What Are the Technical Challenges in Industrial Implementation of Photocatalytic Disinfection

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocatalytic Disinfection Background and Objectives

Photocatalytic disinfection has emerged as a promising technology for water and air purification since the discovery of the photocatalytic properties of titanium dioxide (TiO2) in the 1970s. This technology leverages the ability of certain semiconductor materials to generate reactive oxygen species (ROS) when exposed to light of appropriate wavelength, which can effectively inactivate a wide range of microorganisms including bacteria, viruses, fungi, and protozoa.

The evolution of photocatalytic disinfection technology has seen significant advancements over the past four decades. Initial research focused primarily on TiO2 as the photocatalyst of choice due to its stability, non-toxicity, and cost-effectiveness. However, its activation limited to UV light (representing only about 5% of solar radiation) posed a major limitation for widespread application.

Subsequent research efforts have been directed toward enhancing the photocatalytic efficiency through various strategies, including doping with metals and non-metals, coupling with other semiconductors, and morphology control to increase surface area. These modifications aim to extend the light absorption range into the visible spectrum, improve charge carrier separation, and enhance the overall photocatalytic activity.

The COVID-19 pandemic has further accelerated interest in photocatalytic disinfection technologies, particularly for air purification and surface sterilization applications. This has led to increased research focus on developing more efficient photocatalysts and innovative reactor designs for practical implementation.

The primary technical objectives in this field include developing photocatalysts with enhanced visible light activity, improving quantum efficiency, ensuring long-term stability under operational conditions, and designing scalable reactor systems suitable for industrial applications. Additionally, there is a growing emphasis on understanding the mechanisms of microbial inactivation to optimize the disinfection process.

Another critical objective is addressing the challenges associated with industrial-scale implementation, including catalyst immobilization techniques, reactor design optimization, and process integration with existing water and air treatment systems. The development of standardized testing protocols for evaluating photocatalytic disinfection efficiency is also essential for technology validation and regulatory approval.

Looking forward, the field aims to develop next-generation photocatalytic materials and systems that can operate efficiently under ambient conditions with minimal energy input, ideally utilizing solar radiation as the primary energy source. This aligns with global sustainability goals and the increasing demand for green technologies in water and air treatment sectors.

The evolution of photocatalytic disinfection technology has seen significant advancements over the past four decades. Initial research focused primarily on TiO2 as the photocatalyst of choice due to its stability, non-toxicity, and cost-effectiveness. However, its activation limited to UV light (representing only about 5% of solar radiation) posed a major limitation for widespread application.

Subsequent research efforts have been directed toward enhancing the photocatalytic efficiency through various strategies, including doping with metals and non-metals, coupling with other semiconductors, and morphology control to increase surface area. These modifications aim to extend the light absorption range into the visible spectrum, improve charge carrier separation, and enhance the overall photocatalytic activity.

The COVID-19 pandemic has further accelerated interest in photocatalytic disinfection technologies, particularly for air purification and surface sterilization applications. This has led to increased research focus on developing more efficient photocatalysts and innovative reactor designs for practical implementation.

The primary technical objectives in this field include developing photocatalysts with enhanced visible light activity, improving quantum efficiency, ensuring long-term stability under operational conditions, and designing scalable reactor systems suitable for industrial applications. Additionally, there is a growing emphasis on understanding the mechanisms of microbial inactivation to optimize the disinfection process.

Another critical objective is addressing the challenges associated with industrial-scale implementation, including catalyst immobilization techniques, reactor design optimization, and process integration with existing water and air treatment systems. The development of standardized testing protocols for evaluating photocatalytic disinfection efficiency is also essential for technology validation and regulatory approval.

Looking forward, the field aims to develop next-generation photocatalytic materials and systems that can operate efficiently under ambient conditions with minimal energy input, ideally utilizing solar radiation as the primary energy source. This aligns with global sustainability goals and the increasing demand for green technologies in water and air treatment sectors.

