What Are the Benefits of Photocatalytic Disinfection in Air Purification

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocatalytic Disinfection Background and Objectives

Photocatalytic disinfection technology has evolved significantly since its discovery in the early 1970s when Fujishima and Honda first demonstrated the photocatalytic splitting of water on titanium dioxide electrodes. This breakthrough laid the foundation for subsequent research into photocatalytic applications, including air purification and disinfection. The technology has progressed from basic laboratory demonstrations to commercial applications over the past five decades, with notable acceleration in development following the SARS outbreak in 2003 and more recently during the COVID-19 pandemic.

The fundamental principle of photocatalytic disinfection involves the activation of semiconductor materials, predominantly titanium dioxide (TiO₂), by light energy to generate reactive oxygen species (ROS) that can destroy microorganisms. These ROS, including hydroxyl radicals (•OH), superoxide anions (O₂⁻), and hydrogen peroxide (H₂O₂), attack cellular components of microorganisms, leading to their inactivation or destruction. This process represents a significant advancement over traditional air purification methods that primarily focus on filtration rather than active disinfection.

The evolution of photocatalytic materials has seen several generations of development, from pure TiO₂ requiring UV light activation to doped and composite materials capable of utilizing visible light. Recent innovations include the development of plasmonic photocatalysts and Z-scheme heterojunction systems that significantly enhance photocatalytic efficiency under ambient light conditions. These advancements address earlier limitations related to the practical application of photocatalytic technology in indoor environments.

Current research trends indicate a growing focus on enhancing the quantum efficiency of photocatalysts, developing self-cleaning surfaces with persistent antimicrobial properties, and integrating photocatalytic technology with other air purification methods for synergistic effects. The convergence of nanotechnology with photocatalysis has opened new avenues for creating highly efficient disinfection systems with minimal energy requirements.

The primary objectives of photocatalytic disinfection in air purification include achieving comprehensive microbial inactivation across a broad spectrum of pathogens, developing energy-efficient systems that operate under ambient light conditions, and creating sustainable solutions with minimal environmental impact. Additionally, there is significant interest in developing systems that can simultaneously address multiple air quality concerns, including volatile organic compounds (VOCs), particulate matter, and biological contaminants.

Looking forward, the technology aims to overcome current limitations related to catalyst stability, light utilization efficiency, and mass transfer constraints in air purification applications. The ultimate goal is to establish photocatalytic disinfection as a standard component in comprehensive air quality management systems, particularly in healthcare facilities, public transportation, educational institutions, and residential buildings where airborne pathogen control is critical.

The fundamental principle of photocatalytic disinfection involves the activation of semiconductor materials, predominantly titanium dioxide (TiO₂), by light energy to generate reactive oxygen species (ROS) that can destroy microorganisms. These ROS, including hydroxyl radicals (•OH), superoxide anions (O₂⁻), and hydrogen peroxide (H₂O₂), attack cellular components of microorganisms, leading to their inactivation or destruction. This process represents a significant advancement over traditional air purification methods that primarily focus on filtration rather than active disinfection.

The evolution of photocatalytic materials has seen several generations of development, from pure TiO₂ requiring UV light activation to doped and composite materials capable of utilizing visible light. Recent innovations include the development of plasmonic photocatalysts and Z-scheme heterojunction systems that significantly enhance photocatalytic efficiency under ambient light conditions. These advancements address earlier limitations related to the practical application of photocatalytic technology in indoor environments.

Current research trends indicate a growing focus on enhancing the quantum efficiency of photocatalysts, developing self-cleaning surfaces with persistent antimicrobial properties, and integrating photocatalytic technology with other air purification methods for synergistic effects. The convergence of nanotechnology with photocatalysis has opened new avenues for creating highly efficient disinfection systems with minimal energy requirements.

The primary objectives of photocatalytic disinfection in air purification include achieving comprehensive microbial inactivation across a broad spectrum of pathogens, developing energy-efficient systems that operate under ambient light conditions, and creating sustainable solutions with minimal environmental impact. Additionally, there is significant interest in developing systems that can simultaneously address multiple air quality concerns, including volatile organic compounds (VOCs), particulate matter, and biological contaminants.

