Comparative Analysis of Photocatalytic Disinfection vs UV-C Disinfection

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Disinfection Technologies Background and Objectives

Disinfection technologies have evolved significantly over the past century, transitioning from basic chemical methods to sophisticated physical and photochemical approaches. The historical trajectory began with chlorination in the early 1900s, followed by the introduction of UV-C disinfection in the mid-20th century, which leveraged short-wavelength ultraviolet light to inactivate microorganisms by damaging their DNA. More recently, photocatalytic disinfection emerged as a promising alternative, utilizing semiconductor materials that generate reactive oxygen species when exposed to light, offering a potentially more sustainable approach to microbial control.

The global emphasis on pathogen control has intensified dramatically following recent public health crises, particularly the COVID-19 pandemic, which highlighted critical gaps in existing disinfection infrastructures. This renewed focus has accelerated research and development in advanced disinfection technologies, with particular attention to solutions that can address emerging pathogens while minimizing environmental impact and energy consumption.

UV-C disinfection represents a well-established technology with documented efficacy against a broad spectrum of microorganisms. Operating primarily at wavelengths between 200-280 nm, UV-C radiation directly damages microbial genetic material, preventing replication and effectively neutralizing pathogens. The technology has gained widespread adoption in healthcare, water treatment, and air purification applications due to its reliability and chemical-free operation.

Conversely, photocatalytic disinfection represents a more recent innovation that operates through fundamentally different mechanisms. When illuminated, photocatalysts such as titanium dioxide (TiO₂) generate highly reactive species that attack multiple cellular components simultaneously, potentially overcoming microbial resistance mechanisms that may develop against single-target approaches like UV-C radiation.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of photocatalytic and UV-C disinfection technologies across multiple performance dimensions. These include antimicrobial efficacy against various pathogens, energy efficiency, operational lifespan, implementation costs, environmental impact, and adaptability to diverse application environments. The analysis aims to identify the optimal deployment scenarios for each technology and explore potential synergistic implementations that leverage the strengths of both approaches.

Additionally, this research seeks to map the technological evolution pathways for both disinfection methods, identifying emerging innovations such as visible-light active photocatalysts and far-UVC applications that may significantly enhance performance or expand application possibilities. Through this comprehensive assessment, we aim to provide strategic guidance for technology investment and development priorities in the rapidly evolving disinfection technology landscape.

The global emphasis on pathogen control has intensified dramatically following recent public health crises, particularly the COVID-19 pandemic, which highlighted critical gaps in existing disinfection infrastructures. This renewed focus has accelerated research and development in advanced disinfection technologies, with particular attention to solutions that can address emerging pathogens while minimizing environmental impact and energy consumption.

UV-C disinfection represents a well-established technology with documented efficacy against a broad spectrum of microorganisms. Operating primarily at wavelengths between 200-280 nm, UV-C radiation directly damages microbial genetic material, preventing replication and effectively neutralizing pathogens. The technology has gained widespread adoption in healthcare, water treatment, and air purification applications due to its reliability and chemical-free operation.

Conversely, photocatalytic disinfection represents a more recent innovation that operates through fundamentally different mechanisms. When illuminated, photocatalysts such as titanium dioxide (TiO₂) generate highly reactive species that attack multiple cellular components simultaneously, potentially overcoming microbial resistance mechanisms that may develop against single-target approaches like UV-C radiation.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of photocatalytic and UV-C disinfection technologies across multiple performance dimensions. These include antimicrobial efficacy against various pathogens, energy efficiency, operational lifespan, implementation costs, environmental impact, and adaptability to diverse application environments. The analysis aims to identify the optimal deployment scenarios for each technology and explore potential synergistic implementations that leverage the strengths of both approaches.

Additionally, this research seeks to map the technological evolution pathways for both disinfection methods, identifying emerging innovations such as visible-light active photocatalysts and far-UVC applications that may significantly enhance performance or expand application possibilities. Through this comprehensive assessment, we aim to provide strategic guidance for technology investment and development priorities in the rapidly evolving disinfection technology landscape.