Market Demand Analysis for Industrial Disinfection Solutions

The global industrial disinfection market has witnessed significant growth in recent years, driven by increasing awareness of hygiene standards across various sectors including healthcare, food processing, water treatment, and public facilities. The market for advanced disinfection solutions is projected to reach $8.1 billion by 2027, growing at a CAGR of 7.2% from 2022. This growth trajectory is particularly relevant for photocatalytic disinfection technologies, which are gaining attention as sustainable alternatives to traditional chemical-based methods.

Healthcare facilities represent the largest market segment for industrial disinfection solutions, accounting for approximately 32% of the total market share. The COVID-19 pandemic has substantially accelerated demand in this sector, with hospitals and clinics implementing more rigorous disinfection protocols. Post-pandemic, this heightened awareness of pathogen control is expected to persist, creating a sustained market for advanced disinfection technologies.

Food and beverage processing industries constitute the second-largest market segment, where there is growing demand for non-toxic disinfection methods that leave no harmful residues on food contact surfaces. Regulatory pressures from organizations such as the FDA and EFSA are pushing companies toward more environmentally friendly disinfection solutions, creating an opportune entry point for photocatalytic technologies.

Water treatment facilities are increasingly exploring photocatalytic disinfection as an alternative to chlorination, driven by concerns about disinfection byproducts and chemical residues. Market research indicates that 78% of municipal water treatment decision-makers express interest in chemical-free disinfection alternatives, highlighting a significant potential market for photocatalytic solutions.

Consumer preferences are shifting toward "green" and sustainable products, with 67% of industrial buyers indicating willingness to pay premium prices for environmentally friendly disinfection solutions. This trend is particularly pronounced in Europe and North America, where environmental regulations are more stringent.

The market landscape reveals several unmet needs that photocatalytic disinfection could address. These include the demand for disinfection systems that operate effectively at ambient temperatures, solutions that can be integrated into existing infrastructure with minimal modification, and technologies that offer real-time monitoring of disinfection efficacy.

Regional analysis shows that Asia-Pacific represents the fastest-growing market for industrial disinfection solutions, with China and India leading the expansion. This growth is attributed to rapid industrialization, increasing healthcare expenditure, and growing awareness of hygiene standards in manufacturing processes.

Healthcare facilities represent the largest market segment for industrial disinfection solutions, accounting for approximately 32% of the total market share. The COVID-19 pandemic has substantially accelerated demand in this sector, with hospitals and clinics implementing more rigorous disinfection protocols. Post-pandemic, this heightened awareness of pathogen control is expected to persist, creating a sustained market for advanced disinfection technologies.

Food and beverage processing industries constitute the second-largest market segment, where there is growing demand for non-toxic disinfection methods that leave no harmful residues on food contact surfaces. Regulatory pressures from organizations such as the FDA and EFSA are pushing companies toward more environmentally friendly disinfection solutions, creating an opportune entry point for photocatalytic technologies.

Water treatment facilities are increasingly exploring photocatalytic disinfection as an alternative to chlorination, driven by concerns about disinfection byproducts and chemical residues. Market research indicates that 78% of municipal water treatment decision-makers express interest in chemical-free disinfection alternatives, highlighting a significant potential market for photocatalytic solutions.

Consumer preferences are shifting toward "green" and sustainable products, with 67% of industrial buyers indicating willingness to pay premium prices for environmentally friendly disinfection solutions. This trend is particularly pronounced in Europe and North America, where environmental regulations are more stringent.

The market landscape reveals several unmet needs that photocatalytic disinfection could address. These include the demand for disinfection systems that operate effectively at ambient temperatures, solutions that can be integrated into existing infrastructure with minimal modification, and technologies that offer real-time monitoring of disinfection efficacy.

Regional analysis shows that Asia-Pacific represents the fastest-growing market for industrial disinfection solutions, with China and India leading the expansion. This growth is attributed to rapid industrialization, increasing healthcare expenditure, and growing awareness of hygiene standards in manufacturing processes.

Current Challenges in Photocatalytic Technology Implementation

Despite significant advancements in photocatalytic disinfection technology, its industrial implementation faces several critical challenges. The primary obstacle remains the limited quantum efficiency of most photocatalysts under visible light, with many materials like TiO2 primarily active only under UV radiation, which constitutes less than 5% of solar spectrum. This fundamental limitation restricts large-scale application in real-world settings where artificial UV sources would be cost-prohibitive.