Looking forward, the technology aims to overcome current limitations related to catalyst stability, light utilization efficiency, and mass transfer constraints in air purification applications. The ultimate goal is to establish photocatalytic disinfection as a standard component in comprehensive air quality management systems, particularly in healthcare facilities, public transportation, educational institutions, and residential buildings where airborne pathogen control is critical.

Market Analysis for Air Purification Technologies

The global air purification market has experienced significant growth in recent years, driven by increasing awareness of indoor air quality and its impact on health. As of 2023, the market was valued at approximately 13.6 billion USD, with projections indicating a compound annual growth rate (CAGR) of 8.1% through 2030. This growth trajectory is particularly pronounced in regions with high pollution levels and dense urban populations, such as East Asia, South Asia, and major metropolitan areas worldwide.

Photocatalytic disinfection technology represents a growing segment within this expanding market. While traditional air purification technologies like HEPA filtration currently dominate with around 45% market share, photocatalytic solutions are gaining traction due to their unique value proposition in eliminating not just particulate matter but also volatile organic compounds (VOCs) and microorganisms.

Consumer demand patterns reveal increasing preference for multi-functional air purification systems that address multiple air quality concerns simultaneously. Market research indicates that 67% of consumers now prioritize disinfection capabilities alongside particulate filtration when purchasing air purification systems, compared to just 38% five years ago. This shift has been accelerated by global health concerns, particularly following respiratory disease outbreaks.

The commercial sector represents the fastest-growing market segment for photocatalytic air purification, with healthcare facilities, educational institutions, and hospitality venues leading adoption. These environments particularly value the continuous disinfection capabilities that photocatalytic technology offers without requiring frequent filter replacements or generating harmful byproducts like ozone.

Regional market analysis shows that North America and Europe currently lead in adoption of advanced air purification technologies including photocatalytic systems, accounting for 58% of global market revenue. However, the Asia-Pacific region is expected to demonstrate the highest growth rate at 10.2% annually through 2028, driven by severe air pollution challenges in developing economies and increasing disposable income among middle-class consumers.

Price sensitivity remains a significant factor influencing market penetration. Current photocatalytic systems typically command a 30-40% premium over conventional air purifiers, creating a barrier to mass adoption. However, manufacturing innovations and economies of scale are gradually reducing this price differential, with analysts predicting price parity with high-end conventional systems within 3-5 years.

Consumer education represents another market challenge, as the technical benefits of photocatalytic disinfection are less immediately understood compared to mechanical filtration methods. Successful market players are increasingly investing in educational marketing campaigns that clearly communicate the unique advantages of photocatalytic technology in terms of continuous operation, maintenance requirements, and comprehensive air quality improvement.

Photocatalytic disinfection technology represents a growing segment within this expanding market. While traditional air purification technologies like HEPA filtration currently dominate with around 45% market share, photocatalytic solutions are gaining traction due to their unique value proposition in eliminating not just particulate matter but also volatile organic compounds (VOCs) and microorganisms.

Consumer demand patterns reveal increasing preference for multi-functional air purification systems that address multiple air quality concerns simultaneously. Market research indicates that 67% of consumers now prioritize disinfection capabilities alongside particulate filtration when purchasing air purification systems, compared to just 38% five years ago. This shift has been accelerated by global health concerns, particularly following respiratory disease outbreaks.

The commercial sector represents the fastest-growing market segment for photocatalytic air purification, with healthcare facilities, educational institutions, and hospitality venues leading adoption. These environments particularly value the continuous disinfection capabilities that photocatalytic technology offers without requiring frequent filter replacements or generating harmful byproducts like ozone.

Regional market analysis shows that North America and Europe currently lead in adoption of advanced air purification technologies including photocatalytic systems, accounting for 58% of global market revenue. However, the Asia-Pacific region is expected to demonstrate the highest growth rate at 10.2% annually through 2028, driven by severe air pollution challenges in developing economies and increasing disposable income among middle-class consumers.

