Photocatalytic Disinfection: A Review of Material Thermal Stability

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocatalytic Disinfection Background and Objectives

Photocatalytic disinfection has emerged as a promising advanced oxidation process for water and air purification since the early 1980s. This technology leverages the power of photocatalysts, primarily semiconductor materials, which generate reactive oxygen species (ROS) when activated by light of appropriate wavelength. These ROS, including hydroxyl radicals, superoxide anions, and hydrogen peroxide, effectively inactivate a wide spectrum of microorganisms by attacking their cell membranes, proteins, and genetic material.

The evolution of photocatalytic disinfection technology has witnessed significant milestones, beginning with the pioneering work on TiO2-based photocatalysis by Fujishima and Honda in 1972. The subsequent decades saw the expansion of research into various semiconductor materials, including ZnO, WO3, CdS, and g-C3N4, each offering unique advantages in terms of band gap engineering, visible light activation, and quantum efficiency.

Current technological trends in this field are moving toward addressing key limitations, particularly the thermal stability of photocatalytic materials during prolonged operation. As photocatalytic reactions often generate heat, especially in concentrated solar applications or continuous industrial processes, the structural integrity and photocatalytic efficiency of materials can be compromised at elevated temperatures. This thermal degradation may manifest as phase transformations, sintering, surface area reduction, or the release of toxic components, all of which significantly impact disinfection performance.

The primary objective of this technical research is to comprehensively evaluate the thermal stability characteristics of various photocatalytic materials employed in disinfection applications. This includes assessing their structural, morphological, and photocatalytic property changes under different thermal conditions, identifying critical temperature thresholds for performance degradation, and exploring strategies to enhance thermal resilience.

Additionally, this research aims to establish correlations between thermal stability and disinfection efficacy across different operational scenarios, from ambient temperature applications to high-temperature environments. By understanding these relationships, we can develop more robust photocatalytic systems capable of maintaining consistent disinfection performance under thermal stress.

The ultimate goal is to provide insights that will guide the development of thermally stable photocatalytic materials and systems, enabling their widespread implementation in diverse disinfection applications, including water treatment facilities, air purification systems, self-cleaning surfaces, and medical device sterilization. This advancement would significantly contribute to addressing global challenges in access to clean water and sanitation, particularly in resource-limited settings where sustainable disinfection technologies are critically needed.

The evolution of photocatalytic disinfection technology has witnessed significant milestones, beginning with the pioneering work on TiO2-based photocatalysis by Fujishima and Honda in 1972. The subsequent decades saw the expansion of research into various semiconductor materials, including ZnO, WO3, CdS, and g-C3N4, each offering unique advantages in terms of band gap engineering, visible light activation, and quantum efficiency.

Current technological trends in this field are moving toward addressing key limitations, particularly the thermal stability of photocatalytic materials during prolonged operation. As photocatalytic reactions often generate heat, especially in concentrated solar applications or continuous industrial processes, the structural integrity and photocatalytic efficiency of materials can be compromised at elevated temperatures. This thermal degradation may manifest as phase transformations, sintering, surface area reduction, or the release of toxic components, all of which significantly impact disinfection performance.

The primary objective of this technical research is to comprehensively evaluate the thermal stability characteristics of various photocatalytic materials employed in disinfection applications. This includes assessing their structural, morphological, and photocatalytic property changes under different thermal conditions, identifying critical temperature thresholds for performance degradation, and exploring strategies to enhance thermal resilience.

Additionally, this research aims to establish correlations between thermal stability and disinfection efficacy across different operational scenarios, from ambient temperature applications to high-temperature environments. By understanding these relationships, we can develop more robust photocatalytic systems capable of maintaining consistent disinfection performance under thermal stress.

The ultimate goal is to provide insights that will guide the development of thermally stable photocatalytic materials and systems, enabling their widespread implementation in diverse disinfection applications, including water treatment facilities, air purification systems, self-cleaning surfaces, and medical device sterilization. This advancement would significantly contribute to addressing global challenges in access to clean water and sanitation, particularly in resource-limited settings where sustainable disinfection technologies are critically needed.