Material stability presents another significant hurdle, as many promising photocatalysts suffer from photocorrosion during extended operation periods. This degradation not only reduces disinfection efficacy over time but also potentially introduces secondary contamination into treated water or air streams, raising safety concerns for industrial applications requiring continuous operation.

Scaling challenges persist in reactor design and engineering, with most successful demonstrations limited to laboratory scale. The transition to industrial volumes introduces issues of light penetration depth, catalyst distribution, and flow dynamics that significantly impact disinfection efficiency. Current reactor designs struggle to maintain uniform light distribution throughout large treatment volumes, creating "dead zones" with reduced antimicrobial activity.

Economic viability remains questionable due to high implementation costs relative to conventional disinfection methods. The capital expenditure for specialized reactors, light sources, and catalyst materials, combined with operational expenses and maintenance requirements, often outweighs the perceived benefits, particularly in price-sensitive markets or regions with limited resources.

Standardization and regulatory frameworks lag behind technological development, creating uncertainty for industrial adopters. The absence of universally accepted performance metrics, safety standards, and quality control protocols hampers widespread implementation and commercialization efforts. This regulatory gap is particularly problematic for applications in sensitive areas such as drinking water treatment or food processing facilities.

Catalyst recovery and regeneration systems remain underdeveloped, presenting both economic and environmental challenges. Most current implementations utilize suspended catalyst particles that require complex separation processes post-treatment, adding operational complexity and cost while potentially reducing overall system efficiency.

Integration with existing infrastructure presents compatibility issues, as retrofitting conventional disinfection systems with photocatalytic technology often requires significant modifications to physical layouts, control systems, and operational protocols. This integration challenge particularly affects established industries with substantial investments in conventional disinfection infrastructure.

Material stability presents another significant hurdle, as many promising photocatalysts suffer from photocorrosion during extended operation periods. This degradation not only reduces disinfection efficacy over time but also potentially introduces secondary contamination into treated water or air streams, raising safety concerns for industrial applications requiring continuous operation.

Scaling challenges persist in reactor design and engineering, with most successful demonstrations limited to laboratory scale. The transition to industrial volumes introduces issues of light penetration depth, catalyst distribution, and flow dynamics that significantly impact disinfection efficiency. Current reactor designs struggle to maintain uniform light distribution throughout large treatment volumes, creating "dead zones" with reduced antimicrobial activity.

Economic viability remains questionable due to high implementation costs relative to conventional disinfection methods. The capital expenditure for specialized reactors, light sources, and catalyst materials, combined with operational expenses and maintenance requirements, often outweighs the perceived benefits, particularly in price-sensitive markets or regions with limited resources.

Standardization and regulatory frameworks lag behind technological development, creating uncertainty for industrial adopters. The absence of universally accepted performance metrics, safety standards, and quality control protocols hampers widespread implementation and commercialization efforts. This regulatory gap is particularly problematic for applications in sensitive areas such as drinking water treatment or food processing facilities.

Catalyst recovery and regeneration systems remain underdeveloped, presenting both economic and environmental challenges. Most current implementations utilize suspended catalyst particles that require complex separation processes post-treatment, adding operational complexity and cost while potentially reducing overall system efficiency.

Integration with existing infrastructure presents compatibility issues, as retrofitting conventional disinfection systems with photocatalytic technology often requires significant modifications to physical layouts, control systems, and operational protocols. This integration challenge particularly affects established industries with substantial investments in conventional disinfection infrastructure.

Current Industrial-Scale Photocatalytic Solutions

01 Catalyst efficiency and activation challenges

Photocatalytic disinfection faces challenges related to catalyst efficiency and activation. These include limited light absorption range, slow electron-hole recombination rates, and difficulties in activating catalysts under visible light. Various approaches to overcome these challenges involve doping photocatalysts with metals or non-metals, creating composite materials, and developing novel activation methods to enhance disinfection performance under real-world conditions.- Catalyst efficiency and light utilization challenges: Photocatalytic disinfection faces challenges related to catalyst efficiency and light utilization. These include low quantum efficiency, limited light absorption range, and rapid recombination of electron-hole pairs. Researchers are developing improved catalysts with doping techniques, composite materials, and optimized structures to enhance light absorption across broader spectrums and improve charge separation for better disinfection performance.