Price sensitivity remains a significant factor influencing market penetration. Current photocatalytic systems typically command a 30-40% premium over conventional air purifiers, creating a barrier to mass adoption. However, manufacturing innovations and economies of scale are gradually reducing this price differential, with analysts predicting price parity with high-end conventional systems within 3-5 years.

Consumer education represents another market challenge, as the technical benefits of photocatalytic disinfection are less immediately understood compared to mechanical filtration methods. Successful market players are increasingly investing in educational marketing campaigns that clearly communicate the unique advantages of photocatalytic technology in terms of continuous operation, maintenance requirements, and comprehensive air quality improvement.

Current Status and Challenges in Photocatalytic Air Purification

Photocatalytic disinfection technology for air purification has witnessed significant advancements globally, though implementation challenges persist. Currently, titanium dioxide (TiO2) remains the most widely used photocatalyst due to its stability, cost-effectiveness, and proven efficacy against a broad spectrum of airborne pathogens. Research institutions across North America, Europe, and East Asia have established the effectiveness of TiO2-based systems in reducing concentrations of bacteria, viruses, and fungi by up to 99.9% under optimal conditions.

Despite these promising results, several technical challenges limit widespread adoption. The quantum efficiency of most commercial photocatalysts remains below 10% under visible light, necessitating UV illumination for optimal performance. This dependency on UV light sources increases energy consumption and operational costs, while raising concerns about ozone generation and material degradation from prolonged UV exposure.

Another significant limitation is the catalyst deactivation phenomenon, where performance deteriorates over time due to surface fouling by particulate matter and reaction byproducts. Current systems typically require maintenance cycles every 3-6 months, creating logistical challenges for continuous operation in critical environments such as healthcare facilities.

The geographic distribution of photocatalytic air purification technology shows concentration in Japan, China, South Korea, the United States, and Germany. Japanese companies hold approximately 40% of relevant patents, followed by Chinese entities with 25%. This distribution reflects historical investment patterns and regulatory environments favoring advanced air treatment technologies.

Scale-up challenges represent another barrier to widespread implementation. Laboratory demonstrations have proven the concept's effectiveness, but maintaining performance in large-scale applications with variable airflow patterns, humidity levels, and contaminant concentrations remains problematic. Current commercial systems show performance degradation of 30-50% when scaled from laboratory to real-world applications.

Recent research has focused on addressing these limitations through composite photocatalysts, doping strategies, and novel reactor designs. Visible-light-active materials such as g-C3N4, BiVO4, and metal-organic frameworks show promise but face stability and manufacturing challenges. Similarly, innovations in reactor design, including fluidized bed reactors and 3D-printed structures with optimized flow patterns, demonstrate improved performance but at increased complexity and cost.

Regulatory frameworks present additional challenges, as standards for photocatalytic air purification vary significantly across regions. The lack of standardized testing protocols makes performance comparison difficult and slows market adoption. Organizations such as ISO and ASHRAE are working to establish unified standards, but comprehensive guidelines remain under development.

Despite these promising results, several technical challenges limit widespread adoption. The quantum efficiency of most commercial photocatalysts remains below 10% under visible light, necessitating UV illumination for optimal performance. This dependency on UV light sources increases energy consumption and operational costs, while raising concerns about ozone generation and material degradation from prolonged UV exposure.

Another significant limitation is the catalyst deactivation phenomenon, where performance deteriorates over time due to surface fouling by particulate matter and reaction byproducts. Current systems typically require maintenance cycles every 3-6 months, creating logistical challenges for continuous operation in critical environments such as healthcare facilities.

The geographic distribution of photocatalytic air purification technology shows concentration in Japan, China, South Korea, the United States, and Germany. Japanese companies hold approximately 40% of relevant patents, followed by Chinese entities with 25%. This distribution reflects historical investment patterns and regulatory environments favoring advanced air treatment technologies.

Scale-up challenges represent another barrier to widespread implementation. Laboratory demonstrations have proven the concept's effectiveness, but maintaining performance in large-scale applications with variable airflow patterns, humidity levels, and contaminant concentrations remains problematic. Current commercial systems show performance degradation of 30-50% when scaled from laboratory to real-world applications.