Market Analysis for Thermal-Stable Photocatalytic Materials

The global market for thermal-stable photocatalytic materials is experiencing significant growth, driven by increasing concerns about water and air purification, healthcare-associated infections, and the need for sustainable disinfection technologies. Current market valuations indicate that the photocatalytic materials sector reached approximately $2.9 billion in 2022 and is projected to grow at a compound annual growth rate of 7.8% through 2028.

Healthcare applications represent the largest market segment, accounting for nearly 35% of the total market share. The COVID-19 pandemic has substantially accelerated demand for advanced disinfection technologies in hospitals, clinics, and public spaces, creating unprecedented opportunities for photocatalytic solutions that can operate under varying thermal conditions.

Water treatment applications follow closely behind, comprising roughly 30% of the market. Municipal water treatment facilities and industrial wastewater management systems are increasingly adopting photocatalytic technologies due to their effectiveness against a broad spectrum of contaminants and pathogens without generating harmful byproducts.

Regionally, Asia-Pacific dominates the market with approximately 40% share, led by Japan and China where significant research and commercial development of thermal-stable photocatalytic materials is underway. North America and Europe collectively account for about 45% of the market, with particularly strong growth in healthcare and consumer applications.

Consumer demand for self-cleaning and antimicrobial surfaces has created a rapidly expanding market segment, growing at nearly 9% annually. This includes applications in household products, textiles, and building materials where thermal stability is crucial for product longevity and consistent performance.

A key market driver is the increasing regulatory pressure worldwide to reduce chemical disinfectants and implement more environmentally friendly solutions. The EU's Biocidal Products Regulation and similar frameworks in other regions are creating favorable conditions for photocatalytic technologies that offer chemical-free disinfection capabilities.

Industry analysis reveals that thermal stability remains a critical differentiator in the market. Materials that maintain photocatalytic efficiency across wider temperature ranges command premium pricing, with an average price premium of 30-40% compared to conventional photocatalytic products. This price differential highlights the significant market value placed on thermal stability as a performance characteristic.

Healthcare applications represent the largest market segment, accounting for nearly 35% of the total market share. The COVID-19 pandemic has substantially accelerated demand for advanced disinfection technologies in hospitals, clinics, and public spaces, creating unprecedented opportunities for photocatalytic solutions that can operate under varying thermal conditions.

Water treatment applications follow closely behind, comprising roughly 30% of the market. Municipal water treatment facilities and industrial wastewater management systems are increasingly adopting photocatalytic technologies due to their effectiveness against a broad spectrum of contaminants and pathogens without generating harmful byproducts.

Regionally, Asia-Pacific dominates the market with approximately 40% share, led by Japan and China where significant research and commercial development of thermal-stable photocatalytic materials is underway. North America and Europe collectively account for about 45% of the market, with particularly strong growth in healthcare and consumer applications.

Consumer demand for self-cleaning and antimicrobial surfaces has created a rapidly expanding market segment, growing at nearly 9% annually. This includes applications in household products, textiles, and building materials where thermal stability is crucial for product longevity and consistent performance.

A key market driver is the increasing regulatory pressure worldwide to reduce chemical disinfectants and implement more environmentally friendly solutions. The EU's Biocidal Products Regulation and similar frameworks in other regions are creating favorable conditions for photocatalytic technologies that offer chemical-free disinfection capabilities.

Industry analysis reveals that thermal stability remains a critical differentiator in the market. Materials that maintain photocatalytic efficiency across wider temperature ranges command premium pricing, with an average price premium of 30-40% compared to conventional photocatalytic products. This price differential highlights the significant market value placed on thermal stability as a performance characteristic.

Current Challenges in Photocatalytic Material Thermal Stability

Despite significant advancements in photocatalytic disinfection technology, thermal stability remains a critical challenge that limits widespread application. Current photocatalytic materials, particularly titanium dioxide (TiO2) and zinc oxide (ZnO), exhibit performance degradation when exposed to elevated temperatures during operation. This degradation manifests as reduced quantum efficiency, decreased active surface area, and diminished antimicrobial efficacy over time.

The phase transformation of crystalline structures presents a significant obstacle. For instance, anatase TiO2, which demonstrates superior photocatalytic activity, undergoes irreversible transformation to the less active rutile phase at temperatures exceeding 600°C. This transformation substantially reduces the material's ability to generate reactive oxygen species necessary for microbial inactivation.