- Reactor design and operational parameters: The design of photocatalytic reactors presents significant technical challenges including optimizing contact between light, catalyst, and target microorganisms. Issues such as light penetration depth, flow dynamics, catalyst distribution, and scaling up from laboratory to industrial applications must be addressed. Operational parameters like residence time, catalyst loading, and light intensity need careful calibration to achieve effective disinfection while maintaining energy efficiency.

- Microbial resistance and byproduct formation: Some microorganisms show resistance to photocatalytic disinfection processes, requiring longer treatment times or higher catalyst concentrations. Additionally, the incomplete mineralization of organic matter can lead to the formation of potentially harmful byproducts. Research focuses on understanding disinfection mechanisms against different pathogens and optimizing processes to ensure complete degradation of contaminants without generating toxic intermediates.

- Water quality interference factors: Various water quality parameters can interfere with photocatalytic disinfection efficiency. Turbidity reduces light penetration, while dissolved organic matter can compete for reactive species. Inorganic ions may adsorb onto catalyst surfaces, blocking active sites. pH variations affect catalyst surface charge and microbial cell wall interactions. These challenges necessitate pretreatment steps or modified catalyst formulations to maintain disinfection effectiveness in complex water matrices.

- Catalyst immobilization and recovery issues: The immobilization of photocatalysts on suitable substrates presents challenges related to adhesion strength, surface area reduction, and mass transfer limitations. For suspended systems, the recovery and reuse of nano-sized catalysts after treatment is technically difficult and energy-intensive. Research focuses on developing stable immobilization techniques that maintain catalyst activity while facilitating separation, or creating magnetic composite catalysts that enable easier recovery through magnetic separation.

02 Reactor design and operational limitations

The design of photocatalytic reactors presents significant technical challenges including light distribution, mass transfer limitations, and scaling issues. Effective reactor designs must ensure uniform light exposure to catalyst surfaces, adequate contact between microorganisms and active sites, and efficient fluid dynamics. Operational challenges include fouling of catalyst surfaces, maintenance requirements, and energy consumption considerations for continuous operation.Expand Specific Solutions03 Microbial resistance and inactivation mechanisms

Different microorganisms exhibit varying levels of resistance to photocatalytic disinfection. Gram-positive bacteria, spores, and certain viruses may require longer exposure times or higher catalyst concentrations for effective inactivation. Understanding the mechanisms of microbial inactivation, including cell wall damage, protein oxidation, and DNA degradation, is crucial for developing more effective photocatalytic disinfection systems that can overcome microbial defense mechanisms.Expand Specific Solutions04 Water quality and environmental factors

Water quality parameters significantly impact photocatalytic disinfection efficiency. Turbidity reduces light penetration, while dissolved organic matter can compete for reactive species. pH, temperature, and the presence of inorganic ions can affect catalyst performance and microbial susceptibility. Developing systems that maintain effectiveness across varying environmental conditions remains a key challenge for practical applications of photocatalytic disinfection technology.Expand Specific Solutions05 Integration with existing treatment systems

Integrating photocatalytic disinfection into existing water and air treatment infrastructure presents technical challenges. These include compatibility with pre-treatment processes, post-treatment requirements, and ensuring consistent performance within established systems. Hybrid approaches combining photocatalysis with conventional disinfection methods require careful optimization to leverage synergistic effects while managing operational complexity and cost considerations.Expand Specific Solutions