Market Demand Analysis for Advanced Disinfection Solutions

The global disinfection market has experienced significant growth in recent years, driven primarily by heightened awareness of infection control across healthcare, food processing, water treatment, and public spaces. The COVID-19 pandemic served as a catalyst, accelerating demand for advanced disinfection technologies beyond traditional chemical methods. Market research indicates the global disinfection equipment market reached $2.9 billion in 2021 and is projected to grow at a CAGR of 7.2% through 2028, highlighting substantial commercial opportunities.

Within this expanding market, UV-C disinfection technology has established a strong presence due to its proven efficacy against a wide range of pathogens. The UV-C disinfection segment alone was valued at $1.3 billion in 2021, with healthcare applications representing the largest share at 38%. However, emerging concerns about UV-C limitations—including shadow areas, limited penetration depth, and potential material degradation—have created market openings for alternative technologies.

Photocatalytic disinfection represents a growing segment addressing these limitations, with particular interest from commercial building operators, healthcare facilities, and transportation sectors. Market analysis reveals photocatalytic solutions are experiencing faster growth (9.5% CAGR) than traditional UV-C systems (6.8% CAGR), indicating shifting customer preferences toward more sustainable, continuous disinfection approaches.

Consumer and institutional buyers increasingly demand disinfection solutions that offer multiple benefits beyond pathogen elimination. Survey data from facility managers shows 78% prioritize solutions that can operate safely in occupied spaces, while 65% value technologies with minimal operational disruption. Photocatalytic systems address these needs through continuous operation capabilities and reduced labor requirements compared to intermittent UV-C applications.

Environmental considerations are also reshaping market demands, with 72% of institutional buyers expressing preference for chemical-free disinfection methods. Both UV-C and photocatalytic technologies align with this trend, though photocatalytic solutions offer additional advantages in air purification capabilities, addressing volatile organic compounds alongside microbial contaminants.

Regional market analysis indicates varying adoption patterns, with North America leading in UV-C technology implementation (38% market share), while Asia-Pacific shows the fastest growth in photocatalytic adoption (11.3% CAGR). This geographic variation reflects differences in regulatory frameworks, healthcare infrastructure, and environmental priorities across regions.

The competitive landscape is evolving rapidly, with traditional UV-C manufacturers expanding into photocatalytic technologies through acquisitions and R&D investments. This market consolidation suggests recognition of complementary applications rather than direct replacement, with integrated systems emerging as a promising market segment combining both disinfection approaches.

Within this expanding market, UV-C disinfection technology has established a strong presence due to its proven efficacy against a wide range of pathogens. The UV-C disinfection segment alone was valued at $1.3 billion in 2021, with healthcare applications representing the largest share at 38%. However, emerging concerns about UV-C limitations—including shadow areas, limited penetration depth, and potential material degradation—have created market openings for alternative technologies.

Photocatalytic disinfection represents a growing segment addressing these limitations, with particular interest from commercial building operators, healthcare facilities, and transportation sectors. Market analysis reveals photocatalytic solutions are experiencing faster growth (9.5% CAGR) than traditional UV-C systems (6.8% CAGR), indicating shifting customer preferences toward more sustainable, continuous disinfection approaches.

Consumer and institutional buyers increasingly demand disinfection solutions that offer multiple benefits beyond pathogen elimination. Survey data from facility managers shows 78% prioritize solutions that can operate safely in occupied spaces, while 65% value technologies with minimal operational disruption. Photocatalytic systems address these needs through continuous operation capabilities and reduced labor requirements compared to intermittent UV-C applications.

Environmental considerations are also reshaping market demands, with 72% of institutional buyers expressing preference for chemical-free disinfection methods. Both UV-C and photocatalytic technologies align with this trend, though photocatalytic solutions offer additional advantages in air purification capabilities, addressing volatile organic compounds alongside microbial contaminants.

