborne disease control requires strategic planning across multiple sectors of public health infrastructure. Healthcare facilities represent primary deployment targets, where integration into existing HVAC systems can provide continuous disinfection capabilities. However, implementation faces significant challenges including the need for specialized engineering expertise and potential disruptions to ongoing operations during installation phases.

Cost considerations present substantial barriers to widespread adoption, particularly for resource-limited healthcare systems. Initial capital expenditures for photocatalytic equipment, installation costs, and system modifications must be balanced against long-term operational benefits and potential healthcare cost savings from reduced infection rates. Developing sustainable funding mechanisms, including public-private partnerships and phased implementation approaches, may help overcome these financial hurdles.

Regulatory frameworks present another critical challenge, as photocatalytic technologies must navigate complex approval processes across different jurisdictions. Current standards for air disinfection technologies often lack specific provisions for photocatalytic methods, creating uncertainty for manufacturers and implementers. Harmonization of international standards and development of specialized testing protocols for photocatalytic efficacy against airborne pathogens would significantly accelerate adoption.

Workforce development represents an often overlooked implementation challenge. Successful deployment requires training programs for facility managers, maintenance personnel, and healthcare workers to ensure proper operation and maintenance of photocatalytic systems. Educational initiatives must address both technical aspects and the scientific principles underlying photocatalytic disinfection to build institutional confidence in these technologies.

Public acceptance and risk communication strategies are essential components of implementation planning. Despite the passive nature of photocatalytic technologies, concerns about chemical byproducts, potential exposure risks, and efficacy compared to traditional disinfection methods may create resistance. Transparent communication about safety profiles, operational principles, and performance metrics is crucial for building public trust and institutional buy-in.

Monitoring and evaluation frameworks must be established to assess real-world performance and guide optimization. This includes developing standardized metrics for measuring disinfection efficacy in varied environmental conditions, protocols for regular performance verification, and systems for tracking health outcomes in spaces utilizing photocatalytic technologies. Such evidence generation is critical for continued refinement of implementation strategies and building the case for broader adoption.

Cost considerations present substantial barriers to widespread adoption, particularly for resource-limited healthcare systems. Initial capital expenditures for photocatalytic equipment, installation costs, and system modifications must be balanced against long-term operational benefits and potential healthcare cost savings from reduced infection rates. Developing sustainable funding mechanisms, including public-private partnerships and phased implementation approaches, may help overcome these financial hurdles.

Regulatory frameworks present another critical challenge, as photocatalytic technologies must navigate complex approval processes across different jurisdictions. Current standards for air disinfection technologies often lack specific provisions for photocatalytic methods, creating uncertainty for manufacturers and implementers. Harmonization of international standards and development of specialized testing protocols for photocatalytic efficacy against airborne pathogens would significantly accelerate adoption.

Workforce development represents an often overlooked implementation challenge. Successful deployment requires training programs for facility managers, maintenance personnel, and healthcare workers to ensure proper operation and maintenance of photocatalytic systems. Educational initiatives must address both technical aspects and the scientific principles underlying photocatalytic disinfection to build institutional confidence in these technologies.

Public acceptance and risk communication strategies are essential components of implementation planning. Despite the passive nature of photocatalytic technologies, concerns about chemical byproducts, potential exposure risks, and efficacy compared to traditional disinfection methods may create resistance. Transparent communication about safety profiles, operational principles, and performance metrics is crucial for building public trust and institutional buy-in.

Monitoring and evaluation frameworks must be established to assess real-world performance and guide optimization. This includes developing standardized metrics for measuring disinfection efficacy in varied environmental conditions, protocols for regular performance verification, and systems for tracking health outcomes in spaces utilizing photocatalytic technologies. Such evidence generation is critical for continued refinement of implementation strategies and building the case for broader adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!