Key Industrial Players in Photocatalytic Disinfection Market

The photocatalytic disinfection industry is currently in a growth phase, with increasing market adoption driven by heightened awareness of infection control needs. The global market is projected to reach significant scale as industrial implementation expands across healthcare, water treatment, and air purification sectors. Technical maturity varies considerably among key players, with academic institutions like University of Florida, Arizona State University, and Guangdong University of Technology leading fundamental research, while commercial entities demonstrate different implementation capabilities. Companies such as Ethicon (Johnson & Johnson), DuPont, and Siemens Healthineers possess advanced industrial scaling expertise, while specialized firms like Kinnos, UV Partners, and Singletto focus on innovative application-specific solutions. Challenges in standardization, scalability, and cost-effectiveness remain significant barriers to widespread industrial adoption despite promising laboratory results.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced photocatalytic materials and systems for industrial disinfection applications. Their approach centers on proprietary titanium dioxide (TiO2) formulations with enhanced visible light activity through metal and non-metal doping techniques. DuPont's technology addresses the quantum efficiency limitations of traditional photocatalysts by incorporating noble metal nanoparticles (Ag, Pt) that create localized surface plasmon resonance effects, extending activity into visible light spectrum. For industrial implementation, DuPont has engineered composite materials that combine photocatalysts with polymeric substrates, creating durable antimicrobial surfaces for continuous disinfection in food processing facilities, healthcare environments, and water treatment systems. Their systems incorporate specialized flow reactors designed to maximize contact between contaminants and photocatalytic surfaces while optimizing light distribution through advanced optical engineering.

Strengths: Extensive materials science expertise; established manufacturing infrastructure for scaling production; comprehensive intellectual property portfolio covering formulations and applications. Weaknesses: Higher material costs compared to conventional disinfection methods; performance degradation over time requires periodic replacement; effectiveness varies with environmental conditions like humidity and organic load.

Kronos Co. Ltd.

Technical Solution: Kronos has pioneered industrial-scale photocatalytic disinfection systems based on their proprietary titanium dioxide formulations. Their technology centers on visible-light-active TiO2 variants achieved through controlled nitrogen doping and crystal structure engineering. Kronos has addressed the industrial implementation challenges through a systematic approach to reactor design, developing modular units that can be scaled from small point-of-use applications to large industrial installations. Their photocatalytic systems incorporate specialized light sources with optimized spectral output matching the absorption characteristics of their catalysts, achieving quantum efficiencies up to 15% higher than standard formulations. For water disinfection applications, Kronos has developed immobilized catalyst systems that eliminate the need for post-treatment separation while maintaining high antimicrobial activity. Their industrial implementations include specialized coating processes that ensure uniform catalyst distribution and adhesion to various substrate materials, addressing the durability concerns in high-throughput industrial environments.

Strengths: Vertically integrated from catalyst production to system design; extensive experience in large-scale TiO2 manufacturing; modular approach enables customization for specific industrial requirements. Weaknesses: Higher energy requirements compared to conventional chemical disinfection; performance dependent on light intensity and distribution; requires specialized maintenance protocols for optimal long-term performance.

Core Patents and Research in Photocatalytic Disinfection

Self-Disinfecting Photocatalyst Sheet

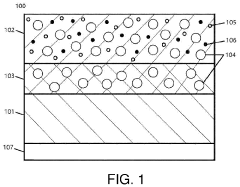

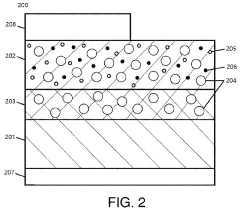

PatentInactiveUS20220089912A1

Innovation

- A self-disinfecting photocatalyst sheet with a covalent bond between a metal oxide primary photocatalyst and substrate, activated by visible light, featuring a secondary metallic photocatalyst for enhanced disinfection and an optional adhesive layer for attachment, along with a color-changing dye for wear-indication.

Environmental Impact and Sustainability Assessment

The implementation of photocatalytic disinfection technologies in industrial settings necessitates a comprehensive assessment of environmental impacts and sustainability considerations. Photocatalytic processes offer significant potential for environmentally friendly disinfection compared to traditional chemical methods, primarily due to their reduced reliance on persistent chemical agents and lower production of harmful byproducts.