Regional market analysis indicates varying adoption patterns, with North America leading in UV-C technology implementation (38% market share), while Asia-Pacific shows the fastest growth in photocatalytic adoption (11.3% CAGR). This geographic variation reflects differences in regulatory frameworks, healthcare infrastructure, and environmental priorities across regions.

The competitive landscape is evolving rapidly, with traditional UV-C manufacturers expanding into photocatalytic technologies through acquisitions and R&D investments. This market consolidation suggests recognition of complementary applications rather than direct replacement, with integrated systems emerging as a promising market segment combining both disinfection approaches.

Current State and Challenges in Disinfection Technologies

Disinfection technologies have evolved significantly over the past decades, with UV-C and photocatalytic disinfection emerging as prominent methods in various applications. Currently, UV-C disinfection dominates the market due to its established efficacy and relatively straightforward implementation. This technology utilizes short-wavelength ultraviolet light (200-280 nm) to destroy microorganisms by damaging their DNA/RNA, preventing replication. The global UV disinfection equipment market was valued at approximately $2.9 billion in 2020 and is projected to reach $5.3 billion by 2025, demonstrating robust growth.

Photocatalytic disinfection, while less widespread commercially, has gained significant research attention. This technology employs photocatalysts (primarily TiO2) that, when activated by light, generate reactive oxygen species capable of destroying microorganisms. The market for photocatalytic products is smaller but growing rapidly, particularly in Asia where air and surface purification applications are increasingly popular.

Despite their proven effectiveness, both technologies face substantial challenges. For UV-C disinfection, limitations include the line-of-sight nature of UV light, which creates shadow areas where disinfection is incomplete. Additionally, UV-C poses potential health risks to humans through direct exposure, requiring careful system design and safety protocols. Material degradation under UV exposure represents another significant challenge, particularly for plastic components in healthcare settings.

Photocatalytic disinfection confronts different obstacles, primarily related to efficiency and practical implementation. Current photocatalysts typically require UV light activation, limiting their application in indoor environments. While visible-light responsive photocatalysts have been developed, their efficiency remains suboptimal for commercial applications. The reaction kinetics are generally slower than direct UV-C disinfection, necessitating longer treatment times.

Regulatory frameworks present challenges for both technologies. Standards for UV-C disinfection vary globally, creating compliance complexities for manufacturers. For photocatalytic systems, the regulatory landscape is even less defined, with limited standardized testing protocols to verify antimicrobial claims.

Energy consumption represents another critical challenge, particularly for UV-C systems which require continuous electricity input. Photocatalytic systems potentially offer energy advantages through solar activation, but current implementations often rely on artificial light sources, negating this benefit.

Geographic distribution of these technologies shows interesting patterns. UV-C disinfection has strong market penetration in North America and Europe, particularly in healthcare and water treatment. Photocatalytic technology development is concentrated in Japan, China, and South Korea, with growing research interest in Europe and North America, reflecting regional differences in technological focus and market needs.

Photocatalytic disinfection, while less widespread commercially, has gained significant research attention. This technology employs photocatalysts (primarily TiO2) that, when activated by light, generate reactive oxygen species capable of destroying microorganisms. The market for photocatalytic products is smaller but growing rapidly, particularly in Asia where air and surface purification applications are increasingly popular.

Despite their proven effectiveness, both technologies face substantial challenges. For UV-C disinfection, limitations include the line-of-sight nature of UV light, which creates shadow areas where disinfection is incomplete. Additionally, UV-C poses potential health risks to humans through direct exposure, requiring careful system design and safety protocols. Material degradation under UV exposure represents another significant challenge, particularly for plastic components in healthcare settings.