Thermal sintering constitutes another major challenge, particularly for nanostructured photocatalysts. At elevated temperatures, nanoparticles tend to agglomerate, resulting in decreased specific surface area and consequently reduced contact between the catalyst and target microorganisms. Studies indicate that ZnO nanoparticles begin to sinter at temperatures as low as 400°C, while silver-modified photocatalysts may experience thermal instability at even lower temperatures.

Surface defect evolution under thermal stress further complicates material stability. Oxygen vacancies and surface hydroxyl groups, which serve as active sites for photocatalytic reactions, undergo significant changes during thermal cycling. Research has shown that repeated heating and cooling cycles can lead to permanent loss of these active sites, thereby diminishing disinfection efficiency by up to 40% after just 10 thermal cycles.

Composite photocatalysts face additional challenges related to interface stability. The thermal expansion coefficient mismatch between different components in heterojunction systems (such as TiO2/graphene or ZnO/Ag composites) often leads to delamination, cracking, and separation at elevated temperatures. These structural failures compromise charge carrier separation efficiency and ultimately reduce photocatalytic performance.

Dopant migration and segregation represent another significant thermal stability issue. Transition metal dopants, commonly used to enhance visible light absorption, tend to migrate and segregate at grain boundaries when exposed to high temperatures. This migration disrupts the electronic structure of the photocatalyst and can lead to the formation of recombination centers that decrease quantum efficiency.

The development of thermally stable coatings and encapsulation techniques has shown promise but remains insufficient for long-term stability under real-world operating conditions. Current protective strategies often compromise photocatalytic activity by limiting light absorption or reducing reactive site accessibility. Finding the optimal balance between thermal protection and maintaining high photocatalytic efficiency continues to be a significant research challenge.

The phase transformation of crystalline structures presents a significant obstacle. For instance, anatase TiO2, which demonstrates superior photocatalytic activity, undergoes irreversible transformation to the less active rutile phase at temperatures exceeding 600°C. This transformation substantially reduces the material's ability to generate reactive oxygen species necessary for microbial inactivation.

Thermal sintering constitutes another major challenge, particularly for nanostructured photocatalysts. At elevated temperatures, nanoparticles tend to agglomerate, resulting in decreased specific surface area and consequently reduced contact between the catalyst and target microorganisms. Studies indicate that ZnO nanoparticles begin to sinter at temperatures as low as 400°C, while silver-modified photocatalysts may experience thermal instability at even lower temperatures.

Surface defect evolution under thermal stress further complicates material stability. Oxygen vacancies and surface hydroxyl groups, which serve as active sites for photocatalytic reactions, undergo significant changes during thermal cycling. Research has shown that repeated heating and cooling cycles can lead to permanent loss of these active sites, thereby diminishing disinfection efficiency by up to 40% after just 10 thermal cycles.

Composite photocatalysts face additional challenges related to interface stability. The thermal expansion coefficient mismatch between different components in heterojunction systems (such as TiO2/graphene or ZnO/Ag composites) often leads to delamination, cracking, and separation at elevated temperatures. These structural failures compromise charge carrier separation efficiency and ultimately reduce photocatalytic performance.

Dopant migration and segregation represent another significant thermal stability issue. Transition metal dopants, commonly used to enhance visible light absorption, tend to migrate and segregate at grain boundaries when exposed to high temperatures. This migration disrupts the electronic structure of the photocatalyst and can lead to the formation of recombination centers that decrease quantum efficiency.

The development of thermally stable coatings and encapsulation techniques has shown promise but remains insufficient for long-term stability under real-world operating conditions. Current protective strategies often compromise photocatalytic activity by limiting light absorption or reducing reactive site accessibility. Finding the optimal balance between thermal protection and maintaining high photocatalytic efficiency continues to be a significant research challenge.