Life cycle assessment (LCA) studies of photocatalytic disinfection systems reveal favorable environmental profiles when compared to chlorination and UV-only treatments. These systems demonstrate reduced carbon footprints, particularly when powered by renewable energy sources. The environmental payback period for photocatalytic installations typically ranges from 1.5 to 3 years, depending on scale and application context, making them increasingly viable from a sustainability perspective.

Water consumption represents another critical environmental consideration. While photocatalytic systems generally require water for operation and maintenance, they consume significantly less than conventional chemical disinfection methods that require dilution and neutralization processes. Advanced photocatalytic reactor designs have demonstrated water use reductions of up to 40% compared to traditional disinfection approaches in industrial settings.

The end-of-life management of photocatalytic materials presents both challenges and opportunities. Titanium dioxide and other commonly used photocatalysts have minimal environmental toxicity, but their nanoparticle forms require careful handling and disposal protocols. Emerging research into catalyst recovery and regeneration techniques shows promise for creating closed-loop systems that minimize waste and maximize material efficiency.

Energy efficiency remains a key sustainability metric for industrial implementation. Current photocatalytic disinfection systems demonstrate variable energy performance, with energy intensity ranging from 0.3 to 2.5 kWh per cubic meter of treated water. Innovations in reactor design and light source efficiency continue to improve these figures, with recent pilot studies achieving energy reductions of 25-30% compared to first-generation systems.

The potential for integration with renewable energy sources significantly enhances the sustainability profile of photocatalytic disinfection. Solar-powered systems eliminate operational carbon emissions and reduce dependence on grid electricity. Hybrid systems combining photovoltaic power generation with photocatalytic disinfection represent a particularly promising direction, with several successful demonstrations in water treatment facilities achieving carbon-neutral operation.

Regulatory frameworks increasingly recognize the environmental benefits of photocatalytic technologies. The European Union's Best Available Techniques Reference Documents now include photocatalytic processes as preferred environmental options for certain disinfection applications, while the US EPA has initiated programs to accelerate adoption of these technologies in municipal and industrial settings based on their favorable environmental impact assessments.

Life cycle assessment (LCA) studies of photocatalytic disinfection systems reveal favorable environmental profiles when compared to chlorination and UV-only treatments. These systems demonstrate reduced carbon footprints, particularly when powered by renewable energy sources. The environmental payback period for photocatalytic installations typically ranges from 1.5 to 3 years, depending on scale and application context, making them increasingly viable from a sustainability perspective.

Water consumption represents another critical environmental consideration. While photocatalytic systems generally require water for operation and maintenance, they consume significantly less than conventional chemical disinfection methods that require dilution and neutralization processes. Advanced photocatalytic reactor designs have demonstrated water use reductions of up to 40% compared to traditional disinfection approaches in industrial settings.

The end-of-life management of photocatalytic materials presents both challenges and opportunities. Titanium dioxide and other commonly used photocatalysts have minimal environmental toxicity, but their nanoparticle forms require careful handling and disposal protocols. Emerging research into catalyst recovery and regeneration techniques shows promise for creating closed-loop systems that minimize waste and maximize material efficiency.

Energy efficiency remains a key sustainability metric for industrial implementation. Current photocatalytic disinfection systems demonstrate variable energy performance, with energy intensity ranging from 0.3 to 2.5 kWh per cubic meter of treated water. Innovations in reactor design and light source efficiency continue to improve these figures, with recent pilot studies achieving energy reductions of 25-30% compared to first-generation systems.

The potential for integration with renewable energy sources significantly enhances the sustainability profile of photocatalytic disinfection. Solar-powered systems eliminate operational carbon emissions and reduce dependence on grid electricity. Hybrid systems combining photovoltaic power generation with photocatalytic disinfection represent a particularly promising direction, with several successful demonstrations in water treatment facilities achieving carbon-neutral operation.

Regulatory frameworks increasingly recognize the environmental benefits of photocatalytic technologies. The European Union's Best Available Techniques Reference Documents now include photocatalytic processes as preferred environmental options for certain disinfection applications, while the US EPA has initiated programs to accelerate adoption of these technologies in municipal and industrial settings based on their favorable environmental impact assessments.