Photocatalytic disinfection confronts different obstacles, primarily related to efficiency and practical implementation. Current photocatalysts typically require UV light activation, limiting their application in indoor environments. While visible-light responsive photocatalysts have been developed, their efficiency remains suboptimal for commercial applications. The reaction kinetics are generally slower than direct UV-C disinfection, necessitating longer treatment times.

Regulatory frameworks present challenges for both technologies. Standards for UV-C disinfection vary globally, creating compliance complexities for manufacturers. For photocatalytic systems, the regulatory landscape is even less defined, with limited standardized testing protocols to verify antimicrobial claims.

Energy consumption represents another critical challenge, particularly for UV-C systems which require continuous electricity input. Photocatalytic systems potentially offer energy advantages through solar activation, but current implementations often rely on artificial light sources, negating this benefit.

Geographic distribution of these technologies shows interesting patterns. UV-C disinfection has strong market penetration in North America and Europe, particularly in healthcare and water treatment. Photocatalytic technology development is concentrated in Japan, China, and South Korea, with growing research interest in Europe and North America, reflecting regional differences in technological focus and market needs.

Technical Comparison of Photocatalytic and UV-C Disinfection

01 Photocatalytic disinfection mechanisms and efficiency

Photocatalytic disinfection utilizes semiconductor materials that generate reactive oxygen species when exposed to light, which can effectively inactivate microorganisms. The efficiency of photocatalytic disinfection depends on factors such as catalyst type, light intensity, contact time, and target microorganisms. This approach offers advantages including broad-spectrum antimicrobial activity and the potential for self-cleaning surfaces that continuously disinfect under ambient light conditions.- UV-C disinfection mechanisms and efficiency: UV-C disinfection works by emitting short-wavelength ultraviolet light that damages the DNA and RNA of microorganisms, preventing them from reproducing. The efficiency of UV-C disinfection depends on factors such as exposure time, intensity of UV radiation, distance from the UV source, and the type of microorganism being targeted. UV-C disinfection is particularly effective against bacteria, viruses, and other pathogens in air, water, and on surfaces, providing rapid and chemical-free sterilization.

- Photocatalytic disinfection systems and materials: Photocatalytic disinfection utilizes materials like titanium dioxide (TiO2) that, when exposed to light, generate reactive oxygen species capable of destroying microorganisms. These systems can be enhanced by doping the photocatalyst with metals or combining it with other materials to improve efficiency. Photocatalytic materials can be applied as coatings on surfaces or incorporated into filters for continuous disinfection under ambient light conditions, offering advantages in terms of sustainability and long-term effectiveness.

- Combined UV-C and photocatalytic disinfection technologies: Hybrid systems that combine UV-C irradiation with photocatalytic materials offer enhanced disinfection efficiency. The UV-C component provides immediate disinfection while activating the photocatalyst, which continues to provide residual disinfection effects. This synergistic approach can overcome limitations of each individual method, resulting in more complete pathogen inactivation across a wider range of conditions and reducing the required UV-C exposure time or intensity.

- Disinfection efficiency measurement and optimization: Methods for measuring and optimizing disinfection efficiency include biological indicators, dosimeters, and computational modeling. Factors affecting efficiency include light intensity, exposure time, reflectivity of surrounding surfaces, and the presence of organic matter. Advanced monitoring systems can provide real-time feedback on disinfection effectiveness, allowing for adjustment of parameters to achieve optimal results. Standardized testing protocols help quantify log reduction values for different pathogens under various conditions.

- Application-specific disinfection solutions: Specialized disinfection systems are designed for specific applications such as water treatment, air purification, medical equipment sterilization, and food safety. These systems are optimized for the particular requirements of each application, considering factors such as flow rates, target pathogens, and environmental conditions. Mobile and portable disinfection units provide flexibility for various settings, while automated systems can integrate with existing infrastructure to provide continuous protection with minimal human intervention.