Current Thermal Stability Enhancement Approaches

01 Titanium dioxide-based photocatalytic materials

Titanium dioxide (TiO2) is widely used as a photocatalytic material for disinfection purposes due to its excellent thermal stability and photocatalytic efficiency. These materials can be modified with various dopants or combined with other compounds to enhance their performance at different temperatures. TiO2-based photocatalysts can effectively decompose organic pollutants and inactivate microorganisms under UV light irradiation, maintaining their structural integrity and activity even at elevated temperatures.- Titanium dioxide-based photocatalytic materials: Titanium dioxide (TiO2) is widely used as a photocatalytic material for disinfection due to its excellent thermal stability and photocatalytic efficiency. These materials can be modified with various dopants to enhance their performance and thermal resistance. When exposed to light, TiO2-based photocatalysts generate reactive oxygen species that effectively kill bacteria and viruses. The high thermal stability of these materials allows them to maintain their disinfection capabilities even under elevated temperature conditions.

- Metal oxide composite photocatalysts: Composite photocatalysts combining different metal oxides demonstrate enhanced thermal stability and disinfection efficiency. These materials typically incorporate combinations such as ZnO/TiO2, CuO/TiO2, or Fe2O3/TiO2 to create synergistic effects that improve photocatalytic activity while maintaining structural integrity at high temperatures. The composite structure helps prevent phase transformation and particle agglomeration during thermal stress, resulting in more durable disinfection materials that can be used in high-temperature applications.

- Carbon-doped photocatalytic materials: Carbon-doped photocatalytic materials, including carbon nanotubes, graphene, and carbon quantum dots incorporated into metal oxide frameworks, exhibit excellent thermal stability and enhanced disinfection properties. The carbon components improve light absorption across a broader spectrum and provide thermal resistance by stabilizing the crystal structure of the photocatalyst. These materials maintain their disinfection efficiency even after multiple thermal cycles, making them suitable for applications requiring repeated sterilization processes.

- Thermally stable coating technologies: Advanced coating technologies have been developed to apply photocatalytic materials onto various substrates while ensuring thermal stability. These coatings utilize binders and stabilizers that can withstand high temperatures without degrading the photocatalytic activity. Methods such as sol-gel deposition, hydrothermal synthesis, and plasma spraying are employed to create firmly adhered photocatalytic layers with excellent thermal resistance. These coatings can be applied to medical devices, air purification systems, and water treatment facilities for long-lasting disinfection performance.

- Noble metal-modified photocatalysts: Photocatalytic materials modified with noble metals such as silver, gold, and platinum demonstrate superior thermal stability and enhanced disinfection capabilities. The noble metal nanoparticles act as electron traps, reducing recombination rates and improving photocatalytic efficiency. These materials maintain their structural integrity and disinfection properties even at elevated temperatures, making them suitable for high-temperature sterilization applications. Additionally, some noble metals provide direct antimicrobial effects, creating a dual-action disinfection mechanism that remains effective under thermal stress.

02 Metal oxide composite photocatalysts with enhanced thermal stability

Composite photocatalytic materials combining different metal oxides demonstrate improved thermal stability and disinfection efficiency. These composites, such as ZnO/TiO2, Fe2O3/TiO2, or WO3/TiO2, create synergistic effects that enhance photocatalytic activity while maintaining structural integrity at high temperatures. The incorporation of thermally stable metal oxides prevents phase transformation and particle sintering, allowing these materials to be used in high-temperature disinfection applications without significant loss of activity.Expand Specific Solutions03 Carbon-based photocatalytic materials for thermal applications

Carbon-based materials such as graphene, carbon nanotubes, and carbon quantum dots can be incorporated into photocatalytic systems to enhance thermal stability and disinfection efficiency. These carbon materials act as electron acceptors, reducing electron-hole recombination rates and improving photocatalytic activity. Additionally, they provide thermal conductivity and structural support, preventing aggregation of photocatalytic particles at elevated temperatures and extending the operational temperature range for disinfection applications.Expand Specific Solutions04 Thermally stable photocatalytic coatings for surface disinfection

Specialized photocatalytic coatings have been developed with enhanced thermal stability for application on various surfaces requiring disinfection. These coatings incorporate binders, stabilizers, and protective layers that prevent degradation of the photocatalytic materials at high temperatures. The formulations often include silica-based compounds or ceramic materials that provide thermal insulation while allowing light transmission to activate the photocatalyst. These coatings maintain their disinfection capabilities through multiple heating cycles, making them suitable for self-cleaning surfaces in high-temperature environments.Expand Specific Solutions05 Noble metal-modified photocatalysts with high thermal resistance