Scalability and Cost-Effectiveness Analysis

The industrial implementation of photocatalytic disinfection faces significant challenges in terms of scalability and cost-effectiveness. Current laboratory-scale successes often fail to translate efficiently to industrial applications due to several key factors. The reactor design represents a primary challenge, as scaling up from bench-scale to industrial-scale reactors introduces complexities in maintaining uniform light distribution, ensuring adequate contact time between contaminants and catalyst surfaces, and preventing catalyst fouling over extended operational periods.

Capital expenditure requirements present another substantial barrier to widespread adoption. The initial investment for industrial-scale photocatalytic systems remains considerably higher than conventional disinfection technologies such as chlorination or UV treatment. This includes costs for specialized reactor materials, high-quality light sources, and catalyst production or immobilization systems. Without economies of scale in manufacturing, these capital costs continue to limit market penetration.

Operational expenses also impact the economic viability of photocatalytic disinfection systems. Energy consumption for light sources constitutes a significant portion of operating costs, particularly when using artificial illumination rather than solar energy. Catalyst replacement or regeneration frequencies further affect the long-term economic sustainability of these systems. Current photocatalysts often experience activity reduction over time, necessitating periodic replacement or regeneration procedures that add to maintenance costs.

Process efficiency at industrial scale presents additional challenges. While laboratory studies often report high disinfection rates under optimized conditions, industrial applications must contend with variable water quality parameters, fluctuating flow rates, and diverse microbial populations. These variables can significantly reduce disinfection efficiency compared to controlled laboratory conditions, requiring either oversized systems or supplementary treatment processes.

Return on investment (ROI) calculations for photocatalytic disinfection systems remain challenging due to the relatively limited commercial deployment history. The lack of standardized performance metrics and comprehensive long-term operational data makes accurate cost-benefit analyses difficult for potential industrial adopters. Current estimates suggest payback periods of 5-8 years for most applications, which exceeds the 2-3 year threshold many industries consider acceptable for new technology implementation.

Competitive analysis against established disinfection technologies reveals that photocatalytic systems currently struggle to demonstrate clear economic advantages in most applications. While they offer benefits in terms of reduced chemical usage and potential for addressing resistant pathogens, these advantages have not yet translated into compelling cost savings that would drive widespread industrial adoption.

Capital expenditure requirements present another substantial barrier to widespread adoption. The initial investment for industrial-scale photocatalytic systems remains considerably higher than conventional disinfection technologies such as chlorination or UV treatment. This includes costs for specialized reactor materials, high-quality light sources, and catalyst production or immobilization systems. Without economies of scale in manufacturing, these capital costs continue to limit market penetration.

Operational expenses also impact the economic viability of photocatalytic disinfection systems. Energy consumption for light sources constitutes a significant portion of operating costs, particularly when using artificial illumination rather than solar energy. Catalyst replacement or regeneration frequencies further affect the long-term economic sustainability of these systems. Current photocatalysts often experience activity reduction over time, necessitating periodic replacement or regeneration procedures that add to maintenance costs.

Process efficiency at industrial scale presents additional challenges. While laboratory studies often report high disinfection rates under optimized conditions, industrial applications must contend with variable water quality parameters, fluctuating flow rates, and diverse microbial populations. These variables can significantly reduce disinfection efficiency compared to controlled laboratory conditions, requiring either oversized systems or supplementary treatment processes.

Return on investment (ROI) calculations for photocatalytic disinfection systems remain challenging due to the relatively limited commercial deployment history. The lack of standardized performance metrics and comprehensive long-term operational data makes accurate cost-benefit analyses difficult for potential industrial adopters. Current estimates suggest payback periods of 5-8 years for most applications, which exceeds the 2-3 year threshold many industries consider acceptable for new technology implementation.

Competitive analysis against established disinfection technologies reveals that photocatalytic systems currently struggle to demonstrate clear economic advantages in most applications. While they offer benefits in terms of reduced chemical usage and potential for addressing resistant pathogens, these advantages have not yet translated into compelling cost savings that would drive widespread industrial adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!