Recent research has focused on addressing these limitations through composite photocatalysts, doping strategies, and novel reactor designs. Visible-light-active materials such as g-C3N4, BiVO4, and metal-organic frameworks show promise but face stability and manufacturing challenges. Similarly, innovations in reactor design, including fluidized bed reactors and 3D-printed structures with optimized flow patterns, demonstrate improved performance but at increased complexity and cost.

Regulatory frameworks present additional challenges, as standards for photocatalytic air purification vary significantly across regions. The lack of standardized testing protocols makes performance comparison difficult and slows market adoption. Organizations such as ISO and ASHRAE are working to establish unified standards, but comprehensive guidelines remain under development.

Current Photocatalytic Disinfection Solutions

01 Environmental and health benefits of photocatalytic disinfection

Photocatalytic disinfection offers significant environmental and health benefits by providing a chemical-free method to eliminate harmful microorganisms. This technology reduces the need for traditional disinfectants that may produce harmful byproducts or cause environmental pollution. The process is environmentally friendly as it uses light energy to activate catalysts that break down contaminants and pathogens, resulting in cleaner air and water without introducing additional chemicals into the environment.- Environmental and health benefits of photocatalytic disinfection: Photocatalytic disinfection offers significant environmental and health benefits by providing a chemical-free method for eliminating harmful microorganisms. This technology reduces the need for traditional chemical disinfectants, which can produce harmful byproducts and cause environmental pollution. The process is environmentally friendly as it uses light energy to activate catalysts that break down contaminants and pathogens, leaving no toxic residues. Additionally, it improves indoor air quality by removing airborne pathogens, allergens, and volatile organic compounds, creating healthier living and working environments.

- Water purification applications: Photocatalytic disinfection provides effective water purification by destroying waterborne pathogens, bacteria, viruses, and organic pollutants. This technology can be implemented in both centralized water treatment facilities and point-of-use systems for drinking water purification. The process works effectively in various water conditions and can treat contaminated water sources without adding chemicals. Photocatalytic systems can also break down persistent organic pollutants and emerging contaminants that conventional treatment methods struggle to remove, making it particularly valuable for addressing complex water quality challenges in both developed and developing regions.

- Air disinfection and purification capabilities: Photocatalytic technology effectively disinfects and purifies air by breaking down airborne pathogens, volatile organic compounds, and odors. When integrated into ventilation systems or standalone air purifiers, these systems can continuously sanitize indoor environments, reducing the risk of airborne disease transmission. The technology is particularly valuable in healthcare settings, public spaces, and transportation systems where maintaining clean air is essential. Unlike traditional air purification methods that may only trap contaminants, photocatalytic systems actively destroy harmful substances, providing more comprehensive protection and requiring less frequent maintenance.

- Energy efficiency and sustainability advantages: Photocatalytic disinfection systems offer significant energy efficiency and sustainability benefits compared to conventional disinfection methods. Many systems can operate using renewable energy sources such as solar power, reducing operational costs and carbon footprint. The catalysts used in these systems are typically long-lasting and require minimal replacement, further enhancing sustainability. Additionally, the process operates at ambient temperature and pressure conditions, eliminating the need for energy-intensive heating or pressurization. These characteristics make photocatalytic disinfection particularly valuable for remote locations or areas with limited access to electricity and chemicals.

- Advanced material innovations for enhanced performance: Recent innovations in photocatalytic materials have significantly improved disinfection performance. Novel composite materials, doped catalysts, and nanostructured surfaces have extended the light absorption range from UV to visible light, increasing energy efficiency and enabling operation under indoor lighting conditions. These advanced materials demonstrate higher quantum efficiency, faster reaction rates, and greater durability in real-world applications. Some innovations include self-cleaning surfaces that maintain disinfection efficacy over extended periods and materials that can be easily integrated into existing infrastructure. These advancements have expanded the practical applications of photocatalytic disinfection across various sectors.