02 UV-C disinfection technology and applications

UV-C disinfection employs short-wavelength ultraviolet light (typically 254nm) to damage microbial DNA/RNA, preventing replication and effectively killing pathogens. The technology has been implemented in various applications including water treatment systems, air purification units, and surface disinfection devices. The effectiveness of UV-C disinfection is influenced by factors such as exposure time, distance from the light source, and the presence of organic matter that may shield microorganisms.Expand Specific Solutions03 Comparative efficiency of disinfection methods

Studies comparing photocatalytic and UV-C disinfection methods reveal different efficiency profiles depending on application contexts. While UV-C provides rapid disinfection through direct DNA damage, photocatalytic methods offer sustained antimicrobial activity even after the light source is removed. Factors affecting comparative efficiency include target microorganism susceptibility, environmental conditions, and the specific implementation of each technology. Combined approaches may provide synergistic effects that enhance overall disinfection performance.Expand Specific Solutions04 Advanced materials for enhanced disinfection efficiency

Novel materials and composites have been developed to improve disinfection efficiency in both photocatalytic and UV-C systems. These include doped photocatalysts with enhanced visible light activity, nanostructured materials with increased surface area, and specialized coatings that improve UV-C reflection and distribution. Material innovations focus on extending the effective spectrum of light utilization, increasing reactive species generation, and improving durability under operational conditions.Expand Specific Solutions05 System design and operational parameters for optimal disinfection

The design of disinfection systems significantly impacts their efficiency. Key considerations include reactor configuration, flow dynamics, light distribution, and contact time optimization. For photocatalytic systems, catalyst immobilization methods and reactor geometry affect performance. For UV-C systems, lamp placement, reflector design, and maintenance protocols are critical. Operational parameters such as pH, temperature, and the presence of interfering substances must be carefully controlled to maintain high disinfection efficiency in real-world applications.Expand Specific Solutions

Key Industry Players in Disinfection Technology

The photocatalytic disinfection versus UV-C disinfection market is in a growth phase, with increasing adoption across healthcare, commercial, and residential sectors. The global UV disinfection equipment market is projected to reach approximately $8 billion by 2027, driven by heightened awareness of pathogen control. Technologically, UV-C disinfection represents a more mature solution with established players like Signify Holding, Ushio Europe, and Current Lighting Solutions dominating implementation. Meanwhile, photocatalytic disinfection is emerging as an innovative alternative, with research institutions (Rice University, Arizona State University, Fudan University) and specialized companies (Synexis LLC, Finsen Technologies) advancing the technology through novel materials and applications. The competitive landscape shows traditional UV-C manufacturers expanding portfolios while research-driven entities focus on next-generation photocatalytic solutions.

Signify Holding BV

Technical Solution: Signify (formerly Philips Lighting) has developed advanced UV-C disinfection solutions that utilize precisely engineered low-pressure mercury lamps emitting UV-C radiation at 254nm wavelength. Their technology includes upper-air disinfection systems that create a zone of UV-C light above occupant level in rooms, continuously disinfecting air as it circulates. They've also developed enclosed UV-C chambers for object and surface disinfection with safety interlocks to prevent accidental exposure. Their research demonstrates 99.9% inactivation of SARS-CoV-2 within seconds of exposure to their UV-C light sources. Signify's systems are designed with precise optical and mechanical design to maximize germicidal effectiveness while maintaining safety standards for human occupancy environments.

Strengths: Established global distribution network; decades of experience in UV technology; comprehensive safety features; proven efficacy against wide range of pathogens including SARS-CoV-2. Weaknesses: Reliance on mercury-containing lamps raises environmental concerns; higher initial installation costs compared to conventional lighting; requires professional installation for safety compliance.