Photocatalytic materials modified with noble metals such as platinum, silver, gold, or palladium exhibit exceptional thermal stability and enhanced disinfection properties. The noble metal nanoparticles act as electron traps, reducing recombination rates and improving quantum efficiency. These materials can withstand high-temperature treatments without significant loss of activity due to the thermal stability of noble metals. Additionally, some noble metals like silver provide additional antimicrobial properties, creating dual-function photocatalytic disinfection systems that remain effective after thermal stress.Expand Specific Solutions

Leading Researchers and Companies in Photocatalytic Disinfection

Photocatalytic disinfection technology is currently in a growth phase, with the market expanding due to increasing demand for advanced water and air purification solutions. The global market size is estimated to reach $3.5 billion by 2026, driven by healthcare, water treatment, and consumer applications. From a technical maturity perspective, the field shows varied development levels across key players. Companies like TOTO Ltd. and Canon Inc. have established commercial applications with thermally stable photocatalytic materials, while Nitto Denko and Kuraray are advancing material innovations. Academic institutions such as the National University of Singapore and University of Pennsylvania are pioneering next-generation photocatalysts with enhanced thermal stability. Emerging players like TriOptoTec GmbH and Exposome Pvt Ltd. are developing specialized applications for specific market segments, indicating a diversifying competitive landscape.

TOTO Ltd.

Technical Solution: TOTO Ltd. has developed advanced photocatalytic disinfection technology centered around their HYDROTECT coating system, which utilizes titanium dioxide (TiO2) as the primary photocatalyst. Their proprietary formulation maintains thermal stability up to 800°C, ensuring long-term performance even under harsh environmental conditions. The company has engineered a unique crystalline structure that prevents phase transformation of anatase TiO2 to rutile at elevated temperatures, preserving photocatalytic efficiency. TOTO's technology incorporates nitrogen doping to enhance visible light absorption while maintaining thermal resistance, allowing for indoor applications with artificial lighting. Their multi-layer coating approach creates a protective barrier that shields the photocatalytic material from thermal degradation while maintaining high antimicrobial efficacy against a broad spectrum of pathogens including bacteria, viruses, and fungi.

Strengths: Superior thermal stability up to 800°C; excellent durability in real-world applications; visible light activation through nitrogen doping. Weaknesses: Higher production costs compared to conventional disinfection methods; requires periodic UV exposure for optimal performance; effectiveness may decrease over time in high-temperature environments.

Kuraray Co., Ltd.

Technical Solution: Kuraray has pioneered a composite photocatalytic material combining titanium dioxide with their proprietary PVA (polyvinyl alcohol) polymer matrix, creating a thermally stable disinfection system. Their technology employs a core-shell structure where the photocatalytic nanoparticles are encapsulated within a heat-resistant polymer shell, allowing operation at temperatures up to 250°C without significant degradation of antimicrobial performance. The company has developed a specialized cross-linking method that enhances the thermal stability of the polymer matrix while maintaining optimal dispersion of the photocatalytic particles. Kuraray's system incorporates phase-change materials that absorb excess thermal energy during temperature spikes, protecting the photocatalytic components from thermal shock and extending operational lifespan. Their materials demonstrate consistent disinfection efficacy against waterborne pathogens even after multiple thermal cycling events, making them suitable for water treatment applications in variable temperature environments.

Strengths: Excellent polymer-catalyst integration; maintains flexibility while preserving thermal stability; effective in both air and water disinfection applications. Weaknesses: Lower maximum operating temperature compared to purely inorganic systems; potential polymer degradation under prolonged UV exposure; higher cost than conventional disinfection methods.

Key Patents and Research on Heat-Resistant Photocatalysts

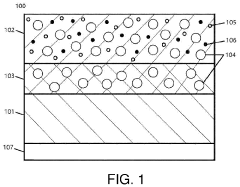

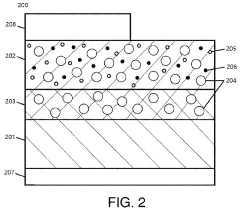

Self-Disinfecting Photocatalyst Sheet

PatentInactiveUS20220089912A1

Innovation

- A self-disinfecting photocatalyst sheet with a covalent bond between a metal oxide primary photocatalyst and substrate, activated by visible light, featuring a secondary metallic photocatalyst for enhanced disinfection and an optional adhesive layer for attachment, along with a color-changing dye for wear-indication.