02 Enhanced disinfection efficiency in water treatment

Photocatalytic disinfection demonstrates superior efficiency in water treatment applications by effectively eliminating a wide range of pathogens including bacteria, viruses, and fungi. The technology can achieve high disinfection rates even for resistant microorganisms that conventional methods struggle to eliminate. When integrated into water treatment systems, photocatalytic processes can provide continuous disinfection with minimal maintenance requirements, making it particularly valuable for both municipal water treatment and point-of-use applications in remote or resource-limited settings.Expand Specific Solutions03 Air purification and indoor air quality improvement

Photocatalytic technology significantly improves indoor air quality by decomposing airborne pollutants and inactivating microorganisms. When incorporated into air purification systems, photocatalysts can break down volatile organic compounds (VOCs), odors, and biological contaminants, creating healthier indoor environments. This is particularly beneficial in healthcare facilities, schools, and other public spaces where air quality directly impacts health outcomes. The technology works continuously in the presence of light, providing ongoing protection against airborne pathogens and pollutants.Expand Specific Solutions04 Energy efficiency and sustainable operation

Photocatalytic disinfection systems offer significant energy efficiency benefits compared to conventional disinfection methods. Many photocatalytic materials can be activated by natural sunlight or low-energy light sources, reducing operational costs and energy consumption. The technology requires minimal external inputs beyond light exposure, and advanced photocatalysts can operate effectively under visible light rather than requiring energy-intensive UV sources. This energy efficiency, combined with the long service life of many photocatalytic materials, makes the technology a sustainable solution for long-term disinfection needs.Expand Specific Solutions05 Self-cleaning and antimicrobial surface applications

Photocatalytic materials provide self-cleaning and continuous antimicrobial properties when applied to surfaces. These coatings can be incorporated into various materials and products to create surfaces that actively destroy microorganisms and decompose organic contaminants when exposed to light. This technology is particularly valuable for high-touch surfaces in healthcare settings, public transportation, and food processing facilities, where maintaining hygiene is critical. The self-cleaning effect also reduces the need for chemical cleaners and extends the maintenance intervals for treated surfaces.Expand Specific Solutions

Leading Companies in Photocatalytic Air Purification

Photocatalytic disinfection in air purification is emerging as a promising technology in the growing air quality management market, currently transitioning from early adoption to mainstream implementation. The global market is expanding rapidly, driven by increasing health concerns and indoor air quality regulations. Technologically, the field shows varying maturity levels across applications. Leading research institutions like University of Florida and Huazhong University of Science & Technology are advancing fundamental science, while commercial players demonstrate different implementation capabilities. Companies like Panasonic, Samsung, and Carrier have integrated photocatalytic technologies into consumer products, while specialized firms such as Aleddra and Molekule focus on innovative applications. Chinese manufacturers including Shenzhen Yitoa and Shanghai Weikai Chemicals are expanding production capacity, indicating the technology's growing commercial viability.

University of Florida

Technical Solution: The University of Florida has developed pioneering research in photocatalytic air disinfection through their Department of Environmental Engineering Sciences. Their approach focuses on novel nanostructured photocatalysts with enhanced visible light activity, particularly modified titanium dioxide composites doped with nitrogen and transition metals. UF researchers have created hierarchical photocatalytic materials with multi-scale porosity that dramatically increases active surface area while improving light utilization efficiency. Their innovations include graphene-TiO2 nanocomposites that demonstrate superior electron transport properties, reducing recombination rates and enhancing quantum efficiency. The university has also developed flow-through reactor designs specifically optimized for air treatment applications, with computational fluid dynamics modeling to maximize pathogen exposure to catalytic surfaces. Recent publications from UF demonstrate photocatalytic systems capable of achieving 99.9% inactivation of airborne bacteria within minutes of exposure, while simultaneously degrading volatile organic compounds to non-toxic end products.

Strengths: Cutting-edge fundamental research capabilities; interdisciplinary approach combining materials science and environmental engineering; access to advanced characterization facilities. Weaknesses: Technologies primarily at research/prototype stage rather than commercial products; scaling challenges for mass production; higher costs associated with advanced nanomaterials.

Carrier Corp.