Ushio Europe BV

Technical Solution: Ushio has developed Care222® technology, a groundbreaking approach to UV-C disinfection that utilizes a specific wavelength of 222nm (Far UV-C) filtered through a proprietary optical bandpass filter. Unlike conventional 254nm UV-C, this technology can be used in occupied spaces as the 222nm wavelength cannot penetrate the outer dead layer of human skin or the tear layer of the eye, making it safer for human exposure while maintaining powerful germicidal properties. Independent laboratory testing has confirmed Care222® modules can inactivate over 99% of SARS-CoV-2 on surfaces at appropriate doses. The technology employs excimer lamps with krypton-chloride gas that, when electrically stimulated, produces the 222nm wavelength. Ushio's systems include ceiling-mounted units for continuous air and surface disinfection in healthcare settings, public transportation, and commercial spaces.

Strengths: Can be used in occupied spaces unlike traditional UV-C; mercury-free technology addressing environmental concerns; effective against a broad spectrum of pathogens including drug-resistant bacteria; can provide continuous disinfection. Weaknesses: Higher initial cost compared to conventional UV-C systems; shorter lamp life compared to LED technologies; requires specific design considerations for effective coverage; relatively new technology with limited long-term performance data.

Core Research Innovations in Disinfection Mechanisms

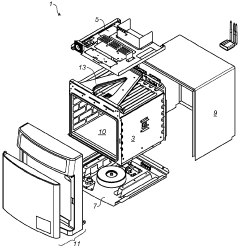

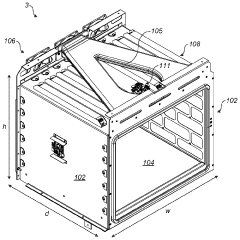

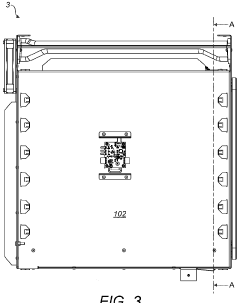

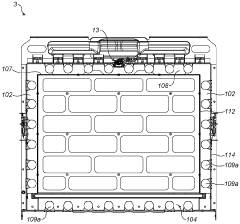

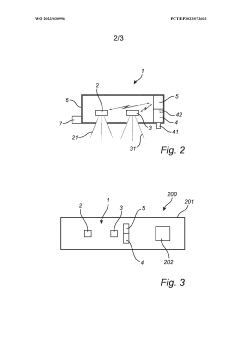

Uv-c disinfection cabinet

PatentPendingGB2614028A

Innovation

- Incorporating a camera assembly with a CMOS sensor or equivalent, recessed into the roof of the cabinet, allows for real-time monitoring and control of the disinfection process within the UV-C disinfection cabinet, ensuring comprehensive field of view and protection from UV-C radiation damage, while maintaining safety and effectiveness.

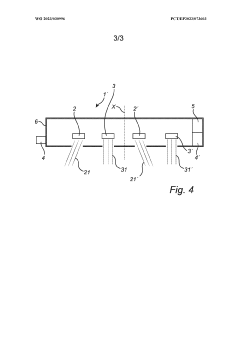

Disinfecting device

PatentWO2023030996A1

Innovation

- A disinfecting device equipped with detectors to assess properties of objects and a controller to adjust the ratio of ionized air molecule and UV light doses based on detected properties, ensuring optimal exposure and extending the lifespan of objects while enhancing disinfection efficiency.

Environmental Impact Assessment of Disinfection Methods

The environmental impact of disinfection methods is a critical consideration in selecting appropriate technologies for water and surface treatment. Photocatalytic disinfection and UV-C disinfection represent two distinct approaches with varying ecological footprints that warrant comprehensive assessment.

Photocatalytic disinfection demonstrates notable environmental advantages through its minimal chemical input requirements. Unlike traditional chemical disinfection methods that introduce potentially harmful substances into ecosystems, photocatalytic processes primarily utilize light energy and catalysts that remain largely intact during operation. This significantly reduces the release of disinfection by-products (DBPs) into water bodies, minimizing aquatic toxicity and bioaccumulation concerns.