Photocatalyst

PatentWO2016185042A1

Innovation

- Development of photocatalysts comprising pyrochlore and perovskite materials with specific structures, such as A2LnM6, where A includes Ca, Sr, or Ba, and Ln includes In, Y, or rare earth metals, which are predominantly used in the form of ceramics, offering high thermal and photochemical resilience, and are catalytically active in the 300-650 nm wavelength range, enabling efficient water splitting, disinfection, and purification.

Environmental Impact and Sustainability Considerations

Photocatalytic disinfection technologies offer significant environmental benefits compared to conventional disinfection methods, particularly in terms of sustainability and reduced ecological impact. The thermal stability of photocatalytic materials plays a crucial role in determining their overall environmental footprint throughout their lifecycle.

One of the primary environmental advantages of thermally stable photocatalytic materials is their extended operational lifespan, which reduces waste generation and resource consumption associated with frequent material replacement. Materials with high thermal stability can withstand repeated disinfection cycles without degradation, minimizing the environmental burden of manufacturing replacement components and disposal of spent materials.

Energy efficiency represents another critical environmental consideration. Photocatalytic systems utilizing thermally stable materials can operate effectively at ambient temperatures, significantly reducing energy requirements compared to thermal disinfection methods. This energy conservation translates directly to lower greenhouse gas emissions and reduced fossil fuel dependency, particularly when the systems are powered by renewable energy sources.

The chemical inputs required for photocatalytic disinfection are substantially lower than conventional chemical disinfection approaches. Thermally stable photocatalysts typically require minimal or no additional chemical reagents, eliminating the environmental risks associated with chemical production, transportation, and discharge of disinfection byproducts into natural water systems.

Water conservation benefits emerge as thermally stable photocatalytic systems can often operate with recirculated water, reducing overall water consumption. This aspect is particularly valuable in water-scarce regions where sustainable water management is critical for environmental protection and resource conservation.

End-of-life considerations for photocatalytic materials present both challenges and opportunities. Materials with high thermal stability often contain rare earth elements or precious metals that require responsible recycling practices. However, their durability means fewer replacement cycles and thus reduced waste generation over time. Emerging research focuses on developing recovery processes for these valuable components to create closed-loop material systems.

Carbon footprint analyses of thermally stable photocatalytic disinfection systems consistently demonstrate lower lifecycle emissions compared to conventional alternatives, particularly when operational longevity is factored into calculations. This advantage becomes more pronounced in applications requiring continuous disinfection over extended periods, such as water treatment facilities or air purification systems in healthcare settings.

One of the primary environmental advantages of thermally stable photocatalytic materials is their extended operational lifespan, which reduces waste generation and resource consumption associated with frequent material replacement. Materials with high thermal stability can withstand repeated disinfection cycles without degradation, minimizing the environmental burden of manufacturing replacement components and disposal of spent materials.

Energy efficiency represents another critical environmental consideration. Photocatalytic systems utilizing thermally stable materials can operate effectively at ambient temperatures, significantly reducing energy requirements compared to thermal disinfection methods. This energy conservation translates directly to lower greenhouse gas emissions and reduced fossil fuel dependency, particularly when the systems are powered by renewable energy sources.

The chemical inputs required for photocatalytic disinfection are substantially lower than conventional chemical disinfection approaches. Thermally stable photocatalysts typically require minimal or no additional chemical reagents, eliminating the environmental risks associated with chemical production, transportation, and discharge of disinfection byproducts into natural water systems.

Water conservation benefits emerge as thermally stable photocatalytic systems can often operate with recirculated water, reducing overall water consumption. This aspect is particularly valuable in water-scarce regions where sustainable water management is critical for environmental protection and resource conservation.

End-of-life considerations for photocatalytic materials present both challenges and opportunities. Materials with high thermal stability often contain rare earth elements or precious metals that require responsible recycling practices. However, their durability means fewer replacement cycles and thus reduced waste generation over time. Emerging research focuses on developing recovery processes for these valuable components to create closed-loop material systems.