Technical Solution: Carrier has integrated advanced photocatalytic oxidation technology into their Infinity® air purification systems. Their approach combines UV-C light with a proprietary titanium dioxide-based catalyst formulation that generates hydroxyl radicals and superoxide ions to neutralize airborne contaminants. Carrier's systems feature a unique honeycomb catalyst structure that maximizes surface area while optimizing airflow dynamics for enhanced contact efficiency. Their photocatalytic technology is designed to operate continuously within HVAC systems, providing whole-building protection rather than single-room solutions. Recent innovations include hybrid photocatalysts incorporating silver nanoparticles that enhance antimicrobial performance while reducing the UV light intensity required for activation. Carrier has conducted extensive field testing showing their photocatalytic systems can reduce indoor bioaerosol concentrations by up to 95% in real-world commercial environments while simultaneously addressing VOCs and odor compounds that traditional filtration cannot capture.

Strengths: Seamless integration with existing HVAC infrastructure; whole-building coverage capability; established commercial installation network. Weaknesses: Higher installation complexity compared to standalone units; requires professional maintenance; effectiveness varies with airflow rates and system sizing.

Key Patents and Research in Photocatalytic Materials

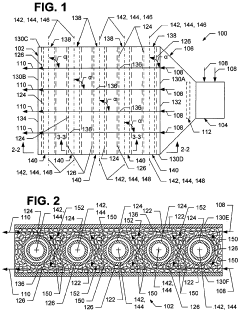

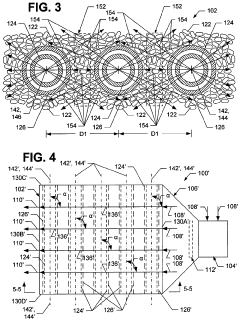

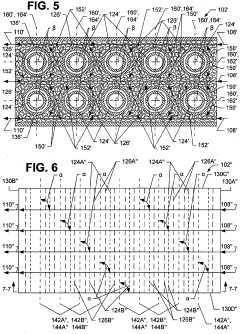

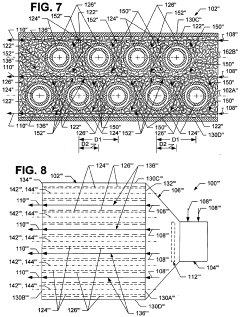

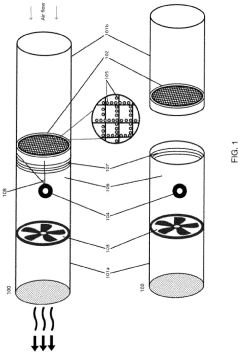

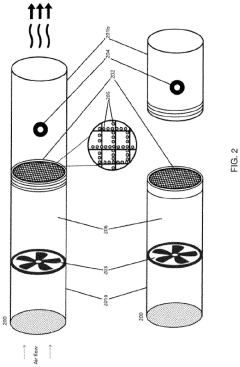

Photocatalytic air treatment system and method

PatentInactiveUS20200405903A1

Innovation

- A photocatalytic air treatment system utilizing reactor beds with photocatalyst-coated media and ultraviolet light sources arranged to maximize irradiance, creating nano-particle structures for increased reaction sites and hydroxyl radical production, combined with a heating unit to enhance reactivity and air flow management.

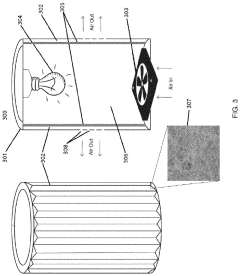

Air-Disinfecting Photocatalytic Device

PatentInactiveUS20220047769A1

Innovation

- An air-disinfecting photocatalytic device with a built-in air circulation mechanism and an air-permeable porous carrier containing a photocatalyst material, activated by a light source, which creates an air pressure difference to pass air through the carrier, trapping and killing pathogens on its surface, with a replaceable and potentially cleanable carrier to maintain effectiveness.