Energy consumption patterns differ substantially between these technologies. UV-C disinfection systems typically require continuous electrical input to power mercury-based or LED lamps, resulting in higher operational carbon footprints, particularly in regions dependent on fossil fuel energy generation. Conversely, photocatalytic systems can operate effectively with ambient light or low-energy artificial illumination, potentially reducing energy demands by 30-45% compared to conventional UV-C installations.

Material lifecycle considerations reveal that UV-C systems necessitate regular lamp replacement, generating electronic waste containing mercury in traditional systems. The environmental burden of manufacturing, transporting, and disposing of these components must be factored into comprehensive impact assessments. Photocatalytic technologies typically employ longer-lasting titanium dioxide or other semiconductor materials that require less frequent replacement, though the environmental impact of nanoparticle production warrants careful monitoring.

Water resource implications also differ between these approaches. UV-C disinfection generally requires clearer water with lower turbidity to ensure effective light penetration, potentially necessitating additional pre-treatment processes with their own environmental impacts. Photocatalytic methods can often tolerate higher turbidity levels and may simultaneously degrade certain organic contaminants, potentially reducing the overall treatment burden.

Climate change resilience represents another important environmental dimension. Photocatalytic systems that can utilize solar energy offer greater operational resilience during power outages and may contribute to decentralized treatment solutions with reduced infrastructure requirements. This adaptability could prove increasingly valuable as climate instability threatens conventional water treatment infrastructure.

Ultimately, the environmental superiority of either technology depends heavily on specific implementation contexts, including energy sources, water quality parameters, and operational scale. A holistic assessment framework incorporating full lifecycle analysis is essential for making environmentally sound disinfection technology selections.

Photocatalytic disinfection demonstrates notable environmental advantages through its minimal chemical input requirements. Unlike traditional chemical disinfection methods that introduce potentially harmful substances into ecosystems, photocatalytic processes primarily utilize light energy and catalysts that remain largely intact during operation. This significantly reduces the release of disinfection by-products (DBPs) into water bodies, minimizing aquatic toxicity and bioaccumulation concerns.

Energy consumption patterns differ substantially between these technologies. UV-C disinfection systems typically require continuous electrical input to power mercury-based or LED lamps, resulting in higher operational carbon footprints, particularly in regions dependent on fossil fuel energy generation. Conversely, photocatalytic systems can operate effectively with ambient light or low-energy artificial illumination, potentially reducing energy demands by 30-45% compared to conventional UV-C installations.

Material lifecycle considerations reveal that UV-C systems necessitate regular lamp replacement, generating electronic waste containing mercury in traditional systems. The environmental burden of manufacturing, transporting, and disposing of these components must be factored into comprehensive impact assessments. Photocatalytic technologies typically employ longer-lasting titanium dioxide or other semiconductor materials that require less frequent replacement, though the environmental impact of nanoparticle production warrants careful monitoring.

Water resource implications also differ between these approaches. UV-C disinfection generally requires clearer water with lower turbidity to ensure effective light penetration, potentially necessitating additional pre-treatment processes with their own environmental impacts. Photocatalytic methods can often tolerate higher turbidity levels and may simultaneously degrade certain organic contaminants, potentially reducing the overall treatment burden.

Climate change resilience represents another important environmental dimension. Photocatalytic systems that can utilize solar energy offer greater operational resilience during power outages and may contribute to decentralized treatment solutions with reduced infrastructure requirements. This adaptability could prove increasingly valuable as climate instability threatens conventional water treatment infrastructure.

Ultimately, the environmental superiority of either technology depends heavily on specific implementation contexts, including energy sources, water quality parameters, and operational scale. A holistic assessment framework incorporating full lifecycle analysis is essential for making environmentally sound disinfection technology selections.

Safety Standards and Regulatory Compliance

The regulatory landscape for disinfection technologies is complex and varies significantly across regions, with both photocatalytic and UV-C disinfection methods subject to distinct safety standards and compliance requirements. In the United States, UV-C disinfection systems fall under FDA oversight, particularly when marketed with medical claims, requiring adherence to specific performance and safety standards outlined in 21 CFR Part 880.6600 for UV radiation disinfection devices. The EPA also regulates these technologies under the Federal Insecticide, Fungicide, and Rodenticide Act when antimicrobial claims are made.