Carbon footprint analyses of thermally stable photocatalytic disinfection systems consistently demonstrate lower lifecycle emissions compared to conventional alternatives, particularly when operational longevity is factored into calculations. This advantage becomes more pronounced in applications requiring continuous disinfection over extended periods, such as water treatment facilities or air purification systems in healthcare settings.

Standardization and Testing Protocols for Thermal Performance

The standardization of testing protocols for thermal performance in photocatalytic disinfection systems represents a critical area requiring immediate attention from the scientific and industrial communities. Current evaluation methods vary significantly across research groups and manufacturers, making direct comparisons between different photocatalytic materials and systems challenging and often unreliable.

A comprehensive standardization framework should include specific temperature range testing protocols, with materials evaluated at incremental temperature points from ambient conditions to their maximum operational threshold. These protocols must specify heating rates, temperature holding times, and cooling cycles to accurately simulate real-world operational conditions that photocatalytic materials encounter during disinfection processes.

Thermal cycling tests are particularly important for assessing long-term stability, as they reveal how materials respond to repeated temperature fluctuations. Standard protocols should mandate a minimum number of thermal cycles (typically 100-1000 cycles) before performance degradation assessment, with measurements taken at regular intervals to track progressive changes in photocatalytic efficiency.

Accelerated aging tests under controlled temperature and humidity conditions must be standardized to predict material longevity. These tests should correlate accelerated conditions with real-time degradation, establishing conversion factors that allow researchers to extrapolate long-term performance from short-term testing data.

Performance metrics require standardization as well, with clear definitions for thermal stability indices. These should include percentage efficiency retention after thermal stress, temperature coefficient of photocatalytic activity, and thermal deactivation rate constants. Such metrics would enable objective comparison between different photocatalytic materials and systems.

International collaboration between organizations such as ISO, ASTM, and IEC is essential for developing globally accepted standards. Current efforts remain fragmented, with different regions employing varied testing methodologies. A unified approach would accelerate technology development and market adoption by ensuring consistent quality assessment worldwide.

Reference materials with known thermal stability profiles should be established and distributed to testing laboratories for calibration purposes. These reference standards would serve as benchmarks against which new materials can be evaluated, ensuring consistency across different testing facilities and methodologies.

Finally, reporting requirements must be standardized to include detailed thermal testing conditions, material characterization before and after thermal stress, and statistical analysis of performance data. This comprehensive documentation would facilitate meaningful meta-analyses and accelerate the identification of optimal materials and designs for thermally stable photocatalytic disinfection systems.

A comprehensive standardization framework should include specific temperature range testing protocols, with materials evaluated at incremental temperature points from ambient conditions to their maximum operational threshold. These protocols must specify heating rates, temperature holding times, and cooling cycles to accurately simulate real-world operational conditions that photocatalytic materials encounter during disinfection processes.

Thermal cycling tests are particularly important for assessing long-term stability, as they reveal how materials respond to repeated temperature fluctuations. Standard protocols should mandate a minimum number of thermal cycles (typically 100-1000 cycles) before performance degradation assessment, with measurements taken at regular intervals to track progressive changes in photocatalytic efficiency.

Accelerated aging tests under controlled temperature and humidity conditions must be standardized to predict material longevity. These tests should correlate accelerated conditions with real-time degradation, establishing conversion factors that allow researchers to extrapolate long-term performance from short-term testing data.

Performance metrics require standardization as well, with clear definitions for thermal stability indices. These should include percentage efficiency retention after thermal stress, temperature coefficient of photocatalytic activity, and thermal deactivation rate constants. Such metrics would enable objective comparison between different photocatalytic materials and systems.

International collaboration between organizations such as ISO, ASTM, and IEC is essential for developing globally accepted standards. Current efforts remain fragmented, with different regions employing varied testing methodologies. A unified approach would accelerate technology development and market adoption by ensuring consistent quality assessment worldwide.

Reference materials with known thermal stability profiles should be established and distributed to testing laboratories for calibration purposes. These reference standards would serve as benchmarks against which new materials can be evaluated, ensuring consistency across different testing facilities and methodologies.

Finally, reporting requirements must be standardized to include detailed thermal testing conditions, material characterization before and after thermal stress, and statistical analysis of performance data. This comprehensive documentation would facilitate meaningful meta-analyses and accelerate the identification of optimal materials and designs for thermally stable photocatalytic disinfection systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!