Environmental Impact and Sustainability Factors

Photocatalytic disinfection technology in air purification represents a significant advancement in sustainable environmental management practices. The process utilizes natural light or artificial UV radiation with photocatalysts to break down pollutants and pathogens without generating harmful byproducts, positioning it as an environmentally responsible alternative to traditional chemical disinfection methods.

The environmental footprint of photocatalytic systems is remarkably low compared to conventional air purification technologies. These systems typically consume minimal electricity, especially when utilizing natural sunlight as the activation source for photocatalysts. This reduced energy requirement translates directly into lower greenhouse gas emissions associated with power generation, contributing positively to climate change mitigation efforts.

Furthermore, photocatalytic disinfection eliminates the need for harsh chemical disinfectants that often contain volatile organic compounds (VOCs) and other environmentally harmful substances. Traditional chemical disinfection methods can release these compounds into the atmosphere, contributing to air pollution and potentially causing secondary environmental contamination. The photocatalytic approach, by contrast, relies on the generation of reactive oxygen species that decompose after reaction, leaving no persistent chemical residues.

The sustainability advantages extend to resource conservation as well. Most photocatalytic materials, particularly titanium dioxide (TiO₂), demonstrate exceptional durability and longevity, often maintaining their effectiveness for years without replacement. This extended operational lifespan reduces waste generation and resource consumption associated with frequent filter replacements required by conventional air purification systems.

From a lifecycle perspective, photocatalytic technology demonstrates favorable environmental characteristics. The primary photocatalyst materials are abundant in nature, and manufacturing processes are becoming increasingly efficient. While the initial production of photocatalysts does require energy input, the environmental return on investment over the operational lifetime of these systems generally outweighs the initial environmental costs.

Water conservation represents another significant environmental benefit. Unlike some air purification technologies that require regular washing or wet cleaning processes, photocatalytic surfaces often exhibit self-cleaning properties, reducing water consumption for maintenance. Additionally, many photocatalytic materials demonstrate hydrophilic properties that prevent moisture accumulation, further enhancing their environmental performance by reducing conditions favorable to microbial growth.

The adaptability of photocatalytic technology to renewable energy sources further enhances its sustainability profile. Solar-powered photocatalytic air purification systems represent a completely carbon-neutral solution for indoor air quality management, aligning perfectly with global sustainability goals and the transition toward renewable energy infrastructure.

The environmental footprint of photocatalytic systems is remarkably low compared to conventional air purification technologies. These systems typically consume minimal electricity, especially when utilizing natural sunlight as the activation source for photocatalysts. This reduced energy requirement translates directly into lower greenhouse gas emissions associated with power generation, contributing positively to climate change mitigation efforts.

Furthermore, photocatalytic disinfection eliminates the need for harsh chemical disinfectants that often contain volatile organic compounds (VOCs) and other environmentally harmful substances. Traditional chemical disinfection methods can release these compounds into the atmosphere, contributing to air pollution and potentially causing secondary environmental contamination. The photocatalytic approach, by contrast, relies on the generation of reactive oxygen species that decompose after reaction, leaving no persistent chemical residues.

The sustainability advantages extend to resource conservation as well. Most photocatalytic materials, particularly titanium dioxide (TiO₂), demonstrate exceptional durability and longevity, often maintaining their effectiveness for years without replacement. This extended operational lifespan reduces waste generation and resource consumption associated with frequent filter replacements required by conventional air purification systems.

From a lifecycle perspective, photocatalytic technology demonstrates favorable environmental characteristics. The primary photocatalyst materials are abundant in nature, and manufacturing processes are becoming increasingly efficient. While the initial production of photocatalysts does require energy input, the environmental return on investment over the operational lifetime of these systems generally outweighs the initial environmental costs.

Water conservation represents another significant environmental benefit. Unlike some air purification technologies that require regular washing or wet cleaning processes, photocatalytic surfaces often exhibit self-cleaning properties, reducing water consumption for maintenance. Additionally, many photocatalytic materials demonstrate hydrophilic properties that prevent moisture accumulation, further enhancing their environmental performance by reducing conditions favorable to microbial growth.