For photocatalytic disinfection, regulatory frameworks are less established but evolving rapidly. The ISO 22197 series provides standardized test methods for evaluating photocatalytic materials, while ISO 27447 specifically addresses antimicrobial activity assessment. These standards are crucial for manufacturers to demonstrate efficacy through consistent testing methodologies, though they do not constitute regulatory approval in themselves.

Occupational safety considerations differ markedly between these technologies. UV-C systems present significant exposure risks, with potential for severe eye damage and skin burns. NIOSH and ACGIH have established strict exposure limits—typically 6.0 mJ/cm² per 8-hour workday for 254 nm wavelength—necessitating comprehensive safeguards including automatic shut-off mechanisms, warning indicators, and restricted access protocols during operation.

Photocatalytic systems generally present lower acute safety risks but raise concerns regarding potential nanoparticle exposure and byproduct formation. The EU's REACH regulation and similar frameworks worldwide increasingly require risk assessment for nanomaterials used in photocatalytic applications, with particular attention to titanium dioxide, which has been reclassified under certain conditions as a Category 2 carcinogen by inhalation in the EU.

Environmental compliance requirements also differ substantially. UV-C lamp disposal must comply with hazardous waste regulations due to mercury content in traditional systems, though LED-based alternatives mitigate this concern. Photocatalytic systems face scrutiny regarding potential environmental release of nanomaterials, with emerging regulations focusing on lifecycle assessment and end-of-life management.

Recent regulatory trends indicate convergence toward performance-based standards rather than technology-specific requirements. The NSF/ANSI 55 standard for UV water treatment systems exemplifies this approach, establishing performance criteria without prescribing specific technologies. Similar performance-based frameworks are emerging for surface and air disinfection applications, potentially creating more equitable regulatory pathways for both established UV-C and emerging photocatalytic technologies.

For photocatalytic disinfection, regulatory frameworks are less established but evolving rapidly. The ISO 22197 series provides standardized test methods for evaluating photocatalytic materials, while ISO 27447 specifically addresses antimicrobial activity assessment. These standards are crucial for manufacturers to demonstrate efficacy through consistent testing methodologies, though they do not constitute regulatory approval in themselves.

Occupational safety considerations differ markedly between these technologies. UV-C systems present significant exposure risks, with potential for severe eye damage and skin burns. NIOSH and ACGIH have established strict exposure limits—typically 6.0 mJ/cm² per 8-hour workday for 254 nm wavelength—necessitating comprehensive safeguards including automatic shut-off mechanisms, warning indicators, and restricted access protocols during operation.

Photocatalytic systems generally present lower acute safety risks but raise concerns regarding potential nanoparticle exposure and byproduct formation. The EU's REACH regulation and similar frameworks worldwide increasingly require risk assessment for nanomaterials used in photocatalytic applications, with particular attention to titanium dioxide, which has been reclassified under certain conditions as a Category 2 carcinogen by inhalation in the EU.

Environmental compliance requirements also differ substantially. UV-C lamp disposal must comply with hazardous waste regulations due to mercury content in traditional systems, though LED-based alternatives mitigate this concern. Photocatalytic systems face scrutiny regarding potential environmental release of nanomaterials, with emerging regulations focusing on lifecycle assessment and end-of-life management.

Recent regulatory trends indicate convergence toward performance-based standards rather than technology-specific requirements. The NSF/ANSI 55 standard for UV water treatment systems exemplifies this approach, establishing performance criteria without prescribing specific technologies. Similar performance-based frameworks are emerging for surface and air disinfection applications, potentially creating more equitable regulatory pathways for both established UV-C and emerging photocatalytic technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!