The adaptability of photocatalytic technology to renewable energy sources further enhances its sustainability profile. Solar-powered photocatalytic air purification systems represent a completely carbon-neutral solution for indoor air quality management, aligning perfectly with global sustainability goals and the transition toward renewable energy infrastructure.

Health and Safety Regulations for Air Purification Systems

Air purification systems incorporating photocatalytic disinfection technology must adhere to stringent health and safety regulations across different jurisdictions. In the United States, the Environmental Protection Agency (EPA) has established guidelines for indoor air quality that manufacturers must follow, particularly regarding the emission of byproducts such as ozone. The FDA also regulates certain air purification devices when marketed with medical claims, requiring substantial evidence of safety and efficacy.

The European Union implements the CE marking requirement for air purification systems under the Low Voltage Directive (2014/35/EU) and Electromagnetic Compatibility Directive (2014/30/EU). Additionally, the EU's REACH regulation controls the use of chemicals in these systems, with specific attention to titanium dioxide nanoparticles commonly used in photocatalytic technology.

International standards such as ISO 16000-36:2018 provide testing methods for assessing the performance of photocatalytic air cleaning devices, ensuring consistent evaluation across manufacturers. The UL 867 standard specifically addresses electrical air cleaners, including those with photocatalytic components, with strict limits on ozone production (below 0.05 ppm).

Workplace safety regulations from OSHA in the US and similar bodies internationally mandate proper ventilation systems in commercial and industrial settings. These regulations increasingly recognize photocatalytic disinfection as an acceptable technology when properly implemented and maintained.

Risk assessment requirements are becoming more comprehensive, with manufacturers needing to document potential hazards associated with UV light exposure, nanoparticle release, and byproduct formation. This includes clear labeling requirements detailing safe operation procedures, maintenance schedules, and potential health risks.

Emerging regulations are focusing on the long-term performance verification of photocatalytic systems, requiring manufacturers to demonstrate sustained efficacy over the claimed product lifespan. This includes protocols for testing catalyst degradation rates and effectiveness against various pollutants over time.

Consumer protection regulations mandate transparent marketing claims regarding photocatalytic disinfection benefits, with several regulatory bodies taking action against unsubstantiated claims about COVID-19 protection. Manufacturers must now provide scientific evidence supporting specific pathogen reduction claims.

Compliance with these regulations not only ensures legal market access but also builds consumer trust in photocatalytic disinfection technology as a safe and effective air purification solution.

The European Union implements the CE marking requirement for air purification systems under the Low Voltage Directive (2014/35/EU) and Electromagnetic Compatibility Directive (2014/30/EU). Additionally, the EU's REACH regulation controls the use of chemicals in these systems, with specific attention to titanium dioxide nanoparticles commonly used in photocatalytic technology.

International standards such as ISO 16000-36:2018 provide testing methods for assessing the performance of photocatalytic air cleaning devices, ensuring consistent evaluation across manufacturers. The UL 867 standard specifically addresses electrical air cleaners, including those with photocatalytic components, with strict limits on ozone production (below 0.05 ppm).

Workplace safety regulations from OSHA in the US and similar bodies internationally mandate proper ventilation systems in commercial and industrial settings. These regulations increasingly recognize photocatalytic disinfection as an acceptable technology when properly implemented and maintained.

Risk assessment requirements are becoming more comprehensive, with manufacturers needing to document potential hazards associated with UV light exposure, nanoparticle release, and byproduct formation. This includes clear labeling requirements detailing safe operation procedures, maintenance schedules, and potential health risks.

Emerging regulations are focusing on the long-term performance verification of photocatalytic systems, requiring manufacturers to demonstrate sustained efficacy over the claimed product lifespan. This includes protocols for testing catalyst degradation rates and effectiveness against various pollutants over time.

Consumer protection regulations mandate transparent marketing claims regarding photocatalytic disinfection benefits, with several regulatory bodies taking action against unsubstantiated claims about COVID-19 protection. Manufacturers must now provide scientific evidence supporting specific pathogen reduction claims.

Compliance with these regulations not only ensures legal market access but also builds consumer trust in photocatalytic disinfection technology as a safe and effective air purification solution.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!